Leaderboard

Popular Content

Showing content with the highest reputation on 12/02/23 in all areas

-

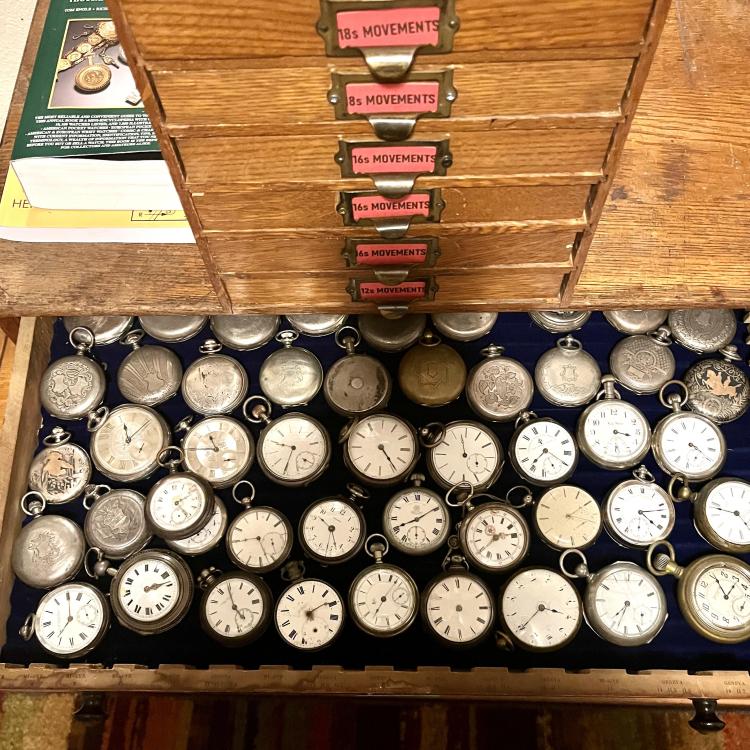

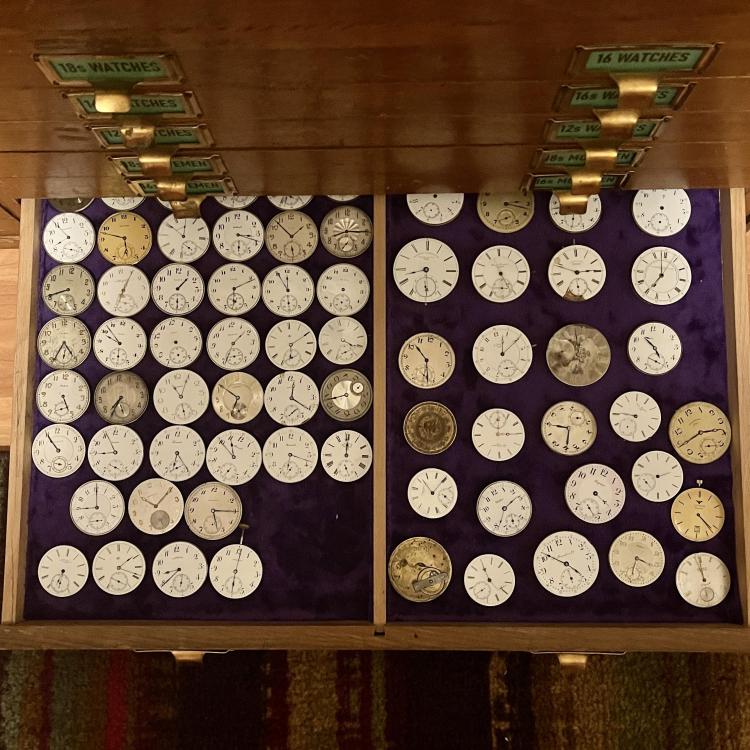

Hi everyone. I just wanted to show a few pictures of my newly organized watches. I’ve been practicing dismantling and reassembling movements everyday but have yet to have the watch work again when I’m done. I have a little watch graveyard building haha. I figure you have to break a few eggs to make an omelet or however that saying goes. This is sooo frustrating but I’m learning. I’ve thought about giving up but I really think I can get it in time. Anyway, I have a lot of questions but I have to decide which one to ask. I don’t want to sound stupid or ask something that has been covered a million times already. I try to search the feeds but it’s confusing. Okay, back to watches… wish me luck lol.4 points

-

You could fabricate a dryer and locate it at that notched out portion of the base. I made one from a 12V PTC car heater and a 3D printed stand and shroud (in ABS) for my DIY cleaning machine. It has worked well and parts come out rather toasty. The shroud may not be necessary, as the heater unit has a fan to blow the hot air up.3 points

-

3 points

-

Hi to anyone who is interested getting to know a cleaning machine which is not a Elma or one of the other usual names! since I`ve had my watch cleaning machine for about a year now, I wanted to introduce it since its not something that is seen very often! Here's a short video for those who don't feel like reading through everything below where I summaraize everything and show its function, settings and the rest: https://www.youtube.com/watch?v=hhNwU6risSo&lc=Ugw1n_nEOT2mDSkHEaB4AaABAg Watch cleaning machine from VEB Glashütte 1. View in its lowered and raised state. 2. Name plate with the reference to the DDR Peoples watch and machine factory in today's Glashütte Sachs. I acquired this beauty in Dresden from a former apprentice out of the German watchmaking town of Glashütte. At the time I had become interested in the profession and the cleaning machine was my first major investment in a machine from the profession. At its core this machine, just like many other vintage machines, is a hand-turning machine where you still have to manually lift and turn the upper disc, where the rubber sealing rings and the motor hang, from one one position into the next after each washing stage to change the cleaning jars and fluids What I particularly like about the machine is its somewhat more "solid" construction compared to conventional vintage machines. For example, the machine has an external guide in the form of a rod that leads the upper plate into position. Another feature is the size and weight of the two disks that make up the main part of this tool. In addition, I must say that I also find the stepped shape of the cleaning glasses and the compact size of the cleaning basket very aesthetically pleasing. The machine is in good condition and I have often started it up to clean the movements which I was working on. However, time has of course not left it untouched. In addition to the somewhat superficial defects such as the some painnt and lacquer peeling off, I noticed relatively quickly that the rubber washers on the upper plate do not all lie flat on the glasses when lowered, which means that the smell of the cleaning fluids cannot be isolated in their respective glasses. I have also noticed that the glasses are starting to have minimal hairline cracks in their shapes. I will probably have to buy a modern alternatives or invest in another machine in the event of a complete shattering. Ultimately, the only disadvantage of this machine, in my opinion compared to other vintage machines, is the lack of a drying system. Until now, I have always used a hairdryer to dry the cleaning basket after the three washes. Thats a bit inconvenient! Overall though, I am extremely pleased with the look and function of this old watch movement cleaner and am extremely proud to be an owner of such a practical piece of history! If you have any questions, comments of thoughts I would be happy to read and answer them in the comments! Here are two more pictures: 3. View of the washers and the basket mount. 4. Size and aesthetics of the cleaning basket.2 points

-

I very rarely use my overcoil tweezers in spite of having a full set. I might use the ones that simply curve the raised coil sometimes, but even there not really. If needing to adjust the actual height where it raises up I do as Mike and Frank mentioned, stout tweezers and wood. But it's rare for that to be truly faulty- I can see on your spring I would probably use two pairs of tweezers* to lift/lower the opposing part of the coil in several places to bring things flat again. To get the last part of the curve right leading to the stud, I set the spring on the upturned cock (spring right-side-up), collet centered over the jewel, and count the coils to the regulator. Then make it so the terminal curve follows that coil of spring. It gets it 90+% there, final tweeks in the watch. *The most dangerous thing you can do is use two pairs of tweezers on a hairspring, but sometimes it's necessary. Careful careful careful.2 points

-

On page 68 he shows how to make a vertical bend by pushing in to a block of soft wood. I've used this method with some 'normal' tweezers to correct a vertical bend.2 points

-

The things I have to do to make the stumps. I have made 2 stumps. One for for the pallet fork (16) and one for the Canon pinion tightening (11) in the above .pdf (about 6 posts above) The bars arrived and I have begun to file. Having no lathe, this is the only method I have. Found a better way then filing all. Hacksaw Ridge2 points

-

Brilliant. Impressive. Well done. No question on this forum is treated as stupid. It's only stupid if you don't ask. Glad you are with us.2 points

-

Was thinking maybe I should Google this to figure out what exactly I have been accused of https://dictionary.cambridge.org/dictionary/english/gatekeeping Interesting definition. But it brings up a problem of the original posting person is doing exactly that. His controlling the information we have or have not to solve the problem. Watch repair involves a lot of detective work in order to do the detective work we require eyes at the scene of the crime and we need a crime report. If we didn't have a picture of a watch in other words we didn't have a scene of a crime and a hypothetical question was asked then we could give hypothetical answers but we would still need a watch or description of a watch because the answers will vary depending upon the watch. For instance some watches you could move the jewels not typically an American pocket watch. As a reminder the balance jewels are different than plate jewels they will tolerate greater out of alignment. Then yes before fixing a problem figuring out what the problem is like has the bridge been bent. Usually on American pocket watches shimming is just a thin strip of paper either in the front or the back of the screw to allow you to tip the balance bridge. Which angles the bridge exactly the same as bending would do or raising marks on the plate.2 points

-

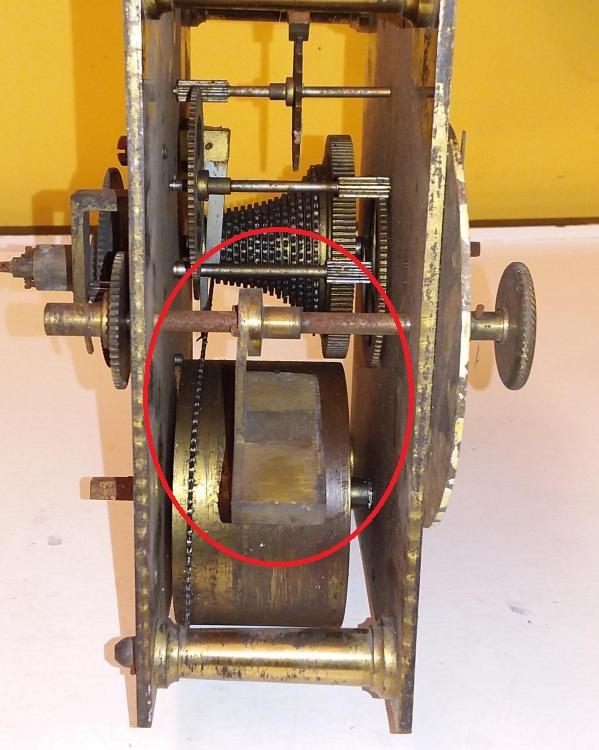

I have never seen anything like this. There is nothing on it that tells me very much. No idea of year but I think it was made in the UK and I don't think it is complete. I find the part ringed strange, because of it I'm sure part of it is missing, as its fixed to the hand set it is some sort of timing mechanism. There are holes on the front plate to support a dial and it would have an hour and minute hand. There is so much wrong I'm thinking its someones invention and it hasn't worked out1 point

-

As @oldhippy says it is a Molnija 3602. If you Google Molnija 3602 you will find loads of useful and interesting information about it.1 point

-

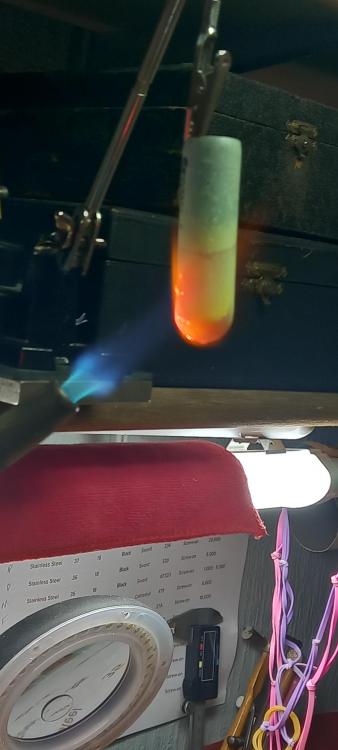

Finally got around to annealing my homemade setting lever. First attempt was half of the old part wrapped in copper strand from flex, that didn't work the copper melted like hair on my head. Second attempt heated the same part just held in the air for 10 mins with a small butane torch gradually reducing the flame and moving it further away. After chipping away the outer carbon layer that had formed i was able to drill with a 0.4 pivot drill part way a hole behind one of the pins so i could remove it. Very slow going and had to sharpen the drill 4 times, gave up that idea and decided to stop fannying around. Final attempt involved the use of a compressed air pistol cartridge for the annealing cylinder a couple of spoonfuls of ground charcoal scavenged from my chiminea and 20 minutes of the old faithful Rothenberger torch. Yeah, no don't try this in your upstairs converted bedroom its not a particularly safe practicebut i am a professional and did have contingency plans in place if things started to go pear-shaped, and its fricking freezing outside. Results to follow.1 point

-

I hate working on overcoils - you have to be careful with resting the tweezer tips when making adjustments as you can mess up coils below. I'll be having nightmares tonight1 point

-

So good luck! There are overcoils that climb without those 2 bends, but really rare and made by masters. Yours is not at all a master's work. Easiest way to correct bends in the height is a very rigid tweezers with sharpened tips, pushed with the hairspring blade into wood (just mentioned above) - no #7 at all! Even better than pushing is driving with slight hammmer blows. Try first with scrap hairsprings! Frank1 point

-

I have empathy for overcoil issues- not for the inexperienced or the faint of heart. Questions I have often go unanswered but I’ll be interested in the pros weighing in… …that said I think fortunately for you you are adjusting rather than creating and I don’t think yours looks so bad. A couple think out loud thoughts- first is the weight of the stud causing much of the ‘roller coaster’? Examine what it looks like off the balance wheel but in the stud. You may only have to apply Fried ‘in the flat’ techniques to correct… …and I’ve used the rodico trick to help with terminal but not for an overcoil. Again yours doesn’t look so bad so maybe- again mounted stud with balance missing- a little adjustment to center the collet could be all the improvement you need?1 point

-

This watch (Chronoswiss) uses an chronometer grade ETA 2892-2 and has been serviced just once in his life by the manufacturer. So the end play adjustment was done by ETA or Chronoswiss.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You might find this helpful. 704789946_TZIllustratedGlossary(2).pdf1 point

-

Haha its cold in Hull mate. My missus is on her way to Leeds now. If you see 4 drunken women causing trouble in Leeds center, stay well clear1 point

-

Welcome Ian, so of the same principles apply to watches only on a much smaller scale. What can go wrong ? Just about everything you can imagine .1 point

-

1 point

-

Mine starts off like that, gets progressively more chaotic until I have no choice but to tidy again. Rinse and repeat.1 point

-

I could never work at a tidy bench, mine was a complete mess, stuff all over the place. No question is stupid so feel free to ask anything. We are all here to help. Photos can help a lot as some on here like you are beginners and do not have the experience as others but like to join in.1 point

-

Total guess, folding pendulum for travelling? By the marks on the barrel, the weight seems like it moves across the barrel. @oldhippyis the man for this.1 point

-

1 point

-

1 point

-

The problem is from my point of view I can't help you without more information. But I respect your right to withhold the information from me that would allow me to give you a proper answer. Because I find these discussions frustrating if I ask questions and get no answers the message board has a wonderful solution to help me out. This will be the last answer you ever get from me I am going to blacklist you this way I will never see you ever again and I will not get frustrated again. You will not be frustrated with silly questions and it's a win-win for both of us.1 point

-

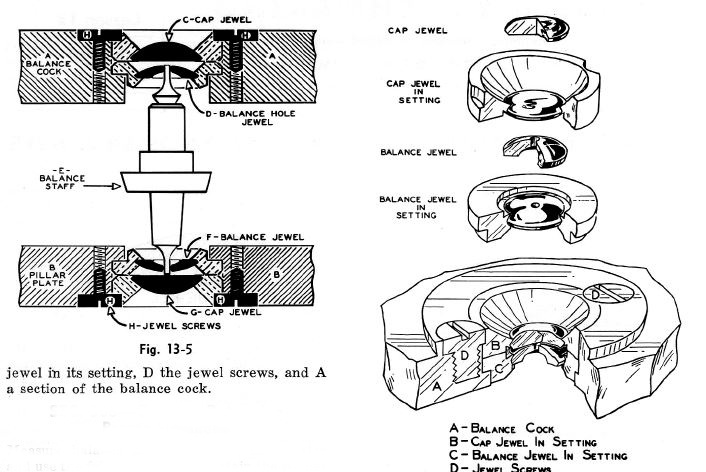

I have a picture which will also help with the other problem I thought maybe a picture would help as to what the problem is with American pocket watches typically. Notice that there is a hole jewel in a setting and it's held in place with the cap jewel That's also in a setting. They're both typically friction lightly into the whole which usually requires a tool to push them in or out. Then there held in place with two screws. This means there is zero adjustment even if you had a jeweling tool as there's nothing you can do they are what they are. Then we don't really get a good image the balance jewel as its hole is a different shape to the plate jewel. Specifically the hole itself has a curvature to it to reduce the friction on the side. Then there are some plate jewels that do the same thing but usually find those in more expensive watches1 point

-

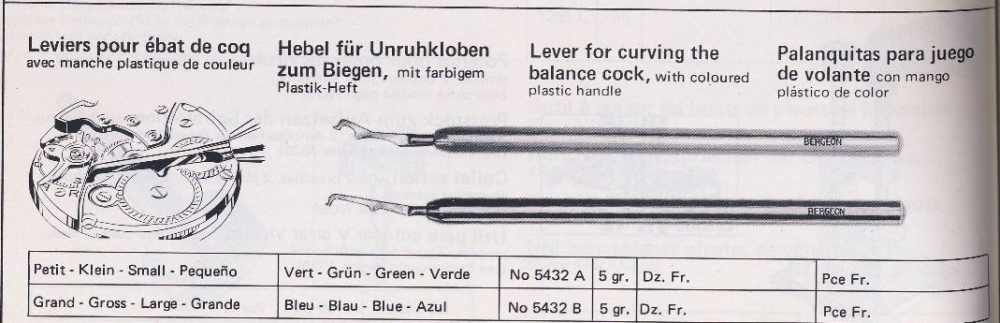

Bending the cock, the top and bottom jewels would not be in perfect alignment (thats if they were to begin with ) how much affect would this have ? Would it cause the pivots to bind on the bearings ? ( a check for sideshake afterwards should determine that ) If anything i would consider a shim lifting all of the cock a better easy alternative. Seems obvious to state but the cock may have been previously accidentally bent downwards and need returning to original position. John does not gate keep, quite the opposite in fact. To full help someone to diagnose a fault, the more information provided the more accurate is the advice.1 point

-

When you look at this problem it could be a number of issues like end shake butt end shake doesn't magically change by itself pivots don't magically grow longer. They can grow to being shorter typically broken off. But is there anything else that would cause the exact symptoms that you have that I quoted above? For instance your pictures could use a little work but still they tell us this is a really nice pretty watch and hairspring is it where it's supposed to be? For instance you look at the image below and go find it up above it looks like the regulator pins are just barely touching the top of the hairspring. The problem with this is if the hairspring is down too low it rubs on the balance arms and that will simulate exactly the problem you're having. So it's very important that the hairspring be absolutely parallel and that every single time you look at a watch you look to make sure it's parallel. Although all of us will agree that seeing of that can be a bit of a challenge. No matter what if that hairspring is touching the balance arms you will have running issues. By the way how do you know that that was actually done by the manufacturer? Usually when people are manufacturing watches they will adjust the balance staff to fit their watch. This is usually done after the fact by people who don't have the tools to adjust the balance staff pivots to the proper length. Now there are minor exceptions to things like this some manufacturers will put it in a piece of usually metal across the entire bottom of the bridge. To raise the bridge up parallel and not to put at angle very common on Russian watches where manufacturing tolerances need to be worked on and Thin sheets of metal solve that problem. I thought we didn't have too much horizontal plane now we have too much what happened? Oh what about if you could purchase a tool that came from a Swiss company and it came in a yellow box would it make bending the balance bridge acceptable? One of the problems for problem solving is a number of items we need to have to understand how to solve the problem for instance jeweling tool helpful for? As I could tell from the pictures this is a pretty watch. But what does that mean well is a link below this is a very fine railroad grade 21 jewel watch everything should function perfectly At least it did when it left the factory who knows what's happened to it since then https://pocketwatchdatabase.com/guide/company/elgin/grade/270 Now back to the jewels jeweling tool would it be of any use not really. Notice all those little screws holding the jewels in. Usually things with end stone's people removed for cleaning then of course you have to be carefully make sure you get them back down where there supposed to be and that they're still parallel plus you will be careful not the strip the little screws. But basically those tools are where they are they can be moved downwards a little bit not recommended though you can actually reduce the thickness of the shoulders of the hole jewel but that's not really what you want to be doing in fact that would violate one of your rules If you were to reduce the thickness too much you wouldn't build a get the in the stone on properly. Typically lie time you're adjusting the whole jewels are if you're fitting a new jewel Here's a website for identifying watch parts for Elgin watches http://www.elginwatchparts.com/ One of the problems when you look at vintage parts especially Elgin where there information tends below more complete than other companies they will tell you considerable variation in a lot of the parts. This is where mixing and matching off other watches becomes an issue1 point

-

More than likely if it's a vintage quartz it will require servicing. Start a new discussion with your quartz watches with pictures the movement So they can find you servicing information. It doesn't always go by that name if it's what I think it is. It's a Band-Aid fix on a quartz watch. It's like taking a mechanical watch that needs to be serviced removing the balance wheel removing the pallet fork in winding it up's list train spins really fast for a little while and then putting it all back together and it will magically run because now it's clean. Which of course it really isn't and it just buys you some time. In the case of the quartz watch it spins the train hopefully making it to run sometimes it does sometimes it doesn't but it's a Band-Aid fix the watch probably have to service providing there is something else wrong with it.1 point

-

Hi Ross. I toyed with an idea such as yours a while back but never got it done,, maybe when I get a little more mobility I shall resurrect the idea, one for the list.1 point

-

Hi Ross the answer is does it work as intended, if so it’s neither amateur or anything else it’s a working tool adapted to overcome some short comings. Well done you.1 point

-

…of the vintage watches I work on 8 out of 10 cats need at least the barrel arbor play addressed and usually the center wheel too. In hindsight a staking set would have been after screwdrivers and oilers but before winders… A new set will be a hard and expensive endeavor. Get in line at Cousins…or study the auctions for used. I think I was lucky as the set I have is well loved but the bloke before me thought of everything I may need. Thanks mate…1 point

-

1 point

-

Zero, you are welcome to use this content in the wiki if desired, as I read it through though, I see a few typos that I would like to correct, as soon as I work out how to edit posts…1 point

-

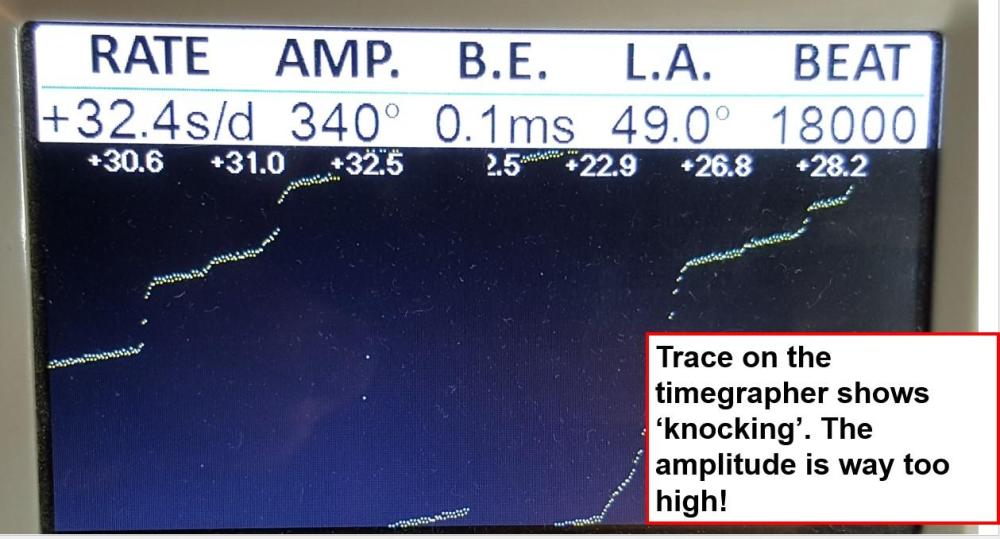

When you say 'very little movement' what does that look like? You need to be a little more specific. Does the balance rotate freely when given a puff of air both ways? Is the pallet jewel fully locked with the escape wheel tooth when you try to rotate the balance, as the escape tooth might be caught on the pallet jewel impulse face and the guard pin is left touching the safety roller because the pallet stone is slightly too short, or rather the lock isn't deep enough with the escape wheel. If it is overbanked the balance will only turn in one direction, as the impulse jewel is on the wrong side of the horn and would need taking out and re-fitting it again. Is this the case? I'm curious when you take power off the mainspring, you say the crown rotates very slowly. Is this with the mainspring fully wound and then taking off power? Did you check the end shake of the barrel when seated between the barrel bridge and the mainplate and did you check the end shake of the barrel arbor inside the barrel? If there is no end shake this would do exactly what you have described, as the mainspring is binding, but it wouldn't explain the watch running on the bench and not on the wrist. But just because you find one problem doesn't mean there aren't several Have a look at this discussion from a couple of weeks ago week regarding pallet stones: This is called 're-banking', also known as 'knocking', not overbanking. An easy mistake to make. It looks like this on the timegrapher when the movement is close to being fully wound1 point

-

As you have nice numbers I assume you have a timing machine what's the amplitude? Then ideally the timing results in more than one position not just dial down may be crown down and a picture of whatever you using for timing machine often times we might see something you don't1 point

-

Maybe you need more power to see things better? One of the problems with the microscope is sometimes you don't see the big picture. I don't suppose you have a timing machine? Because something that visually looks like it's running great on the bench may not actually be running that wonderful.1 point

-

I really doubt that a printed plastic base will be of any use for you. Its fundamental quality is being an anvil with heavy mass to make hammer blows efficient. A printed base can hold a stake, but without heavy mass it will flex and make hammering very inefficient. Frank1 point