Leaderboard

Popular Content

Showing content with the highest reputation on 12/12/23 in all areas

-

Hi. Exactly so NEW, when I started there was no videos , no internet. What you learnt was from the few books you could lay your hands on and working on old watches and clocks. There were no scopes cameras and no high magnification it was all done with a loupe. I got my bits from. T.G Loaders, watchmakers supply co or AG Thomas by snail mail although it was faster than today’s post as long as Dick Turpin was on holiday. You made mistakes of course but as parts were hard to get and a long wait not many. The old adage. Measure twice. Cut once. Today we have a vast array of help, plentiful access to parts and books, tools we all take for granted. So spare a thought for the old guys of long ago and not so long ago trying to make a living.5 points

-

I agree, there's no excuse not to put them in individual marked pots. I don't even scratch a service date into a caseback, because if you think about it, who does that benefit? The customer can never see it to tell when the watch was last serviced. The invoice will tell them that and most of the time it's not just a date, which means nothing to the next guy servicing the watch. It just devalues the watch as a whole by scratching anything anywhere on a case or movement, but I'm a bit of a purist when it comes to stuff like that4 points

-

3 points

-

There was more on the dial side on the retention plates for the date ring. Maybe the guy was old and just had a crappy memory, couldn't be bothered to write notes or sketches or label up separately. It's an old mid 50's design movement so before photographing was such an easy process, we take that for granted these days. Poor old guy might have had a dozen watches stripped down on his bench, struggling to make a living and here we are slagging him off 60 years later .3 points

-

I'm glad you like my Instagram posts! I'm going to start putting some stuff on my YouTube channel, as I haven't posted there for a long time. It's a shame that videos can't be posted on this site, as I would post a lot more here as well, especially some lessons I have written which include a lot of video content. My second-year students have just started their first chronograph watch; the Valjoux 7733 and Poljot 3133, which have pretty much the same layout. There's a lot of video content to show how to set all of the 5 eccentric studs and what those studs adjust. I might edit the lesson by taking out the videos and posting them here because there seems to be little out there to explain eccentric studs and how to set them correctly. Lots of YouTube videos showing strip downs of chronographs and assembly, but little explanation of the chronograph mechanism. That gives me an idea for a YouTube video to explain just that!3 points

-

Tension rings tend to be associated with watches with improved water resistance. The extra tension keeps the crystal tighter to the case. So it does matter from an original watch specification, replacing with whatever it comes with is usually the best route. Tom2 points

-

I think its best not to pick up any bad habits regardless of what watch it might be. A short cut attitude can become the norm if you let it get out of control.2 points

-

Great walkthrough! You're right, very similar layout for your notes on the photos. Great minds think alike2 points

-

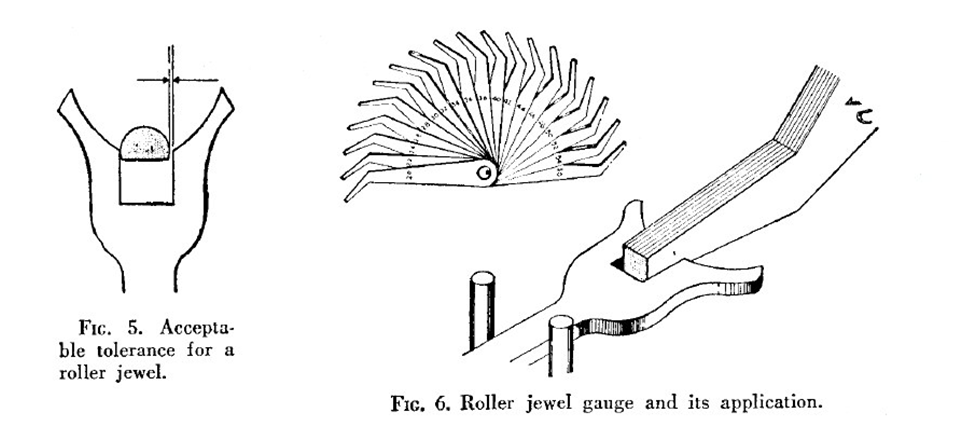

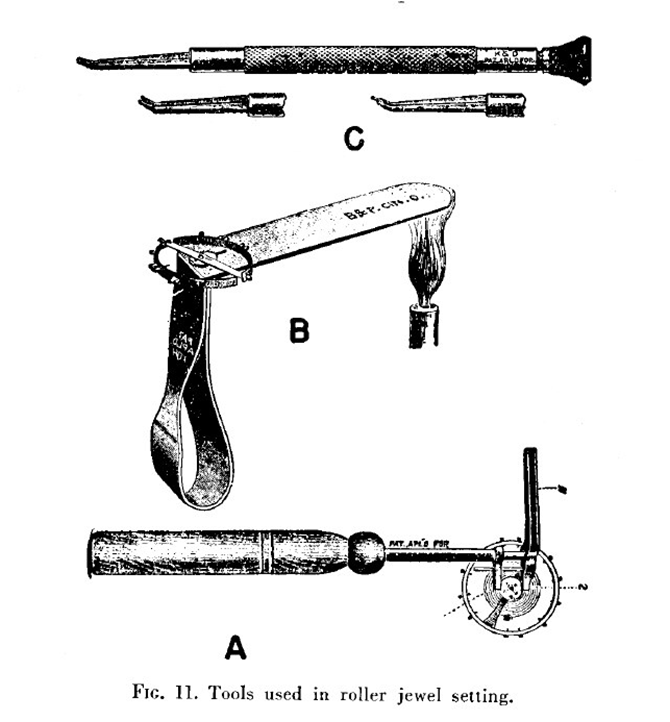

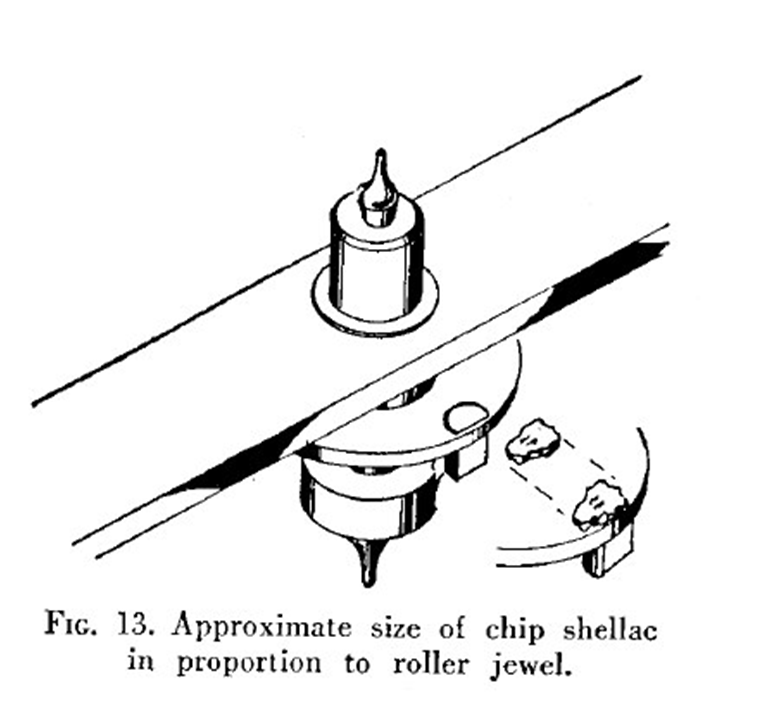

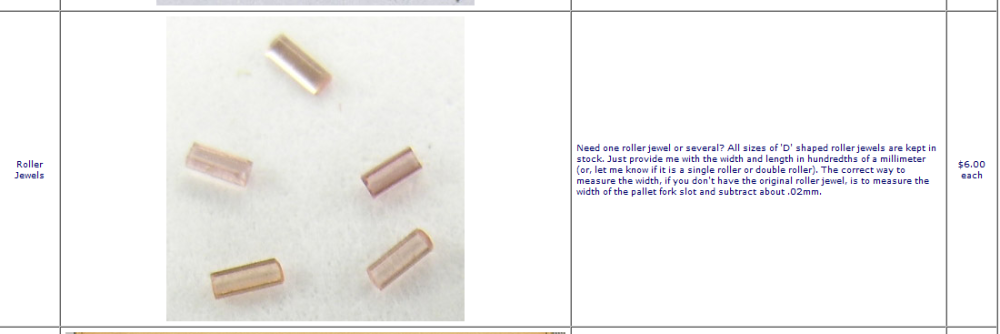

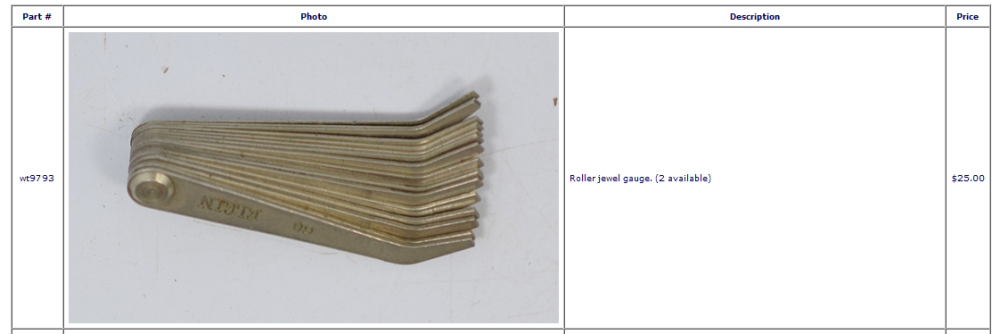

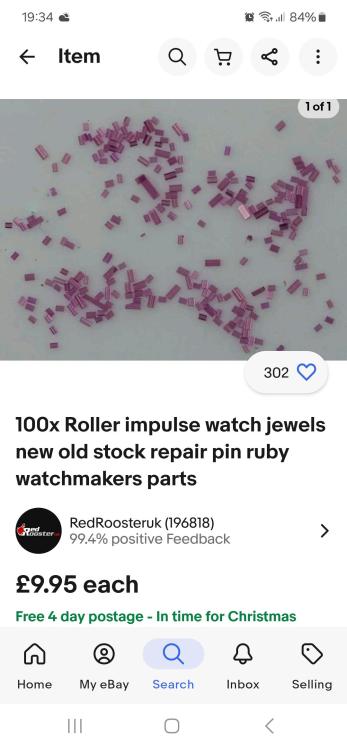

One of things I always like to do with incoming watches and you're making an observation the watch is not running but if you get the balance wheel to rotate you always look to make sure that the pallet fork is moving. It's actually quite common on pocket watches for the balance to move the pallet fork not because of roller jewel missing.. Then from the look at your balance wheel it appears to be a single roller versus a double roller watch? The reason I bring this up is single roller watches require longer roller jewel's so often times modern assortments will not have a jewel long enough. Then it's so sad the roller jewel's been stolen by a previous watchmaker and now we have to throw the whole watch away because you don't have a roller jewel if only there was something you could do? No murdering another watch to seal its roller jewel is not an ideal solution.. If only we were dealing with watch repair we would have something to do like replace the roller jewel? Then yes occasionally have a weird sense a humor it's based on your research and the outcome of your research that you get a weird paragraph up above. Then we're going to need some tools and a few more tools after that plus it be really nice if the ruler was unfortunately broken off rather than falling off because that means there should be a little piece left that you can measure. Otherwise we have to do it the other way So if you don't have the old jewel you need a roller jewel gauge they, of course in a variety of styles and shapes you could use a machinists or an automobile shop feeler gauge. In other words you need something to stick in the slot and measure its width and then the jewel is just a tiny bit smaller. We also need some shellac and roller jewel of the suitable size and a heck of a lot of patience to get up to go into its hole. Then yes they do make special tweezers reporters but you still have to get the roller jewel into those so doesn't really matter the roller jewel is a pain in the something to get into the hole. Then a variety of tools to hold it when you heat up and apply the shellac. Then once the shellac smelted in the jewel is not go fallout you can gently straighten it out and get it where it's supposed to be. Here's a better picture of the tool for holding newly roller table.. You will also note this is a double roller watch shorter roller jewel Yes the pictures make it look so easy Then looking up to the assortment a roller jewel's is a good thing to do I done it before except of course it helps to have the right assortment like a vintage assortment versus a modern assortment or what about this website? Let me just snip something out for you Then on another page he has one of these Okay this will get you started2 points

-

I've come across a few movements where the person before me has scratched in numbers on the plates, in a huge size... seeing this you know you are in for a rollercoaster ride of a repair/refurb.2 points

-

If you like watching watch repair videos on YouTube, be careful of scammers. I was contacted by someone saying that they were Marshall from the Wristwatch Revival channel and noticed a comment of mine about my grandfather's watch. He offered to use my grandfather's watch for one of his servicing videos. I would need to send him my watch and $250 to cover the servicing and parts. Fortunately, that got my scam meter pegging high. I tried to get a hold of Marshall myself, but was unsuccessful. I passed on that offer. Marshall mentioned in a couple of his recent videos about a couple of his other viewers that fell for the scam. Fortunately, they were able to get their watches back. He didn't say if they lost money in the process, but I suspect so. So be wary of anyone contacting you out of the blue (not just from Marshall's channel). If they are asking for money, be very wary. Confirm that they are who they say they are.1 point

-

I often think about my dad fixing watches every day. No camera, no videos, no internet...1 point

-

Hi the skills are the same but partaking in the horological art has got much simpler interning terms of information and teaching guides. We had none of Marks courses back then it was down to brain power and observation.1 point

-

Whilst I totally agree, no one realised in the past that things were difficult, it was as it was. We all remember the Yellow Pages or other nationalities equivalents, we knew no better or at least had no other option. The Internet has made searching things much easier and videos to watch, instead of 2d drawings are a great help, also cheap ( at least relatively) microscopes, make life easier. The skills of watch repair though, haven't changed for hundreds of years.1 point

-

Armoured crystals tend to be fitted to watches that have a water resistance requirement, often diving watches but not always. Meant to resist the depth compression of the crystal's sidewalls.1 point

-

Hi my last comment on this post. As I said before we can make any clock work by BODGEING it up but that’s not the point. The point is there are wrong parts in it and it needs to be put right as it is it’s worthless can’t be sold only as bits even then you would be hard pressed to get your money back. Case closed.1 point

-

1 point

-

Thanks Dell funny you should post this i was only looking at those yesterday. Its the adapter i would need and then a drawbar. My lathe takes 15 mm collets, i found some 23mm collets for a Leinen 3 days ago so hopefully some will turn up eventually . I wondered if there are ER collets that fit to the headstock.1 point

-

1 point

-

1 point

-

Hello and welcome to the forum, Sit a while and let the saddle cool and enjoy the company of likeminded souls.1 point

-

Hi Andy. You will be able to use this as an exercise in what to look for when buying clocks , like I mentioned before you can bodge clocks to make them “ work” and to the unwary buyer look ok bur are In reality a load of rubbish. Yours is such a case but is salvageable with the correct bits but at cost. This is why Old Hippy said enough is enough . It becomes not cost effective. . One could spend a deal of money on it, new case ( correct one) , new leader etc. I have an Enfield movement in the shop somewhere and may be a case if you are interested PM me we maybe able to save it yet.1 point

-

1 point

-

A certain watch shop I know, writes a code in the case back with a permanent marker (sharpie). They keep a database of the codes so that they can record the service history.1 point

-

This involves hands, dial plate, date disk removal to gain access to the keyless and while there to check the minute train as well. The least would be keyless has misaligned, and what caused it, and likely to need a part replaced with new. This is a fine jewel, best to entrust it in experienced hands. Rgds1 point

-

1 point

-

It is indeed a Frankenclock. I knew nothing about repairing clocks until very recently. The clock case pictured was altered by myself using my far from legendary woodworking skills to remove two plugs from the case to fill the holes left behind in the act of adjusting the case for my movement, the central low hole Was also plugged by me. the suspension spring is 14 mm long bought from Cousins based on something I read on a clock repair forum, as this movement arrived without one. currently after some tweaks it is around 20 minutes down on a full day. I bought this movement to tinker with and learn some clock repair skills, I will no doubt buy more to further learn. I have no time to become a master of this craft but I respect the opinions and advice of all who are.1 point

-

Welcome to the WRT forum. I joined WRT forum several years back , still haven't figured out what makes it so addictive.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You will find a wealth of info on here. If you can't find what you are after just ask. Photos can help a lot.1 point

-

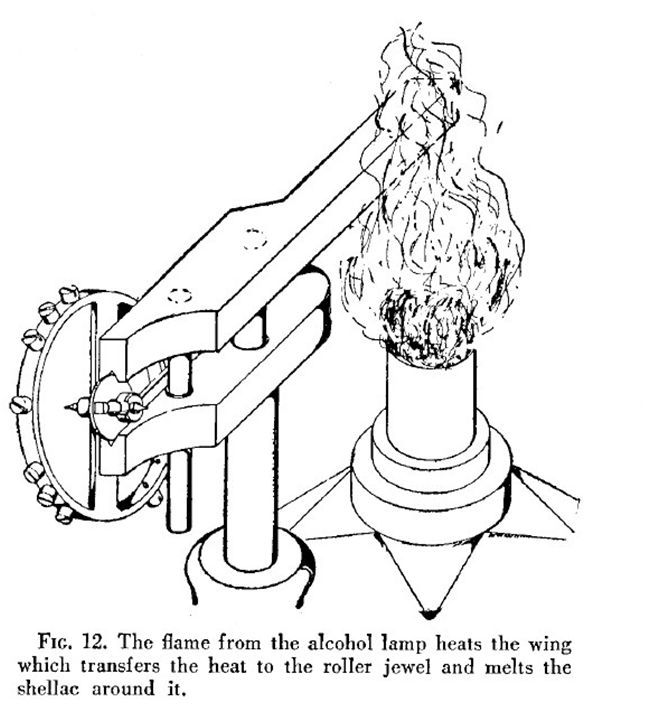

I find replacing a roller jewel one of the most fiddliest's jobs to do. Getting the jewel in place at the correct depth and dead straight is easier with the roller table removed in my experience rather than having it still attached to the staff. I still use the tool in Fig12 above, as no direct heat is given to the roller table and the shellac has some time before setting hard1 point

-

I just had a look at the photos and thoroughly enjoyed them! Your photo illustrations reminded me of my own walkthroughs where I too use rectangles around the explanatory text and the arrows. I just the other day published my Citizen 8200A walkthrough. That would be highly interesting, so yes, please do what you can!1 point

-

Try emailing Dave at https://www.daveswatchparts.com/ he has some Standard movements and parts. You may be able to find a new roller, or balance.1 point

-

Who needs a soldering gun when you have a blowtorch. Personally on my long list of projects that I haven't got around to doing I was thinking about the heater cartridge out of the 3-D printer. Figuring out a way to hold the roller table holder and my pallet fork holder Plus of course throwing in temperature control so I can free up my hands to play with the shellac. Traditionally watch repair they used alcohol lamp. Except in between used alcohol dries up and then you grab a small butane torch which is not what I recommend doing because it's really hard to do a good job and really easy to do something bad. But unfortunately at work that's all I have is the small butane torch. Fortunately I almost never do a roller jewel and even less likely to do a pallet stone.1 point

-

Good point. If they ask for money don't touch them. It is unbelievable the amount of phone calls I get all from scammers. I lead them a merry dance then tell them to *uck off. Half the time you can't understand what the bugger say.1 point

-

I have said many times the leader is the wrong one, your photo proves that, it will also cause the pendulum to have a poor swing. I don't see any reason to mess about with this clock you can pick up much better in its proper case for around £30.1 point

-

Manual is good, but one has to know how to read it... Here, on the picture, I have shown with the big arrow the 'screw' that regulates the reset hammer. The small arrow shows a gap in the hammer that will change when the screw is turned. You have to reduce the gap. Actually, the hammer must be regulated in a manner that the reset surface for the seconds heart will rest firmly on the heart, and the reset surface for the minutes heart will alow a little free play of the heart. This free play should be smaller than half minute to + and - of the arrow on the subdial.1 point

-

1 point

-

Ross, I got one of these a while ago and have had mixed results. The problem is that the blade has a small point on it and this can cause it to dimple the good side of the dial. Its a balancing act, as you need to press hard enough for the blade to cut into the dial back otherwise the blade just spins without doing anything, but when you do press hard enough you end up dimpling the dial, so you can't win. Maybe it's just me? I tried taking off the point, but then the blade wanders when you are trying to cut into the back of the dial so is pretty much useless. Just my experience, any maybe you can get it to work for you, but just thought I'd give you a heads up. This is the reason I have built my own welder/soldering set up.1 point

-

Out of curiosity since the watches I typically work on our vintage American pocket watches where exactly are you going to get a new balance complete? Then straightening up a balance bridge that's already been modified by others are you suggesting I should not fix a problem?1 point

-

You shouldn't have to modify the parts of the chronograph because now you may possibly have to fix the adjustment that you've made by modifying depending upon where you did it Usually chronographs are filled with adjustments everything is usually adjustable in some way. There will be a lot of screws that are Not really screws but are offset cam is for adjusting things. This is where if you're not familiar with a chronograph you really should have a service manual which shows all the adjustments.. So I'm attaching a PDF a little light reading.. Then if you do do an adjustment and it doesn't seem to fix the problem put it back where you found it because are probably introduce a new problem.. Zenith_Zenith 3019PHC.pdf1 point

-

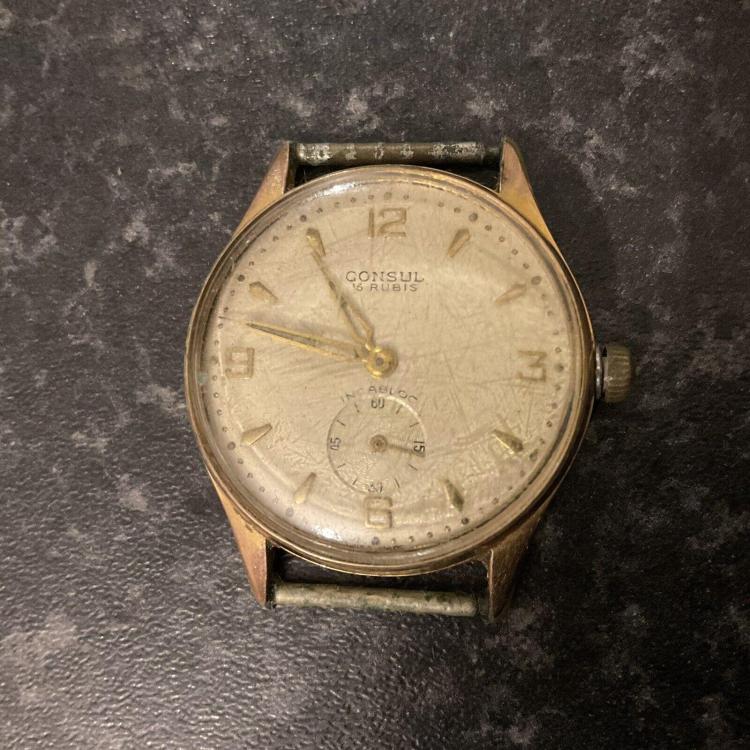

This 404 club candidate has a pleasing 1950s vibe to it. A Consul 16(?) Rubis. Incabloc, probably gold plated. It also claims to be that rarest of all beasts in the modern world, a 100% Swiss watch. Consul, based in La Chaux-de-Fonds, seem to have pitched themselves as a quality maker. They submitted some of their mechanical timepieces ("chronomètres-mécaniques") under the wristwatch category ("chronomètres-bracelet") to the observatory competition in Neuchatel, Switzerland ("Le Concours chronométrique de l`Observatoire de Neuchâtel"), that subsequently passed the stringent tests and became certified as observatory chronometers and therefore received a "Bulletin de Marche" from the observatory, even receiving a "1er prix" in 1958. This particular example has seen better days, and could certainly use a thorough cleaning, a service and a crystal (and possibly a new crown). The hands also look to need re-luming. I have no idea what makes it tick, as there were no movement shots. Another "mystery movement" watch. There is a good chance that it has an "in house" re-engineered consul branded AS movement, as a number of the other Consul watches I found online had these. There is even some speculation that they may have supplied Consul engineered movements to Girard-Perregaux.1 point

-

Actually typically I never use paper I prefer to bend the balance bridge. But as per some discussion somewhere in the universe apparently bending the balance bridge causes people to become unhappy but it does solve a problem and it works fine. Then it does bring up a problem of a thin sliver of watch tissue paper under the balance bridge will be protected by metal on both sides with possibly only the ends exposed to a miniscule amount of air. Then depending upon the type of watch sealed to varying degrees so the amount of moisture getting into watch to screw up the paper should be almost nonexistent much more likely to start rusting the watch up : real life could be better just to deal with the balance staff like you're supposed to do and not have little slivers of paper or foil or people gathered Jing the plates the raise up spots of metal none that should exist the balance staff should be the right length.1 point

-

thanks. i can't imagine going through all those looking for a fit; i'm too impatient. but i'll have a look. thanks again.1 point

-

1 point

-

Beauty in the eye of the beholder. Can't get into these open works thingies. Don't mind seeing the workings via the back. But I find that the machines works view through the dial is confusing and detrimental to use. As I said Beauty in the eye of the beholder.1 point

-

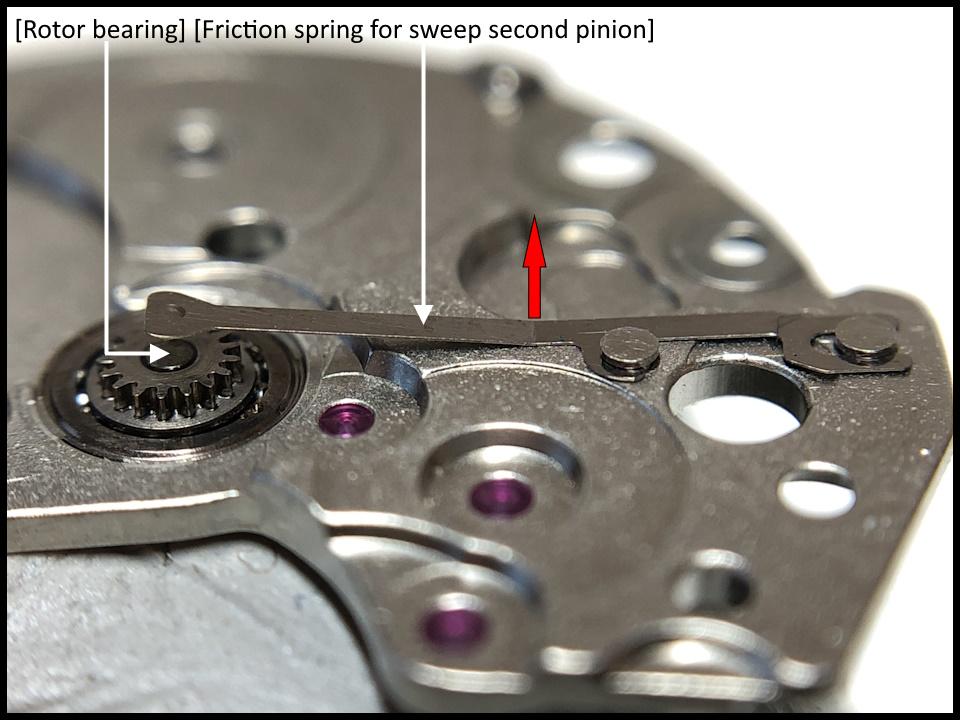

Disassembly pictures here (Please sort the pictures by name in ascending order) Assembly pictures here (Please sort the pictures by name in ascending order) Introduction To make a long story short, I've got about 100 Indian Citizen watches in my possession. It is one of these 100 watches shown in the pictures above. There is no major fault with them other than that none of them work. We all know that Citizen is a Japanese brand, but these watches are manufactured by HMT in India under license, probably sometime in the 1980s or 1990s. So, what do you do if you have 100 fine new old stock Indian Citizen watches that don't work? Well, you service and repair them, and then you sell them for a reasonable amount of money. How hard can it be!? Selling them, once they work, has happily proved quite easy, but repairing them has proved more challenging. So far, every movement has been full of gremlins to defeat. As usual, I want to remind those of you who have no previous watch service experience that this service walkthrough should not be seen as a tutorial on how to service a movement. It takes a lot of tools, consumables, training and know-how to succeed. Fortunately, there are several excellent resources, like WRT, and watchmaking schools online, and believe me, after six years I still find it insanely interesting and fun! About the assembly and disassembly pictures Unlike the disassembly pictures, the assembly pictures document screws, lubrication, and tips and tricks. Regarding the lubrication, I have not found any specific documentation for this movement. Instead, I have used my judgment and experience. It took some experimenting with the lubrication of the date and day change mechanics to get to work smoothly, so I feel a little extra proud of that. About the Citizen 8200A / Miyota 8205 movement The movements in these watches are designated Citizen 8200A on the rotor. In practice, they are identical to Miyota's calibre 8205, and if I'm not misinformed the watch manufacturer Citizen owns the movement manufacturer Miyota so there's a natural explanation. I have previously created a service walkthrough for Miyota's calibre 9015 which is often found in more expensive micro brands. Miyota's 82XX series of movements, such as the 8205 are instead found in more affordable micro brands, but there is no doubt that it is fundamentally an excellent and reliable movement. So, what do you find when you open an Indian Citizen like this? You find a well-constructed, well-functioning, albeit simple movement. In my opinion, it has a minor construction flaw, but I will report back on that. I have no idea how Indian HMT operated, but my impression is that these movements were assembled in an unsuitable environment, to say the least, by people with low-quality tools and a lack of knowledge of what a movement is and how it works. However, the movement parts themselves generally seem to be of decent quality, but when you take the movements apart you find fingerprints, hair, fibres from clothing, glue, and sometimes what I guess could be food residue. I.e. you find everything found in a typical home, so maybe that's where they were put together. As for the lubrication, sometimes it's OK, sometimes it's missing, sometimes it's in the wrong places, and sometimes there's way too much. However, once repaired, serviced, demagnetized, and adjusted these Indian movements work very well, so well that I don't think you can tell them apart from their siblings that are manufactured and assembled in Miyota's factories in Japan. Following are some tips and tricks that I hope will be useful. Stuttering second hand As in many other movements, the second hand is driven indirectly via the teeth of the third wheel, and to prevent the second hand from stuttering around the dial in a jerky fashion, a friction spring is pressed against the short side of the sweep second pinion. If the friction spring is not tensioned enough, it will not do its job. If this is the case, which is quite common, then the distance between the tip of the friction spring and the rotor bearing can be slightly increased by prying the friction spring slightly in the direction of the red arrow away from the rotor bearing. Balance staff end-shake I have long wondered if it would be practical to increase the end-shake of a balance staff using ordinary aluminium foil of the type you usually have in your kitchen, and now I have had the opportunity to test it. I admit it's not a very elegant or perhaps even correct solution, but it seems to work unexpectedly well, at least with this calibre. The aluminium foil that I have in my kitchen is exactly 1/100mm and after I built up the balance cock with two layers the end-shake was perfect. Guard pin The metal that the pallet fork's guard pin is made of on this calibre is unusually soft and therefore easy to deform, above all in height, but therefore also easy to correct. Several of the copies I worked on had a deformed guard pin. Normally, the guard pin should run parallel to the fork horns. Why this problem seems to be so common is hard to answer, but maybe my Indian colleagues were a bit careless with their tweezers when handling the pallet fork, or it's a matter of poor QC. Who knows!? The tip of the sweep second pinion You might think that all the parts for a certain calibre would be identical, and they largely are, but one exception is the tip of the sweep second pinion whose diameter can vary between different copies of this calibre. It is therefore not certain that the second hand from one copy will fit on another. I have not discovered any more exceptions than this. The Automatic Winding The automatic winding on Miyota's movements, including their premium movements such as the 9015, is unidirectional. I've always thought that would mean it's half as efficient as bidirectional winding, but in practice, unidirectional winding seems to be about as efficient as bidirectional winding. As can be seen from the picture, which shows the underside of the barrel and train wheel bridge, not many parts are needed for the automatic winding. I think this simple and well-functioning solution is elegant! Glue or shellac? The first time I took this calibre apart I suspected that the balance spring was attached to the stud with shellac, but after cleaning the movement in my watch cleaning machine where the final rinse is 99% IPA, I no longer think so. Instead, I think it's glue that simply looks like shellac. A small construction flaw I have had a user of this movement break the winding stem and misalign the threads in the crown believing that he had to pull hard to get the movement into position to set the time. I don't blame him! This movement has what I would describe as a design flaw that makes it impossible to pull out the winding stem when it is in a certain position. When you pull out the crown, the sliding pinion moves inwards (upwards in the picture). If you are a little unlucky then the pin (lug) on the sliding pinion will be right opposite the pin on the day and date corrector (as in the picture) so that the two pins collide with each other. When this happens, it becomes impossible to pull out the winding stem to its extreme position to set the time. If you then use force to pull it out, one or a few parts of the keyless work will unfailingly break. Most likely, the stem will come off and the threads in the crown will become crooked. What one must do as a user of the watch to ensure that the pins do not collide with each other is to rotate the crown slightly while pulling out the stem. When you rotate the crown, you also rotate the sliding pinion, which means that the pin on the sliding pinion does not risk colliding with the pin on the day and date corrector. Other documentation I am attaching a couple of PDF documents for the movement and thank @JohnR725 for links to a couple of interesting articles about the collaboration between HMT and Citizen. That’s it! Thanks for reading! Citizen 8200,8210,8260,8270,8280.pdf Spare-parts-reference-for-the-Miyota-8205-8215-movement.pdf HMT Watches: The Rise and Fall of India’s Watchmaking Titan HMT Watches: A walk down the memory lane1 point

-

so the banking pins are not straight but would straightening them fix any problem or generate new problem? In other words are they bent for a reason for instance this tool comes in a whole bunch of sizes and allows you to bend the baking pin for a specific reason. Now as you can see for the tool is designed to Billy go in and adjust when the balance wheels in place when you don't have the balance wheel there because you want to make it nice and straight then you wouldn't need something fancy like this. But sometimes having a tube to put over it is nice because it allows you to see things a little better. If you had access to staking set punches for instance sometimes one of those will fit over the banking pin if there's enough room. You might Billy do it with your tweezers.1 point

-

Order placed! BTW, I really enjoy your posts on https://www.instagram.com/jonthewatch/ Wow, I feel ashamed I couldn't come up with that "obvious" idea myself! Thanks!1 point

-

@Jon I have seen one with a stand for the desk, shouldn’t be too hard to knock something up. By the way that link you posted now has it for £18 still free shipping. so tempted Tom1 point

-

1 point