Leaderboard

Popular Content

Showing content with the highest reputation on 11/28/23 in all areas

-

4 points

-

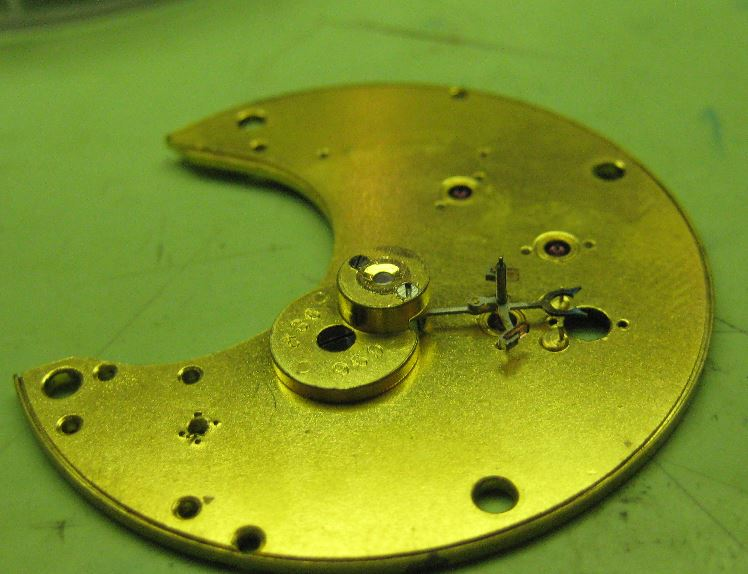

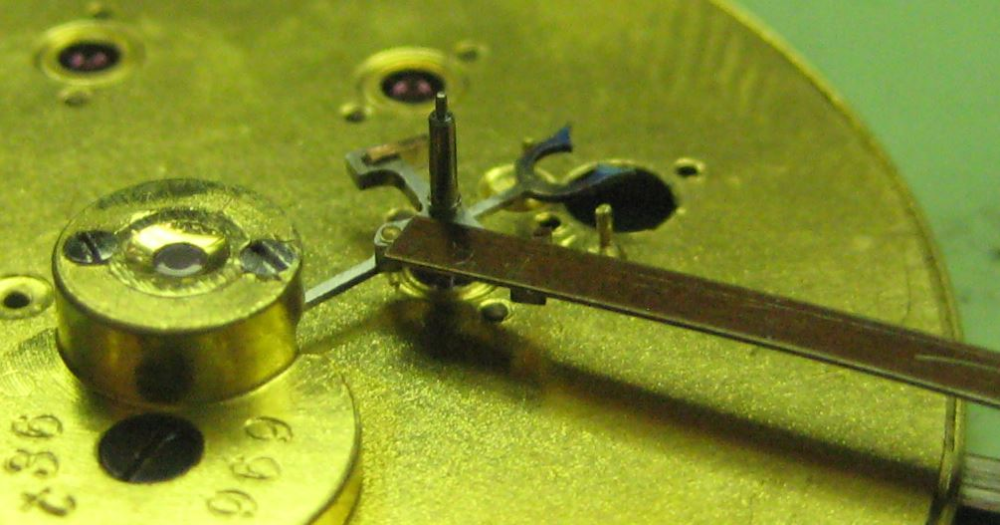

Check out the AS 1012, made in the bajillions, balancestaffs.com lists 9 different staffs. Even for calibers where there are only 2 or maybe 3 variants, I make the staff if it needs one. You never know if you will get exactly the right one, even from a reliable seller (mixups happen), and you never know if someone in the past mic-macked things to fit a wrong staff (broached out the roller table, or balance hole, or...). The potential time wasted finding the staff, ordering, trying it, figuring out that it's wrong, is just too much. I think the only staff I've ordered in recent memory was for a Valjoux 7733, which they had in stock and was definitely cheaper than my time to make it. And there is exactly one type across that caliber family. When making, I have more than 5 dimensions on my drawing. Diameters: pivot, above hs collet, hs collet, balance seat, hub, roller (2 dimension), and between roller and lower pivot (this and above hs collet are critical for shock settings). Lengths, I measure from the top pivot, to: collet, balance, hub, underside of hub (where roller seats), end of roller, end of staff. A couple more if shock setting. So 14+ dimensions.4 points

-

I decided to do a little improvisation last night. I had a case where the sides were extremely worn, dented, etc. The case lines were nearly worn completely down. I've wanted a lapping machine for some time but those are far too expensive for my humble budget. I improvised by hooking up one of my sanders to a voltage regulator to bring the speed down as much as I could. I put some 1000 grit paper on the disc and started to gently work the side of the case. I'm quite surprised at what I was able to accomplish with these rag-tag tools and bit of creativity. I'm limited by the table because it can only adjust to 45 degrees, so there are some angles on that case I won't be able to reach properly. While looking up pictures on the internet of other examples of this case it looks like there was not a sharp line between the side wall and the lugs, so I just tried to bring back a gentle curve between those to sides. Not too bad for my first attempt! I'm going to keep moving forward and go up to 2500 grit and see what I can get out of this before moving on to the polishing wheel.3 points

-

2 points

-

It has a distinct whiff of Aegler 825 about it, but with a slightly different train bridge shape. Aegler was a major supplier of movements to Rolex right up to 2004 when Rolex bought the company outright. It would help if we could get a main plate diameter and a look at the keyless works but my money is on the Aegler.2 points

-

2 points

-

This is to compensate for printing error. My printer tends to make inside cuts a little smaller than the design. It gets worse the smaller the hole. So "a little bit" for me is typically 0.2 to 0.3mm2 points

-

2 points

-

Hi Waggy. it could be the cct board, I have had some that smell a little but not as you would notice without getting your face close up. May have been worn by a fisherman /merchant.2 points

-

When I was in school we always installed the stem and the keyless first. From memory it's because it gives you something to hold onto you now have a stem to grab. But the reality is also you can use it to let the power down or wind the watch up. As I typically work on pocket watches I have a morbid fear of even using the screwdriver do anything with a pocket watch as there's so much force their so much chance of bad things happening. As far as winding goes like Seiko where there is no key lesson a lot of the early ones then they expect you to use the screwdriver to wind it up. But letting the power off that can always be a challenge because that's a two-handed operation one to release the click and the other to somehow left the screwdriver spin slowly releasing the power well there's a reason why there's a stem on the watch and it's very handy for letting the power off. Oh don't worry we all make interesting mistakes from time to time. It's how we learn or at least how are supposed to learn sometimes you forget the silly little things you shouldn't be doing and then you get a reminder.2 points

-

Finally got a chance to do some scanning. Omega document on self lubricating mainsprings. As far as I know this is my place were I've ever seen any hints at all as to how the self lubricating mainsprings get their lubrication. Then I made a reference to a book by way of a video but I wasn't sure if anyone was really paying attention to the video and the problem is he just talks about how wonderful the book is which it is but I thought maybe we could do a little better book review today. I scanned in the index section so you can see all the wonderful stuff that's in the book. Then I scanned in the first section on the oscillation system where it explains all about that. As we keep seeing a reference to isochronism on the second PDF page bottom right the reference to isochronism. Notice what it says about the escapement it's a bad thing. Then amplitude the reasons why it decreases and reference to gear train issues which is why we would have timing fluctuations. Watches do a beautiful job of averaging over time I'm not sure if eight hours qualifies as enough time depending upon where the problem is in the watch. But in a case we get a nice thing that explains all of and just stuff about the oscillation system pretty simple reading then I skipped over the balance wheel section we don't need that. Then people's concern over the hairspring such a simple thing a little spiral a metal how complicated could that be? Oh and then I got distracted in the middle of scanning which is why it's in two separate PDFs but it's all there a little more light reading for you. So now you have your reading assignment Omega technical guide number 30 1963 self lubricating mainsprings.pdf Watch adjustment Jendritzki s3.pdf Watch adjustment Jendritzki s2.pdf Watch adjustment Jendritzki s1.pdf Watch adjustment Jendritzki index.pdf2 points

-

I feel you pain, I was almost finished with an accurist a week or two ago and had to let down the wind (can't exactly remember why now) and used a screwdriver to wind it down as I held back the click. I had a similar result as you did when the screwdriver slipped and made a horrible spiral mess of the ratchet wheel, to add insult to injury the screwdriver carried on and mashed up the center wheel - not my greatest moment! fortunately I had a donor I could steal from, but more by good luck than good planning. I always wondered why the guys on the YouTube channels went to all the trouble of reinstalling the winder to let down the power, as using a screwdriver is so much easier...guess I had to learn that lesson the hard way!2 points

-

I just had a roller coaster on this Wittnauer with an AS 1585N movement. Got it a few months ago and it was running strangely with a hesitation in the seconds hand every few seconds. Almost went backwards for 1 tick...so stripped it down tonight and think it was likely the mainspring / barrel. So got it back together and everything running nice with decent amplitude and low rate delta up versus down dial and low beat error. The kicker was that I tried to let the power out with the rachett wheel screw and the driver slipped and absolutely made a mess of the wheel finish...OMG don't let the children see this...it is awful. Going to see if I can source another wheel. On the bright side the dial is spectacular and it is running nice. And the carnage shot...1 point

-

That watch appears to be the same concept as Seiko Kinetic. If so, you may need to replace the capacitor (the thing that looks like a battery). I have serviced several. The caps go bad eventually. Chips are not made of "silicone" but rather "silicon." Silicon does not smell.1 point

-

1 point

-

1 point

-

They don't have a picture of the 700 just the 710 with the sweep second but yes it looks right http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Rolex_7101 point

-

It looks like a Rolex 700 not 600. Superbalance. The cushion case. dial sometimes called a ‘bow tie’… I have one of these I’ve been trying to revive. It was going to satisfy my urge for a rolex. None of the three listed balance staffs for the movement fit the existing collet or roller- too narrow. I did read somewhere these were not so much produced with interchangeable parts. I will buy that theory… I just bought another working movement to frankenwatch it if I can get the stem to fit…1 point

-

Here's the company that made Rolex movements up until 2004 one Rolex finally had 100% controlling interest in the company. So now it's a Rolex company although as Rolex solely acquired more and more the company I suspect towards the end they probably were making movements for anyone except Rolex https://www.watch-wiki.net/doku.php?id=aegler It's always nice to tell people that before 2000 for the Rolex movement was made under contract by somebody else. A long time ago at a chapter meeting of the national Association of watch and clock collectors somebody was liquidating a estate before the days of eBay. Which worked out very nicely for me because I bought quite a few interesting watches all grossly underpriced. But one of my amusements was the fake Rolex? I asked why it was fake and was allowed to look at the movement couldn't see the movement because it was covered by the automatic mechanism of one jewel. Also when I asked why it was fake the one jewel thing was pointed out and the spelling of course the words were all wrong so he figured it was fake. So should I risk $25 on a fake Rolex and then I saw the balance wheel just like yours which is why I now have a really nice not fake I believe 635 movement. It doesn't mention at the link when they switched over to the newer style or the interesting style balance wheels but yours is possibly in this series like the 600 Or at least it's really close to this as a guess http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Rolex_6001 point

-

Hello everyone, I can now report the my work on this watch is done. Apart from the regular movement service, the bizarre ratchet wheel and correcting the sideshake of the barrel, it took a lot of careful work to clean the dial and buffing the hands and hour markers. Also gave it a new crystal and some very light manual case polishing with Cape Cod cloths. It is now going back to its owner, who's grandfather had bought it. I had some additional troubles with the automatic module, specifically the wear on the rotor bearing. While the rotor wasn't touching the movement when gently turned, it did rattle and touch when shaken a bit. I had to order three rotors until I finally got one that was in good enough shape. Thankfully not too expensive. Here are some pics of the final product:1 point

-

I have some NOS parts to it, drop me a note in case you came to need spares.1 point

-

Yes, this is Aegler, for Rolex. They called that balance the Superbalance. Rolex 600. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Gruen_8191 point

-

1 point

-

Typically with American full plate 18 size watches in a variety of other full plate watches is a problem with getting the pallet fork in depending upon how the balance is arranged. So it presents a challenge of where some people will assemble the watch upside down to get the pallet fork in first whereas a much nicer way is to fashion clip to hold the pallet fork in and then bring the bridge down with the pallet fork. Of course you do have to be careful to make sure things are proper alignment otherwise you end up with watches with the pallet stones get knocked out or you end up cracking one of the bridge jewels. The concept is really quite simple just grab a short piece of broken mainspring heat up and folded over like this Oh and I got fancy on this one I cut a slot in the end so to go over the arbor itself Then here's the problem of pallet fork has to go in kind of underneath where the balance wheel goes which is why you cannot put the plate down with the pallet fork in place because it will not go in where it's supposed to be. Here's the clip in place Here's the alternative version that doesn't have the slot So basically just a little clip to hold parts on that have to come down with the plate unless a course you want to assemble it upside down which isn't always possible either seems like a nice plan on paper but I was found it didn't work well which is why would prefer to use the clip. So I believe that switch being referred to here something similar could be made1 point

-

Cod be the circuit boards or the silcone Chips and that crystal is Battered, i smelt it when i was doing a load of them a couple of years ago, kind of an acidy leccy smell that i couldn't quite Plaice. Not strong but enough for you Tuna-notice. Anyways I'm sure Eel sort it Waggys not daft and if the circuits are Fried then a new movement should only be a few Squid.1 point

-

No such thing as a perfect measurement, only good enough for the task. Some applications, within 10m would suffice, others 10mm, 10 microns etc. A bit like " no model is correct but some are useful "1 point

-

1 point

-

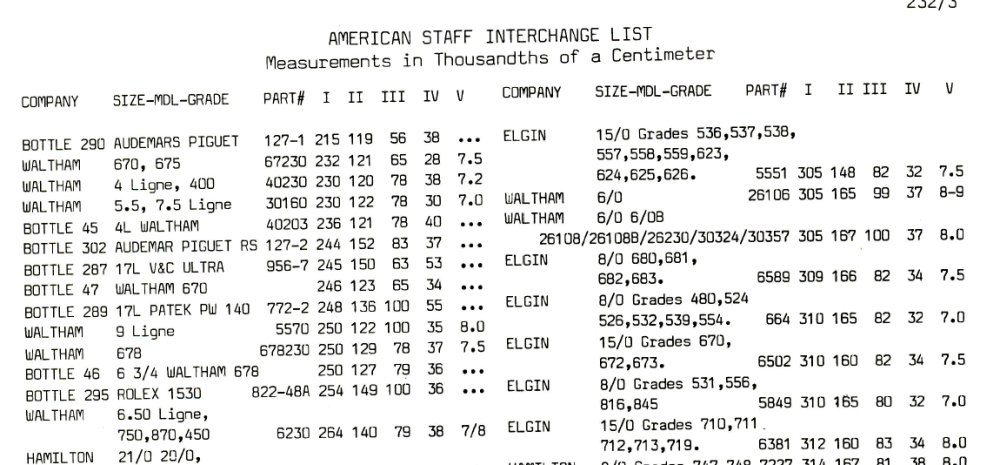

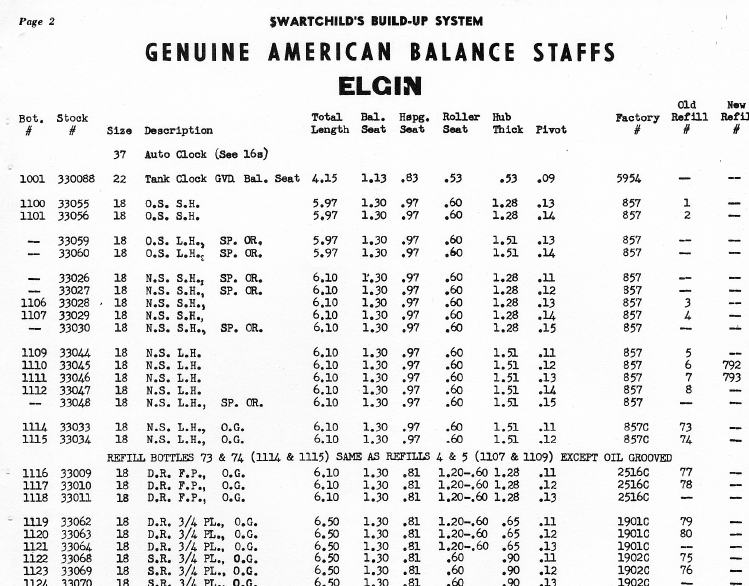

Oh other complications with getting the right staff. I have a theory at least for aftermarket American pocket watch staffs that some of them were deliberately made over size. In other words they expected the watchmaker to reduce them to the proper dimensions to fit. Although one another discussion group somebody suggested that theory was wrong. I based it on one particular balance staff which was a Hamilton 992B staff where there's only one staff it's of friction staff and the aftermarket was physically too large and needed to be reduced just a little bit to fit. So I get suspicious of aftermarket staffs versus original from the company staffs. Which brings up the problem of especially with eBay you have no idea where the staffs came from when they're not in the original package. Thinking about measurements the book that I got the dimensions from its real purpose is listing of American pocket watch staffs by size. Here's a sample at the very beginning of the book. It doesn't actually say that but my understanding is somebody took a very large assortment of balance staffs and they went through and measured all of them that's were always dimensions came from. But once again there are conflicting theories are thoughts that some of these dimensions are wrong. Or because I can't quite remember the book may be action made up of several people doing measurements and unless they calibrated their micrometers you can always end up with minor little variations because well you just can always have minor little variations.1 point

-

Hi. One way to jig it would to place the plate on a base and mark the plate screw holes and fit two pins., this holds the plate stable. Next fit one spring held in with a piece of rodico and it’s adjacent part then when all in place with a sharp tool take the tension off the click aNd mark the spot. Repeat with the other spring. You now have the makings of the jig with the two steady pins in. All that needs to be done is to fit the two pins to de tension the click springs. Job done, and it’s ready for use. Just an idea.1 point

-

Most brands mark their movement/calibre number on the main plate underneath the balance. Rolex also marked most of their calibres there until the introduction of the Rolex Calibre 1030. Also worth noting Rolex have not always produced their own movements so this vintage movement might well have been produced by another manufacturer.1 point

-

Interesting invention, https://www.breguet.com/en/history/inventions/magnetic-pivot1 point

-

Haha the link doesn't take me anywhere Joe but at least you tried . Haha well if she sits on me then shes gonna have a big problem and thats not what we're thinking, my missus would break her neck1 point

-

I am sure you are experiencing some sort of 'ism' here. It's just not magnetism.1 point

-

Her at your service , waits or sits on you , http://artpictures.club/autumn-2023.html1 point

-

I can't tell from your images is it doesn't say if you had a standard staff versus a staff for a balance shock protection system conceivably could have identical dimensions but shaping differences. In other wars the shock protected ones will have different ends then a standard staff. So while the pivots of the same the shoulder will be different as part of the protection system that's where you might have a difference perhaps Then there is a way of figuring out balance size pivots if it has a shock jewel system. You would go look up the jewels for the system and will usually tell you the hole size of the jewel. Then things could be worse you could be trying to do an American pocket watch staff. My personal all-time favorite is Elgin factory number 857. How many 857 staffs do we have exactly? Yes there's different pivots sizes but that's very common on American pocket watches that don't come in more than one pivots size for the most part there are some that only come in one pivots size but there's usually pivots size variations. C a notice that there are actually four separate groups of 857 all the course with different pivots sizes. This is why have a whole when ever-changing balance staffs always measure the old so hopefully order the right thing. Always measure the new staff to make sure it does agree with the old to avoid those unpleasant surprises.1 point

-

1 point

-

Haha Then you're pretty much screwed Michael, i also have a Liz but look on the bright side you might not have a joint account for much longer . Haha some blokes dont have a choice Ross, i think you might be confusing advice and guidance with order and instruction1 point

-

1 point

-

After you fixed all the problems how does the watch look in various positions? Is amazing what defects can do to screw up timekeeping and until the watches running in good condition it's hard to tell if the balance has a problem or not from a poising error. Then this is a modern screwless balance more than likely it does not have a poising error unless somebody's modified it. The factory poised it within the specifications of the watch it may not be perfect but it still should be reasonably poised unless you're having other issues which you are having. So now how does it look in various positions that you fixed all the problems? Certain positions like in the timing machine results above for you had random dots sort of? One of things nice when you getting weird stuff from the timing machine is to listen to the sound of the watch. That's the downfall of the Chinese timing machines they don't have audio like when she typically does. When you listen to the audio and you're having rubbing bumping hitting issues a lot of times you can actually hear that. Hairspring bumping in the something can be quite musical the sound it makes for instance balance wheel a course bumping in the things you'll hear that a lot of the times the timing machine season shows you that but if you listen often times you could hear there's a problem1 point

-

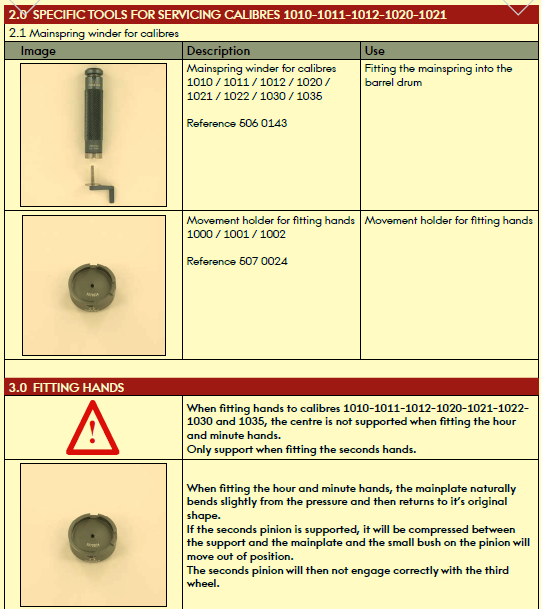

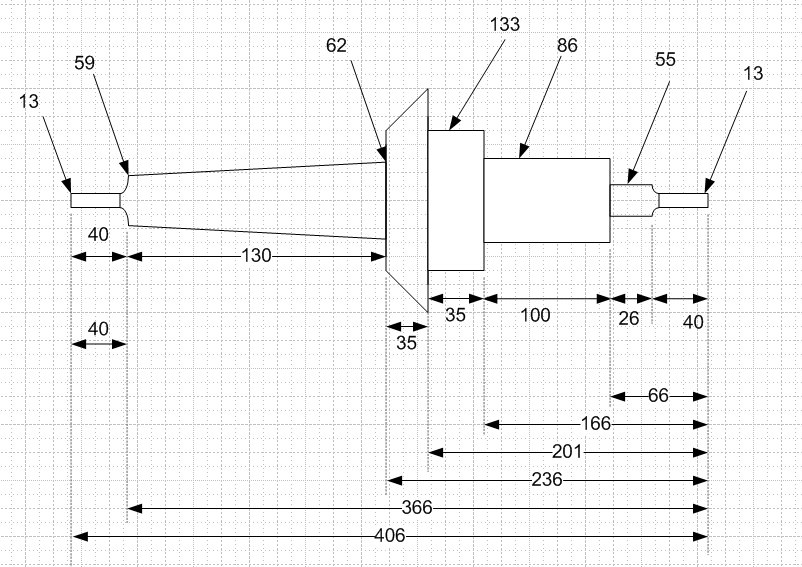

I'm afraid it's wishful thinking if the automatic was supporting for putting the second hand on. This movement has a lot of very peculiar things which may or may not be specified in the vintage technical service guide. So Omega had a supplemental guide of general instructions specific for this grouping of calibers. For instance special tools special tool just to put the mainspring in and special movement holder for putting the second hand on all of the family of calibers because when you put a the second hand on you probably don't actually have the automatic on and it doesn't really support anyway1 point

-

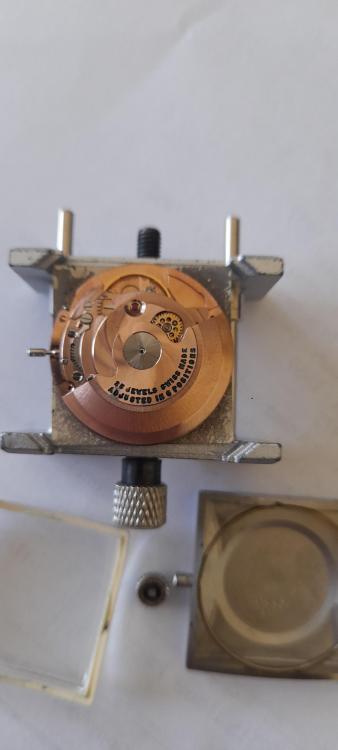

I've just finished an Omega last night for my son to gift to his girlfriend for Christmas - long story, anyway he owes me big now! Just a reminder that the Omega screws as well as being small also have tight (slim) screw slots, so you will need to keep your screwdrivers extra sharp and dressed or you will spin out and damage the copper finish. The copper finish will scratch even if you look at it the wrong way. I used all brass tweezers last night instead of my usual titanium ones. PS I'm calling it a 'copper finish' for expediency, although I'm not sure exactly what it is, maybe butterfly wings judging on how fragile it is1 point

-

The balance wheel is unlevel and needs to be poised, as is, you would be seeing big delta in positional variation1 point

-

Michael. Best choice and investment you could have made. Been there, worn the T shirt. You've taken your brides advice. She has guided you well.1 point

-

Joint accounts. Liz will know. Not right now, but she will. ps. I’m a Michael please.1 point

-

1 point

-

Just wanted to post to thank everyone for their help. I got there in the end. Key thing was finding the correct end stones, I think. I found someone selling end stones on eBay just labelled as "2836 end stones" and they were the right size. I noticed after getting the correct end stones that one of the chatons was damaged, so in the end I replaced the whole balance wheel/cock and used my one good chaton on the other side. Amplitude is now somewhere between 270 and 360 (not sure exactly), so I'm carrying on. Automatic /self-winding is done and working. Just finishing the face side of the watch. Keyless works is done. So hopefully no more major problems and just a few hours to go! Thanks again, Lee1 point

-

Very nice looking holder. However, utilitarian guy that I am, it takes too long to print. I rendered with a "high speed" profile and it still takes 1hr and 15 minutes to print. I reduced the height to 20mm and got the print time down to 56 minutes. Then reducing the base OD gets it down to 44 minutes. All of these times are tolerable. I tend to start on a watch and then go print a precise holder and I want that quickly. Mine takes 18 minutes. Aside from the time (which is my nit issue), it is a beautiful design and very well done.1 point

-

I can tell you no matter how big you have your workshop it will never be big enough. Good luck with it and don't forget to post some photos.1 point

-

Hi again - no problem removing the crystal with a thin blade and the crown split from the stem easily so I was able take movement out of the case. It is an ETA 2542 movement and is in very tidy condition and runs well. My next step is just a minor outside clean and put it back in my collection. Once again thanks for the good advice and I look forward to sharing my next project - a recently acquired TAG Formula 1. Bilo1 point

-

1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)