Leaderboard

Popular Content

Showing content with the highest reputation on 12/23/23 in all areas

-

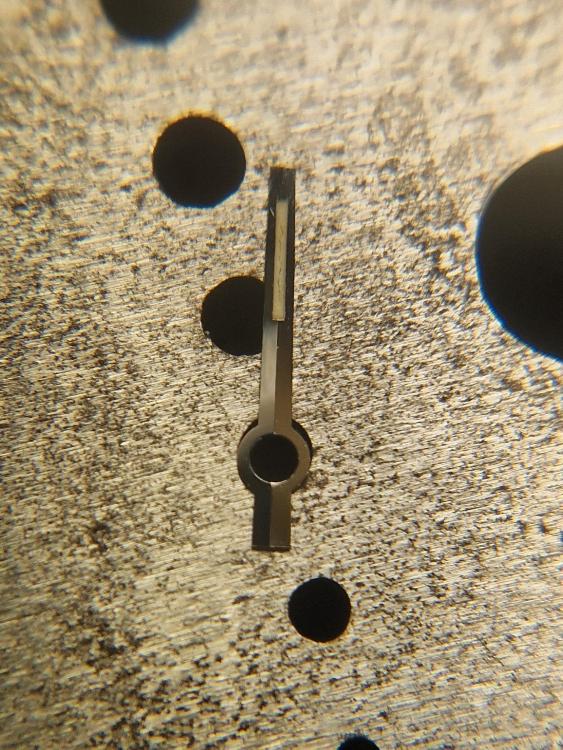

OK...more like a "place" than a "center." I will be spending half my time here, so I needed some way to do horology. Since Accutrons need a subset of my tools, and I have about 50 to work on, I decided that I could setup to do just Accutrons here. I still need a cleaning setup...working on that! I have the microscope, test set, and the hand tools. Today, I took an Accutron that was not working, opened it up, adjusted the index and got it running. It needs a cleaning, but I was proving the tool set to see if anything was missing. Hopefully I will solve the cleaning methodology over the next couple of weeks.9 points

-

Thanks very much. @Neverenoughwatches The naphtha worked just perfect and I was able to unwind the traditional way releasing the click. Everything is very gummed and stuck. The movement looks very nice and it might be because it was never touched for service since it was assembled first time! Thanks again. Merry Xmas from down under, Melbourne-Australia.3 points

-

3 points

-

I actually like some of the colorful dials. I have at least one in my stash, if not more. I think the one I'm thinking of was a 404, but I actually bought it because I just liked the way it looked. Come to think of it, the Indian watches are probably what the Russian watches used to be. The real value leader. They're robust and simple and have some really good features. It's not like you can't find piles and piles of Russian watches that are, as Stephen Colbert would say, "is potato". You DON'T have to deal with the shims and crap. I don't think you get as much variety in terms of complications, but boy do you get a wide range of color! Personally, I'm no unicorn farmer, but I'm sick of all the white-black spectrum everything trend. It would be REALLY easy to specialize in HMT watches, build up a really nice parts stash from cheap Mumbai specials. Maybe even Mumbai some specials of your own... Just have a rainbow of genuinely decent, inexpensive watches to sell off for tool money, give to friends, etc.3 points

-

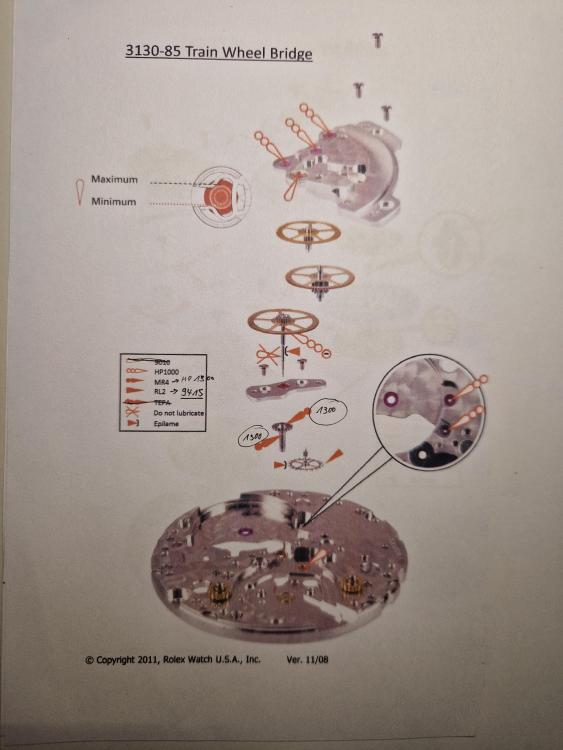

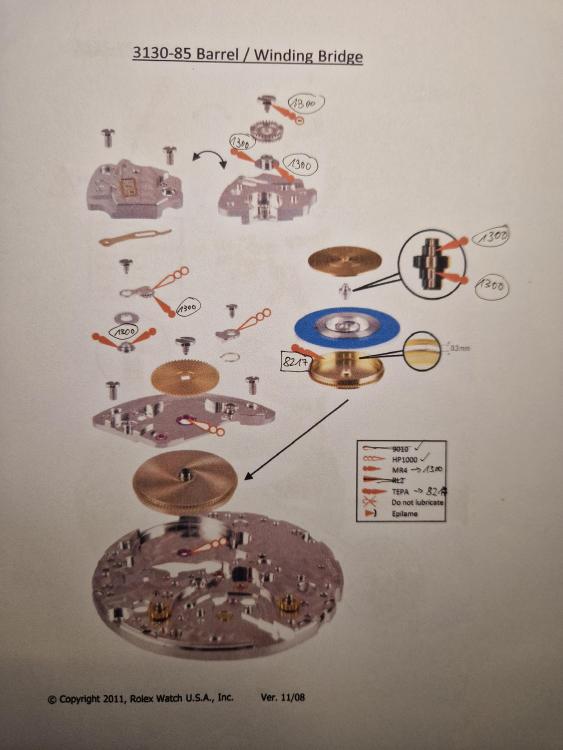

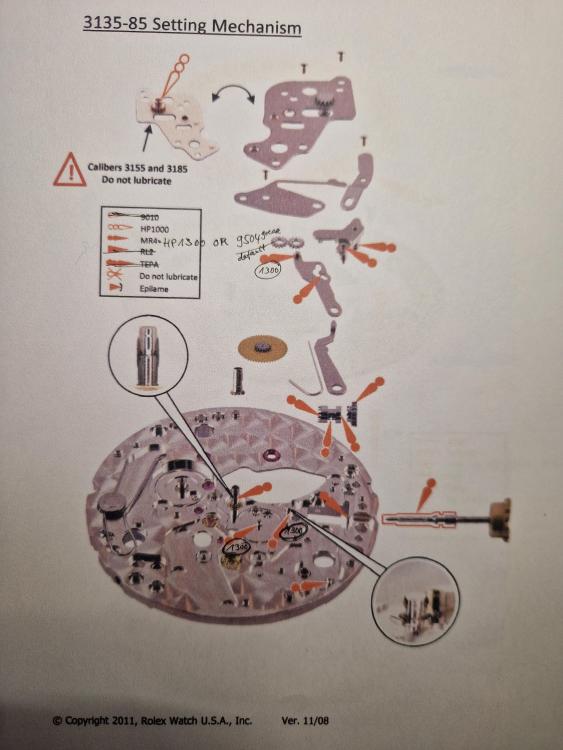

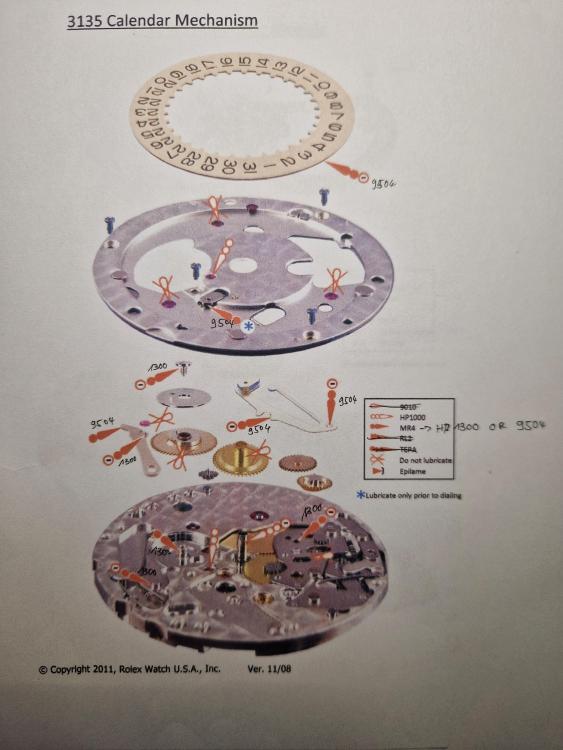

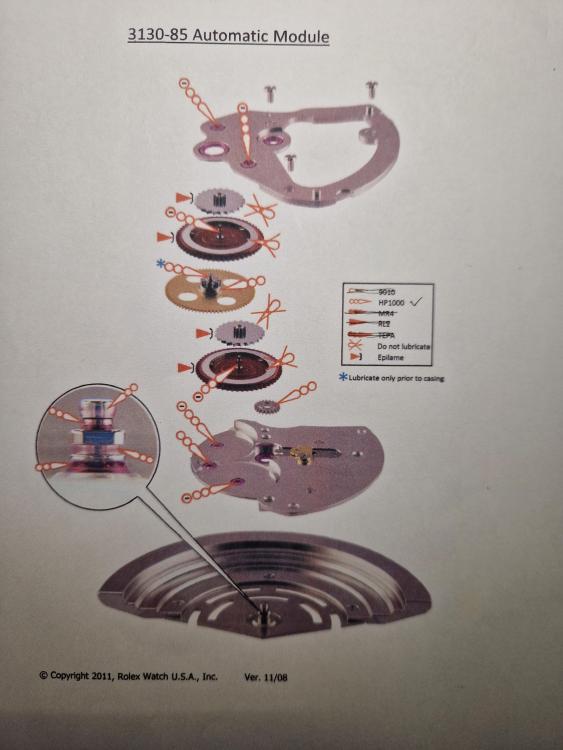

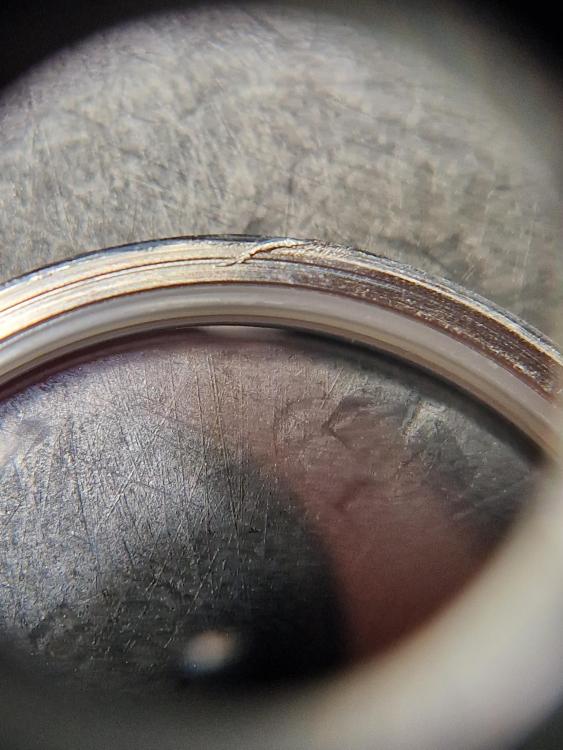

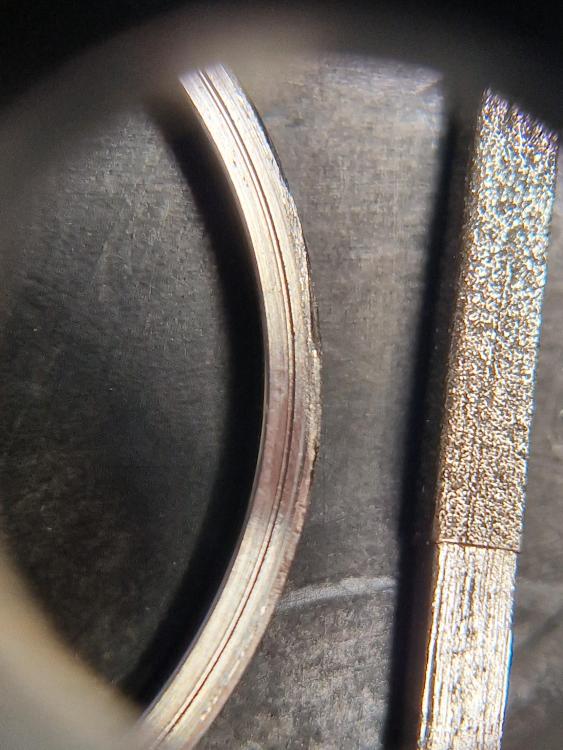

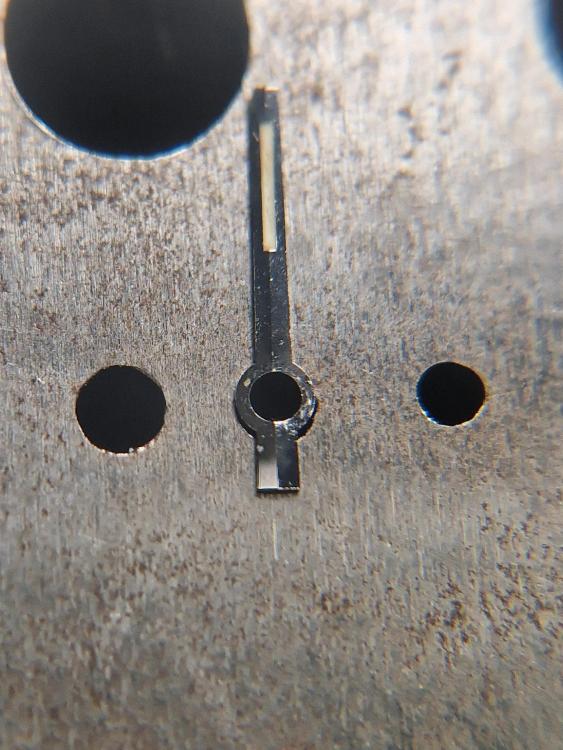

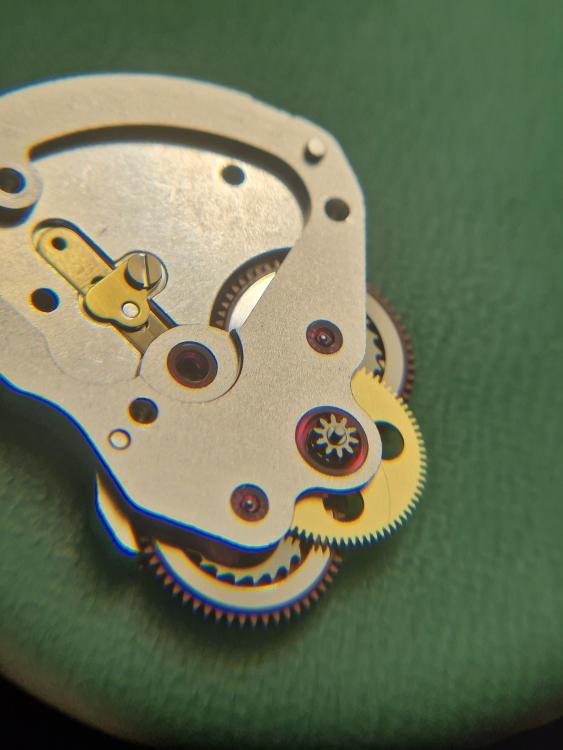

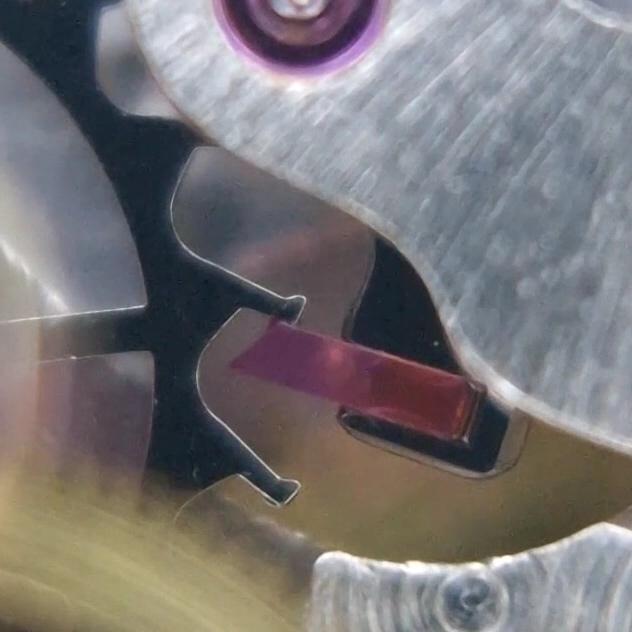

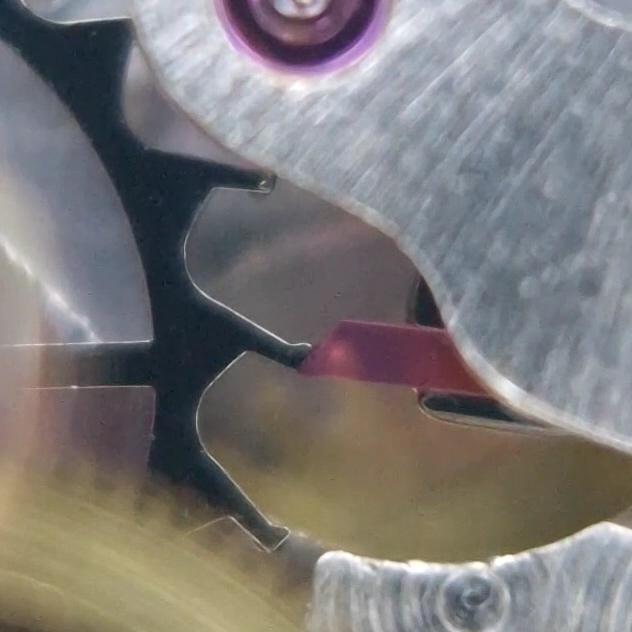

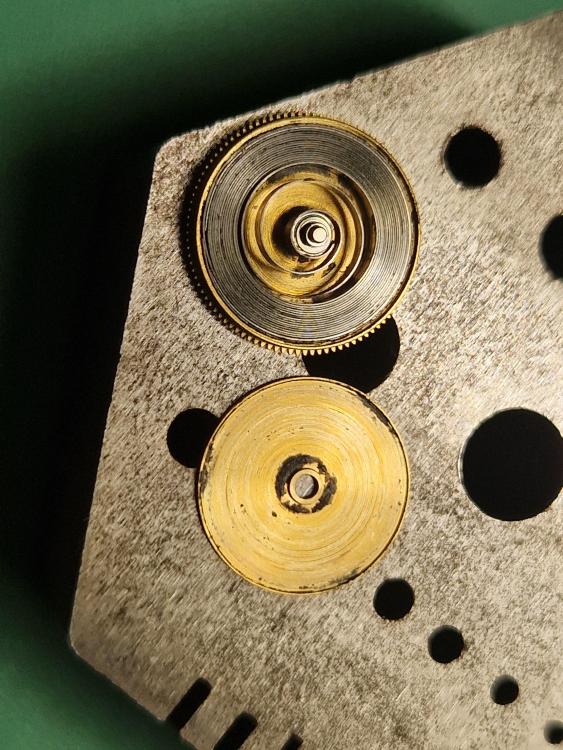

Hello all and merry Christmas (in advance)! I just finished a service on a Rolex 3135 in a lovely Datejust 16220. First, here are some overview pictures of the movement: The watch was in overall good condition, but it was running a bit fast and inconsistent (across positions) and amplitude did not reach 250 even fully wound and dial up. Upon disassembly, I did notice some a bit of dirt and some jewels/pivots had run almost dry. The barrels shocked me again (similar to the Rolex 2035 that I recently serviced): Thanks to @JohnR725, I had access to detailed oiling charts and service training guide: https://www.watchrepairtalk.com/topic/3626-rolex-3135-beat-error-adjustment/?do=findComment&comment=234180 After some good pre- and final cleaning, I assembled exactly as prescribed by the Rolex training guide that I followed the service guide in detail. For lubrication, I followed the Rolex oil chart, also posted in the link above. One particular issue is the Rolex lubricant "MR4". It seems to be somewhere between a very thick oil (like HP 1300) and a grease (like 9504). I used either HP 1300 or 9504 as a replacement and depending on the particular locations. My final "interpretation" of the oiling (with Moebious oils) is as in the pictures below. Regarding the pallet fork, the Rolex training guide seems to suggest a rather large quantity of 9415. Consequently, I put more than I usually would (but still less than the suggested amount by Rolex). See pictures below. What are your thoughts? For the automatic module, as show in the Rolex oiling chart, I treaded the reversers with Epliame and was VERY light on the lubrication of the "internal pivot" (see screenshot). As prescribed, I did not oil the internal ratchet/click mechanism of the reversers. Case: The previous watchmaker left me a present under the bezel. I noticed that it was not sitting perfectly even on the case. He (or she) must have removed the bezel in a way that damaged it a bit. I filed the damaged metal away with a diamond micro file. Bezel back on with my trusty Robur (with 3D printed adaptors for "standard" M4 dies). The dial and hands also got a bit of cleaning : Before: After: Casing: 1. align the case clamps on the movement with the matching groves in the case. That's how that looks. Turn everything around and slide the movement into position. Insert the stem. Done. At full wind/dial up. Vertical positions are running a bit faster (+8-10 seconds). I may look into regulating that further. I'll eventually post more results. To conclude, my usual "artwork": Merry Christmas to everyone!!!2 points

-

Sometimes if you go on German eBay, eBay.de, and type in what you are looking for in German, such as 'watchmaker's tools, which is 'Uhrmacherwerkzeuge' and in the 'Condition' state 'Gebraucht' which is 'used', because they haven't listed the part as 'International shipping' it won't appear on our eBay. Result! No one in this country is seeing it! I find if you ask the seller if they would ship to the UK they are more than happy to. It's a good trick with most watchmaker's tools that won't appear on our eBay. Try it, you'll be blown away at what you find and the low prices that they go for. It's the same for Italian, Spanish, and French eBay as well as many others. A trick I learned before Brexit. Keep it under your hat. Wink wink!2 points

-

2 points

-

Hi, 46 years old. I live in the US. I got into watch repair to fix a sentimental watch that was not worth paying a pro to do it. It was amazing to replace the movement mysef! I've since collected a number of old watches I was happy to polish and replace crystals to fix up. It's very satisfying to pay$ 10-$15 for a beat up old watch to fix it up into a gem! I appreciate new watches as well that are bargain finds for the specs they have.1 point

-

https://www.ebay.com/itm/296117480530?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=4KkjO2stSJK&sssrc=4429486&ssuid=v36TsHWBSw-&widget_ver=artemis&media=COPY I found this donor watch but am not sure of the condition of the balance. Buying from India always has its risks1 point

-

Check out the variation list matey. Page 509.1 point

-

Cheap, to rebuild. Far better than the cheap units IMHO. The big cap is $10. All of the other components total less than $51 point

-

1 point

-

1 point

-

The cost of a new instant demagnetizer is rather expensive. An Elma unit from Cousins is £207.95. Even with replacing components on the vintage unit, it should be significantly less cost. Not sure on the cost of components yet (which should not be a lot), but I only paid $50 for the unit.1 point

-

Once the various components are replaced, will it be more effective than a cheap modern demagnetiser? If not why bother? Genuine question's, I'm just interested. I have two demagnetisers, one cheap Chinese one, works OK, one homemade, a central heating pump with the rotor removed, very powerful.1 point

-

1 point

-

Ah. From what I had been reading it does seem like those should be replaced. The switch sticks in the down position, so that may also get replaced. Seems just like a two position switch, so a momentary on SPST switch would do. I see the capacitors rated up to 600V but not sure the voltage that the switch actually sees. Great idea. Having that, I could keep the demagnetizer plugged in but switched off. The visual verification of it on or off, that the LED provides, is nice.1 point

-

I have a model 700 and 600. I bought a third 600 and converted it to an analog ammeter. 25uA meters are kinda rare.1 point

-

The Omega F300 is actually much easier to repair than the 214 and 218. It still requires a Bulova 700 test meter though. IMO the 214 is the biggest pain. If you don't follow procedure, disastrous consequences will result.1 point

-

Hi. LWS is correct in saying toss them and replace them , the paper ones are wax coated which breaks down , in any electronic re furbish they are removed and replaced by modern types1 point

-

Typically if you look at watch company specifications for timing is not supposed to wind it to the max and put it immediately on the timing machine. They usually have a recommended settling down time or whatever time it varies basically 15 minutes up to an hour is considered fully wound up.1 point

-

I remove the balance & fork, drop the rest of movement in naphta, sometimes a gear might need bit of encouragement to free up the train. The fluid slows down speed of the gears , just leave the movement submerged for soaking.1 point

-

1 point

-

The older capacitors were sometimes wax coated. Sometimes this coating can break down or melt.1 point

-

And here is the keyless of ( the copy) Malnija 3602 for comparison if Bob did take poctures. https://17jewels.info/img/movements/m/molnija/Molnija_3602_Zifferblattseite.jpg Rgds1 point

-

1 point

-

Sounds like things could be really gummed up, i had one just the same a couple of days ago. I added placed small drops of naptha on to all the jewel heads with a syringe, the following day it was all but free to unwind. Sounds like its gummed up tight.1 point

-

Just the way of the world John, its about control, enormously wealthy companies controlling what and when people can have and cannot have as and when THEY decide. Look at computers and technology, its for sure way more advanced than WE are led to believe, stacked high,kept in storage and on hold. But releasing it all in one go or as its developed doesn't benefit the ones that have it, so its handed out in small bite sized pieces. Then its a nice consistant high income each year for the ones that have it. The same obviously happens in the pharmaceutical industry, who knows what THEY can actually cure ? WE dont ! Its about THEM and US or am i just a conspiracy theorists , dont even get me started on Covid.1 point

-

Oiling - a good idea, but cleaning of the old hardened oil is needed first. And this is done with full dissassembling of the movement. You can put some fresh oil on the pivots of the balance for test, and may be it will start working, but soon will stop again Be verry careful with the coil - it is easy to damage by simply scratching it with something, balance magnets for example1 point

-

The thing for me is things move on, we didn’t use seatbelts in the ‘60s, not invented yet, should we go back to those days? I don’t believe so. As for finger cots they were not available for the most of the time watches have been made, does that mean we shouldn’t use them? Hell no! In my opinion, having been involved in the creation of the internet we enjoy here, things will progress, there is no such thing as “best practice “ only “best CURRENT practice “ Tom1 point

-

good write up, I had to wait about 3 years before the right one came up at the right price on Ebay and bought mine 2 years ago for £80 boxed as well, I have only used it twice with limited success as I never quite new how and never got round to researching its correct use. Again I only thought it was for balances, good to know it can be used for other wheels. Thanks for sharing and taking the time to do the write up.1 point

-

1 point

-

At home I have just the disc with jewels all the other bits and pieces are either missing or somewhere else. On the other hand when I was at work once with a bent balance pivot and not wanting to replace the staff The tool came in very handy and I basically didn't use the bits and pieces that are a guide. I started with the biggest hole and eyeballed it and it worked out really nice. Nice straight pivot didn't have to replace the balanced staff and everything was good conceivably depending upon things are probably break the staff and I don't remember if I refinish the pivot afterwords are not. I'm tending to go with I just straightened out and everything was fine then because the Swiss can they've upgraded the tool probably updated the price also. There is with the new version looks like and a PDF attached of how you're supposed to use the thing. 7135 7136 30350 new.pdf1 point

-

Nice write up. I have had success with this tool as well. There was one in my Seitz press set…I’ve only tried it with a balance so nice to see some success with other parts as well Not according to the instructions from Seitz. As neverenoughwatches says it is there to steady the wheel in the pivot hole. I have been placing the arm on top of a wheel to hold the pivot as vertical as possible then I rotate the wheel from the opposite side with a couple horsehairs. Start with a larger hole and slowly work down near the pivot diameter. As you start to straighten there’s a slight bit of resistance in a new hole that lightens up after a few full turns. It is actually a quite satisfying tool to use when it works…1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.f0fdcb904fb94600b8d08cf1e4ea5a6b.jpg)