Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/16 in Posts

-

A few drops of lemon i have heard of but never tested. I usually leave them as they are. Clean the best i can with Rodico.2 points

-

1 point

-

1 point

-

It must move, otherwise the rate can't be regulated. Also, if it has an etachron style pin, that is used for regulation and adjustment also.1 point

-

You adjusted what? There is no preload in the airspring. If the rate changes that means the effective hairspring length has changed.1 point

-

The shop I worked in years ago were Longines agents. You are correct in oiling the arbors both ends. If the spring goes you replaced it with a new unit. Back then spare parts were in abundance, I don't know about today, if you can't obtain the unit I suppose a new spring will have to do.1 point

-

Its a strange one as the amplitude is good. When you fitted the shock spring did you check it is secure i.e. holding the cap jewel in all positions.1 point

-

1 point

-

1 point

-

You need that as well a timegrapher. Otherwise you can't do watch repairs or maintenance.1 point

-

This will do the trick. Its always a good thing to demagnetize the watch you are going to work on first, saves a lot of time. http://www.ebay.co.uk/itm/like/161822826949?limghlpsr=true&hlpv=2&ops=true&viphx=1&hlpht=true&lpid=122&chn=ps&googleloc=9045125&poi=&campaignid=207297426&device=c&adgroupid=13585920426&rlsatarget=aud-133395220866%3Apla-131843268786&adtype=pla&crdt=0&ff3=1&ff11=ICEP3.0.0-L&ff12=67&ff13=80&ff14=1221 point

-

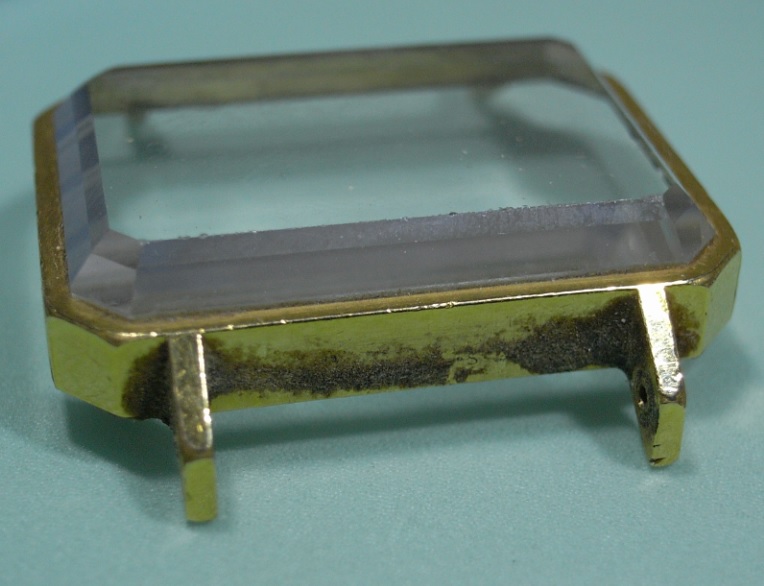

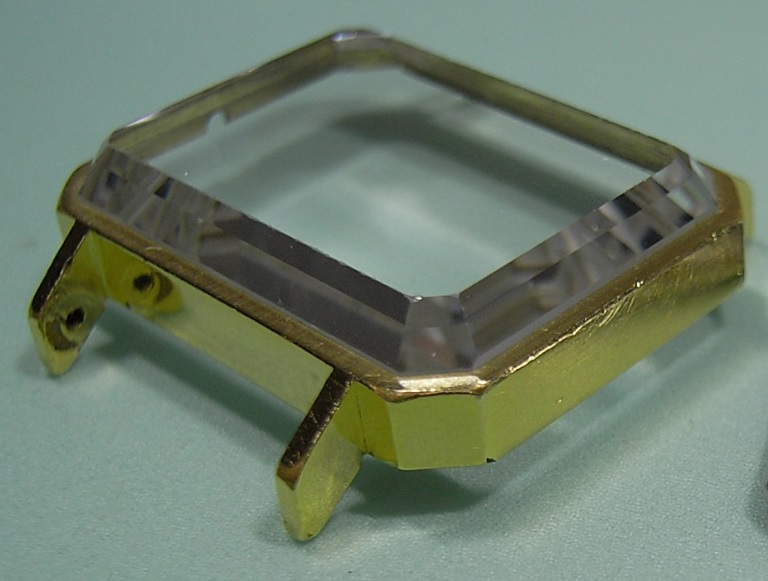

Just a quick update on the progress of the 620 service. As I am still waiting for the Mainspring to arrive from the UK I took the time to clean the Case and Caseback. The condition of the Case was good, with just the typical dirt and grime between the Lugs and around the Pendant. With a little gentle cleaning the finish on the Case came up rather nicely. So now it's just a waiting game for the part to arrive and assembly to begin1 point

-

1 point

-

Hobbyist ... for the reasons above not really feasible to be a full time watch repair person. Also people tend to be expect chronometer grade performance from all types of junk just because its 'Swiss'. Lets face it, nothing can match a 10dollar Casio for accuracy! Anil1 point

-

I'm not familiar with the UG movement specifically but would imaging that it follows the general design of most other auto winders (full and micro rotor) in that the power is constrained within the barrel on the input side via a click on the ratchet wheel and not through the auto wind coupling. In which case I doubt that the coupling clutch is the culprit. My first suspicion would be the arbor hook not hooking securely into the hole on the inner end of the mainspring, or the bridle slipping way too soon against the barrel wall. Make sure that the arbor hook locates properly in the inner coil. Did you lubricate the barrel walls, and if so what did you use? You should be using a braking grease which actually prevents the bridle slipping too soon, but then lubricates the bridle/wall interface when it does slip. If you use the wrong grease then it may well slip too soon. Also, have you used the correct replacement spring? If the new spring is too short then when you get to a state of partial wind the inwards pull on the outer coils as you wind further can pull the bridle away from the barrel wall releasing all the power in one go.1 point

-

Low amplitude coupled with a fast rate are classic symptoms of sticky hair spring coils. Frenchie's advice is spot on; remove the upper jewels to improve the circulation of cleaning fluid around the pivot and jewel surfaces, and clean the balance and cock, and jewels in naphtha. The naphtha will not affect the shellac on the impulse jewel so you can leave it in for a reasonable amount of time without any ill effect, I'd give it about 5 minutes. If you swirl it around then only do so very gently; a safer approach to agitation is to use a blower to gently blow bubbles through the hair spring. When you take it out place it on absorbent tissue and use your blower to dry it all thoroughly before reassembling and oiling. Don't forget to demag as magnetism is just as much a cause for sticky hair springs as contamination. Once it is back together carefully inspect the hair spring for flatness and for clearance with the underside of the cock. If it is touching either the balance wheel arms or the underside of the cock you will still get poor amplitude and an increased rate. Good luck.1 point

-

Swish gently you don't want to end up with a tangled up hairspring... If you have a small blower you can use it to speed up the drying. If not, air drying is fine. I assume "main jewel" is the lower jewel, right? You only oil the lower jewel once (I'm pretty sure it's a typo, but I'd feel bad not pointing it out)1 point

-

Yes, you don't need to remove the hairspring from the cock. I'd remove the jewel too (don't loose it !!!!) (been there done that...)1 point

-

Your video is in slow motion, correct ? Yes, you can use lighter fluid. Dip it in, swirl it around GENTLY, for a minute or so maybe ? The jewel hole is also very part. A sharp piece of pegwood would help.1 point

-

I've boiled and repainted but there's an art to that see my Helvetica needs TLC post it can be dangerous as usually the small writing is printed on the lacquer butvi dont boil i soake in just boiled water for a few minutes as Frenchie said any ammonia based cleaner works well I've also had some good results with diluted stain remover about 5parts water 1 stain remover . You'll never get a flawless dail whatever youdo and i think if its an older vintage watch a bit of age related stainage adds to its character. The lacquer on yours has bubbled and it looks like its lifted the silver too. Mick1 point

-

1 point

-

1 point

-

1 point

-

Yeah, a high maintenance girl friend is quite a project! I vouch for that...so in case there is any interested, I'm exchanging my 50 year old wife for two 25 years old girlfriends! Cheers, Bob PS. 2 x 25 = 50 fair trade!1 point

-

I used 3 in one oil for both my lathes. If you buy chucks second hand make sure they are good, not chipped or forced to hold stuff that is to big for the chuck making it out of line. You have got hold of some nice tools.1 point

-

Nice catch . Those are really nice tools. Congratulations. BTW i have a balance staff i need to1 point

-

I use car motor oil 5W40 ; not sure this is the best but no pb with it For the collet my Donald de Carle say they are 0.625 mm pitch (same as Boley 8mm, Star, Marshall Peerless, Lorch 8mm ... ; the most common type)1 point

-

Hi Nice buys - make sure you change the staking set hammer though ;). I don't know if you are familiar with the site but there is some info. on your lathe at http://www.lathes.co.uk/coronet-precision/ There is also some information on collets at the bottom of this page http://www.lathes.co.uk/watchmaker/ Stephen1 point

-

0 size, 7 jewel, grade 1, stem wind, pendant setting, made around 1910, ~11,220 total made, if the case is in good shape, as it looks, it should clean up nice, good find, but not great find, like that SBWco 'logo' on bridge, noted different style/material balance screws and does not have huge case screw marks from re-casing, so probably original case, clean dial, no hairlines present. Someone may have stuck pin hanger on to wear, then later a chain on swivel. This watch was not made to hang on pin, otherwise the 12 would be at hinge side, (so you could read it whilst wearing)1 point

-

I must admit i didnt look for it. But making it was fun, and now i can make it in any size for any watch1 point