Leaderboard

Popular Content

Showing content with the highest reputation on 05/18/16 in all areas

-

3 points

-

2 points

-

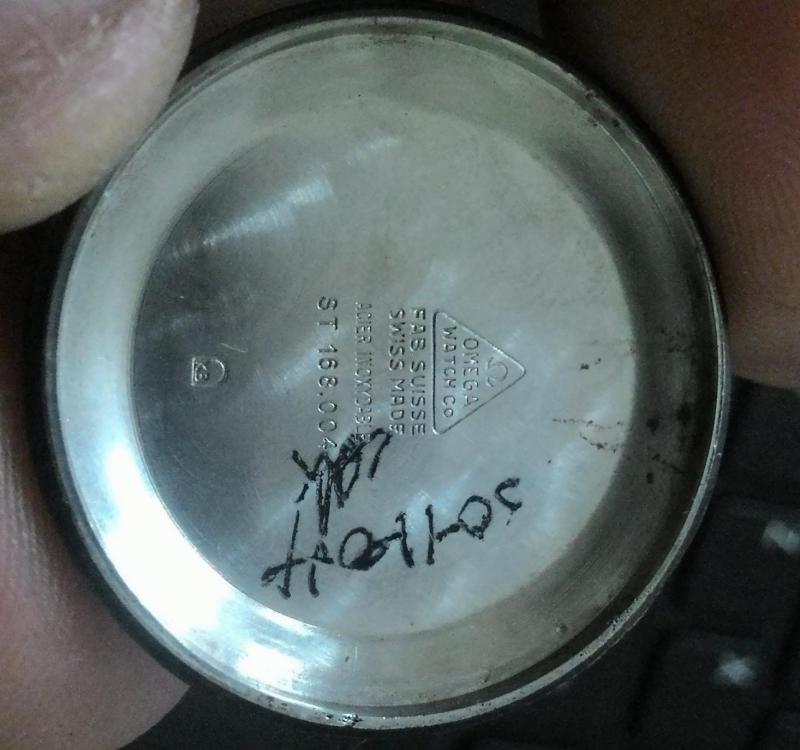

Hi All, Just got this Omega Constellation which is also known as a 'pie-pan' due to the dished dial. This is the larger cased version which is not as common as the normal sized Constellations and apparently produced for Japan, Singapore,Indonesia and Thailand markets (no mention of Malaysia , where I'm at!). It also has a hidden crown, not so common among Omegas of the period. It dosn't have a gold constellation on the back tho'. Now the interesting bit....Prior to this I have read about the 'landmarks' in Omega where they had produced consecutive batches of watches which passed the COSC test..historical because all the movements were consecutive. The three landmarks were a run of 1,000 (in 1949), 20,000 (in 1959-60) and 100,000 (1964-66). When I got the watch the first thing I checked was if I had gotten lucky and 'scored' one of the watches from the batch of 100,000...Well the batch of 100,000 comprised of movement serial numbers from 24,410,000 to 24,509,999...as it turned out I got lucky! My watch has the serial number of 24,422,084 which is the 12,084th of the batch of 100,000. Movement runs well but I think it could do with a clean..the plates look a bit tarnished, hopefully a cleanup will improve it. Also the rotor has been changed as the colour doesn't match. No real issue as this was probably done back in the day when function overuled cosmetic appearances, I'm just happy that it was swapped out before the worn pivots marked the main-plate/bridges. I do have some other 5xx movement so I may swap a more appropriate one here. The balance bridge is also the same hue of the rotor but I don't think I'll mess with it for now. cheers! Anil1 point

-

That's a nice looking Omega lovely clear dial might be old fashioned for some but I love old things the older the better. I would be proud to have that on my wrist.1 point

-

I've attached an image out of the eta manufacturing information with the timing results they expect from this watch. The problem with waiting long periods of time before servicing your watch is a variety of problems can pop up not always visible on the timing machine. For instance rust because the gaskets breakdown with time especially on the crown. Rust makes a really nice grinding compound. Then of course the lubrication's don't last forever they can do a variety of things usually none of them good over time. Then it just depends on how much you using your watch taking out occasionally couple times a year conceivably might never have to service the watch ever again they're just not going to be enough where. But on a watch being worn on a daily basis past five years and a little moisture the cost of servicing will go up considerably conceivably reaching a point of time where the watch grinds itself to dust and I can't be serviced.1 point

-

1 point

-

1 point

-

1 point

-

Most, if not all of the budget or lower end Seiko autos use the Magic Lever system for the auto winder. It is only when you get into the mid-range movements like the 5106 or 5606 calibres found in the LordMatics and PressMatics and such like, as well as the top end Seiko calibres used in the King Seiko's and the Grand Seiko's, that Seiko uses a more conventional set up with reversers, and the issues of winding efficiency and rotor orientation go away. Also, I'm not sure that the question of left handed or right handed (and therefore crown up or crown down with the arm hanging down) is an issue as the orientation of the 3 pivot points will be 90 degrees either way. It is only if the watch is oriented crown left or right during the majority of the winding activity, or if the rotor is inadvertently incorrectly fitted that winding efficiency is impacted. Even then, the loss of efficiency may never be noticed. If a watch that has a >36 hour power reserve from full wind is only winding at 67% efficiency, it will still get a 24 hour power reserve from a days activity which would normally give a full wind. If that watch is worn every day, then it will never stop and the watchmakers error will never come to light. It would only be if the watch was left unworn for more than 24 hours that the watch would stop, and quite likely the average "man in the street" would just assume that it was because he wasn't wearing it. I would be quite suprised to find that any more than just a few % of people actually know what the power reserve of their watch should be, and actually go out of their way to test it. And those that do are almost all likely to turn up on this forum1 point

-

Just added 3 more. Get to 20 and then sell sell sell or keep keep keep. Need to service some of them.1 point

-

This was a mod I did a few years ago. Seiko 6309 7040. Check out the second hand you aviators. It was one of those bits and pieces, junkyard builds. I actually wear it a lot as its a bit of a favorite, fits good and is very comfortable to wear. I just serviced it recently and it's running very nicely. Not bad for a watch that serials from 1980.1 point

-

1 point

-

another real bargain is movement lots from ramon in the phillipines. i forgot his seller name. anyway, he often has seiko auto movements in lots of 12 - 16 for less than 20 bucks. this is a treasure for someone wanting to take one apart and perhaps do some diagnosing.1 point

-

Once the hands and dial are fit you can do a visual check. If you hold the watch in the 12 up position and watch the second hand come down from 12 towards the 6 position. As it pass's the 6 and starts to go up back towards 12 it should be a constant sweep and not judder back as it fights gravity, you can also give it a slight tap to make sure the second hand still doesn't drop back a second or two. Repeat this as it pass's 12 to make sure it doesn't jump forward slightly. presuming you have already checked for up and down end shake, which would be obviously not enough tension then the amplitude seems good, it's not even dropping in the hanging positions, although this might change when you get the hands and dial on its perfectly normal. For future reference a good test for the tension is to spin the train before you put the pallets in by slightly winding the mainspring and then release the tension on the pinion friction Spring, if the 4th wheel turns a couple of times then normally you are somewhere near the correct friction. If the wheels spin loads of times the friction is too much, and if the wheels don't spin anymore you haven't enough friction on the Spring.1 point