Leaderboard

Popular Content

Showing content with the highest reputation on 11/29/23 in all areas

-

Dive on in there Richard, watch repair is like being married. Good days very good days, some bad some very bad but you can’t let go .50 years on still the same and a nice comfy dint in the wall you have made with your head over the years. Have a beer there is always tomorrow.3 points

-

I decided to do a little improvisation last night. I had a case where the sides were extremely worn, dented, etc. The case lines were nearly worn completely down. I've wanted a lapping machine for some time but those are far too expensive for my humble budget. I improvised by hooking up one of my sanders to a voltage regulator to bring the speed down as much as I could. I put some 1000 grit paper on the disc and started to gently work the side of the case. I'm quite surprised at what I was able to accomplish with these rag-tag tools and bit of creativity. I'm limited by the table because it can only adjust to 45 degrees, so there are some angles on that case I won't be able to reach properly. While looking up pictures on the internet of other examples of this case it looks like there was not a sharp line between the side wall and the lugs, so I just tried to bring back a gentle curve between those to sides. Not too bad for my first attempt! I'm going to keep moving forward and go up to 2500 grit and see what I can get out of this before moving on to the polishing wheel.2 points

-

Don't remember where I saw it but with the etachron system where you basically have one and two they did a modification in later generations. There was some reference to they changed I have quite remember why they made some change there for reasons that I can't remember and I don't remember where I saw that. Possibly in some of the Swatch group documentation I obtained but finding that would be really difficult. So yes they made modifications right at that instant location because there must've been some reason why. It might have even had to do with heat treating from my memory but just not quite sure that I course regulator pin spacing is important. Especially when you can adjust it things become more interesting because then you can hopefully get things better. Don't know if that's answering your question at all other than basically everything that moves in the watch probably affects timekeeping after all it's a mechanical watch. But as I said before over time they will tend to average out all their problems hopefully.2 points

-

It gets easier with practice, keep going This afternoon I has the same problem as you - I fitted a mainspring where the inner coil was much smaller than the arbor. You can either take the spring out, and open the inner coil slightly with some round nose pliers, or do what I did. Put the arbor over the inner coil and press down lightly with some tweezers. Then I used an old sharpened oiler. Push it vertically down in to the end of the spring, to force it out a bit so it goes round the arbor, then slide the oiler back around the coil, opening it as you go, and in pops the arbor !2 points

-

My guesses.. 1. wood chips for drying parts in after the final rinse. A bit of an archaic practice these days. 2. could be French chalk for brushing cleaned clock plates with.... or maybe diamantine powder for polishing.... could also be oilstone powder, also for polishing, although the stuff that I have got is slightly greyish. 3. Blueing pan. Fill it with brass chips, place item to be blued on the chips and hold the pan over a spirit burner. 4. & 5. Pallet warmer for softening the shellac in order to adjust the pallet stones.2 points

-

These movements are well worth the few quid that they can go for. I know Nicklesilver rates them. I've got into a bit of a habit of researching for known reliable well made movements, picking up the odd few orphans then searching out an externally good watch that they can donor for. Sounds a bit backward but its actually much more cost effective than post searching for a donor. This way any replacement parts are already sourced. Ok you might be waiting to find a watch you like, but you've only spent a few quid instead of paying good money and then being on a wait if it needs fixing. All you are doing is adding a few quid onto that watch but potentially saving a shed load of time.2 points

-

Do you know John that is a piece of advice that i rarely see given. I always run a brush around the edge of a caseback before its removed. I think its just an automatic task that we all do, especially with a battery watch that is only haveing a replacement battery. A beginner might not even think about doing it.2 points

-

Remember when you using your tools to make sure that you remove all the dirt from around the case back before you remove the back. You don't want to drop anything into the quartz watch movement as their very intolerant two things like that. Then it would be nice if we could have a picture of the movement and of course the case in the back.2 points

-

I have a link to where you can find a parts list for each of your watches. Then you can click on the part that you're interested in and it will cross reference with all the watches that have the same part. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2846 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ETA_2836-22 points

-

Tom's right 8 years is a long time for a standard battery to be sitting in a watch. Depends when the battery's energy was drained. When you have it open you may find some battery leakage, sometimes just a spot or two under the battery. Mop up anything you find as best you can, it should really have thorough clean and relube but that is probably going beyond what you expected to do. Post up some pictures when you have it open.2 points

-

Depending on the condition of the gasket on removal of the caseback you might not need to replace it. If we find we need to replace the gasket generally we measure them up and order an equivalent generic one from a material supplier. I would be concerned if it has been sitting for so long needing a battery replaced that the old battery may have leaked and corroded other parts. open it up and provide us with pictures and we will do all we can to guide and help you along. Tom2 points

-

2 points

-

Remember the early electric watches are partially mechanical so you're halfway there. It's the electric part that bothers people. The mystery parts the black box that you need test equipment To figure out what's going on you can't look at it like a mechanical watch that's the problem for most people. It definitely becomes a problem with the watches of working then they really have a problem. Now that you have that book you can get the whole set of all of his books. Like for instance this is a really nice book to get as it has an entire section on straightening out hairsprings. But apparently comes in a whole bunch of variations CF be careful to get the right one?2 points

-

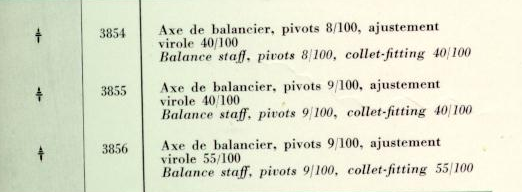

The 700 series parts look interesting in that it appears to be there were lots of variations.Looks like they had both flat and over coil hairsprings which both of them at one time were available as separate hairsprings. Normally with the over coil because of premade they were available but it's shows on the parts list the flat hairspring was available. Then amusingly the old days where things were available like they hairspring collet comes in two separate sizes which would explain why your staffing has different sizes and even had the replacement Pin for the collet. Here's what I have for the balance staff numbers then a little bit of specifications. But the problem with parts lists are this is what was in existence when the parts list was made if the watch was made after this widget probably was there were probably more variations.2 points

-

Are you sure the new balance complete has the ferquency your watch needs ? Aparently the new balance complete is 28800 beater whereas your watch needs a 21600 beater, 21600÷ 28800= .75 45÷60= .75 No , that wont do it. Rgds Thats your micro adjustor.2 points

-

2 points

-

Hello everyone, I can now report the my work on this watch is done. Apart from the regular movement service, the bizarre ratchet wheel and correcting the sideshake of the barrel, it took a lot of careful work to clean the dial and buffing the hands and hour markers. Also gave it a new crystal and some very light manual case polishing with Cape Cod cloths. It is now going back to its owner, who's grandfather had bought it. I had some additional troubles with the automatic module, specifically the wear on the rotor bearing. While the rotor wasn't touching the movement when gently turned, it did rattle and touch when shaken a bit. I had to order three rotors until I finally got one that was in good enough shape. Thankfully not too expensive. Here are some pics of the final product:2 points

-

Did the smell Ling-er? Tight back use your mussels, if all else fails pawn it. PS. I have broken my broach, it's now a roach.2 points

-

I remember repairing this type of clock. Well made as well. Someone has had a go at the bush for the hammer as it looks as if someone has used a punch on it, it is also filthy dirty.1 point

-

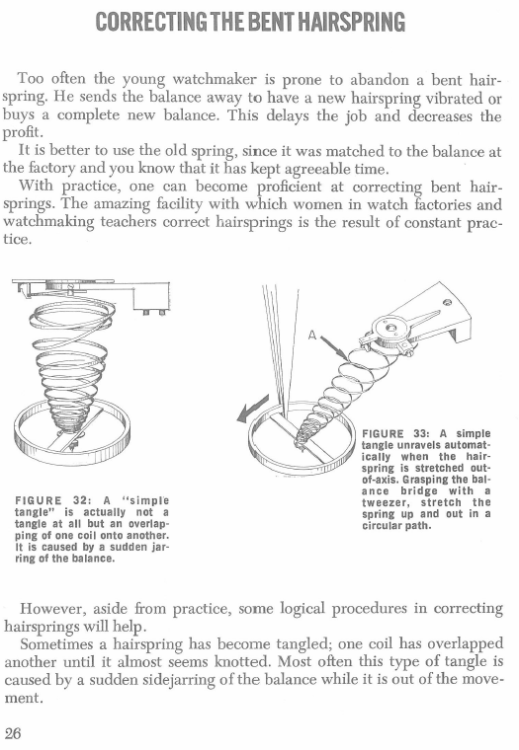

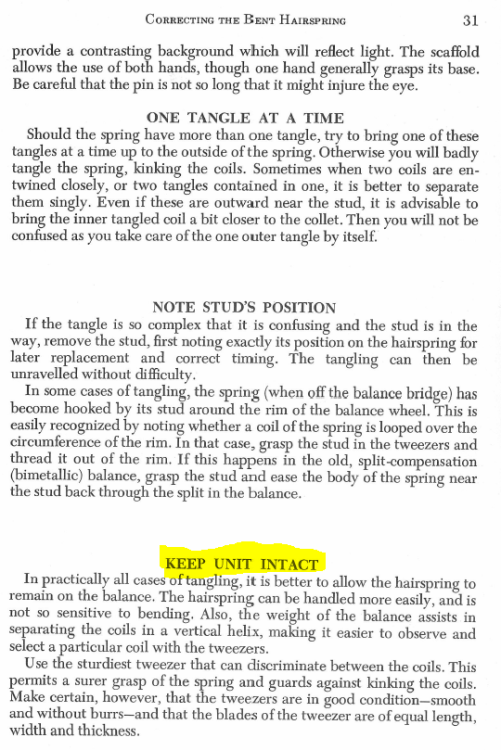

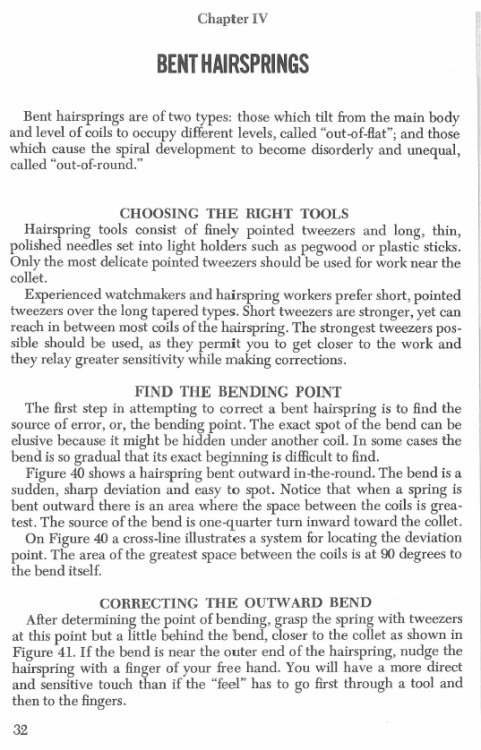

Sometimes my dictation software doesn't do the best job so let's try again. The book comes in variations are those variations importance maybe maybe not. But let's compare the table of contents and see if it would be of it of any help at all to anyone in this discussion So basically they're identical except there is a section starts on page 26 ends on page 43 it's titled Correcting the bent hairspring wonder if that would be to use? Then much farther down something about replacing wheel chief which I doubt any of us would ever do I might've done it wants sometime in my life it's the other section that's the more interesting section is why gave you the page which explains which edition that I have why made the reference to separate editions because? The table of contents of this book doesn't exactly agree with the contents itself for instance what do we find on page 26 of my book well it looks like this Then as I scroll through the missing section of your book page 31 has something interesting on the bottom. This often comes up when people are dealing with their hairspring crisis often times in the group people say remove it from the balance wheel and it's not what's recommended it's easier to work with it when it's all together although it be easier to not to have to deal with this at all. Now we get the page 32 which is weird because it's section what exactly and in the next section has the exact same Number and it's almost like this section is into separate section so it was inserted at some point in time or possibly removed from the other books but it's back to my caution the book comes in variations make sure you get the right variation otherwise you're missing what I consider a really useful section on fixing distressed hairsprings.1 point

-

We feel your pain … I struggled with arbors the same way, until… So for when the going gets tough or if you just want to try a different technique- instead of the anvil or the bench or whatever to rest the barrel upon, use one of those pithwood buttons, a big one, flat with a good hole in the center. It grips the barrel sufficiently so you can use the arbor to gently open the spring. Arbor hook in the spring gap, light pressure with the tweezers and turn the whole kit (not the arbor) opposite the spring direction so it opens up the coil and accepts the arbor…and if it doesn’t work, the button’s grip on the barrel will allow you a free hand to manipulate the spring a bit with a tool to coax the arbor in. Makes quick work of it every time or your money back…1 point

-

I was thinking maybe something along the lines of this design with interchangeable jaws. This design uses two springs, but a central one should be fine to open up the jaws. Though, a design without guide rods would be nice, so you just need to worry about getting a screw and a spring (and maybe a nut). The Meyers #58 is a really nice movement holder, but they can be hard to find and go for a really high price when you do. I was lucky to find one for a great price. Having a 3D printed option would make it reachable by more people.1 point

-

If its cork that is used for drying. White power I would say diamantine powder, french chalk is normally in a block.1 point

-

Poor you. We all come across movements that can be a pain in the ass. You have to just keep plodding along. What type of screwdrivers are those?1 point

-

I'll take a look and see if I have one in my "to be serviced" pile. I think the posts only need to be as tall as the spring, so pretty short and stubby. In fact they can't bee too tall or they would interfere with the top bridge when it was placed. They don't have to be round either, they could be longer than they are wide and then on the side of the post opposite the spring, they could taper down, from the top of the post to floor of the jig, which I think would give it some strength.1 point

-

1 point

-

Hi Lee, Base movement of ETA 2824 and 2836 are entirely interchangeable, and both calibers are most common of ETA's , so your next project can be either of said calibers in need of balance complete. Rgds1 point

-

White powder I don’t know- radium lume? The first bit of kit looks like the chips and wand for bluing screws and hands and such. what hold and control the heat perhaps…wand for holding over the flame How about borax flux for the powder?1 point

-

Rust in the barrel, the spring is shot by the barrel and arbor are ok. So a decent watch only in need of a spring, crown and crystal.1 point

-

1 point

-

I see you found the replacement battery when I was looking online I was hoping for a technical sheet but they don't seem to exist I did find a couple of people including one on eBay would sell a replacement movement. Then several people of course did have the replacement battery I was kinda surprised that this existed because I only thought that Seiko and the Swiss had a kinetic type watch. I always thought citizen was big on solar power and left kinetic the Seiko. Then just as a reminder this is a quartz mechanical watch like any mechanical watch from time to time they may need servicing. Typically the kinetic watches represent minor service issues in that they use a lot of plastic including the Seiko watches. So cleaning fluids become more interesting so is not disintegrate the plastic. So any time you a quartz movement out you want to be very careful to make sure that there's no dust or dirt or anything to deserve very intolerant to anything versus the mechanical watch then the save some time to explain some things I've attached a Seiko technical bulletin. This one is interesting because they acknowledge that it has a battery versus a capacitor. It does have some rather dramatic changes to things so your watch doesn't have something that Seiko kinetic's have which is the button to tell what your power reserve is. You look on the second page of the PDF will see the interesting problem although since you haven't seen the tech sheet for a capacitor version it's not as obvious. First off we start off with how to wind up your watch you want to have a specific rhythmic motion to get the rotor spinning because only if it spins can it generate electricity to charge up the capacitor/battery. What becomes interesting with a battery in a kinetic versus the capacitor is it requires way way more charging. So notice it says it takes 250 swings to get it to charge up for one day of use. Or approximately 500 swings to get two days of use. You'll notice they make reference to something that typically people tried a DIY this with a variety of things. Seiko had a charging station plugs in has a power adapter power the thing it would place the watch at various positions depending upon which model you have it had a timer for how long it ran and images charge the thing up and you wouldn't have to swing it perpetually but when it was available it used to cost $250. But still it's really nice to have if you have a kinetic watch and if you could find one otherwise you will have the do an online search and see people a bad varying degrees of luck with DIY but because you don't have the push button to see how the charging is going then you're not know how well that works now reason I'm pointing out all of this how much swinging you have to do if you're only getting a few minutes of run time and providing the watch doesn't need to be serviced you need to really shake the watch a lot more and do it rhythmically is kind of a rhythmic procedure for that. Yes the benefits of things you learn by taking classes including a class on kinetic watches. She work up a nice rhythmic motion and see if you get a little more run time Perhaps Seiko kinetic 5M54A.pdf1 point

-

1 point

-

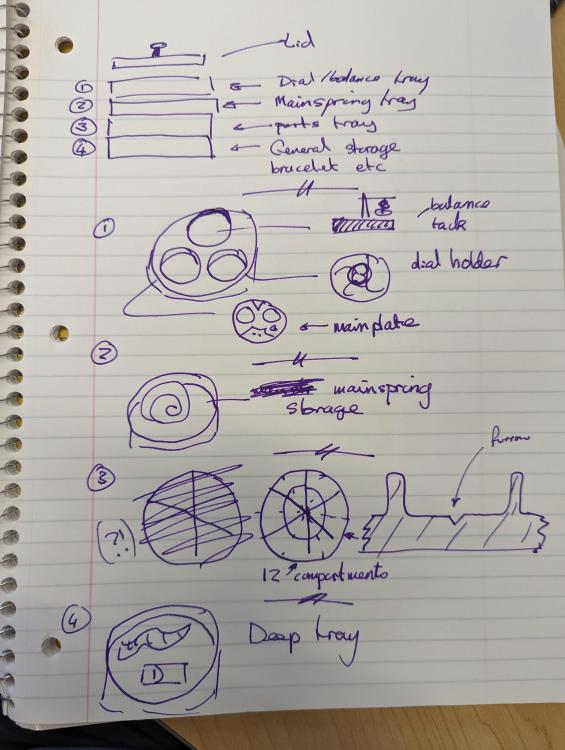

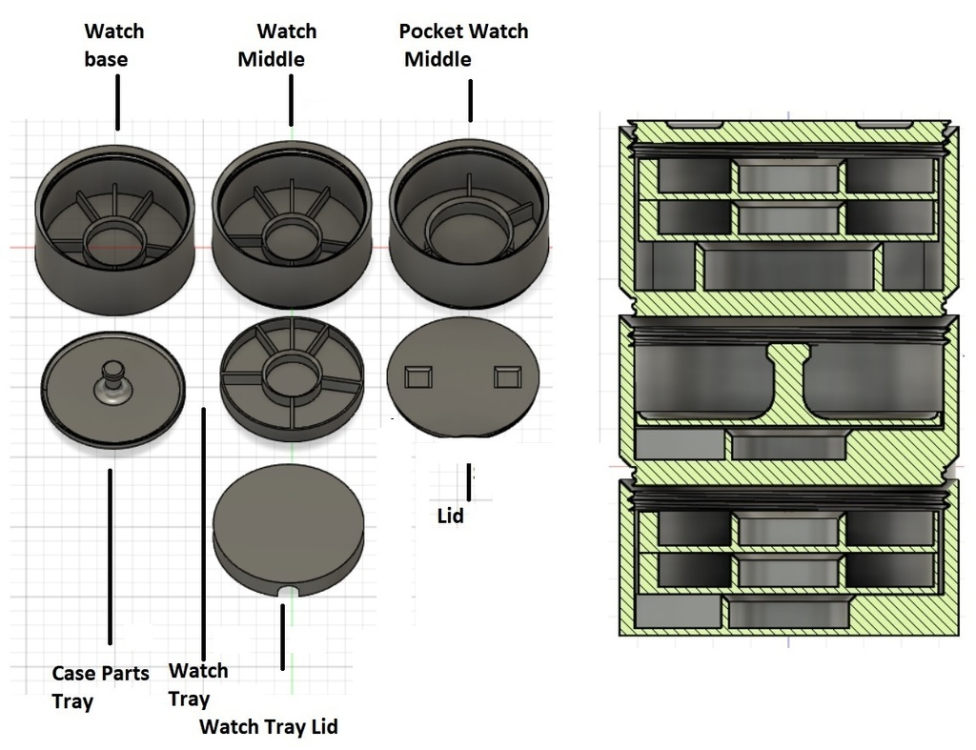

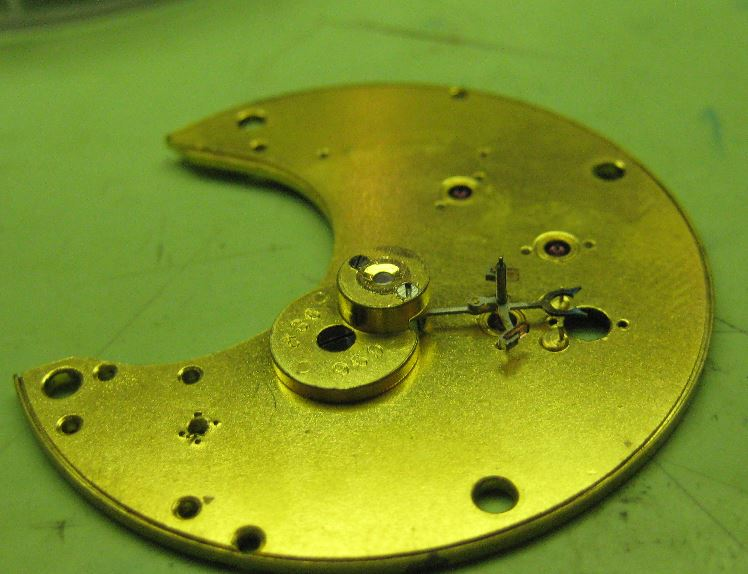

After accepting the fact I am a messy worker I need to find a better way to store watch parts (all parts) while I am working on them and also while I am storing them, for example when waiting for parts etc. Currently I use the normal bell type parts/dust trays, and have also tried the yellow type from CousinsUK as seen being used by Mike on My Retro Watches. Each is good, but not a complete solution. I still have a dial holder floating around, and a balance tack with a balance on (depending where I am in the re-build process) there is also a bracelet kicking around in various stages of re-build and movement rings, cases, case backs, old/new crystal(s). If I have to store these it can be problematic and parts can easily become misplaced or orphaned, and the tops cant be secured so if you knock it over you are hooped. One of my other major gripes is also that the bottoms are flat on the parts trays, meaning that you have to chase the ratchet wheel and other flat parts around trying to pick it up with your tweesers, and maybe scratching them up in the process. So I have decided to design a parts tray (system) that fixes all of the above! Here is a sketch Lid: self explanatory, except it will have a course thread on it so that you can screw it down for long term storage 1) Dial and (temporary) balance and mainiplate storage 2) compartment about 10 mm high to store the mainspring 3) Parts tray, 6 compartments each divided into 2 (inner ring) to make a total of 12 compartments, each will have a furrow which will allow the tip of the tweezers under a flat component, and also somewhere for the screws and wire springs etc. to be when you try and pick them up 4) large open compartment for bracelet, case, caseback etc..... I'm anticipating that each compartment will screw into the next but also be freestanding, the design will be modular, so you can change the order they screw together or if you don't need compartment x then you don't have to include it in the stack. Thoughts, ideas? Actually, this guy beat me to it.... (LINK) so may just tweak the design a little:1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. You will need a lot of specialised machinery to make many of the parts for watches. Very expensive stuff.1 point

-

I have a half memory (maybe my subconscious is blocking it out?) of doing one of these in a rotary watch (?). Unfortunately I don't have one right now, but if you provide some dimensions, I'll give it a go. Only concern is that thin posts/pins printed by 3D printer are very weak, so one would need to glue in a brass or steel pin or something?1 point

-

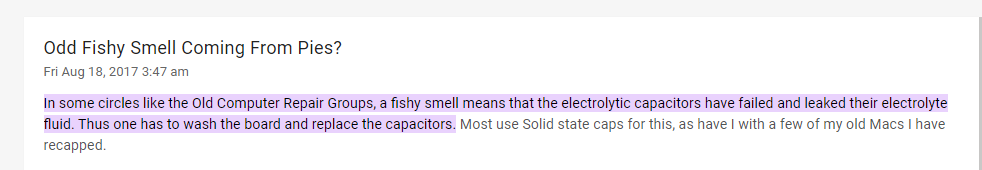

Hi there, yes the watch will tick for a while when being worn, but will die shortly after taking off. Could you help with the spec of the rechargeable lithium battery, I'll pull the capacitor tonight and post pictures. Seems to be, the rotor seems to charge up the battery/capacitor, all is working, but I think the battery/capacitor cannot hold more than a few minutes of charge and I will have to replace it. I think I managed to figure it out, the movement is a Mayota BP10 - from my googoo search I found a site that calls out a Citizen 295-6000 capacitor as the replacement. Just placed on order on eBay, CousinsUK won't post to me in my location as it's classed as dangerous goods Oh my, you put a lot of effort into this I also managed to find this on a Raspberry Pi site (LINK), it states that a bad capacitor can leak its fluid and smells fishy, this jives with the watch being unable to hold a charge.... cue the fish pie jokes!1 point

-

Yes it definitely looks like a Seiko kinetic sort of. The yes all the capacitors went bad and as far as I know them all of the kinetic I would replaced with rechargeable lithium batteries. Even though in the stores they will tell you that the replacing your capacitor that as far as I know the capacitors are all no longer in existence1 point

-

I've wondered about this. Among the quartz watches I have opened, some of the most tightly sealed screw backs smelled strongly of rotting potato or vegetation inside. And not old ones either, Citizen or Casio in clean condition just getting their first battery change after 3 or 4 years. The fact that you didn't all reply to the op that "oh yeah quartz watches usually stink" means I have to keep wondering.1 point

-

That watch appears to be the same concept as Seiko Kinetic. If so, you may need to replace the capacitor (the thing that looks like a battery). I have serviced several. The caps go bad eventually. Chips are not made of "silicone" but rather "silicon." Silicon does not smell.1 point

-

1 point

-

What I liked when Seiko had their other lubrication guides. I've attached them specifically on lubrication only in you get a nice side view. Seiko-Oil-5106A.PDF Seiko-Oil-5606A.PDF Seiko-Oil-6106A.PDF Seiko-Oil-6206A.PDF Seiko-Oil-7005A.PDF1 point

-

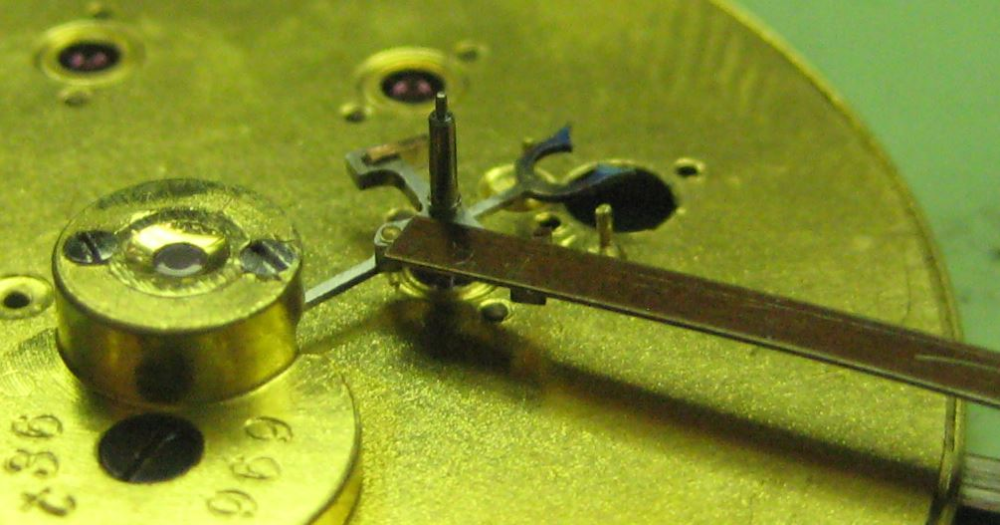

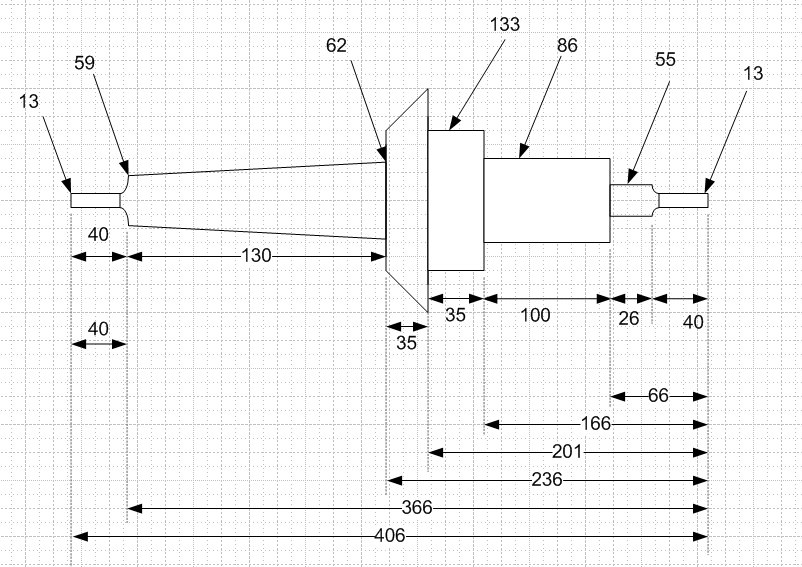

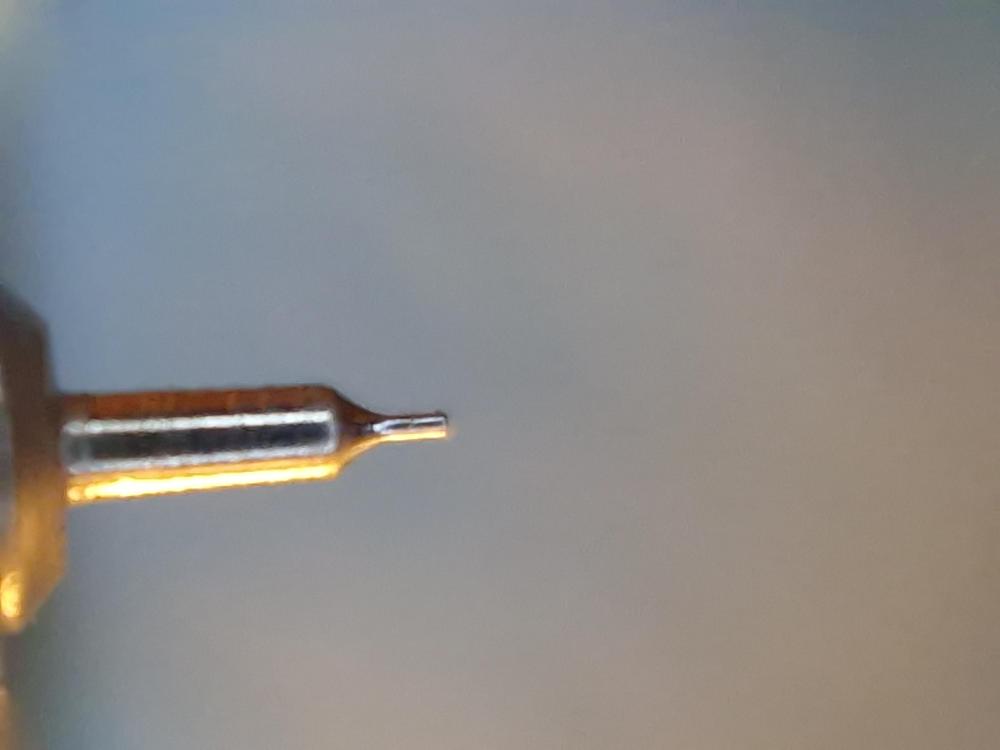

Typically with American full plate 18 size watches in a variety of other full plate watches is a problem with getting the pallet fork in depending upon how the balance is arranged. So it presents a challenge of where some people will assemble the watch upside down to get the pallet fork in first whereas a much nicer way is to fashion clip to hold the pallet fork in and then bring the bridge down with the pallet fork. Of course you do have to be careful to make sure things are proper alignment otherwise you end up with watches with the pallet stones get knocked out or you end up cracking one of the bridge jewels. The concept is really quite simple just grab a short piece of broken mainspring heat up and folded over like this Oh and I got fancy on this one I cut a slot in the end so to go over the arbor itself Then here's the problem of pallet fork has to go in kind of underneath where the balance wheel goes which is why you cannot put the plate down with the pallet fork in place because it will not go in where it's supposed to be. Here's the clip in place Here's the alternative version that doesn't have the slot So basically just a little clip to hold parts on that have to come down with the plate unless a course you want to assemble it upside down which isn't always possible either seems like a nice plan on paper but I was found it didn't work well which is why would prefer to use the clip. So I believe that switch being referred to here something similar could be made1 point

-

Cod be the circuit boards or the silcone Chips and that crystal is Battered, i smelt it when i was doing a load of them a couple of years ago, kind of an acidy leccy smell that i couldn't quite Plaice. Not strong but enough for you Tuna-notice. Anyways I'm sure Eel sort it Waggys not daft and if the circuits are Fried then a new movement should only be a few Squid.1 point

-

No such thing as a perfect measurement, only good enough for the task. Some applications, within 10m would suffice, others 10mm, 10 microns etc. A bit like " no model is correct but some are useful "1 point

-

1 point

-

Check out the AS 1012, made in the bajillions, balancestaffs.com lists 9 different staffs. Even for calibers where there are only 2 or maybe 3 variants, I make the staff if it needs one. You never know if you will get exactly the right one, even from a reliable seller (mixups happen), and you never know if someone in the past mic-macked things to fit a wrong staff (broached out the roller table, or balance hole, or...). The potential time wasted finding the staff, ordering, trying it, figuring out that it's wrong, is just too much. I think the only staff I've ordered in recent memory was for a Valjoux 7733, which they had in stock and was definitely cheaper than my time to make it. And there is exactly one type across that caliber family. When making, I have more than 5 dimensions on my drawing. Diameters: pivot, above hs collet, hs collet, balance seat, hub, roller (2 dimension), and between roller and lower pivot (this and above hs collet are critical for shock settings). Lengths, I measure from the top pivot, to: collet, balance, hub, underside of hub (where roller seats), end of roller, end of staff. A couple more if shock setting. So 14+ dimensions.1 point

-

Thanks for the scanned pages John, this is a book i would really like, but I'm holding out on buying it new for now I'm sure ebay will provide me with an alternative in due course. The section on isochronism and poising some of it has gone over my head and needs a few reads to better grasp more of it. The next section on hairsprings, the first couple of paragraphs has me needing to ask a question about terminal curves. What we normally call the terminal curve, the last 90 ° section of the spring that sits between the curb pins that is bent away from the main body of coils . If that section is necessary ? Jendritzki diagrams show a hairspring with only a final bend to locate the hairspring to the correct position to fit into the stud. I have come across hairsprings without that long end curve and actually added one as i thought it was missing and unadded to a raw spring. It looks like its not really needed as long as the spring follows the same arc as the regulator. And having a bend past the active point into the main body of the spring could affect the hairspring's oscillation. Its obviously only a small portion depending where the pins sit on that curve. But I'm thinking the active point could also be pulled from that bend as well as from the pins, a straight line so to speak directly from the collet to the curb pins should make the oscillations more even. From point A to point B with no diversion, if I'm taking nonsense feel free to tell me to shut up I have to reply here to you @VWatchie this where it all started. Congratulations on instigating a rather complicated topic, i hold you responsible for my morning's headache1 point

-

Hi @VWatchie, Thanks for the reminder! I did get it. Pros: - the integrated light is useful - you have about 5mm focal length, which, for example, is just enough to cover the distance between train bridge and pallet fork. - magnification is decent Cons: - the light is not very strong and will struggle to properly illuminate the pallet fork if it's 5mm away... - magnification is like a macro lens. Nowhere near "microscopic". In the end, it's good, useful but not really a revelation. As a result, I haven't used it much so far. Here are a few pictures I was able to take:1 point

-

404s are almost always obscure brands. Those in Europe can find name brand Russians on occasion, but we're pretty much limited to stuff you've never heard of here. That dial says the movement is jeweled. No count means one to meet the minimum definition, so it'll be the balance cap jewel opposite the dial, and may not actually interface with the balance staff. Pin lever. I went through a phase where nearly every 404 I found was one of those.... Baumgartner 866, I think.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)