Leaderboard

Popular Content

Showing content with the highest reputation since 05/25/24 in all areas

-

Five months ago I decided it was time to learn basic polishing and received much-appreciated help in the "Please help me buy a polishing machine" thread. Usually, I prefer to keep the patina especially if I or the owner of the watch has had it in their possession for a long time and shares a history with it. That the watch and of course the movement should always be clinically clean after a service I consider a matter of course. I also think that really expensive watches should avoid polishing, at least if you can't do it correctly and preserve the original shape of the case. I have learnt during this period that accidents can happen very quickly if you don't really know what you are doing, so training is a necessity. Having said that, although the result is not perfect, I feel very proud of my achievements so far, and I hope you like the before and after pictures because there are quite a few. Before the refurbishment: After the refurbishment:8 points

-

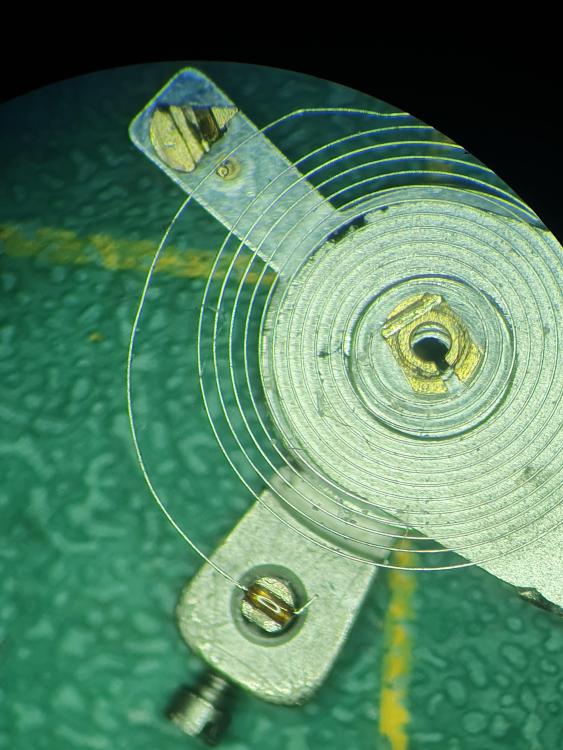

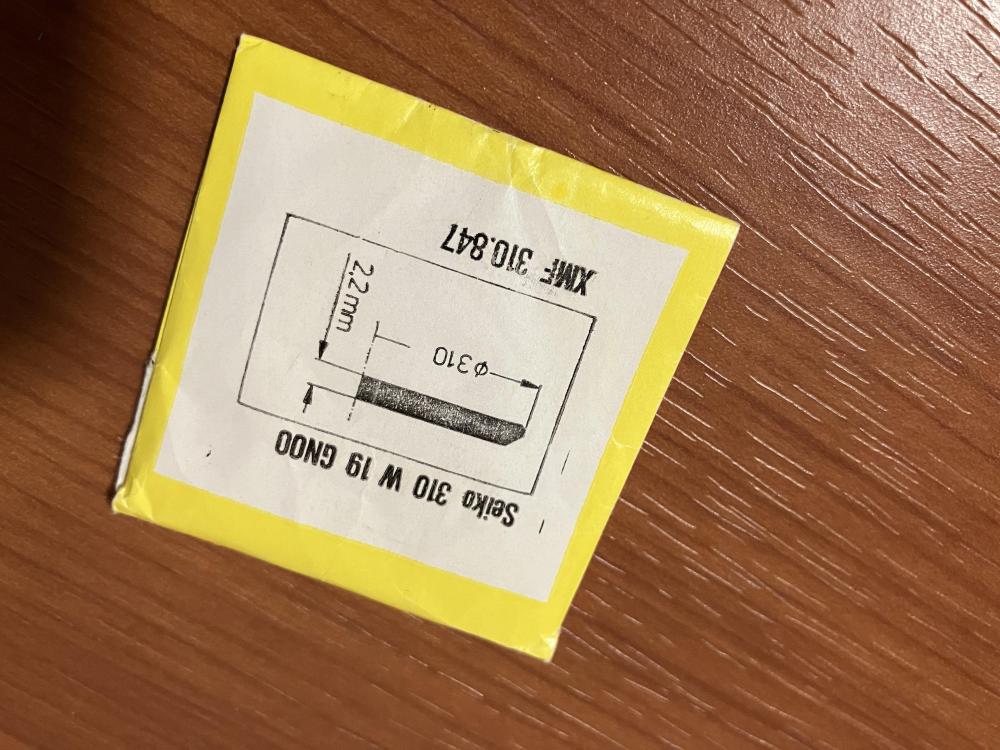

Yey finally got back around to finishing this. One of the first watches i ever bought when i started for a fiver it was put aside as the amp was really low around 150° and it had a cracked fancy crystal and i didn't know what the hell i was doing back then. Re started this about 3 days ago by finding a new oversize crystal in a big box of fancy shapes i aquired. The shape is known as a military rectangle which curves to match the case, after grinding to shape and carefully filing i had a good tight fit ( no glue might i add ) I'm a-nal when it comes to fitting bits together that comes from being a 1st class joiner . Tried everything to get the amplitude up but it was a no go 180 DD was the max i could get the Oris 291 is an old pin pallet 1940's and wasn't playing ball and the spring was a teeny tiny round effort of coils. Found another with just about the same profile, .01mm extra on the strength, the hight was bang on but it needed trimming to length and a new tongue fitting , that was today's mission. Mission accomplished and the old Oris has been turbo charged to 250° Here is a few wrist shots and the tg DD, we wont discuss any vertical positions if thats ok did i mention it's an 80 year old pin pallet. Strap is temporary so dont panic i have a little taste in wrist wear at least.7 points

-

Why is it when that little voice says, "This is a bad idea," we always want to talk ourselves out of it? I had the low blood sugar jitters earlier, but insisted to myself that I'd be able to oil an especially tiny cap jewel on my friend's Omega 1001. With lots of concentration, I nailed it. But when I put the hole jewel on top, it was too much oil and it squoze out everywhere. It didn't spread on the cap jewel much thanks to the epliame I'd applied, so it was more than it looked like from the top. Back in the cleaner, dried, re-epilamed, dried. Time for a second try, but now I was more shaky even than the first time. "This is a bad idea," my brain told me. "Take a hike, brain," I said as I watched the oiler jiggle into my microscope's frame. And just like that, the jewel was a tiddlywink and flew out of sight in the blink of an eye. With a strong UV flashlight and the waste of a lot of time I did find it on my desk, but that's some stress I didn't need in my day. So friends, listen to your body, and listen to your brain when it tells you now's not the time for precision work.7 points

-

I've never touched my life without alcohol . I'm your complete opposite Ross6 points

-

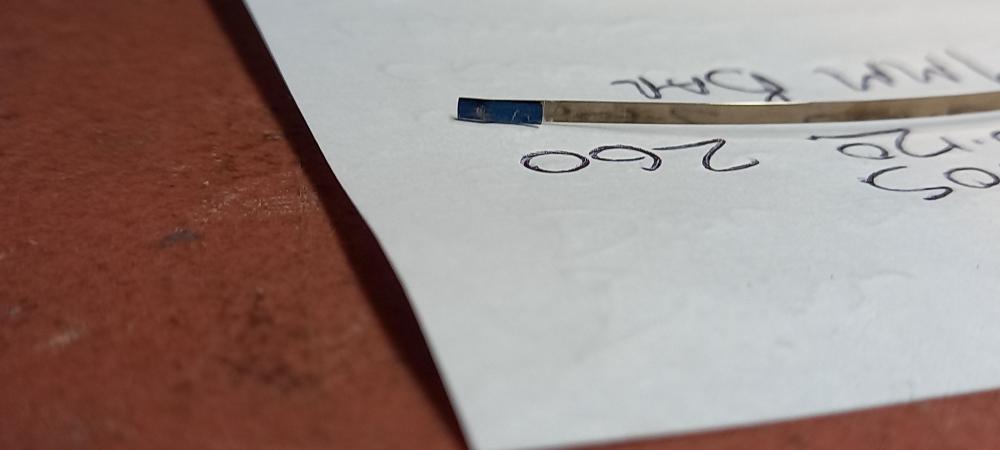

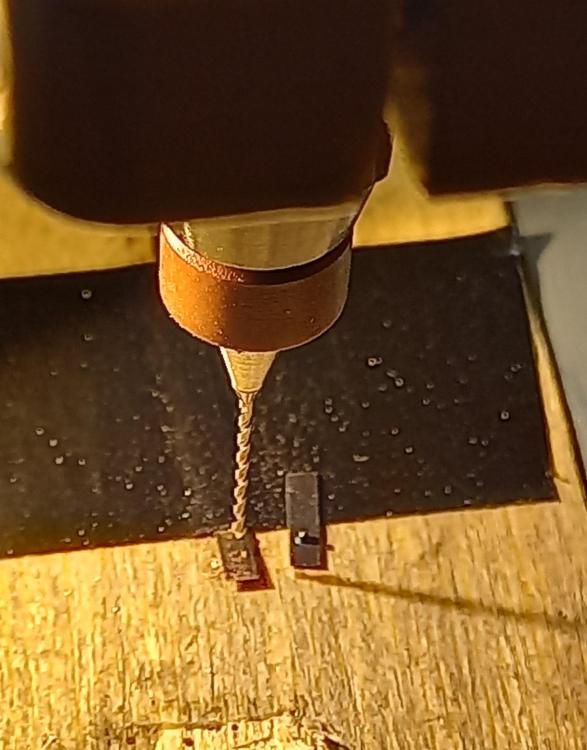

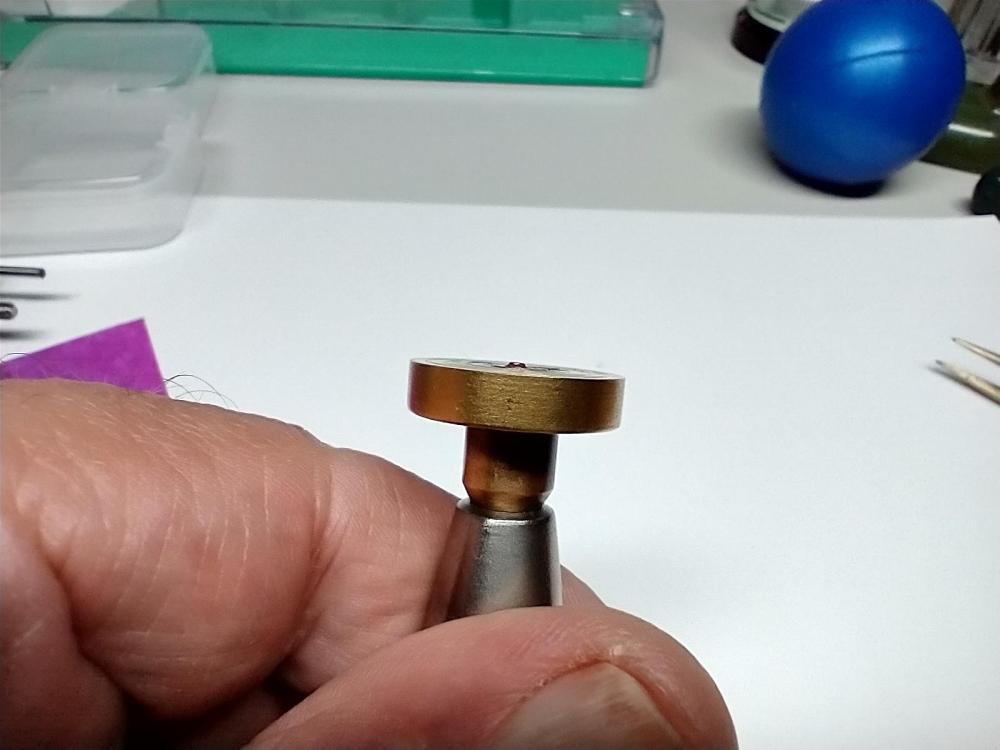

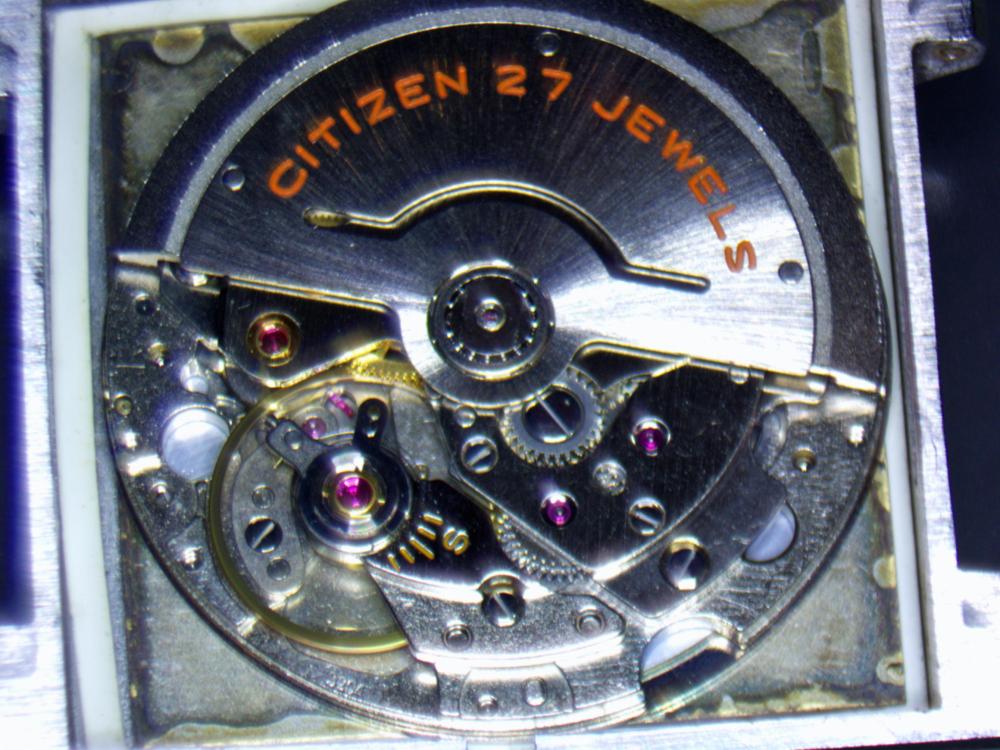

Hi guys, Some of you who have been stuck down the rabbit hole of watchmaking know that a fair part of it is finding a solution to a particular problem, especially when it come to vintage watches and all their idiosyncrasies. And, to find the solution, some unorthodox approaches and methods are employed. I find a good watchmaker will find a way to overcome. So, I'm servicing this Tissot 784.2 and find the centre wheel jewel is toast. The flat side of the jewel which the centre wheel sits on is intact, but the oil sink/dial side is crumbling and half of it is gone. It might last this way for some time, but maybe not and I'm guessing more on the latter. When I pressed it out, it fell apart. I teach my students there are two golden rules of watchmaking. Rule one: You are like the S.A.S. with servicing. You are in and out with no one knowing you were ever there. Not leaving gnarled screw heads and scratched bridges, etc. Rule two: Always think and consider the next watchmaker who is going to work on the watch. Don't leave obvious problems, or bodge something together, knowing it will create problems for the next watchmaker who works on the movement. If rule one is adhered to, rule two covers itself. The point I'm making here is, I could have left the centre wheel jewel and it might have lasted, but that's leaving the problem for the next guy and not very SAS. For some reason Seitz have discontinued the jewel size I needed (Sods law!), so I found one in a scrap movement that was the correct inside diameter. 0.8 mm to take a 0.79 centre wheel arbor. The outside diameter of the replacement jewel was 1.5 mm, so I had to ream the centre hole a little bigger from 1.19 mm to 1.49 mm. The problem was the jewel was 0.4 mm deep, so sat proud on the dial side and stopped the cannon pinion from seating properly, as you can see from this photo. I needed the jewel to be 0.27 mm deep like the cracked old one. Now, synthetic jewels are made from aluminium oxide with some colouring thrown in. Aluminium oxide is what is coated on wet and dry paper and as I don't have a diamond honing wheel, I decided to glue a piece of 400 grit onto a blank 8 mm collet and glue the jewel to a faced off wax chuck. Make sure the jewel is off-centre. Then I used my 8 mm lathe to hone the jewel from 0.4 to 0.27 mm. I can only use a GIF, so here it is... Then I lay another jewel that is 0.4 mm deep next to the one I'm honing and compare how much has been honed. I use a feeler gauge between the wax chuck and the wet and dry to gauge how deep the jewel is, so when I remove the jewel from the chuck using acetone, I know it is pretty close to what I want and found on my bench micrometre that I had honed it to 0.275 mm, so 0.005 mm bigger, which I'll force myself to live with. I was pretty impressed by the accuracy of doing this by eye with no CNC or even micrometre gauges whilst honing, just a rudimentary feeler gauge I made. Then I pressed in the jewel with a jewelling tool and set the correct end-shake for the centre wheel and ensured the cannon pinion sat correctly without touching the centre wheel jewel. There was no real need to polish the face of the jewel, as it isn't an acting surface, but could have done using the same method with different diamond micron pastes to get a mirror finish. The whole process probably took me close to an hour to figure out and work. Obviously the next time, it would be half as long. The diamond wheels would have made the job a lot quicker, as the wet and dry was wearing out making honing more difficult. I think with a diamond wheel, this could be done in a matter of minutes. A lot of the time was taken soaking the wax chuck in acetone and gently teasing the jewel away from the chuck. Because the jewel is so slim it is also very brittle and will easily break if this stage is rushed, so it's a matter of being patient and letting the acetone do its work and wipe away the melted superglue and gently prying it off with your fingers, not tweezers. You can't gauge how much pressure you are putting on the side of the jewel if you use tweezers. I could have saved myself time and effort by making a brass bush to fit, but I didn't like that idea I had robbed a jewel and broken one of my cardinal rules, which was more 'Dad's Army' rather than S.A.S.! It's a very similar way I hone down brass bushes, as parting them off on a lathe can't get total accuracy on the depth, so I finish them off like this. Now I've been successful using this method, I'm going to invest in some different grade diamond wheels for my lathe. These kind of skills and problem solving, I teach here in South London in evening first and second year courses. I hope this gives you ideas of overcoming obstacles and another reason to buy a lathe!5 points

-

It is a good example of what happens if you use a mop wheel in the wrong way. You can see that the engravings have been rounded off. The correct method would probably have been to sand it by hand with wet sandpaper to an increasingly fine degree on an aluminium sanding block. But now I just had the goal of getting the case back clean and scratch-free quickly. After all, I paid no more than £11 for the watch and had originally only intended to use it as an everyday watch. Had it been someone else's watch, I would have asked the owner first. However, when I polished the lugs and the case, I was very careful to preserve the original shape of the case, especially the lugs, which easily become rounded otherwise. I feel that I succeeded well with that. It's all about having a strategy and using Kapton tape. Yes, it is! The problem was finding a new glass gasket because the ones I found were either a tenth of a millimetre too wide or too narrow. In the end, I chose a glass gasket that was a tenth of a millimetre too wide. However, it fitted better than I expected so maybe I measured wrong, despite being very careful, or maybe it's not all that sensitive. To make it easier to press in the glass, I first lubricated the glass gasket with a little silicone. It worked perfectly and the glass sits as if it was moulded into the case.5 points

-

Today felt like a Timex day, so I've been sporting a classic. One of my favourite vintage watches, a 1969 Timex Marlin. Just for the record, as I recall this is a 404 club watch, and arrived pretty beaten up, and in need of a service. Its probably worth somewhat more than four quid after a little TLC. The picture probably doesn't do it justice. Wearing it, the watch looks and feels almost new.5 points

-

Never touched alcohol in my life. I don't need alcohol to be stupid. Just comes naturally.5 points

-

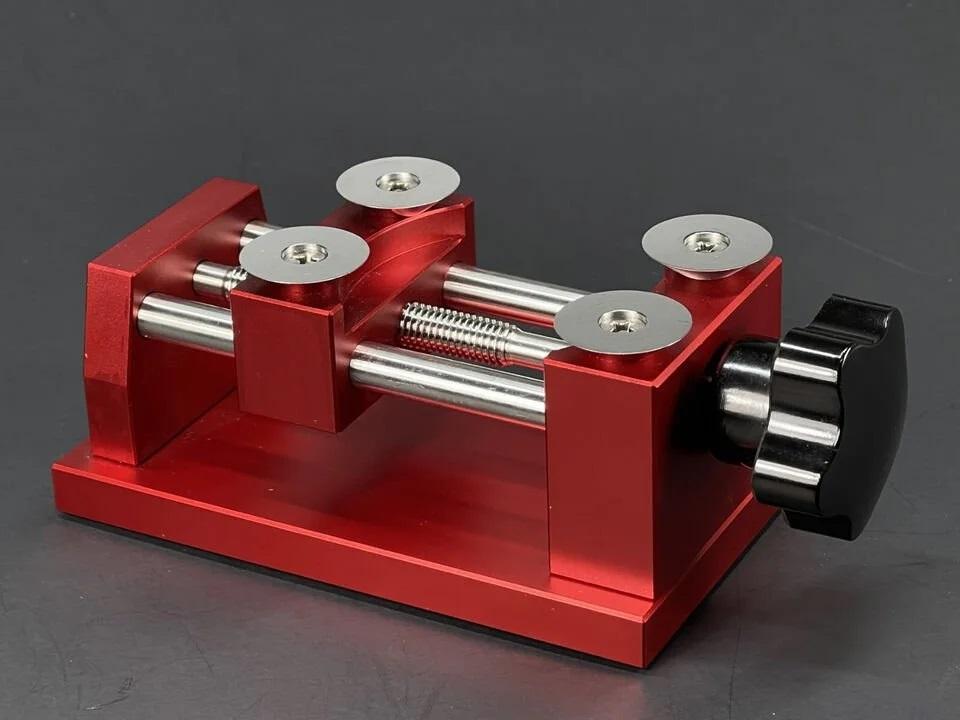

An update to my post above, i got this type of bezel remover yesterday, absolutely perfect, the build quality is very good, no slop or play, perfectly aligned, no manufacturing defects, i've tried it on a couple bezels and it just works how it should, it's a solid bit of kit, i'm more than impressed. The scores on the door say it's a 10 out of 10 from me. What a difference in build quality from the first bezel remover i got, i slagged the first bezel remover off as chinese junk but this one makes up for it.4 points

-

These days I never use tweezers to fit a barrel arbor. I got myself two Bergeon barrel arbor holders (1.5mm and 1.0mm) and I'm super happy with them as they take the stress and fear out of fitting arbors. As with all things Bergeon, they are costly, but it's still worth it in this case. Also, should I ever have or want to retire from repairing the second-hand market for quality tools is excellent.4 points

-

Well it showed up from Pakistan, and it looks like my gamble paid off. There's some staining on the dial, but I think that's to be expected. Otherwise it looks great and I can't wait to clean it up! The only issue is the bracelet is too small for my beefy wrist. Size comparison with my Seiko Kinetic 5M62.4 points

-

I enjoyed this: https://www.bbc.com/news/articles/c4nn7gew9zxo4 points

-

4 points

-

If the hood will not slide off there might be a catch on the left side as you look at it. open the door and feel up inside to the left. Hoods normally slide of or lift off. Due to age it can be a very tight fit so a little force is needed but be careful not to pull the whole case with movement in side over, you don't want it to come crashing down. The lines are fraying and need replacing it isn't even on the pulley.4 points

-

3 points

-

I've used this kind of tool for a couple of years to remove bezels. The trick is not to rely on the screw knob to exert the force to pop the bezel off. I think I've shared how I use this tool before. The trick is to screw the blades down into the gap between the bezel and the watch case, and apply slight pressure only. Then I use a nylon faced hammer and tap on the movable jaws. The small amount of slack in the screw threads allow the tapping to push the blades a little further into the gap. This can be confirmed by the loosening of the knob after a few taps. Retighten the knob and repeat until the tapping does not loosen the knob any further. The blade would have reached the vertical lip of the case. By now, the gap would have widened enough to allow a thicker blade of a case knife to finish the job. I usually put the watch dial up instead of dial down. This way, I can sometimes press down on the watch crystal and the bezel would pop off. But my tool is Korean made, not Chinese. The blades have not shown any wear or damage after two years of use.3 points

-

I started out using a bow, but now I much prefer using a retractable ID card holder, as shown in this video (at 13min)3 points

-

I love Timexes. But there is absolutely no money to be made if we were to do a full disassembly, clean and oil. But with the advent of the ultrasonic cleaner, I wonder if we can get away with just dunking the fully assembled movement, sans the dial and hands, into the ultrasound. It should be better than the dunk and swish method.3 points

-

Plus you're a rough a%£e joiner, who only needs to be within 4mm, decorators calk will fill the gap. Hehe. Watch this https://youtu.be/os3Vthd_Us4?si=43Bc8ItUh4Z4zh7N3 points

-

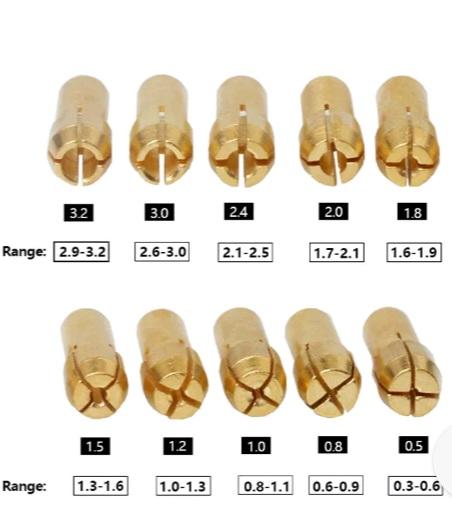

I used to worry about the jaws of a pinvice scratching the arbor's shaft at the lid end. After polishing up the arbor and using a pin vice to hold it i couldn't see much of any marks at x10. I thought about using these a while back, Dremmel collets , i have a few but not enough of the right size, i like the fact that the inside is a nice round smooth finish and they dont have a sharp gripping surface on the jaws like some pinvices do, also these ones are made of brass. You can buy the holder separately.3 points

-

That’s the regulator arm off the balance cock by the looks of it. If the fall dislodged that I would think there will be much worse damage and you’ll need a watchmaker to repair. Tom3 points

-

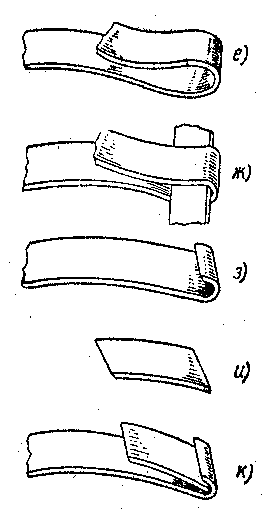

Instead of just folding the spring end back, it is beter to use this way, shown in old book. Jus folded back end often breaks after some time The small aditional piece can be hardened (rather not anealed). No hardening of mainspring neither of internal , nor outer end needed as @nickelsilversaid. I prefer riveting and drill the holes without anealing. Never thought that there may be problem with centering the holes, may be that's why I never had3 points

-

3 points

-

3 points

-

...but not too hard like me on a first attempt (see the crack?) : Mind you, getting a full replacement rotor in NOS condition (you don't want to buy a used one with already worn axle) will set you back several hundred dollars. PS: here is a nice video on the rotor axle replacement. As @Jon said, it's definitely doable. I was just stupid..3 points

-

Unitas Was the original Swiss manufacturer now of course it's made by Swatch group or specifically ETA. I have a link to their website and while I was there I downloaded the tech sheet for you which I'm attaching. Oh and as this is the newest version of the tech sheet it of course has the etachron regulation system which Yours being the older version does not but otherwise everything else is exactly the same. https://shopb2b.eta.ch/en/6498-1-6498-1-5.html Nice that you're the first one that's there it's always bad with other people been there before you as they can get very creative with things that will cause problems. Then don't think of this is a pocket watch think of it as a large wristwatch because that's basically what it is. It's why it's the classic choice for training watch repair. Although usually for training and watch repair we recommend purchasing the clone eight by the Chinese as it's considerably cheaper than the Swiss version that you have. But otherwise this is basically just a really large wristwatch very nicely made and they typically run very very well. ct_6498-1_fde_482382_10.pdf3 points

-

Hi Rich, Yes, You can polish the arbor pivots and the barrel holes, but it will be beter to burnish them. The normal reason one will do it is if there is bad surface by the manufaturing or signs of degrdation of the surface due butting from no lubrication or hard particles for example, and it is done to prevent the bearings from fast wear when working in such state of surfaces. Othervice, do not expect significant change in amplitude because of the polishing. This is what I think, but You can try before/after with no change in other conditions and make own conclusions.3 points

-

I don't usually do it but I just burnished and polished a barrel arbor a couple of weeks ago. The upper arbor was rusted and pitted, so it was a necessary job. I chucked it in the lathe and used the rough side of the pivot polisher first, then the smooth side. And finally polished it with autosol on a wooden popsicle stick. It still had some deep pits but that was all I dared to polish. I also used a smooth broach to smoothen the barrel cap hole before polishing it with a bamboo toothpick.3 points

-

Both ends of the Poljot 2612.1 hairspring were "secured" with some kind if crappy glue. They came loose when I was straightening the spring. I placed all parts on the balance cock and used liquid shellac (dissolved in a bit of alcohol) to attach them again. I found using liquid shellac works easier then heating the solid stuff. The job is already fiddly enough without the need for a heatsource as well, but you need to be patient as it takes a few days for the liquid shellac to fully harden.3 points

-

I don't think the younger generation is trashing the watches they find. They don't have a ton of disposable income, so I'm pretty sure they're selling them off. There's always some arbitrage, but it's hard to imagine even the most ignorant and callous sock drawer digger throwing out something like that. I think they're coming back in style. Demand side increase. Sorta like vinyl. Most people wear iWatches/stream music. The sentimental/nerdy types wear a proper watch/listen to vinyl. CDs exist for music that wasn't ever pressed or just to catch some of the mass market; everything new is either streamed or vinyl. Watches are going the same way; quartz is for that range of years where it was what was found in the high end stuff (though I'm pretty certain mechanical was king even then), but it's really only for if you really want that very specific watch. Otherwise, it's just to pick up the bottom of the market that is still spending money. The people who are actually interested are buying mechanical, because it's what's actually interesting and engaging. Unfortunately, the new market is big bucks. Vintage is half the price with 70% the cache. More if you're suitably intentional and picky with your buys. That's admittedly a bit of speculation... I'm cloistered up here in my mountain hideout, and avoid other people as much as I can get away with...3 points

-

My 2p worth. Thyme tea may be wonderful stuff. I'm a scientist at heart. I believe in the "Scientific method". I worry that people fall for the "Naturalistic fallacy" - just because something is "natural" they think it is better than something "processed". Nature is not cuddly and friendly. It is out to kill and consume you. I don't understand people who prefer a "raw" product, just because it is "natural". It may contain any amount of active/dangerous chemicals, possible poisons, carcinogens (as seen is some Chinese medicines) etc. I prefer 'real' medicine, where the active ingredients are identified and synthesized. It is rigorously tested to prove that it works (not just a placebo as a lot of 'alternative' medicine is), and is shown to be safe. I'll stick to the processed drugs thanks.3 points

-

Hi all, this is the one I asked about opening the case a couple of days ago; I've just finished re-assembling it, its running well and looking quite nice. The strap is the one it came with, which is Gruen branded branded. It's a bit dried up but a couple of doses of Lexol should see to that. It just needed new spring bars as one had disintegrated and the other was too short. The case has some rough spots in the plating, such as the upper right strap lug, but nothing too obvious at a distance. I have sent enquiries to a couple of local platers to see if it can be refinished at a reasonable cost. I've not tried any electroplating yet and I'm going to start with nickel on another very badly worn one, originally chrome or nickel plated, rather than a gold one.3 points

-

I propose something that all right minded people can agree on Rich: that barley, hops and yeast, are natural, safe, and indeed essential to life and well being. Cheers mate2 points

-

Thinking of natural substance isn't anthrax natural? Okay true it's been enhanced by people for chemical warfare but at its base is a natural product? One of the problems with natural is that perception is it's harmless. In other words if it wasn't harmless you have to go to a doctor get a prescription it come with cautions warnings and typically natural does not. So the perception would be natural can be harmless where unfortunately that is wishful thinking. Often times dosage strength of natural can vary. We really should break this discussion up in the three categories? Categories like stuff from pharmaceutical companies. Natural products that people take as a substitute or replacement for a pharmaceutical product. Then the natural feel-good products that are probably for the most part harmless.2 points

-

I agree entirely Richard. Most drugs are initially extracted from plants. An infusion made from brewed malted barley and hops makes me feel great. And a brewed barley distillate even better2 points

-

One of the most toxic nerve agents developed is VX. The median lethal dose for an adult is 6-10 milligrams. That's milligrams!! But good old mother nature, where everything is wonderful and safe, can top that by some margin. Botulinum toxin has a median lethal dose of 1-2 nanograms. That's about 5000x more toxic than VX. You mean the "money making pharmaceutical industry" who save millions of lives every year ? In the 20th Century it is estimated about 300-500 million people died of smallpox. Due to scientific research, a vaccine was found, which led to the total eradication in 1977. If we 'trusted nature', millions would still be dying every year.2 points

-

Actually it looks quite decent? This seems to be a variation amongst the 1000 machines of what they show. So for instance those numbers above the line are showing the rate within the specific time range probably of the averaging range. I'm guessing if you change the averaging range to longer time span the numbers will spread out. Then some of the 1000 machines have the ability to change the basically the gain control which is really nice for watches that have issues with Properly picking up the signal for variety reasons. Then the graphic display this is a classic back to the days of paper printouts before the numbers existed. Yes the vintage timing machines in the past spit out a paper tape you would look at the graphical display to make diagnostics and the see if your watches either fast or slow and out of beat. They just lack the numeric display an amplitude. I'm attaching a couple of PDFs even though the graphical display is on a LCD versus paper there identical to what they used to be so a manual for paper tape machine on interpreting works just fine for the modern timing machine. Timing-Machine-Charts.PDF Witschi Training Course Document Nr. 71.1010D35e.pdf One of the things remember when you're looking at a liquid crystal screen is there are pixels. So it's hard to do a angle when you have pixels. This is where the 1900 is better because the pixels are a lot smaller. The problem with pixels versus a linear display is that you can't actually do an angle sort of. So where's as it is angling up words in this case indicating a running fast as you switching from one line to another that is where you see the weird pixel arrangement. So basically nothing is wrong the display looks outstanding. Oh and timing machine procedures? It's good to establish a procedure like for instance you wind the watch up and let it run for 15 minutes to an hour that's considered fully wound up. Initially you can wind the watch really really tight and get incorrect reading so you need a little bit of settling down time. Then for diagnostic reasons it's always good to check the watch in more than one position. The minimum would be dial-up and dial down and for a wristwatch crown down. Then it's also nice if you wait 24 hours later and checked the watch again which is good for diagnostic reasons.2 points

-

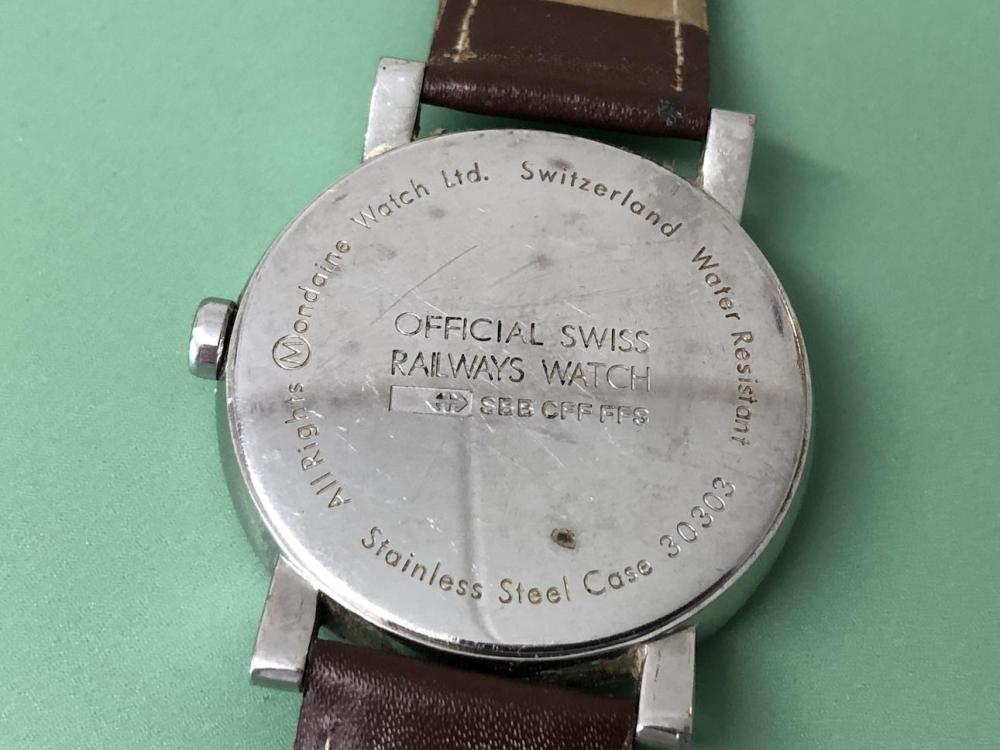

Maybe the movement was already replaced and it’s not the original. This could be very likely if it was originally a stop-2-go movement as mondaine stopped using them and they became obsolete as mondaine has the rights over that technology. Tom2 points

-

When we're younger its the voice of reason, when we're older and it tells us to do unreasonable things then it's the voice of insanity. Not to worry you wont be alone we're all heading in that direction sooner or later When we're drunk we think it's a perfect state for doing lots of things . Sooooo glad i dont drink anymore, can you imagine?2 points

-

When I hear that voice in my head and I start talking back. I'll know it's off to the funny farm for me.2 points

-

Never heard of it. I don't intend to try it. The best thing I have used and my late mother used it on me when I was a child was vicks vapor put some in a bowl with hot water put a towel over you head and bowl and breath in the vapor.2 points

-

If I mess up oiling a cap jewel. I wipe it with Rodico, dunk it in some IPA and rub gently on some tissue paper. I usually don't need to reapply epilame.2 points

-

The hairspring collet is so off-centered that when the balance is put in it's pivot holes, the 2nd coil overlaps the 1st.2 points

-

Following up on this old thread. I bought another one of these clocks on ebay (I just love these old electrics with Westminster chimes). Did a full disassemble and clean and had the same issue with the chime not having enough strength. Well, since the last one I serviced, I learned how to disassemble the MS barrels. I guy on the NAWCC forum had done it. The picture I am attaching is from him (I did not take pictures). So, I took this clock apart again and disassembled the chime barrel. Oiled the spring, and reinstalled. Wow, it made a world of difference. I would say this is the most complicated horological unit I have ever worked on. Complicated, because there are five different things that must be calibrated...one of which must occur while assembling the plates. While I have worked on more complex watches (alarm watches), there is no calibration beyond setting the hands.2 points

-

2 points

-

That sounds good Ross. I'll mention a couple of things if thats ok,that may or may not help and you may already be aware of them. If i start at the top, the pegwood and lighter fluid for pre cleaning , not all lighter fluids are the same though and it can be difficult to work out what you have. So lighter fluid is mostly naptha, also known by many other names such as benzine, probably more accurately described as petroleum ether. Lighter fluid also has other ingredients that relate to what it is actually used for ie. to improve the flame necessary to burn with the use of a fluid fill lighter and it could be these other chemical ingredients that often leave a residue on the surface of watch parts that many of us see ( try the drop on a mirror test ). So logically we want to make use of the same cleaning ability of petroleum ether but without the added ingredients that cause residue. We can do this by purchasing pure grade petroleum ether which is available from Ebay, I've just had a look and its around £25 / litre yes it is more expensive than lighter fluid, i guess maybe a tenner more per litre. So just a couple of notes to add to this, when choosing a lighter fluid, naptha, benzine, whatever you want to call it or the form you buy it in, try to get hold of one that is labelled " light distilled " or "light naptha " also sometimes called " light aliphatic " this is the carbon to hydrogen ratio, an example of its equation might be something like C3 H6 , its these two symbols that tell you how light or heavy the naptha is. The higher the H ( hydrogen) atom value is the lighter the chemical is and will evaporate quicker. High C ( carbon ) atom naphtha is heavier , evaporates more slowly and may be the cause of too much left residue on watch part surfaces. So in summary aim for a higher H value than C carbon value on the label. I'll find a good example of what to look for and come back with it. Other things to note are 1. A professional brand cleaner like Elma or L n R is probably cheaper than the petroleum ether, certainly when the ether is bought in one litre bottles and it could even be cheaper than the lighter fluid which is in the region of £1.50 for 100ml - 120ml tins. So thats more or less covered the cleaner to use, but now try soaking your pegwood in your cleaner ( lighter fluid ) before pegging the jewels, it will soften the pegwood making it a more pliable dirt dissolving tool . You can leave any watch parts that have shellac on them soaking in lighter fluid, i used to do it all the time when i started and was using light fluid and i know oldhippy did this as well when he was in the trade. I've done it overnight before without any problem to the shellac, so a couple of hours soak will be absolutely fine. Its just NOT to do that with the isopropyl as that will almost certainly soften the shellac .2 points

-

Never. Good comment about the DIY thread. Yes I have seen it. Adapted a few thing to make my own systems of cleaning. Adam and Gentlemen are my 'go to' for inspiration. I only have about 18" by 18" as my working area for cleaning. I have adapted. This is my system. After disassemble and checking I begin the clean with pegwood and lighter fluid. Fiber brush if needed. Everything , except shellac items, balance bridge and pallet fork, into lighter fluid jar. Large items at base and others into baskets. Jar into ultrasonic warm water. 3 x 2 min. Balance and Pallet in small tray and lighter fluid dripped and allowed to gently clean. All blow dried Everything from jar moved into 2nd jar containing Isopropyl alcohol. Ultrasonic 3 x 2 min. Balance and pallet dripped with Alcohol for under 1 min. Everything out and placed under nail blower for 10 min. Before assembly I recheck all parts for damage. This is when I make my decision to order parts as I can see what needs to be done. My system in now pretty good. Well, at least for an amateur.2 points

-

That's one of the Bergeon tools I have. Reasonably cheap, and the tips are well shaped and harder than the cheaper versions. Yes, cheapo versions do work, but you are always reshaping the tips - like hand levers. After fiddling with cheap levers I eventually bought some Horotec ones. Not cheap, but well worth the expense. BTW how can Bergeon justify £56 for a silicone cushion or plastic dial support, when this nicely machined bit of metal is just £12?2 points

-

2 points

-

Demagnetize it first and the tools you are using. Get yourself a tin of Ronsonol lighter fluid. A small jar with a screw on lid. Put the balance in that for a few minutes, get some tissue paper put the balance on that then dry with you bench blower, oil both staff pivots and put it back in the movement. This is what I always used to do never had any problems. I have tried one dip and it was rubbish a waste of money. Ronsonol is very friendly to shellac so no worries there.2 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)