Leaderboard

Popular Content

Showing content with the highest reputation on 03/17/24 in all areas

-

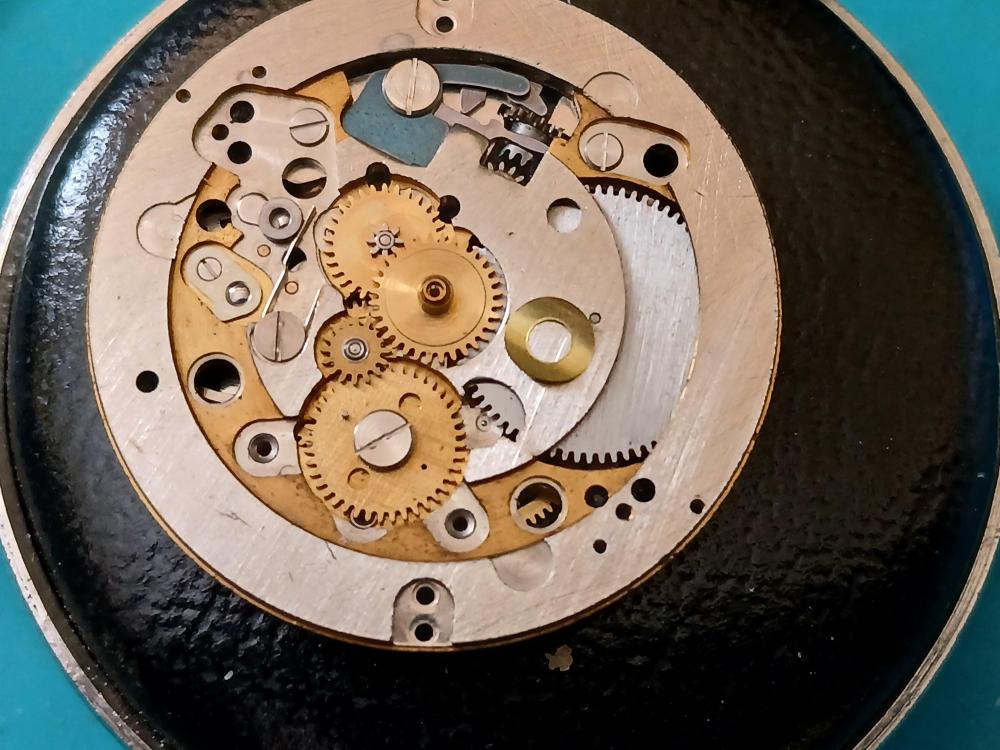

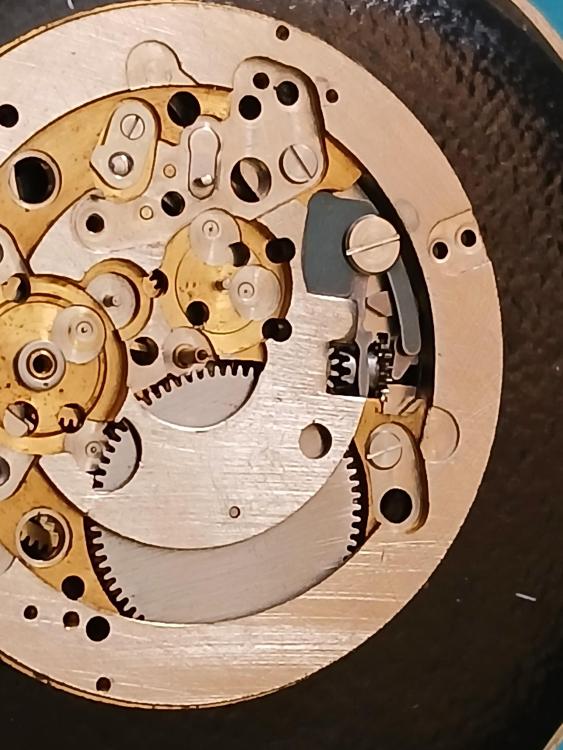

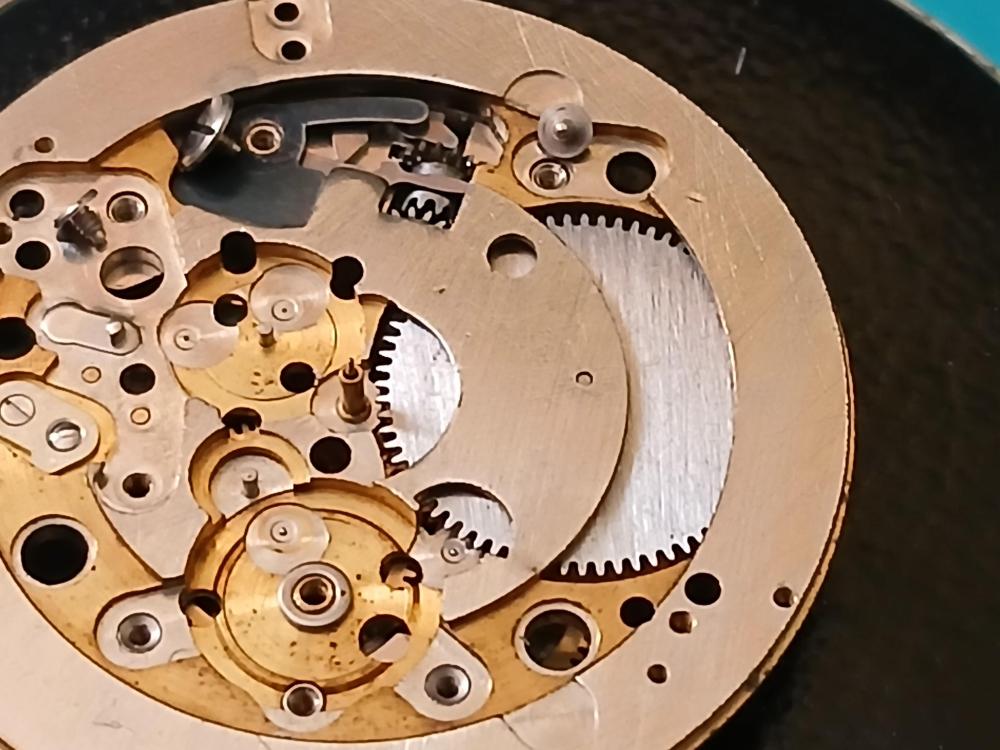

Well, I've done it. completed my first service on a pin movement. It was a non runner when I purchased it. When doing the service I found the reason. Two items on the crown wheel stopping rotation. Removed and cleaned. Only a cheap watch, but I wanted to try my skill. Pin are more difficult than jewelled watches, in my opinion. Running well. Disassembly 1 hr. Cleaning 1/2 hr. Assembly 1 1/2 hrs. Followed members instructions. Photograph each removal and watch in reverse for assembly. Happy bunny. thank you to all. Ross3 points

-

The first thing I'd do is fix that terminal curve, so you have the same gap all along it. It must be distorting the hairspring when mounted. - bringing the outer coil too close to the stud. Possibly hitting it at higher amplitude. Oddly enough, this seems to be the same problem I'm having at the moment - giving plots very similar to yours. Hairspring re-shaping time. It's an easy fix for you, no need to remove the spring. Then re-assess.3 points

-

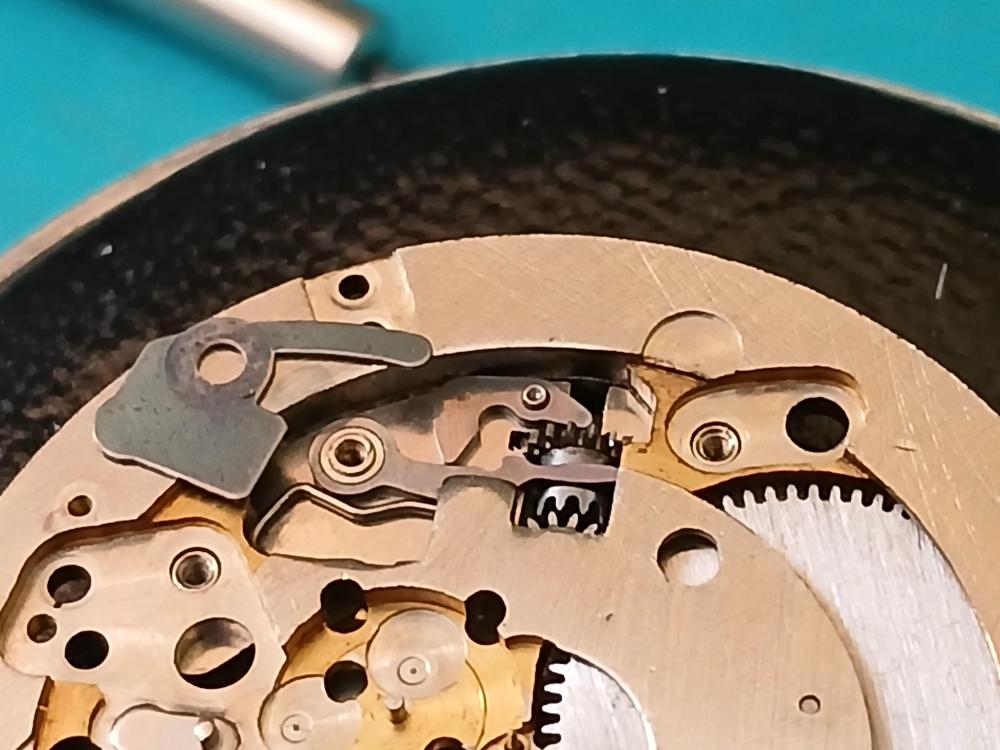

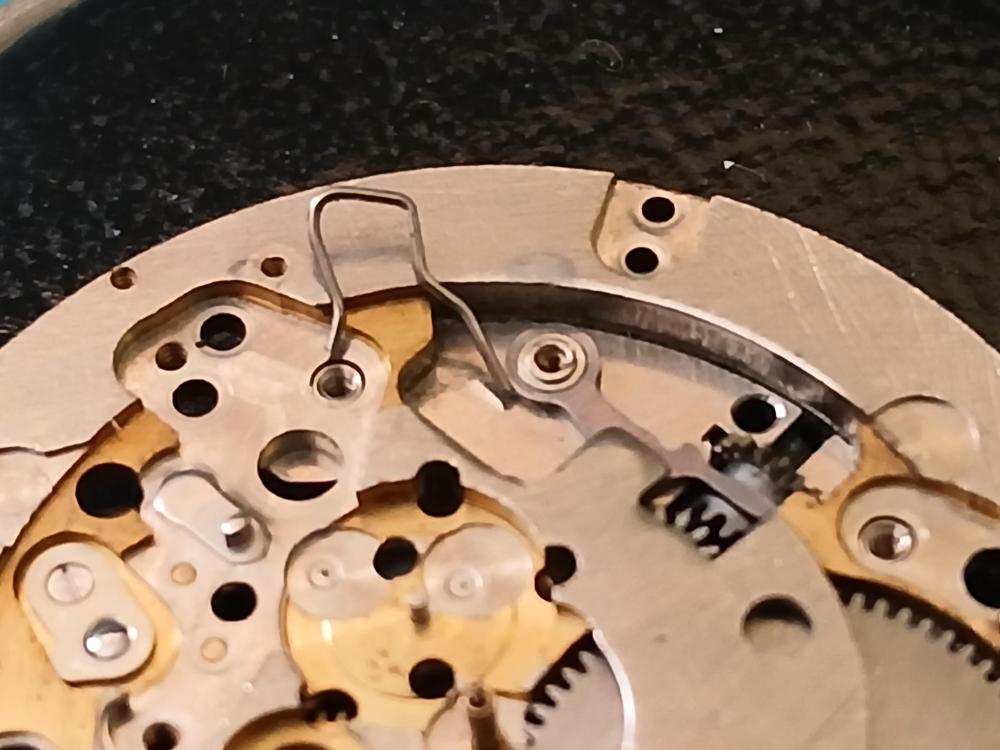

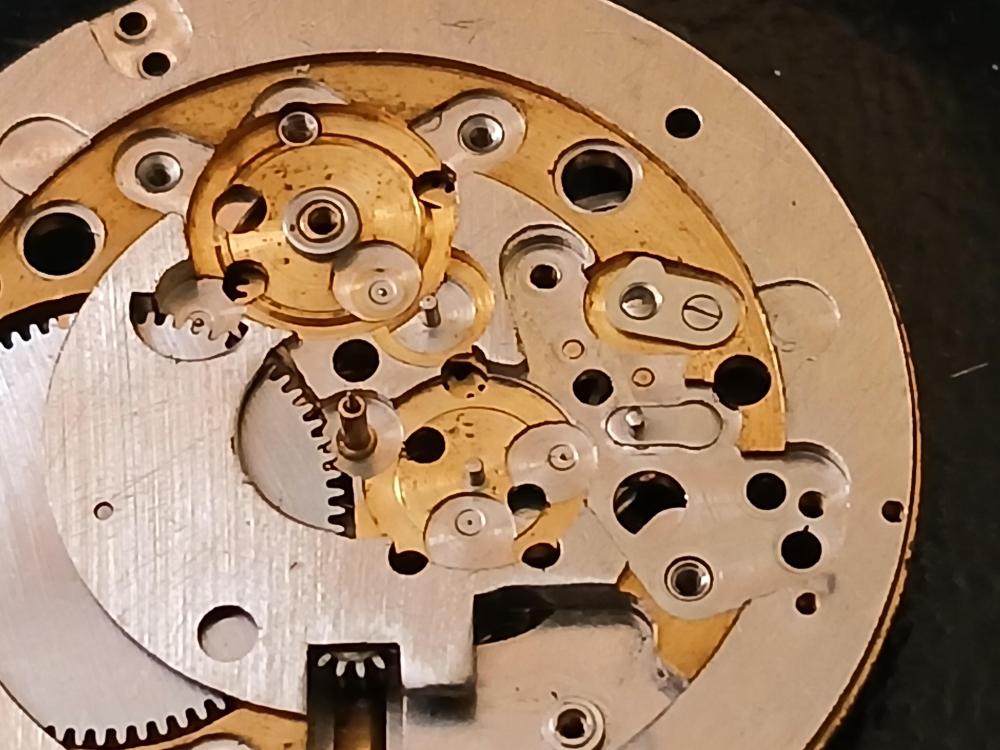

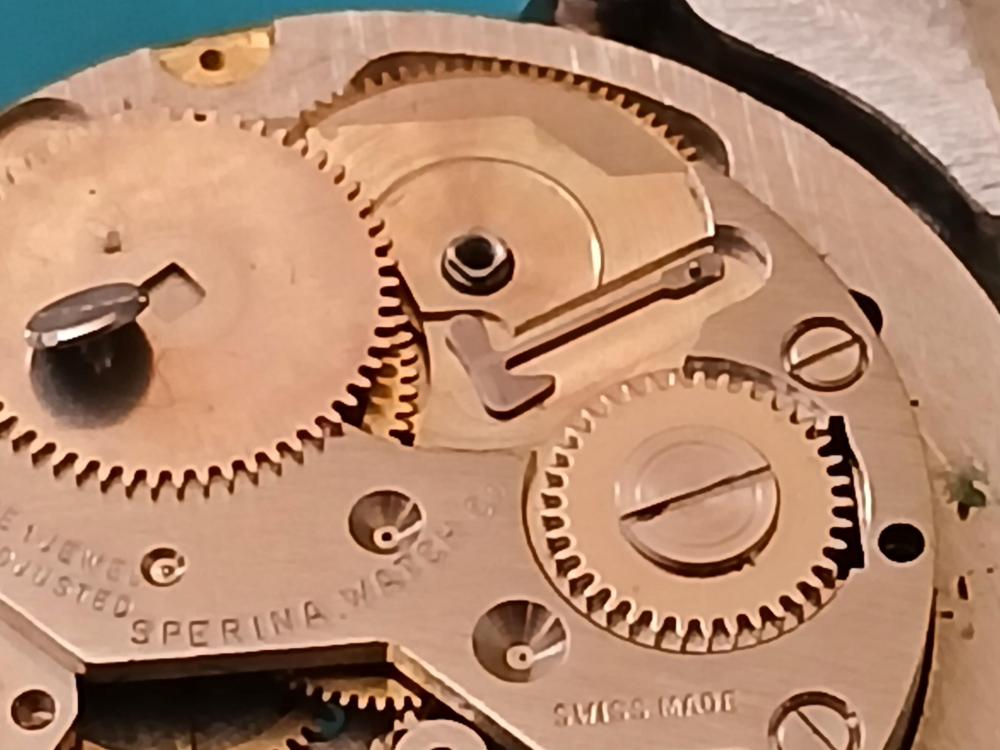

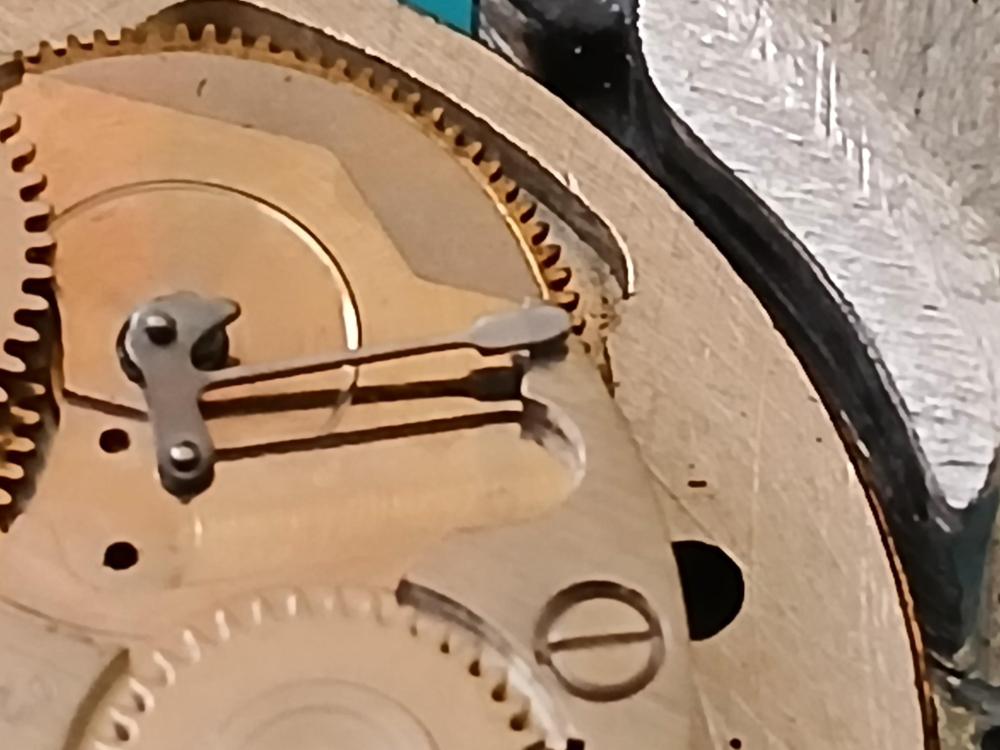

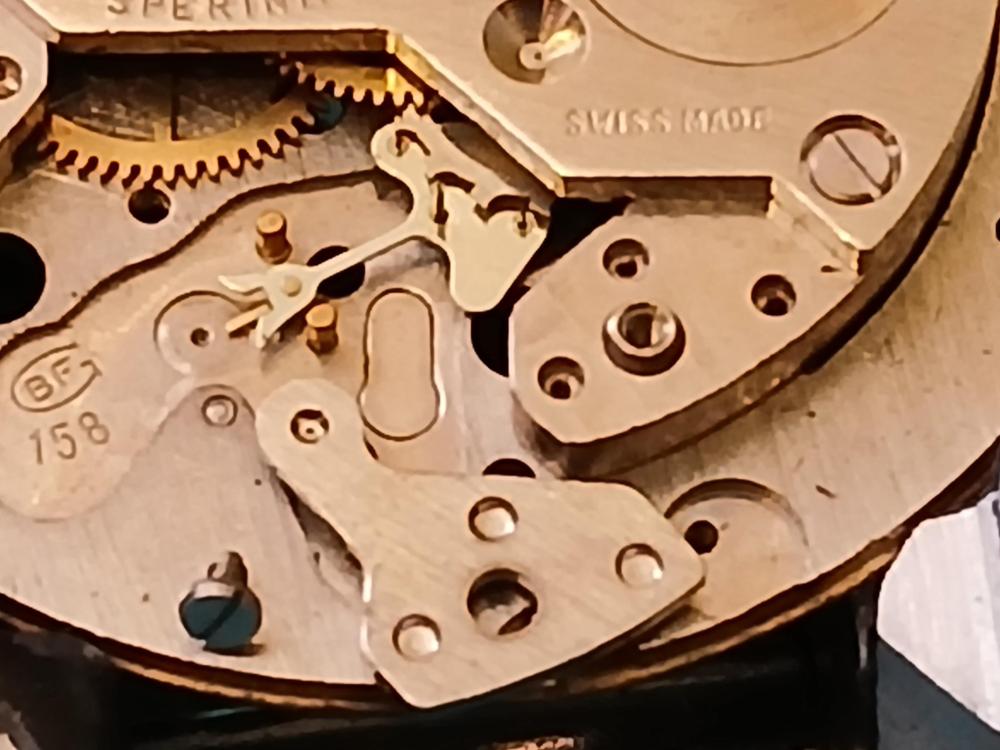

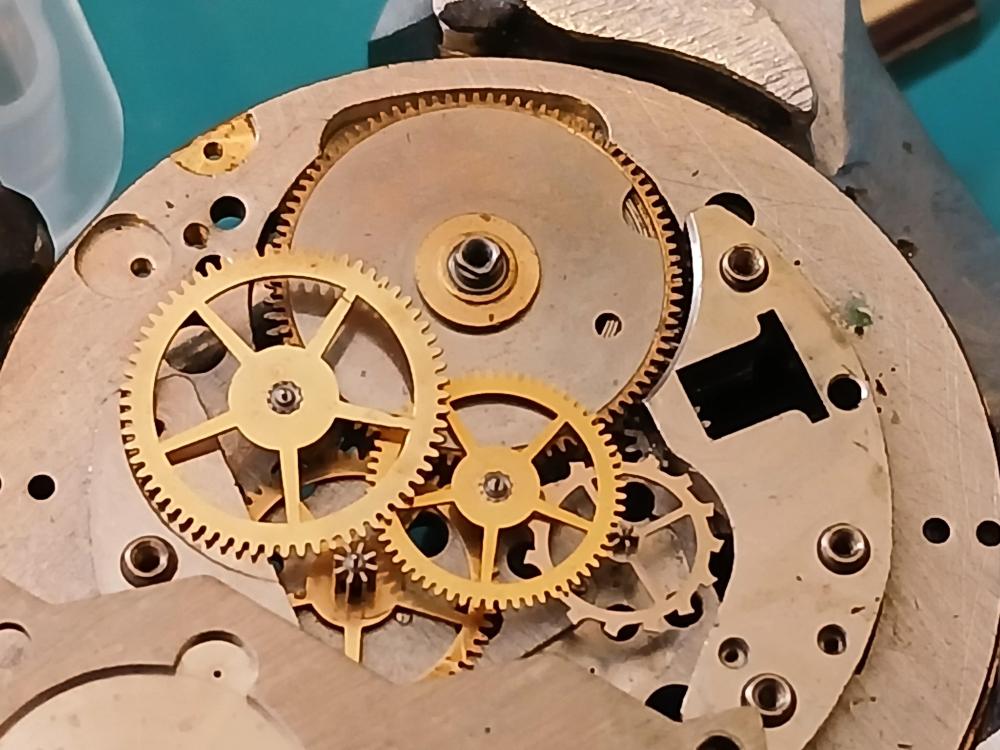

Haven't posted for a while as I've had family visiting and then sick with a cold . but did manage to work on this Gruen (AS 5203) watch which has really grown on me. It also has a cool escapement setup, and an even stranger keyless works (no sliding pinion!). Picture of pallet fork (stock image): Here is the before shot: Movement with and without automatic works: Here is the dial side showing the complicated keyless works without a sliding pinion Here is a closeup on that pallet fork in the movement: showing only 1 banking pin The image below shows the mechanism where the hands setting wheel is not horizontally brought into position, instead it engages and disengages vertically, rather than use a sliding pinion (stock image): And here is the finished watch with its new strap and crystal (original was cracked):3 points

-

OK, I can't see something criminal near the collet. At least, no touching can happen there thow I was thinking this possible. Then, the angle beginning-end is between I and II diagram, and such angle will make the movement work faster when low amplitudes and slower when high, so this choice is the best for the way the movement behaves, and if changed, the problem will only get depper and worse. So, seems that there is no problem here. Then the only point I can think of where such behavior can be caused is the studd where the hairspring can touch in high amplitude. So, please, assemble the balance again in movement and manually move it in direction so the hairspring expands to the maximal angle - 330 degr or so, and look at the distance between studd and hairspring and if it will touch the studd in some angle. At this moment I can't see another possible reason for this behavior. The terminal curve is really not perfect and can be rectified, and this must make the studd stay a little bit away from the hairspring2 points

-

2 points

-

I have successfully completed my first attempt at electro-plating. I have a few cases that were prepped by stripping the old plating and fully polishing (which took ages doing by hand). About 2 weeks ago I bought a book on the subject of electro-plating. I read the book cover to cover a few times (it was a very small book), and I thought I had a pretty good understanding of the process of electro-cleaning, surface activation, and the application of bright nickel plating. I also received some incredible help from a member of this forum who provided me with some info and tips that they've learned throughout their time in plating. I'm happy to say that my first try at this wasn't a total failure! Here are the results just after the final rinse. I wanted to plate about 20 microns on the case. My thought was that it would give me a little cushion to smooth out some of the defects. Thankfully the defects were actually quite minor. There was a small section where the plating looked to have a slightly rough surface. I believe this occurred when I was adjusting the position of the case in the tank. I bumped the anode and it came into contact with the case for several seconds. Everything else turned out quite nicely, with the exception of that rough patch. About 1 minute on a soft cotton buff with some white Dialux smoothed it out beautifully. I'm really pleased with the results!2 points

-

I do hand tool woodworking (luthiery, furniture, etc.). Requires have an incredibly sharp blade. I forget what grit my finest diamond hone is, but I finish with lapping compound on a steel backed strop. There exists a grade of hone called "surgical". I don't know if it was a medical standard at one point, still is, or if it was just as fine as could be had at some point in time, but I go way past that. Done correctly, you have no need for sand paper or any other abrasives. You get a glass smooth finish right off the blade with no fine dust to worry about. The trick to cutting pithwood is a really sharp blade, and kinda roll it on the table top. That'll get you one clean side, because the bevel of the blade will slightly crush the other side. Still usable, just not as pretty. Sounds like the commercial guys can get both sides clean, which would be nice. You might be able to get away with a fresh razor blade, and that would probably get you two OK faces.2 points

-

The need and benefits of fixing the terminal curve near the stud is obvious and go without saying, once trued, a bit of adjustment at the bend is neccessary to wholey center the spiral, a fix which not much hope can be pinned to , to get rid of this presumably actual erratic rate, , as VWatchire already tried another watch on TG and observed similar erratic rate again. Rgds1 point

-

Its always better to have the hs breathing as concentric as possible. What i learned very early on was that a hs can look great just on its own but when its held at two points ( 1 fixed and 1 continuously rotating back and forth ) its concentricity and attitude can change dramatically if those 2 points aren't set up correctly. A lot of watch repair i think is determining what funcion group an issue resides in. Loss and fluctuating of amplitude can reside in every group . Closing down on a problem is an amateur's biggest weakness that can only be strengthened with experience. I agree with Mike, although the path this discussion has taken is really interesting and quite deep , maybe overthought .1 point

-

VWatchie, the vids you posted on youtube didn't open on my tablet. Did it show the sprial breathing at high amplitude? Thats the only sure way to see if the outer circle hits the stud, or sticking or fouling itself. Top view vid of the sipiral running at real high ampplitude, replaces guesses with certainty, keep in mind please THE HITTING CAN BE INTERMITENT, so you can't loose taking vids for a minute. Rgds Joe1 point

-

That's what it looks like, yes! Yes, but I don't know if that is a problem or would explain the huge differences in rate (as previously described). I do hope @nickelsilver and @nevenbekriev will share their thoughts about what they see.1 point

-

Voltage on the probes is no constant: it depends on the connected resistor. In fact they output a current, no voltage. Important: voltage across the coil under test must be lower than about 1 V, else the circuit can spoil the result. Therefore special watch testers. The lower the test result compared to full range, the lower the voltage on the resistor/coil under test. If you test a separated coil, no Fluke or other meter can damage your coil. Fran1 point

-

I cant see exactly what you are seeing watchie, but i have worked on a lot that were not pinned. Only way i can describe it is a slit cut into the side of the collet, the hs is then put into the slit then closed up and the hs trapped inside it1 point

-

1 point

-

Acetone or nail polish remover that is the two I know of.1 point

-

I cut this using a 100 year old cut throat razor and just slicing through. The holes are where I've been poking an oiler into the end of the stick. Your razor does have to be shaving sharp though, which is a heck of a lot sharper than most (any) disposable razor blade. You could also use a microtome blade, which is effectively the same thing but is used to prepare thin tissue sections for microscope slides.1 point

-

I'm fairly certain it's cut commercially with a spinning razor sharp blade, like a meat slicer. I've never been able to get such a clean cut with a brand new high end Japanese razor knife.1 point

-

1 point

-

@VWatchie mentioned recently that he wets a piece of pith wood with degreaser and pushes the pinions into it to clean them. So, I dug out my pith wood and tried to cut some buttons off them and made a real royal mess. I try again later with a new razor blade and see if that helps. Or maybe I just have a bad batch of pith wood.1 point

-

1 point

-

Mikepilk I'll show this post to the owner when he arrives next week Never. I'll ask him if he would allow his name to be known. If he says yes, I will PM you1 point

-

If you check Fluke's spec sheet, the voltage you mentioned is under no load condition. The measuring current is in the order of uA. Should be safe for coils. I use a Taiwan made DVM and have never blown any coils to date.1 point

-

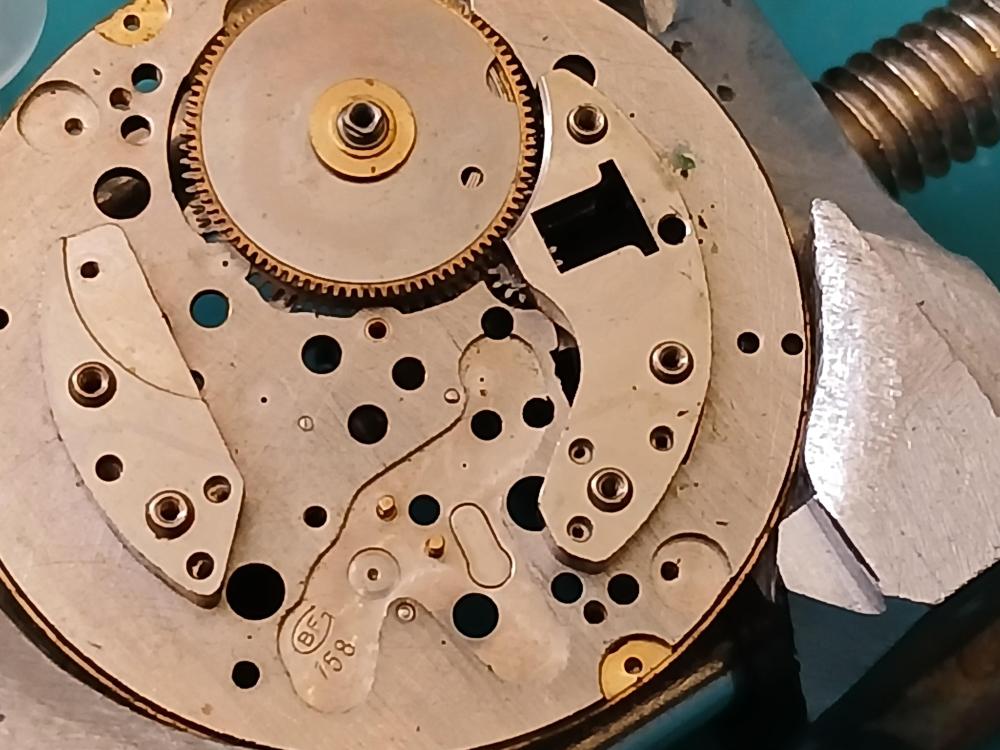

The grail of Smiths watch collectors imo and I'm sure in anyone else's would be Hillary's watch now in a museum never to be owned by anyone. Next in line would be any of the other 13 that were issued to the first Everest climbers whose party reached the summit. Unlikely these would come up for sale, i dont know if their whereabouts are known. Then we have the 27 Greenland issues, o e of which is on your bench ( I'mstill extremely jealous ). Take a moment to read the link i posted earlier. Ps. The crown does not match the crown issued. Who was it originally given to if you dont mind me asking.1 point

-

You could oil the cap in the usual way, but there's the danger it will be spread all over as you fit it. Or oil from the other side. I put some a small bit of oil on the cap to help capillary pull it through. Then oil from the other side of the jewel and poke something sharp through the hole - I have an old balance staff mounted in some brass tube. Or a sharpened oiler. But this way requires removal of the balance. So I would do it the first way1 point

-

Beautiful watch Ross. I'm a big fan of Smiths watches for a few reasons . You have a famous watch there on your bench, I'm extremely jealous. https://www.waecce.com/blogs/news/thge-1 Here you go Ross. This is exactly what the watch is. Not to worry you Ross but this could be a very expensive watch. John Hunt led this expedition same guy that led the Everest climb. This is one of watches that was issued by Smiths to the 27 lads that set off on that journey. The owner one of them ?1 point

-

Depends. If you're interested only in inspecting jewels, it's probably fine. Overkill and a lot of dedicated bench space for a single purpose tool (even by watchmaking standards), but you would be able to really get in there. If the goal is a microscope for the purposes it's generally used for around these parts, that's a non-starter. Too high power (and single power from what little information is available?), too little working distance. If you're looking for a watchmaking 'scope, there's a way-too-long thread on the subject under the title "stereomicroscopes" or similar. Currently, it seems the best deal going on the best watchmaking setup is the Eakins on Ali-X in the neighborhood of $400-some odd. A bit more layout, a LOT more scope, totally changes your watchmaking experience.1 point

-

Hi Khan. Before proceeding make a thorough check of the repaired areas to be sure you are not bridging tracks and causing short circuits as some look a bit rough. Then assemble the watch and fit battery or use a1.55v supply connected to the Plus +. And Minus - contacts The contact points for the supply with the meter to verify the power is reaching the circuit board and reaching the CMOS. Chip then check each coil with the meter for a pulse. If your meter will allow you to with micro amps scale. Some meters don’t go as low as that. Checking the circuit board without proper instruments is not easy (oscilloscope) and meters. If the CMOS is not getting power it will not work.and will not pulse the coils and the rotor. The attached below will help you understand the quartz watch a little better. Cheers. Witschi Training Course.pdf1 point

-

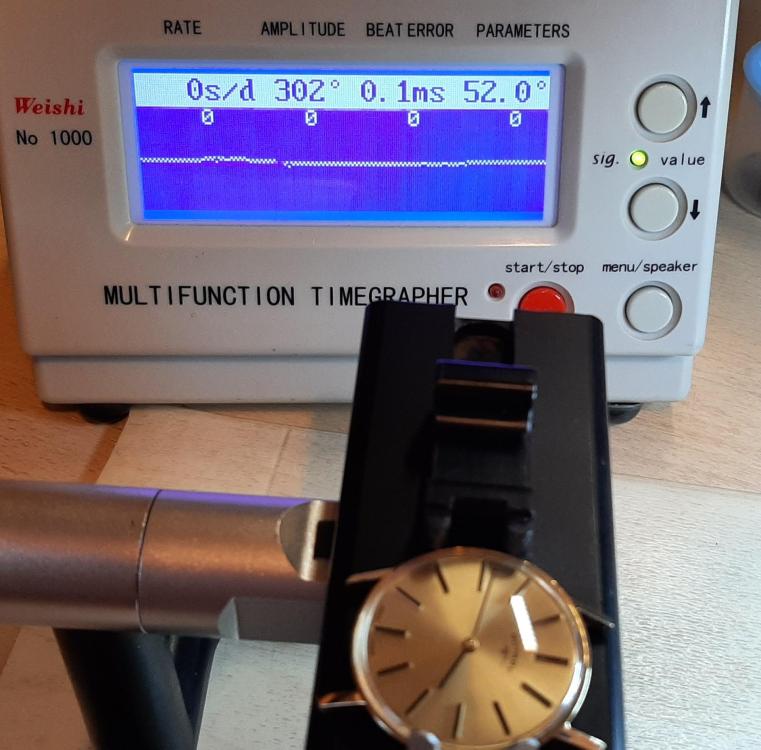

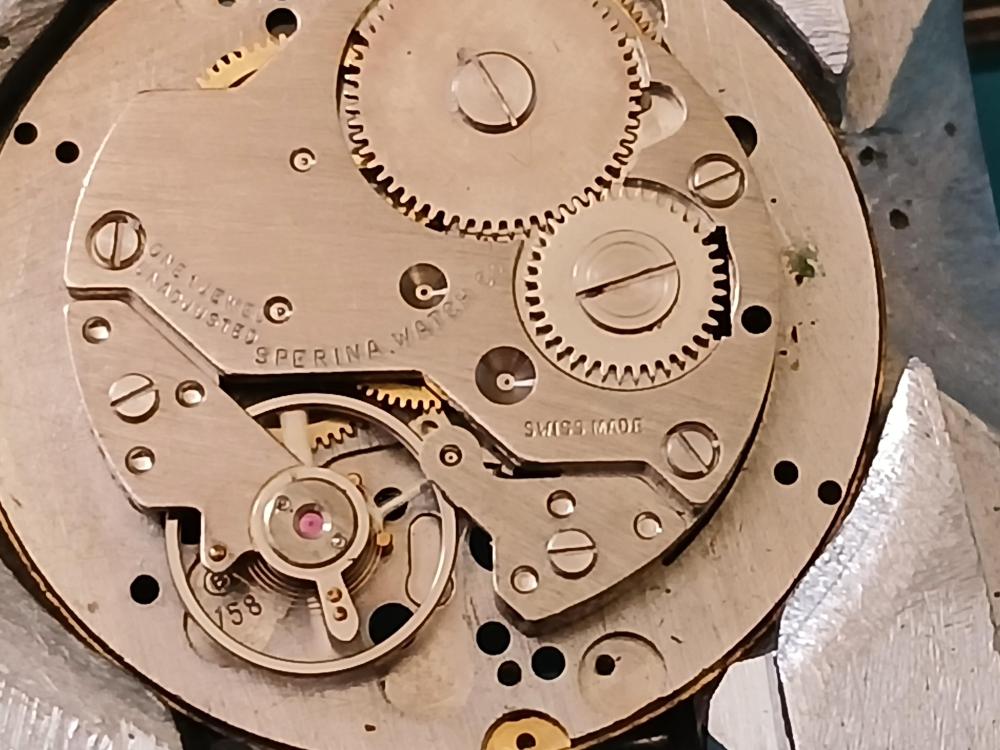

Just arrived, a Longines 30L. I've been looking for one of these for a long time. I've been a fan of Longines since I got my first, I love the quality and elegance. In the thread "looking for a simple, ultra-precise hand-wound movement - suggestions?", @nickelsilver suggested the larger Longines (30mm movements). The higher grade version of this movement (30Z) were used as observatory chronometers. So I decided I needed one. I'm expecting good performance. It's not going to just sit in one of my cases, I'm going to regularly use it. I bought it as "spares or repair", so was expecting a damaged balance. But on first look, the balance and hairspring seem perfect. It just seems to have a broken mainspring. Result BTW @nickelsilver, you also recommended Peseux as good movements. I bought a cheap Rotary with a Peseux 7050. Looked like it had been serviced by a gorrilla - the pallet fork was bent about 30°, missing pallet jewel, hairspring all out of shape. So I wasn't expecting great performance. On the timegrapher yesterday, looking good ! (I'll be buying more Peseux - good quality at a good price )1 point

-

its a lot of work but can be repaired, I would save for parts/spare and find a donor to finish if it is worth it to you....1 point

.thumb.jpg.ca502b3e67e1e13936648168231d15c1.jpg)

.thumb.jpg.b2036d29fafacc5dd87762d69c98ea08.jpg)