Leaderboard

Popular Content

Showing content with the highest reputation on 09/02/16 in Posts

-

3 points

-

First of all I apologize I don't have pictures for this service since it was done before I joined to this lovely forum, anyhow I hope this is the right location to post my notes from this adventure. Well, I own this Omega ultra thin very nice watch Cal 620 for ~5Y and recently I decided to service it. Since it’s my 1st service, it took me some time to get the required oils and extend my tool set. Besides this, as a preparation, I watched one of the excellent series by Mark and learned a lot. In general, everything went smooth and the main challenge was to deal with very small size of the movement. Another challenge was to clean the movement. I tried to contact some watchmakers to use their cleaning machine but they all refused (they afraid losing market share!!!). Therefore I followed Mark’s instruction using lighter liquid and clean it manually. I have no doubt that this can never be as clean as cleaning machine but this what I could do L. At the end, I’ve started to calibrate the watch but I found it very difficult since there is no second hand. After spending few frustrating days trying to calibrate the movement, I understood this impossible without timing machine so I bought a one. When putting on the timing machine, I discovered that the rate is very unstable and each tiny movement of the regulating lever, the rate changed by ~100 of seconds/day. Examining the balance wheel closely, I found that the end spring is bent and looks like it is touching the neighbor wire while oscillating. It took me few hours back and forth to reshape the spring but finally, the rate became controllable and I got the watch to ~10sec/day!2 points

-

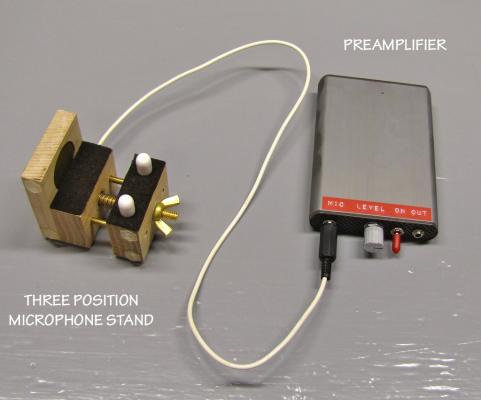

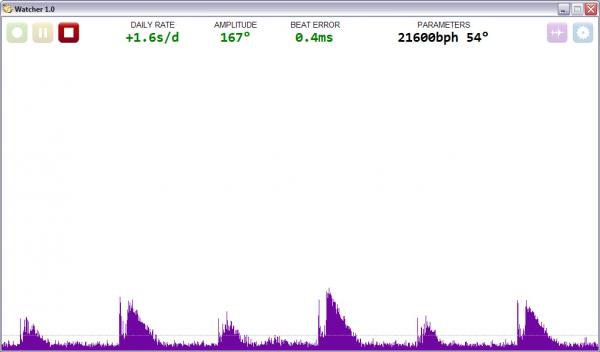

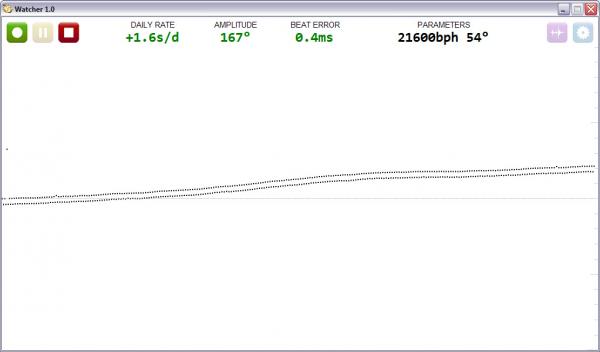

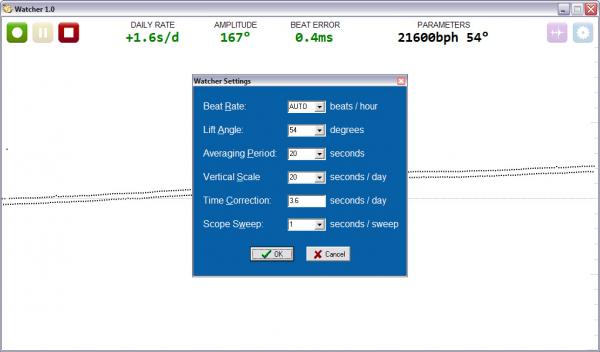

I'm a watch DIYer, having serviced two watches myself, partially using tools of my own making. One thing I've been working on over the last few months is my own PC based timing machine. I've finally got something working reliably, and thought I'd preview it here. My plan is to eventually write up a detailed article on my web site describing how to build the hardware, and providing a download for the software. I may also produce a "pro" version of the software with more features, to be sold for a reasonable fee. Here's the hardware, all home made of course: The next picture shows the timing trace from my "Black Lagoon", a modified Invicta 8926OB with a Seiko NH35A movement (yes, the amplitude is quite low and tends to fluctuate, topping out around 220 degrees - apparently this is par for the course for Seiko movements): In this picture, the software is in scope mode, showing directly the ticks and tocks. Notice how with this movement, they alternate in loudness. Since the scope mode was run after the timing mode, the scope also shows the threshold that was used by the timing mode to detect the start of each tick. And this is the settings window: Here's a brief list of features so far (I have to resist creeping featuritis): Numerical display of daily rate error, balance amplitude, and beat error. Horizontal "paper tape" mode with sub-pixel vertical resolution that can show fluctuations that are too small to see on a typical stand-alone timing machine. User selectable averaging period. Rate determination using linear least squares, which gives a more meaningful reading than just naively averaging the rate. Automatic signal and noise level determination. There's nothing to adjust. Aggressive noise filtering in the software to keep the hardware simple. Automatic rate detection for common rates. Simple, uncluttered, fixed-size display (1024x600). Scope mode to aid in diagnosis of various watch faults.1 point

-

Since I was working on the Landeron 48 with wrong dial, from which I used the case and a Landeron 151 and correct dial to make a new watch, I saw this Landeron 248 sitting in the drawer at my desk and devided to finally tackle the issue it had: a slipping mainspring. I documented the disassembly of the movement vith 3 videos, the first of which is here below: Hope you enjoy1 point

-

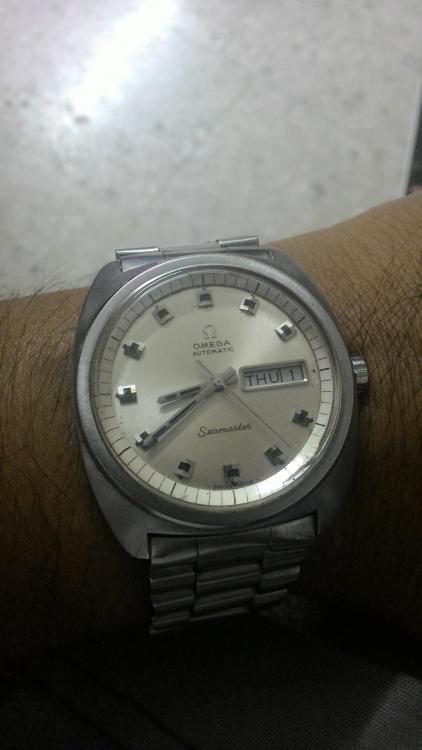

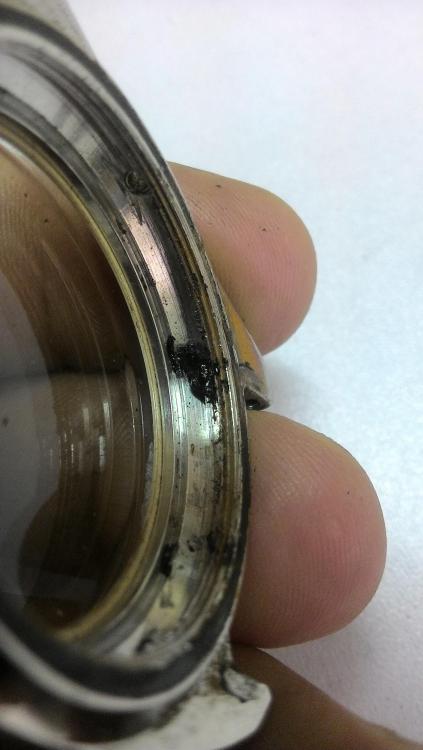

I've had this cushion cased Seamaster for a few years and wore it off and on. For some reason I was under the impression it had a10xx series movement which is not really as nice as the 5xx / 7xx series. The movement is running fine but the movt seemed to be a bit loose in the case, noticeable when the crown is pulled to set the time. Also there was a gap between the dial and the chapter ring at the 2-4 o'clock position (above picture is after, didn't take a 'before'). Well I took it apart last weekend to see if I could fix these issues. First thing I was happy to note is that the movement is a 752, not a 10xx, can't explain why I thought differently. The next thing I noticed was that the movement was stuck fast in the case. Taking a closer look it seemed that the movement ring/holder is not correct for this case being too small. To solve this problem someone had jammed some bits of old o-ring around the edges to hold the movement in place. This bits of o-ring had degraded into a gooey like substance which was a pain to remove from the case and movement ring. The caseback gasket was also as hard as a rock. The movement ring fitted to this watch, while did not seem to be correct for this case, was correct for the 752 movement. Fitted to the movement/dial the dial and stem-hold lined up perfectly. This made me step back and re-look at the movement ring again. I noticed that it had a groove which seemed to be made for an o-ring, also the case had a sizeable gap which seemed to indicate that there would be something (absorber) which would fit this gap and afford some level of bump protection, similar to what Certina did with their DS series. The absorber would not be a full ring as hole for the stem was in the middle of the groove in the movement ring, again, this is what Certina did as their movement absorber had a gap for the stem.. Well to cut a long story short, I had some 1mm and 1.5mm section o-rings and these fit in well enough so that the dial sits flush and the movement is held firmly in place. The bump-protection offered by the o-ring is not much as compared to the ring in the Certina DS it is much stiffer, the one in the Certina being more 'spongy'. Anyone have any experience with this model and can shed some light on this model? Another issue I found was this big bump on the caseback sealing surface which corresponds to one of the tool slot on the back. Probably someone used a chisel to get the caseback off in the past? Had to file and sand it down otherwise it would've ripped the new caseback o-ring. Finally.. as this has a 752 movt.. I think I'll be wearing this more often so it deserves a service soon! I can explain why having a different movement will affect my attraction to a watch but that's how it is! Anil1 point

-

There's plenty of info about this on the internet. My personal feeling is you would have to clean the parts hundreds of times under the same conditions using the identical way to cause any fatigue. The modern watches of today are more likely to wear out before anything like that would happen.1 point

-

1 point

-

1 point

-

2 out of 3 actually, the other one I will show you next week...1 point

-

I think you're going to find that hard gummy oil conceivably may never come off especially in pivots which is why you're supposed to use peg wood. Then commercial cleaning fluids are made out of variety of substances one of which is used to brighten the plates so they come out nice and shiny. That is a really nice but leave it into long and you start etching plates. This is why typically I won't go over five minutes with ultrasonic cleaning and the solution. It does depend upon temperature if the solutions hot it's going to be much more aggressive. Then alcohol and shellac they're all a little different. The machine at work the last two rinses are isopropyl alcohol it seems to have zero effect on shellac. I use wood alcohol at home but limit the exposure to just a few seconds as the very very final rinse.They change the formula of the commercial rinse I was using and it didn't seem to want to dry as fast even with heat so a final final rinse of alcohol and I had no problems with that. Then when working on pocket watches especially old pocket watches always check the jewels afterwards anyway. The shellac will become old possibly with time and sometimes it's not shellac. The longer the watches had exposure to a variety of repair people the more creative they've gotten so it's always good to check to make sure the jewels are still in place.1 point

-

That's one reason you may want to limit how long because it becomes hot...but somehow not too hot to cause what CB describes if the chemicals are used at room temperature (by the time they get too hot, the process is already over so to speak)...I suppose we are talking about a "regular" ultrasonic, not a home brewed one... The chemicals could be an issue if they are not the "customary" ones for this application, since alcohol based chemicals will act on the shellac in addition of being flammable. Flammable chemicals are not recommended for ultrasonics.1 point

-

Hi uzii! Very good beginning! I'd say, outstanding! The watch is also a beauty...I simply love Omegas. Yes, good tools are not only necessary but essential for quality work...although with the tools you have I have nothing to say about quality, you have lots of that. As far as a cleaning machine, you can make do with a jewelry ultrasonic one, the cheap ones. Of course, a proper machine would be better. I like the "cow" saying! Although, we all tend to by the cow for that cup of milk (in watchmaking). I don't mind, I have plenty of cows for just one cup of milk...in addition, they keep me company! This talk about cows...it is strictly horologycal...not to be confused with the wife... Cheers, Bob1 point

-

Excellent job, George! Pity your camera quit on you! Those are quite a pair! Cheers, Bob1 point

-

Not ultra-sonic but I have a spare set of jars for my cleaning machine. Whenever I change the cleaning solutions the old stuff goes into the spare jars specifically for use as a pre-clean on the really grotty movements. Usually a very dirty movement goes in whole prior to disassembly and goes through a complete wash/rinse/dry cycle in the old chemistry before I break it down to component level for a proper clean in the fresh stuff. This not only helps to get the most out of the cleaning fluids but it can also help to ease the disassembly process, even helping to free up really tight or stuck screws.1 point

-

1 point

-

1 point

-

I hav bought a Stowa pocket watch 11 months ago with both balance pivots broken. Now i had repivoted both and of the staff.1 point

-

Depends on how many watches you are going to repair or if like me the cleaning part you do not enjoy. I had my L&R refurbished & it is the one tool I could not do without. It cleans better than a ultra sonic (in my opinion) & it is almost a effortless task. However if my memory serves me well £1500 for the purchase & re-furbishement. I used this company run by a guy Graham Baxter. http://www.delphelectronics.co.uk1 point

-

Very stylish indeed. The dome adds a nice touch and the overall package just screams old time watch maker. Keep an eye on uncle larrys site as he has stakes come up all the time. Looks like many years of use left in the old girl yet. As far as paint goes have a look into getting it powder coated, way nicer shine and super hard. We used to have our hydraulic jacks done and it would amaze me how many home projects came back with the shop work lol1 point

-

Watching them now! I don't know how I could miss all these posts! Ok, I know, I've been away! I can't have the cake and eat it too! Cheers, Bob1 point

-

Just following this adventure George! Seems you are quite a wizard solving what seems to be unsolvable! Good going and yes, please, show us your progress! Cheers, Bob PS. Looking at those screws in the front of the dial I can't believe someone "fixed" the watch that way!1 point

-

That's not rubbish. Its a 30 hour Longcase clock dated about 1790 no later then 1800. There's a lot of work involved in putting it in good working order. Pity it doesn't have its original case. Its what as known as a cottage longcase. The painting of a cottage on the dial has nothing to do with the clock name. Very basic sometimes crude movements would be called such a name. More then likely the case would be made of oak and very plain.1 point

-

1 point

-

Jdrichard, There is a sound mechanical reason that concentricity errors should be kept as small as possible. This is due to a property called moment of inertia. I don't have the ability to use standard math symbols with my keypad so I will try to use what I have. The formula to describe this is: I = int (m) R^2, dm. m=mass I=moment of inerita dm= small particles of mass R=the radius from the center of gyration The critical element in this is R^2 (R squared) which means that when the rotating element is not concentric, the error increases by the square of the radius. This is why it is so critical for the watch pivots to be as absolutely centered as possible. david1 point

-

Handy chart for checking different Seiko movement coils? https://www.seikoserviceusa.com/img/pdf/battery-no-cross-reference-chart.pdf1 point

-

here is my watch collection. most of them are having stories behind... 1) Breitling Chrono Avenger on Pro1 Ti bracelet. this is my daily watch. one year ago it suddenly started loose 25sec/day. I de-magnetize it and it came back to COSC... 2) JLC auto caliber P812 bumper style. Sometime ago, weight oscillator pivot was broken. I bought a movement for parts and replaced the weight oscillator. 3) Omega caliber 620 ultra thin 6.5mm, manual wind. My 1st fully serviced watch following Mark's amazing videos. 4) Oris 44mm Day Date 300m water resistant, my daily watch prior to the Breitling. No special story just a nice and chunky watch. 5) Baume et Mercier quartz purchased only since I like its shape and looking - the case shape, the roman dial, the band and the flat glass. If it was a mechanical watch I would rank it as 10. 6) Atmos clock: I will post the picture and the full story later in the Clock forum. This clock deserve a dedicated thread! Hope you like this, uzi.1 point

-

1 point

-

Had purchased a seized up 100ish old Illinois Pocket Watch. Looked like this It was not running at all, so I took Vin's advice and removed the balance and the palate fork to see if the gear train would run. Of course I first let down the mainspring. The wheel train would not run freely so a disassembled the complete watch: I then cleaned the movement plates, gears and wheels in lighter fluid. I also cleaned the jewels with a tooth pick (sharpened). I did not remove the keyless springs as they were fine, but they did go into the lighter fluid and I did wipe everything with a fine paint brush. Following the cleaning, I 9010 and D5 oiled the jewels etc. And used the thick stuff on the keyless work. Then I built the watch up from the mainspring, 2nd, 3rd gear plates: to the 4th gear and escapement. Then I checked the free run of the gear train (after oiling ). It worked like a charm. Finally I put back the cleaned palate fork and lowered the balance cock into place. I still had a hard time moving so I removed the cap jewel from the balance and cleaned and oiled the balance jewel. Wow, what a difference. The balance amplified was 310 and the watch was frictionless. I put back the cap jewel (fires adding a very small amount of 9010 on the inside flat part of the cap jewel). The watch is now running really well. Next job is to find good hands and the current hands and completely rusted.1 point

-

Wearing a Luch GP dress watch with the 2209 movement. The 2209 is a bit unusual the below is an excerpt from a famous german movement reference site. With an intermediate wheel between central minute pinion and a separate minute wheel the complete train is moved to the periphery. And due to the indirect sweep second, there is also no second wheel in the center. Thus neither balance nor barrel is overlapped by any wheel, and the complete height is avalaible for barrel and balance. The result is a rather low profile without reducing sturdiness or accuracy. Looking at the movement picture I just realised that the hairspring seems to be a bit out of round..ie coils not centered. Keeping good time for the last 4 hours though. One thing about russian watches is that even lower grades have a Breguet overcoil hairspring...but not on this watch however. Despite being targeted to the the higher end of the market, it has a normal (non-overcoil) stud. This is probably because the focus of the designers was to achieve a thin movement and an overcoil would have added more height. Anil1 point

-

It;s been almost a month since this little journey with this Germinal Voltaire and the AS 1746/47 began , and I am pleased to announce that this little gem is still running properly and keeping good time . Since finishing the repair i ordered a new watchband for it and it arrived today . I choose a Hirsch Wild Boar leather band in a very nice Honey Brown color with White contrasting stitching . I proceeded to sand and polish the crystal , gave the crystal and case a spa treatment in the ultra-sonic , re-assembled the watch and installed the new band . I can honestly say that it's looking pretty spiffy . Once again , Mahalos to all that helped me through this one . I did learn from the experience .1 point

-

any middle to high end jeweler is going to have a StarWeld or similar laser onsite and can make the repairs very quickly. I do these all the time in all sorts of metals. Just make sure they are equipped with argon for titanium or the weld won't be reliable. I generally start pricing at $20.00 so its definitely affordable1 point

-

1 point

-

The second part of the video is finally ready: Enjoy... The third and final part will be uploaded in a few days.1 point

-

I recently completed work on the timepiece that actually got me interested in watchmaking. I purchased the movement (in pieces) for a vintage Omega Speedmaster a few months back and have been diligently working on putting it back together. It was a pricey endeavor but what I've learned from the experience is invaluable and having the watch ticking away in hand at the end of the project was reward enough. I picked up the movement in February and knew it was missing some parts. I counted the minute recording wheel and hour recording wheel as bits that were missing but also couldn't locate the minute recording pawl and pawl bridge. It turns out they were inside of the semi assembled movement but unfortunately I didn't realize that until I had already ordered replacements- oops! Included with the movement was the front case, hour, minute, and sweep second hands, and some spare parts the previous owner had acquired. He warned me that the watch hadn't worked properly before it was disassembled but I had confidence that I could sort it out. First thing I set to do was assemble as much of the movement as possible to determine what else was missing and what may be broken. It became apparent quickly that there were many screws gone! There weren't many parts missing other than those I've already noted but I did manage to lose the click spring when it shot away from my tweezers. I've since become more adept at dealing with wire springs and don't attack any of them without two hands. When breaking down the movement for cleaning I discovered that the chronograph blocking lever screw had been broken off in the plate. Extracting the remains of the screw from the plate was actually easier than procuring a replacement screw. I placed the plate in a solution of alum and warm water over night and the screw was eaten away. The steel posts and eccentrics in the plate I protected from the alum with silicon caulk which I later removed with a bit of pegwood. After cleaning, I began reassembling the watch but was stopped short when I discovered the mainspring barrel gear teeth were damaged. I replacement was ordered straight away. Now I was ready to assemble the movement. I made sure to inspect all jewels and pivots before putting the gear train together. And I was rewarded with an exceptionally well beating movement. This was a relief since I've spent more than enough time on my previous projects straightening hairsprings, truing balances, and correcting beat errors. Next the chronograph layer came together. This takes quite a while since there are so many bits to lubricate and test the motion of before moving on to the next bit. Also, with so many screws missing I had to stop several times to order replacements. Below is the movement prior to final adjustment. A screw is missing at the top and the chronograph bridge screw isn't correct but it gets the job done. I discovered that the previous owner had already procured the missing hour recording wheel so that saved me a bit trouble. And the dial side came together quickly. The hour recording wheel is turned directly by the barrel and the blocking lever wasn't set properly before I put the dial on so the hour recorder creeped which required me to go back and remove the dial and re-adjust the blocking lever. I'll remember the importance of that adjustment the next time I do a chronograph repair! I needed to purchase a replacement dial and a full set of hands as well. I could have reused the hour and minute hands that came with the movement but since they were scuffed and faded and wouldn't have matched the other four hands I sold them to pay for a whole new set. It's not something I regret though because with the new dial and hands the watch looks about good as new. The case I had was missing the caseback and pushers but I found a gentleman who was selling the case (with pushers) and caseback together so I purchased the lot. I also procured a replacement dust cover since that turned out to be missing as well. No point in doing a job unless it's done right I suppose. And there you go! I'm quite happy with the result here. It was expensive but I now have a complete and fully functioning Speedmaster. The chronograph worked without a hitch and the watch has kept impeccable time too. It took quite a long time to get this one together but the patience has really paid off. I really love working on chronograph movements and am hoping to do a Venus or Valjoux soon but my next project is a bit more eclectic- a Cinderella watch by US Time from the 1960's! This will be my first pin pallet service. (excitement!)1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.jpg.1f1517560c2ef51f77026be0f6736080.jpg)