Leaderboard

Popular Content

Showing content with the highest reputation on 01/21/24 in all areas

-

The legal minimum manufacturer's warranty on new goods is two years. For the first 12 months, any faults are assumed to have been there from the date of manufacture, unless they are obviously the result of abuse. In the second year, the burden of proof transfers to the consumer, i.e. you might have to prove that the fault came from the manufacturer. Often, manufacturers don't make this distinction and repair on warranty up to two years after purchase no questions asked.4 points

-

3 points

-

Hi Ross. Methinks it’s time for Nucejoes can of coke, looks a bit grim in there.3 points

-

Hi @Birbdad He may well be your first , and you are confident in your abilities to do a good job but there is not a professional watchmaker out there who will warranty a watch for three years. It’s bad business practise. You in the first instance know how he wears his watch and what he doe# when wearing it . Golf for instance is a great wrecker of watches. When asked how it broke the answer just a game of golf. once the watch has left you know matter how good you are you have no control over what happens. A good client will willingly accept three to six months as it’s either the same ot more than the usual warranty. The fact that you are giving this is warranty proves to the client you take pride in your work, very rare have I had one back under the warranty I give including batteries. Do not sell yourself short. You have put the hours in learning the job invested in tools oils etc. It ts not a cheap hobby by any means.3 points

-

Having worked in IT for the majority of my working life I suspect watches will be considered the same, “I done nothing “ and “you were the last person to touch it so it’s your responsibility for life” I can think of lots of ways “normal “ use would break a mechanical watch by the uninformed/unthinking. ”it stopped while I was washing the car and it all steamed up, I haven’t had time to get it back to you for the past 6 months “ cue @Nucejoe ‘s shares in coke going up Tom3 points

-

Hi. With cars and other electrical items you purchase an extended warranty after the original twelve months has passed, with repairs etc I would offer three months as not all clients are truthfull. Case. Having had the watch serviced etc he wears it for twelve months, when drilling with a hammer drill the watch stops so under the warranty in your case three years he returns the watch saying it keeps stopping . Upon your inspection you find a bent pivot or at worst a broken balance which may cost you several pounds to replace or a staff the same. You are duty bound to fix it under the warranty. Even the professionals only give three months. Some years back my brothers Omega Seamaster was serviced by Omega and three months warranty in respect of parts fitted. So charge a fair price and three months. When I do batteries I tell the client he has twelve months warranty on the battery should it fail within that time I replace F.o.c. And I have had very few back. Reason is that you do get rogue batteries even though I only use top quality RENATA. What you do is your own affair and with your consience3 points

-

3 points

-

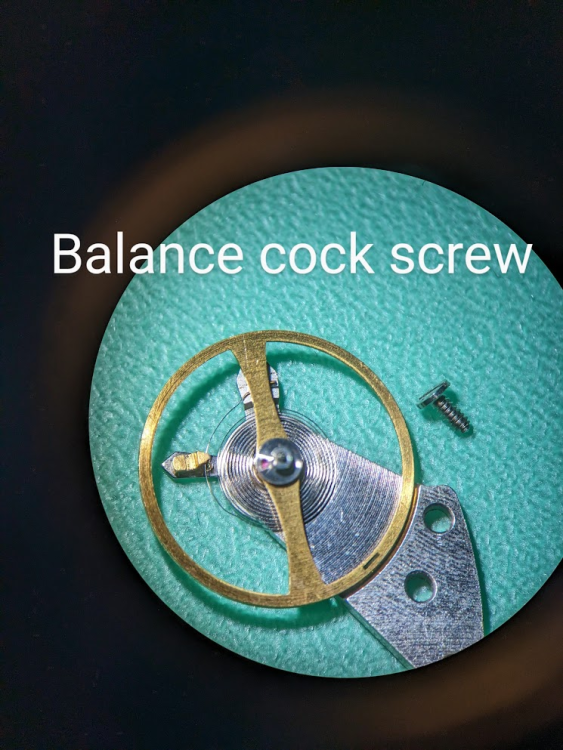

If something looks super delicate, it probably is! (yes, that's the dial side shock setting spring thing snapped in half!) Fortunately this was my "learning" movement, the seagull st3601 that I've been following Mr. Lovick's lessons with. Now, I could try to source the part, and I think I might make an intellectual exercise of it, but I don't imagine that it's worth the shipping for a learning device to repair rather than get another movement and try again. On the bright side, I learned a bunch in this teardown, and the train of wheels went together very nicely, and it was the first time I'd wound a mainspring (using the rs-winders 3D printed winding tools) so on the whole, this was a positive despite the failure.2 points

-

Well done. In situ it looks brilliant. I won't ask how much time you spent on this one...unless your friend is your bookie your friend owes you big. (You can quote me...haha)2 points

-

I've seen quite a lot of watches of this era which are made from solid nickel with a chrome plating. In some instances where the chrome has been damaged the underlying Nickel has shown through with a very yellow colour.2 points

-

2 points

-

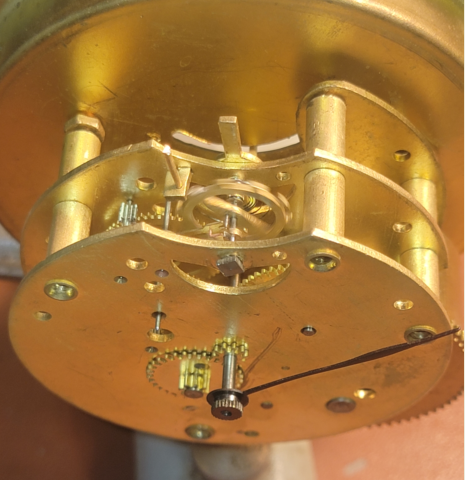

"Once cleaned, reassemble, bag, label the calibre and all usable parts". Doing, as Richard and rehajm have suggested. Even going to try Nucejoe's Coca Cola clean. Just a note. The movement is an AR167, not AR77. Keypads pressed in error. Regards to all. Ross2 points

-

See, the thicker endstone will lead to bigger force in the shock device spring, as it will be more bent than normally. The thinner - vice versa - will lead to smaller force, and even in some cases to no force at all and free play, which is not acceptable. But, if the spring apyes some force and the setting is pressed to the bottom of the shock device, then the thickness of the end stone will make no difference on the axial free play of the balance. Well, this is true if the diameter of the stone is correct - it must be not bigger than the 'nest' in the setting so it will go in, and it must be not to small so not to sink and touch the hole stone. I guess the problem really is replaced setting with one that is similar, but higher. Putting the enstone upside down will make free play smaller, as the rounded surface of the stone will go closer to the hole stone. May be Topic starter will be able to solve His problem this way. This is not so good probably in terms of oil retention, but yet will be some decision if it will ensure normal axial free play and amplitude.2 points

-

'That's not going to get better...' Sorry mate. Good news is your attitude towards it is brilliant. I've over paid for a few unsalvageables, even after seeing the movement. Give it a 'permanent' home in a parts tray and you can pick away at it when you have only short time, you can find out what it needs instead of the bin, experiment with new techniques, discover you can save elements as your skills improve, etc. I have a waltham A-11 that was always a rusty 'parts' watch but with all the above it is a set of hands away from being a wearable timekeeper...keep at it...2 points

-

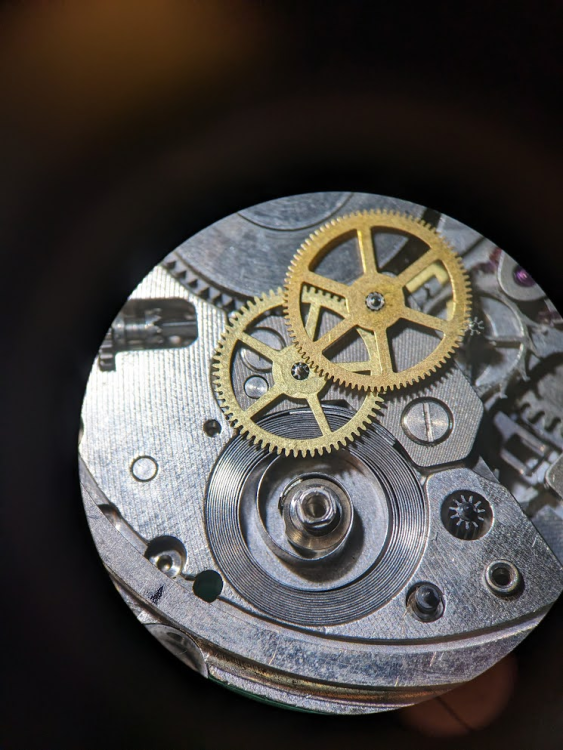

We have differences here in terminology... What You show last is the center wheel, also called 2nd wheel. Center as it stays in the center, the minute hand is on it's arbor. The Crown wheel is actually the escape wheel in verge escapement. It is shown with arrow in the picture And what You seems to call central wheel, is actually the balance. The balance staff in this escapement is called 'VERGE' or in German 'SCHPINDEL' By the way, I didn't see on You picts the small pinion that I talked about - the one on the end of repeater train that regulates the speed of repeater. Is it there?2 points

-

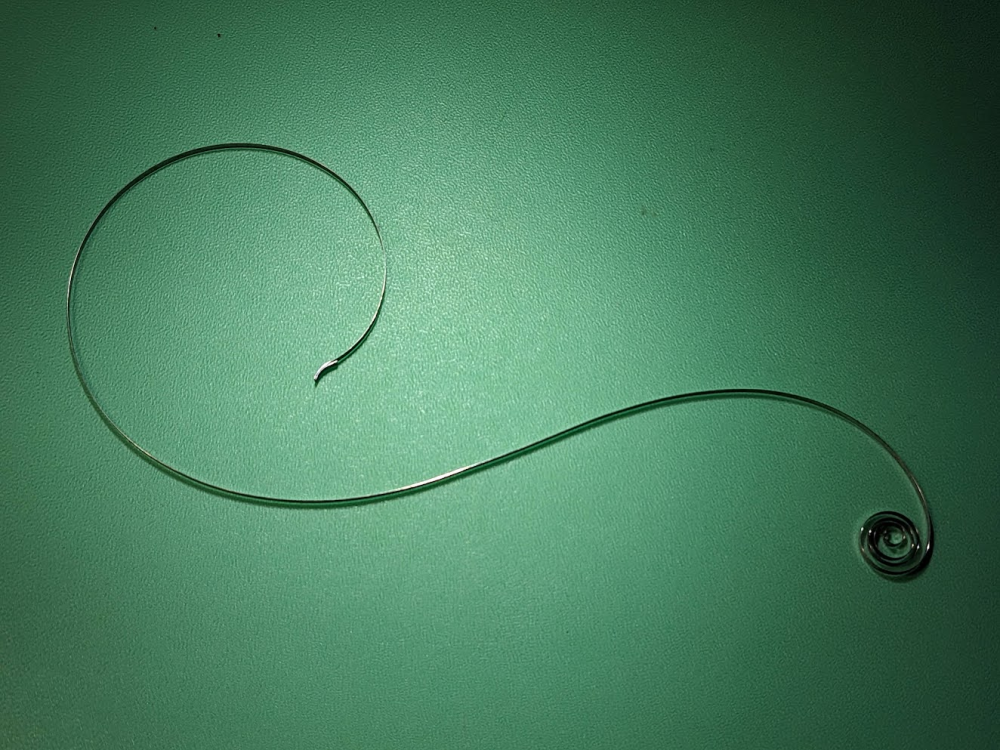

Ramble away - I'm still battling trying to get that Breguet overcoil at the correct height - getting enough clearance and allowing for a little endshake is a real challenge. The microscope is no good at looking sideways. Yes I know I can get a decent view if you hold the movement sideways. My problem was getting things in focus - with a 0.5 Barlow lens on my Amscope it's just beyond the zoom limit. Just tried it without and Bingo - the working range is close but the image double the size so will do nicely for balance fiddling. There will now be an intermission for Irish Stew....2 points

-

The V-L scale and the square that can be turned is for adjustment of repeater speed. On the bottom of the square part is the hole of the last bearing of the repeater train, where only small pinion with no table sits. Turning of the square changes the distance between this pinion and the wheel that iti is meshed to. !!! decreasing the distance is possible beyond the point where the pointer leaves the scale and forcing in this direction will lead to breaking the pivots of the small pinion!!! What I wanted to see is the teeth of the crown wheel. The crown wheel is seen, but it teeth are under the down side balance kock, so please make picture from another angle, that alows to see the teeth. Actually, the teeth are seen on the next picture and seem to be good. The chain is placed on it's place AFTER assembling of the movement. It is easier to do it when the movement is assembled, but balance is not in it's place, so the train can move freely. Then, the barrel end (hook) of the chain is attached to the hole on te barrel. The barrel is rotated by wooden stick untill the chain is fully wound on the barrel. Then, the fusee end is atached to the fusee, some force is aplyed to the barrel in order to strain the chain and to let the train move untill the fusee gets to the position where the chain is strained and no more turning of the fusee is possible. Then, holding the barrel not to let the chain get loose, the ratchet wheel is put on the square of the barrel arbor, the arbor is rotated in a manner that the spring is wound a little and will hold the cain strained, and the click is engaged with the ratchet wheel. Then, block the train and wind the spring slowly (by the fusee arbor) and the same time observe if the chain goes correctly on the fusee channel. If needed, help the chain not to go out the channel, this is only when first winding. After that, release the train and let the spring unwind by train turning. !!!All train bearings must be oiled!!!2 points

-

"Always a risk not seeing what is inside the watch." Have to agree. However, it has taken me 3 hours to disassemble. Observations. I was not the first. Dial side. Dial and calendar = gunk every where. Looks like glue? It wasn't, but flakes everywhere. Scrap WD40 on seized parts. Nearly everything. 3 seized screws broken heads. Barrel bridge. Balance cock. Train bridge. Gentle easing on bridges and cock and they lifted past the head. Phew? The balance spring is in superb condition. All parts appear in good condition. Amazing. All will be reusable after cleaning. 1. Broken part. Calendar quick jump lever. (Bummer, this is the part I needed). Spring for Calendar jump lever missing. (I've got one of these) Really enjoyed this disassemble. No pings or damage on my part. Video made of the whole thing. Not going to post it as I would have to learn how to re-edit. Been so long since I used the video software.2 points

-

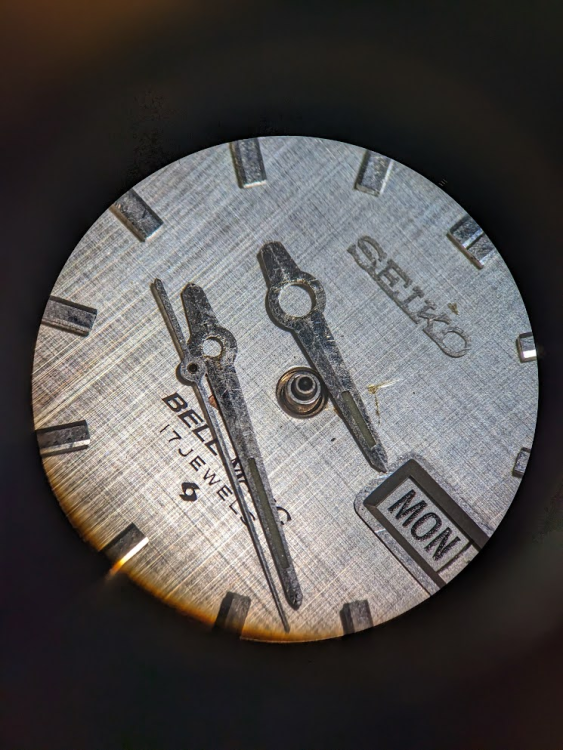

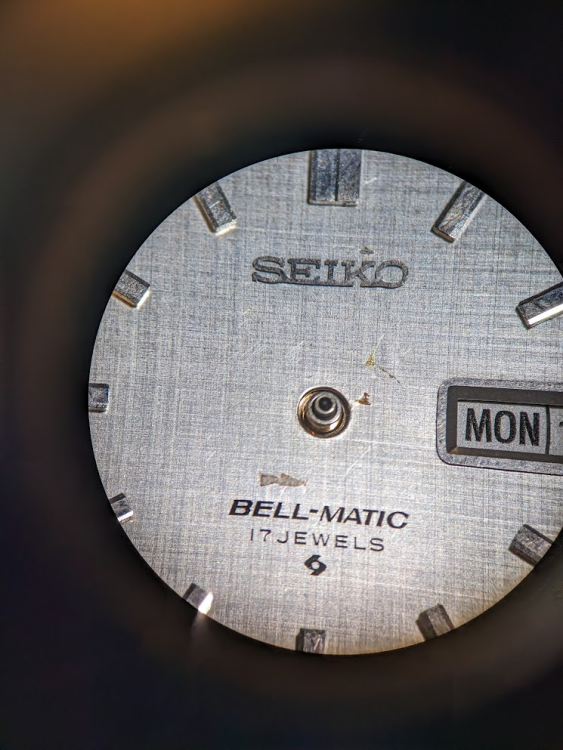

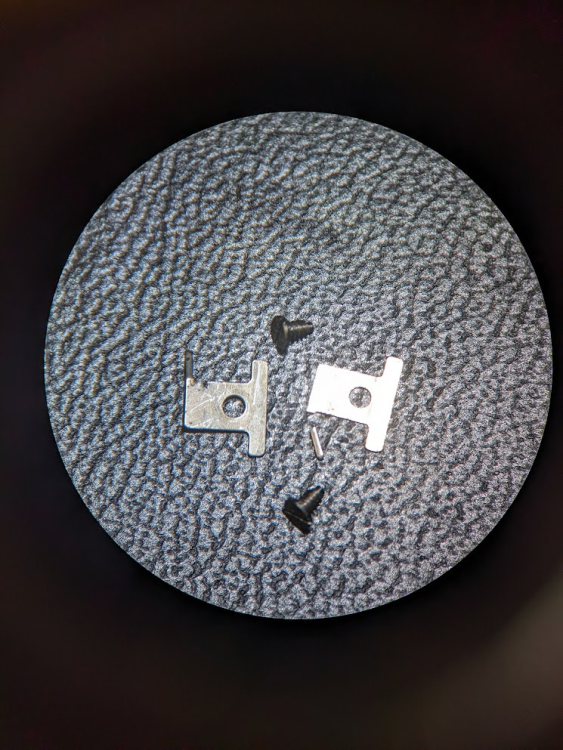

Alright, got a tiny little crowbar and cracked this sucker open. So far i mostly like what i see. Somebody who had no business inside this thing was inside it. Lots of hairs and fibers, lots of pretty mangled screw slots and tweezer slip marks. Sad cuz the movement appears to be pretty pristine aside from that and a gross greasy film covering everything. I low key raged when i got a close look at the hands and saw somebody tried...very incompetently to set them with tweezers. Even more rage inducing, this dial looked lovely other than what appeared to be some debris on it. That debris is actually corrosion where whoever tried to set those hand slipped multiple times gouging and scratching the finish allowing moisture in. It's rust under the dial finish which is making it bubble up. Some good dial news is what I thought was a very ugly unattractive patina is actually some weird greasy residue. A little work with a pointed qtip and the indices and hands look about a million times shinier! Seemed like a bad omen but immediately i notice one of the alarm set ring retaining thingy's is broken. Sigh, hopefully I can find a new one What i thought was some light corrosion or ugly patina is the same greasy residue that has covered EVERYTHING. No idea what that is. It's just a film on everything. But that means this movement will absolutely shine when it's clean! Was so pleased to see the balance looked pretty great. Could probably use a little shaping towards the beginning of the terminal curve but I am not gonna mess with it unless i absolutely have to. New balance completes for this thing are almost 100 bucks if i screw it up. Also this is how i'm keeping track of screws. Labeling and photographing each set. The ONLY fault this thing seemed to have was the alarm stopped working two days after i got it. Well now i know why. Somehow the arbor slipped out of the mainspring, the center coil of the mainspring was elevated a bit and was pushed out. The mainspring is perfectly in flat still. I have no idea if this is a worn out or healthy mainspring. If anybody knows plz chime in. If i could reuse it that would be nice, though the winder to put it back in will cost me about 35 bucks more than a new one lol. but it would nice to have it on hand for future services as this is a keeper. That's where i am now. Tomorrow i'll take apart the calandar/alarm side.2 points

-

Just thought I would add a side note to my recent restoration, I used some super glue gel instead of regular super glue and found it far better to use on replacing the dial markers, here's how I did it in case anyone is interested Positioned the loose dial marker in its correct position on the front of the dial With the dial marker held in by friction I turned over the dial, so the back was now facing up I then opened up the super glue gel and squeezed a small blob out of the tip of the tube so it was just visible on the tip of the tube I then used a tooth pick to scoop up a small blob of gel from the tip of the tube I then dabbed a small droplet/blob of glue onto the foot of the dial marker that was sticking through the back of the dial with the tooth pick gel Being gel the glue stayed where I put it with little risk of running through to the front of the dial Being gel it has a slightly longer setting time, so you have time to play with it a little before its too late After it dried I moved onto the next one for good measure I also re-glued the markers which hadn't become free, just in case they were thinking about it Hope this helps2 points

-

Haha i was trying to think of examples where a customer would not consider he had damaged the watch. I came up with playing golf, my next was a genuine case of me drilling out a door lock for somebody that had lost their key. I was wearing a timex that i had just repaired, it stopped halfway through the job. The impulse pin had jumped over the fork slot through excessive vibration, an easy fix but i should have known better than to wear it and use a drill. Customers can be funny people, with some if its stopped working then its stopped working and they dont care why. Might seem over the top but if its to be a regular thing then a simple detailed written warranty will cover your back. Any new watch i have bought was only guaranteed for one year.2 points

-

I found this thread really informative. I too have struggled trying to figure out a reasonable rate to charge. I've become known (in my small local circle) as the guy who works on old Seikos. While that sounds a bit dull, there is some truth to that statement. I have a soft spot for those old 6138 & 6139 Seiko chronographs from the 70's and have done a number of them (along with other watches of course) for myself and friends. With friends, it's always been a 'handshake' type deal where they pay me a few dollars for my time and cover any parts costs. They are also not in any rush to get their watch back (as I do this work during my off-hours). I have had several people ask me to service their old Seiko chronograph, or other type of watch. I am very comfortable with those movements and do not have any fear of taking on the work, but I honestly do not know what a fair rate would be. I've always done them for my own enjoyment or for friends who've begun to appreciate those watches more as they've seen my past projects.2 points

-

Managed to rescue this Seiko 7009A (August 1978), it needed a new crystal and date change return spring (the huge banana shaped one), the bracelet needed some TLC on the bufing machine and re-shape some of the bent links, and the rest is original. I had to do a lot of gluing on the dial to replace all those markers, fortunately they were all still there , then re-lumed the hands, Before, lots of : After: 250 degrees amplitude and 0.0 beat error + 5 seconds/day face up and -5 seconds/day face down so very respectable for this old timer.2 points

-

I'm in the process of replating an old Tudor watch case. I assumed it was nickel over brass, but I stripped the nickel and it isn't brass. The surface is quite rough so I want to put on a thick coat of copper first. I'm using acid copper plating solution. So if the case is zinc, I need to put a thin layer of nickel on first. Any ideas what metals were used for old watch cases ?1 point

-

Yes. I suffer from being a relative newbee to watch restoration (have been learning for the past 2 years and done several pocket watches but nothing like this) and a definitely a virgin to a "verge fusee" let alone a repeater. Here is the crown wheel front and back and the last repeater pinion. I also added the fusee with chain. Thank you Neven for all your help. Your explanation on how to set the chain is excellent. Are there any books or papers on these watches? They are not discussed in any other books and I have most of them. Thanks, bob1 point

-

All of my watch/clock work is gratis. I get something from it though--experience, and satisfaction! I think about six hours total. When I am not doing horology or driving my tractor, I am an expert witness for patent litigation. If those six hours were on a patent case, it would bring a handsome sum! Alas...it is horology!1 point

-

I totally agree, only sold them because most of them didn't work, the charity shops would have no interest and neither do I. After postage, I probably made £1 but someone might repair them, which is better than being thrown away.1 point

-

I did consider selling them off too. But being a collection of either cheap quartz/fashion watches I thought better of it. They don't seem to fetch much after fees/postage and the such on ebay. You can buy quartz watches by weight it seems! After chatting with my local charity shop and seeing that these seem to sell for them. I thought this could be a good way of moving them forward.1 point

-

Hi Rob welcome fella. Joe's advice is bang imo. Get watches of little value but complete to begin learning with. Less stressful knowing that mistakes are not so painful. Mangled mainsprings are non repairable whereas mangled hairsprings can be. The possibility of replacing a mainspring though is higher.1 point

-

Seikos are not crap! This is crap (see below). I picked this at a car boot (swap meet or flea market here in the states) for $5. I showed the seller that it was fake and we had a brief conversation about why would someone fake a Seiko? I could not help but posting it here because I think the OP's watch is what this watch is trying to be. An interesting aside is that the quartz movement is a Sunon SP28 and has 4 beats per second and so kind of looks like it "sweeps" like a mechanical. I may cross this into another case as the movement is worth more than the $5 as is the case...1 point

-

My mantra, which I repeat over and over : "never buy a watch unless you see pics of the movement" (But I am guilty of not doing this on some cheap watches which seem OK. And yes, I have ended up with Mubai Specials )1 point

-

1 point

-

1 point

-

1 point

-

I don’t think I’ve ever seen a dial lose the markers en masse like that. The conditions to bring that about must be interesting… Well done as always Waggy! …a good point but for a watch literally rescued from the bin I’ll allow it…1 point

-

Hello and welcome to the forum, nearly as expensive as fixing cars but I am sure the wife appreciates you being at home.1 point

-

1 point

-

You could use them to remove the cannon pinon. I always recommend use the right tool for the job, there are many tools for the removal of cannon pinons. nevenbekriev, what has your video got to do with the original question? Please do not hijack a thread just to post something. You can start a new thread. I might remove it.1 point

-

i am from Switzerland......... i knew about this, what a shame for Swatch-Group ! the best Answer is to replace this Movement with a Selitta SW200, still swiss made and you get Parts..... regards, Ernst1 point

-

I think the pallet fork finally sat in place randomly and got power. Well, the watch is running. I really appreciate everyone's help! Is the watch from 1978 according to the serial 855656? Again thanks to everyone, this forum is very helpful for someone new like me. (And excuse the mold on the dial. The person who sold this to me said it didn't run for many years)1 point

-

That looks easy enough to make.1 point

-

Hi. It’s usually a sign that the battery is low, change that. If you have a meter check the old battery anything below 1.2 v. I believe is not good. Although I have had watches running on 1 v ?1 point

-

Unfortunately, 219 index wheels are difficult and hard to find. They aint the same as a 218 wheel. Took me a year or two to source last one, and that came from dead movement I got by sheer chance... My advice would be to change the entire movement to a 218x Much easier than finding parts for the lesser common 219... They are completely interchangeable as a movement (although some of their parts are not)--providing you choose the right type, ie, day date to day date...1 point

-

Just finshed the square watch here the rest of the photos. Outline. and then chipping away the glass photo can be seen aboved. ended up having to start a new one since i over cut one of the corners. Over all this took a good bit of time, about 5 broken crystals but being that this was my first time doing custom crystal i think over all it came out well, happy to put my name on this and return it to the customers. with more pratice i hope to do this much quicker. and maybe someone will have some tips or others tools i'll be able to use to make it quicker. As a side not how much does this type of work normally cost? Currently im charging 45$ CAD retail for this.1 point

.thumb.png.305ae08be18e65c1bd64ca360f7495c9.png)