Leaderboard

Popular Content

Showing content with the highest reputation on 12/01/23 in all areas

-

Well. Like me, you've begun. Information from a beginner What ever you do, don't begin on a watch you or your bride own and treasure. Go to a boot fair and get some old watches for a few pound. They might or might not work. Doesn't matter. Exactly as Mark says. Look and practice, then practice, practice and then, practice some more. Do each stage systematically. Open then close, do it again a few times. Next stage, depending on the watch. Take it out of the case. Put it back in, take it out, put it back. Show your bride what you can do. Get encouragement. What ever you do, don't take a watch fully apart. You will not remember where anything goes, you will be heavy handed and break a pivot. Oh yes you will. Been there, worn that T shirt. I still have 3 watches that I need parts for, and cannot be obtained. If only I knew what I knew now, or be a gentle as I am now. 2 were heirlooms so to speak. So upset with myself. Could I do them now? Oh yes. Hope this helps.4 points

-

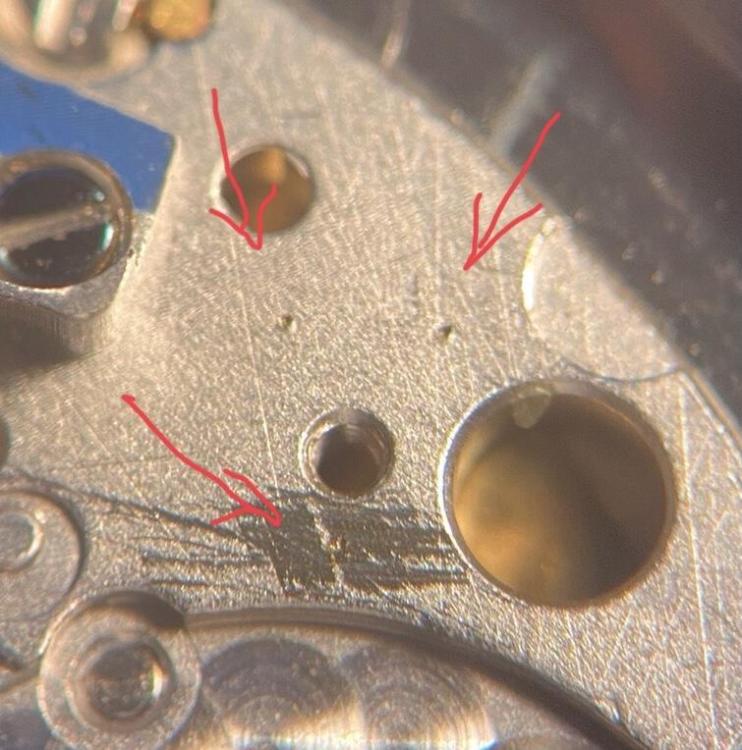

Addition to my above comment. I followed a number of videos on doing a full service of a particular watch. 'Only started last week', load of bull. Yes I was able to follow, disassembled and even assembled. What did I achieve? I had damaged balances, springs, broken pivots on escape wheels and centre wheels. Lost 3 jewel springs. Scratched plates. Put wrong screws in wrong places. Re-sized hands inadvertently by forcing them off. And more. Many things I would never do now. Rush in, and you need members of this forum without a doubt. Thank goodness for them.3 points

-

What really helped me with my first few watches was to setup a camera and record the disassembly as well as taking lots of photos. It can be easy to forget which part goes where or the order the parts need to be reinstalled.3 points

-

The jewel collets are only good for working on the centre part of the jewel, like resizing the hole or oil sink. I've only tried resizing an endstone which was a little big and thick. I mounted the flat surface of the endstone on a brass rod with shellac. Centering the stone was a real pain. I had to warm the brass rod until the shellac softened, then spin the rod at a low speed on my lathe and used a pegwood to centre it before the shellac hardened. I reduced the diameter of the stone using a #1000 diamond file. Then worked up to #2000, then #3000. Similarly, I thinned the convex surface using diamond files. Polishing the adjusted surfaces was another pain. I used diamond paste on a popsicle stick to polish the rough surface. It took a really long time. Maybe using the diamond paste on a harder surface like brass might have been more effective. I gave up when the stone reached a semi glossy finish. I figured that the finish of the edge and convex surface of the endstone doesn't really affect the performance. That was the first and last time I adjusted a jewel. I don't even remember which watch it was. For hole jewels, I would choose a jewel that has the correct size hole but if it is slightly larger, I would ream the setting hole to fit the jewel rather than try adjusting the diameter of the jewel to fit the setting. I still have a few watches with cracked or broken balance jewels. But working with jewels is such a pain that I would rather root canal at tooth. Good luck with resizing your jewels.3 points

-

Was thinking maybe I should Google this to figure out what exactly I have been accused of https://dictionary.cambridge.org/dictionary/english/gatekeeping Interesting definition. But it brings up a problem of the original posting person is doing exactly that. His controlling the information we have or have not to solve the problem. Watch repair involves a lot of detective work in order to do the detective work we require eyes at the scene of the crime and we need a crime report. If we didn't have a picture of a watch in other words we didn't have a scene of a crime and a hypothetical question was asked then we could give hypothetical answers but we would still need a watch or description of a watch because the answers will vary depending upon the watch. For instance some watches you could move the jewels not typically an American pocket watch. As a reminder the balance jewels are different than plate jewels they will tolerate greater out of alignment. Then yes before fixing a problem figuring out what the problem is like has the bridge been bent. Usually on American pocket watches shimming is just a thin strip of paper either in the front or the back of the screw to allow you to tip the balance bridge. Which angles the bridge exactly the same as bending would do or raising marks on the plate.2 points

-

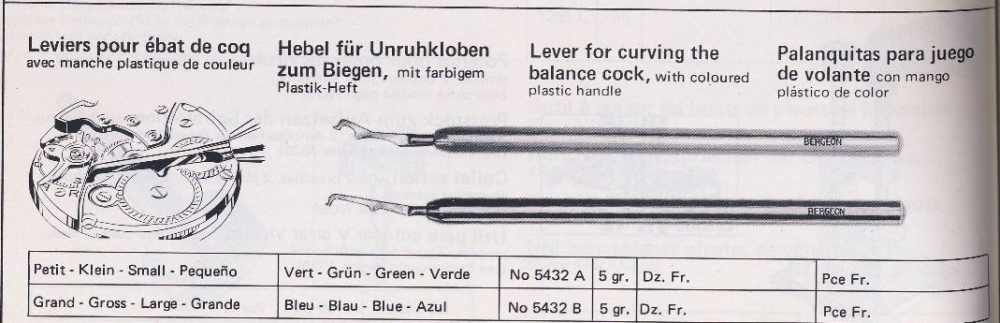

When you look at this problem it could be a number of issues like end shake butt end shake doesn't magically change by itself pivots don't magically grow longer. They can grow to being shorter typically broken off. But is there anything else that would cause the exact symptoms that you have that I quoted above? For instance your pictures could use a little work but still they tell us this is a really nice pretty watch and hairspring is it where it's supposed to be? For instance you look at the image below and go find it up above it looks like the regulator pins are just barely touching the top of the hairspring. The problem with this is if the hairspring is down too low it rubs on the balance arms and that will simulate exactly the problem you're having. So it's very important that the hairspring be absolutely parallel and that every single time you look at a watch you look to make sure it's parallel. Although all of us will agree that seeing of that can be a bit of a challenge. No matter what if that hairspring is touching the balance arms you will have running issues. By the way how do you know that that was actually done by the manufacturer? Usually when people are manufacturing watches they will adjust the balance staff to fit their watch. This is usually done after the fact by people who don't have the tools to adjust the balance staff pivots to the proper length. Now there are minor exceptions to things like this some manufacturers will put it in a piece of usually metal across the entire bottom of the bridge. To raise the bridge up parallel and not to put at angle very common on Russian watches where manufacturing tolerances need to be worked on and Thin sheets of metal solve that problem. I thought we didn't have too much horizontal plane now we have too much what happened? Oh what about if you could purchase a tool that came from a Swiss company and it came in a yellow box would it make bending the balance bridge acceptable? One of the problems for problem solving is a number of items we need to have to understand how to solve the problem for instance jeweling tool helpful for? As I could tell from the pictures this is a pretty watch. But what does that mean well is a link below this is a very fine railroad grade 21 jewel watch everything should function perfectly At least it did when it left the factory who knows what's happened to it since then https://pocketwatchdatabase.com/guide/company/elgin/grade/270 Now back to the jewels jeweling tool would it be of any use not really. Notice all those little screws holding the jewels in. Usually things with end stone's people removed for cleaning then of course you have to be carefully make sure you get them back down where there supposed to be and that they're still parallel plus you will be careful not the strip the little screws. But basically those tools are where they are they can be moved downwards a little bit not recommended though you can actually reduce the thickness of the shoulders of the hole jewel but that's not really what you want to be doing in fact that would violate one of your rules If you were to reduce the thickness too much you wouldn't build a get the in the stone on properly. Typically lie time you're adjusting the whole jewels are if you're fitting a new jewel Here's a website for identifying watch parts for Elgin watches http://www.elginwatchparts.com/ One of the problems when you look at vintage parts especially Elgin where there information tends below more complete than other companies they will tell you considerable variation in a lot of the parts. This is where mixing and matching off other watches becomes an issue2 points

-

I'm pretty sure that nobody has actually found the bottom of it yet so if you're just starting out then I'm afraid you've got a long way to fall.2 points

-

I'm not surprised its bloody China. Put together by child labour in some sweat shop with no fire escape.2 points

-

A little bit of elbow grease and here are some of the tools cleaned up Canon pinion tool before: And here it is after Used some of Will Kirk's (Repair Shop) cleaning solution to clean the dirt and old varnish off the handle, then made some shellac to protect it, finally some of my home made beeswax polish. Cleaned the parts up in dish detergent, then IPA to remove any water, naphtha to remove any grease and a quick visit to the buffing machine and some Brasso, another full clean and then oil/grease and reassemble. This is the pin vice before: And here it is now: Similar treatment to the pinion tool above And here is the brass truing and poising caliper before And after Didn't to too crazy with this, just some Brasso and some 3-in-1 oil on the hinge I also worked on the 4 sided movement holder: After I cleaned it up I found some blue paint, so thought what the heck:2 points

-

It's a fake and it is a very poor movement. China or India I expect are the rip off countries.2 points

-

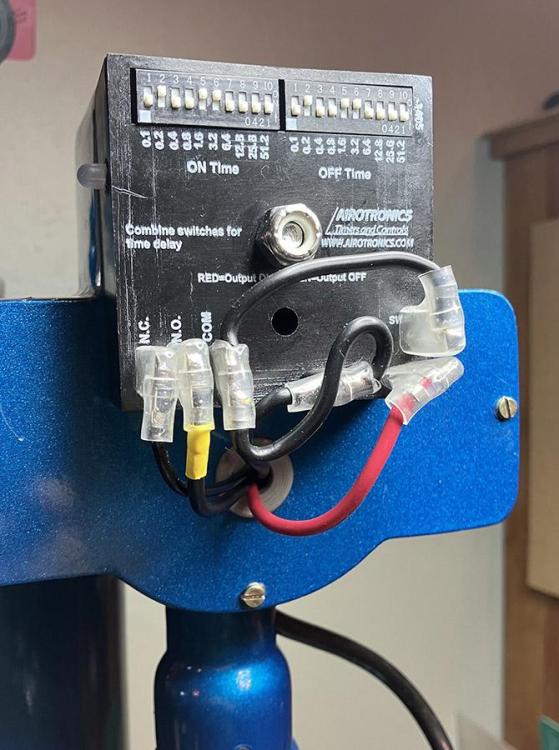

I finally got around to taking photos of my changes. Full setup. For baffles in the jars, I went the L&R route. I did a 4-wire variant of the original circuit. It does have a minor drawback where switching to "forward" while the red light is on will pass current through both windings for a few seconds which isn't so good for the motor. Creative soldering is required to get 2 wires on each spade connector. This is the 21EW91 switch set for 5 second intervals. Plenty of room for the motor with the right-angle connectors. 3D printed TPU grommet. I managed to relocate the LED so I can see it from the front. Potted circuits are a pain! Master switch and fuse. Also a 3-wire cord that properly grounds the body, plus the really good jar seals. I hope the helps someone out.2 points

-

2 points

-

Bending is deforming the balance cock, so even if one manages an acceptable adjustment , he creates a job for the next repairman to find and fix the fault. The next worst aproach is gouging, at least shimming doesn't destroy a part. Mark makes sure to mention gouging is frowned upon when he shows jouging. All of the above are bodge job. There is no need to destroy a watch when we repaire/ restore it. As the OP doesn't have a jeweling tool, lets show him to shim. I should have shown how to adjust by shimming with .01mm accuracy long time ago. I know, I am terrible when it comes to keeping my promises, will do this one soon, if you dont. Then the questions John asked has remained unanswered. Rgds1 point

-

The bending I talk about is no more than 0.1mm , in all cases no visible effect, only fine regulation of the end shake. How many antique pocket watch balance staffs have You turned and replaced? I mean, You can trust me when I say something like this, as I have done many of them.1 point

-

This approach is a dangerous hit or miss, you have no control over the amount of adjusting. Its blindly increasing and decreasing until you get tired and call a end shake acceptible, there is also high risk of breaking the cock screw plus that all parts need to be removed before you attempt or else you be putting all parts in harms way. furthurmore in case that jewels are embeded , jewels would end up not parrallel. Rgds1 point

-

Good advice Ross, the repetitive thing can be extended further still. I would remove a part and reinstall it a few times to reinforce my short term memory retention, there comes a time when you want to let go of relying on walkthrough photos1 point

-

Well I have just received the following Timelab tools all the way from the USA. The 9 set of screwdrivers with spare baleds in each size. A 4 way movement holder. A set of 1mm hand lifting tools. Some hand setting tools. Some springbar tools. A squeezy ball for removing screw on casebacks. A 70mm silicon cushion. First impressions? The screwdrivers are really nice compared to anything I have seen. Makes me realise how much rubbish is peddled as being quality. However, I got rather scared by the smallest one. The 0.8mm. I can't imagine a screw that small. I just can't. Movement holder. This impressed me. Can handle four different sizes on each of the faces. Isn't sloppy as it could easily have been. The hand lifting tools look really nice. Very fine. Again, another tool that makes me admire watchmakers more by the moment. Three different size springbar removal tools. Another tool that you don't think you may ever need until you have seen one. I recall as a teenager, you know the one, know all and know nothing, using a 'precision' screwdriver to remove springbars. Each of them has what looks like a punch on the other end. I suppose it would be more for pushing a spring bar out of a bracelet or strap? Squeezy ball. Is a squeezy ball. Truth will be in the use of. The cushion is really nice. Has a nice weighty feel to it. The working surface is really smooth. No wrinkles. The base is a really nice non-slip material. I'll take some photos tomorrow. I know these aren't Chinese tools, so they don't belong on that other topic, but based on what I know from tools during my apprenticeship etc, I would have no hesitation in recommending any of these. If Bergeon etc are another step up, they must be some seriously good tools. I am worried about how deep and mazey (is that even a word?) this rabbit hole goes.1 point

-

Had the same problem on my first Sekonda. Every time I tightened the balance cock screw, the balance stopped. Watched Mark's course video on the same problem. Made two scratches with a screwdriver which increased the end shake. Did the job. I was impressed with me. Heehee! Been wearing the watch daily for nearly a year now. Loses 12 seconds every week. Can't fault it. Hope you get it sorted1 point

-

Omega never made ball clocks. If you look up Omega clocks you will see what they made. I think they made a few desk clocks some time in the 60's and a few wall clocks and advertising clocks before the 60's1 point

-

Hi the last ball clock I did was total crap but the owner wanted it fixed. It had worn the ratchet wheel teeth on the edge. The movement was one of the undetermined origin and was eight and three quarters by six, big dial magnified by the lens front. It screwed together. In essence rubbish, but looked the part.1 point

-

1 point

-

1 point

-

All of them are considered truing calipers. Although sometimes the used for truly wheels not just the balance wheels. Just different styles of the same tool Too many items I will just snipped out images so we can keep straight what I'm talking about or at least I can figure out where and talking about. This one is a mainspring a Winder you're missing the arbor part. I think I have some someplace I've never used them. Then if I remember right I think the arbor is double-sided you really get curious off to find a picture for you to show you the rest of it Typically these will come in a set of three. There bench keys for winding typically American pocket watches but conceivably European pocket watches that require winding out of the case. In other words in a typical American pocket watch the case has a sleeve which holds in the stamina crown when the movements removed from the case you need a way of winding and setting. I normally not used to seeing these exactly like these but my suspicion is these are used to push jewel settings out of watches. A lot of times when you see him like this is because somebody in a classroom situation made them versus purchasing them commercially. At least sometimes. Now I have to watch my back somebody stalking me oh dear. I do use a specific pin device for that sort of thing because I always regarded initially as a bad pin vice because the jaws were sharp. But I found the sharp jaws quite nice at reducing the diameter of things were for cleaning up things. So yes they do make a specific tool for that purpose but I suspect in the picture of we looked at the jaws carefully it's probably just the pin vice.1 point

-

No jewel moving in this kind of watches and jewels, no jeweling tool needed here. First of all, the endshake must be checked and if no endshake but the balance is almost free. then the balance cock can be lifted alittle. To do so, the balance must be taken off the cock, the cock in place and the screw tightened. Then, lift alittle the cock wit proper tool in ordet ro slightly deform it and thus increase the distance between jewels. Then, put the balance for test (hairspring attaching is not needed at this point) and check the free play, if to much, correct by pressing the cock down (balance out!)1 point

-

Give it a blow with a puffer and see if it runs freely. If not remove the pallet, reinstall the balance and give it a blow again. It should oscillate from about 30s.1 point

-

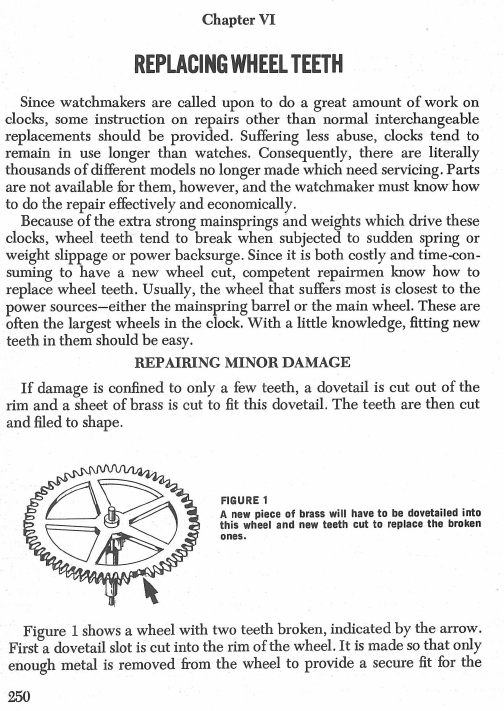

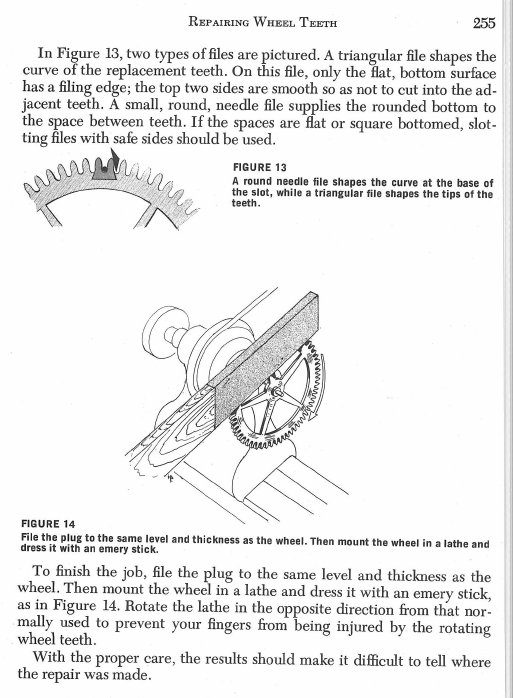

Now that we've grasped the subtle difference in titles one book excludes clockmakers and my copy embraces clockmaking? I do tend to think of replacing teeth as much more common in clock repair which in the first page he explains why So years the first page showing the problem. Then the last page Showing the outcome all done by hand. Much nicer if you have access to the gear cutting set up but it's amazing what you can do with the file in a saw if you're careful.1 point

-

I had never notice the title difference. All I ever knew about was when I'd recommend the book people would end up with the version without they hairspring repairs. Then I also am aware of various editions of the book and I was wondered if that was part of the problem. A lot of times when people do multiple additions over time things get added things get deleted things can change dramatically from whatever it once was at least sometimes.1 point

-

1 point

-

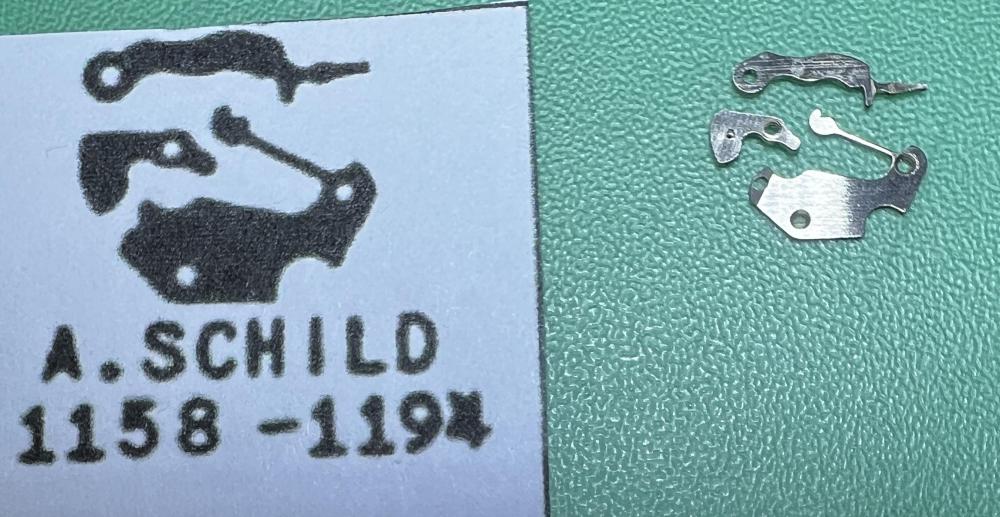

The watch world is littered with examples of ebouche's that have been supplied by one company to be built into watches made by a different company who modify or refinish it to their own requirements (ebouche literally means rough or unfinished), even removing the original manufacturers branding, if it was even there in the first place (it could well be a contract requirement that the ebouche's are supplied un-branded). Such modifications could be technical improvements to the movement, or could just be cosmetic, including changing the shape of the bridges. I very much doubt this is a "copy" of anything, but is an AS1194 supplied un-branded to the client company for them to finish as their own. AS might even have carried out the modifications themselves to the client's specification.1 point

-

I have a Janta Pearl machine too. Changes I've made/making: Added a main switch and replaced the power cord with a grounded plug. Grounded to the case. Remove the spring. I may put it back but shorter. Just long enough so the head won't drop on the glass bottles. I really like the 3" plumbing plug idea for bottle caps. I grabbed those when I saw it. Replace the all the tape with soldered connections and heat shrink. Ordered the automatic relay switch today from Grainger. The version mentioned above by @jimzzilla isn't available currently, so I got 21EW91 which just has a finer resolution, only goes to 102.4 seconds rather than 1024 seconds and DPDT switch 4X850. Perhaps replace the two chocolate bar (aka euro style) blocks with screw terminal blocks. Really happy with all the suggestions to fix it up. Thanks to the group!1 point

-

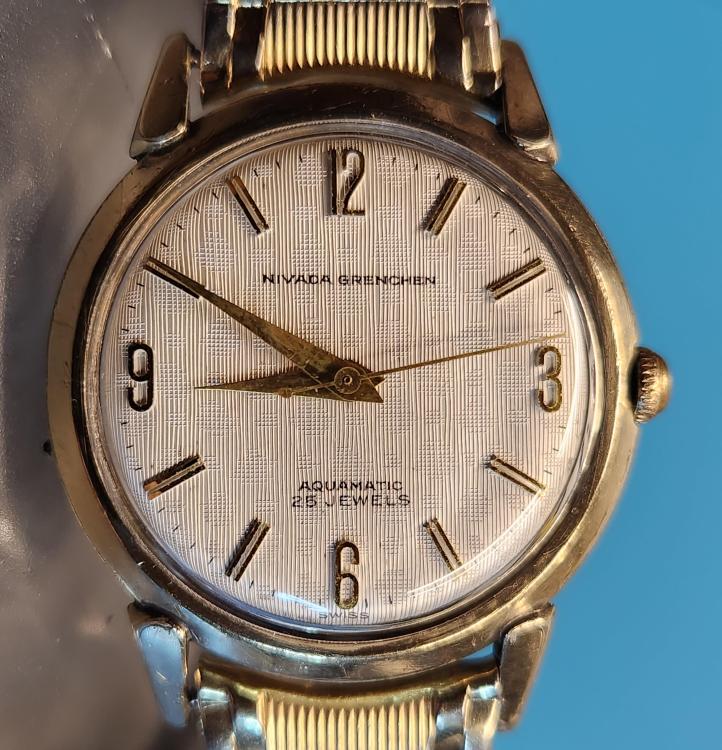

This is one of my favorites. The dial is just stunning. I have had this for a while now but tonight cleaned the case and bracelet and replaced the crystal.all of that and still under $10. An ETA 2452 with 25 jewels. As mentioned elsewhere, this was the base movement for the Tudor 30 jewel caliber 2484.1 point

-

This is the intro, the book is 135 pages long and my scanner's very slow so it's going to take a bit longer than I thought... a Sunday job. KIF Spare Material Catalogue P1-17.pdf1 point