Leaderboard

Popular Content

Showing content with the highest reputation on 07/18/22 in all areas

-

I think it's right to say that a claw tool is not the only way to fit acrylic crystals. Maybe for this watch it is appropriate, since it appears to be a front loader. The other way is a crystal press and dedicated dies which compress the crystal. That has the advantage of removing the risk of scratching it. Another way which also work is when the crystal is close in size to the opening, is to fit with it bare hands. Since these crystals will have to be glued anyway, it will normally hold fine. The other comment that I have for the OP is that leaving aside that after many decades the mov.t will also need to be serviced, as is not advisable to wear extensively an unserviced watch (and that is a big problem, because doing that is costly and takes time and effort just to find someone reputable), is about "cleaning the dial". Is the black damage is corrosion, or chemical reaction to the dial paint, there is practically nothing that can be done. and in fact any maneuver can make it worse3 points

-

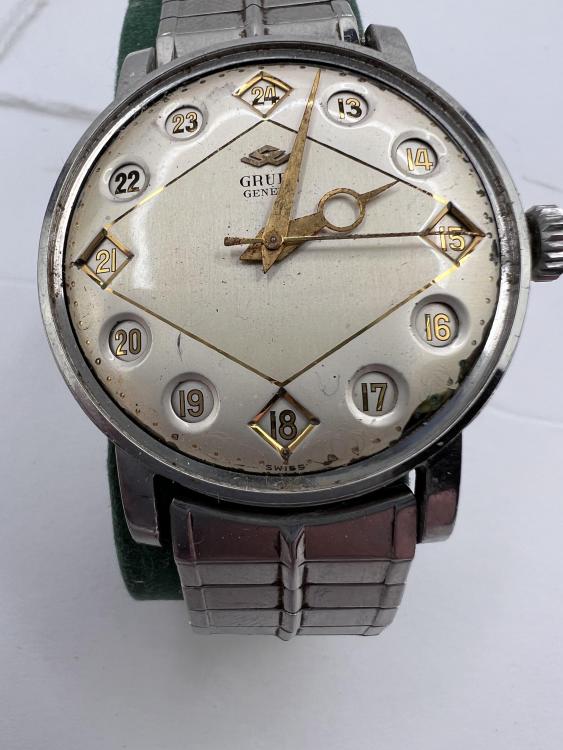

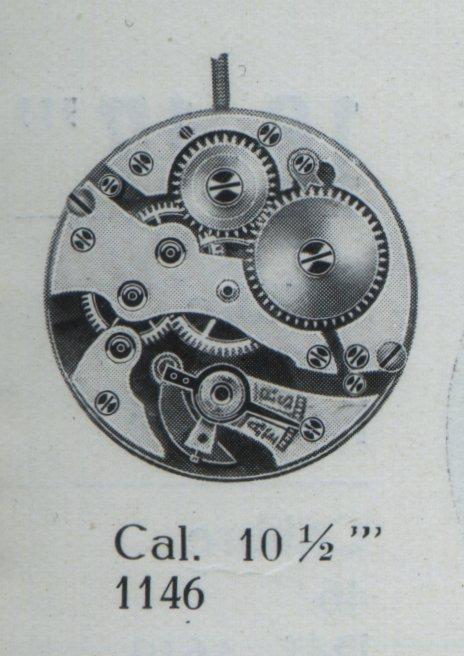

Hi, the movement appears to be running great but the dial needs help and also need a crystal. This watch is really neat, for those that aren't aware of it the watch was very popular with military pilot's in the Vietnam war. The numbers on the dial change from the normal 12 hour format to military 24 hour format after 1 pm. The watch has been stored for a while sans crystal and it appears either mold or something else is on the dial and need advice on how to remove it and also help with the crystal. I haven't installed a crystal on any watch yet but feel confident I could be capable, but I do know when to stop and hand it off to the pros. The inside bezel measures approx 33mm, I say approx. because the digital caliper changes with the amount of pressure applied. The case measures 35mm, Anyway, just want to clean the dial and get a crystal and I would appreciate any help. Thank You!2 points

-

I often fit acrylic crystals with my hands under a microscope. I find that i can bend and manipulate them into place. If done through a scope its very easy to see at which point and how much pressure to apply and when to move around the rim. The only time i use a lift is to occasionally remove a tight crystal that i dont want to risk pushing through from the back. Tighten the lift a fraction at a time until the crystal spins then you are close to lfting it off. Lift with a slight turn backwards and forwards making sure that the lift is not coming free of the crystal. Generally if I've used a lift in the first place i leave it on the crystal if its going back on the watch within a couple of days that way it is all ready set up to put back in place.2 points

-

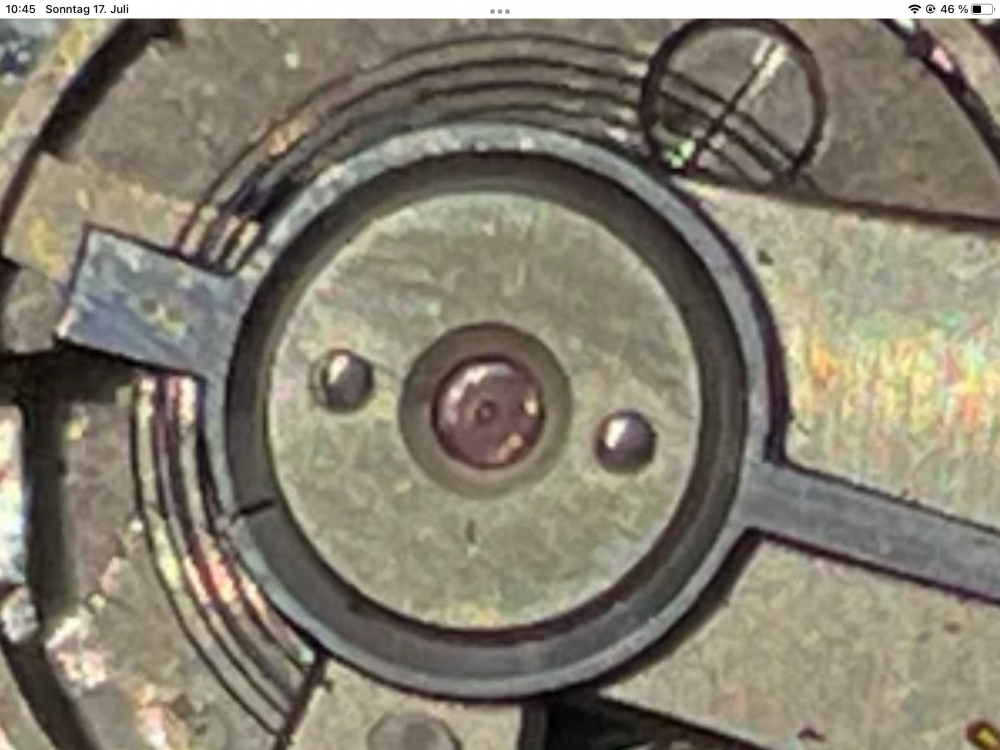

and all your pictures I did not see looking sideways? In other words looking in so we can see the main plate lead see if the balance bridge is parallel to the main plate we could see the balance wheel? yes but it would be fun to see somebody try and not solve the problem. Oh and if they were moving the hole jewel what about the end shake? The end shake is still controlled by the end stones and they're not going anywhere in a watch like this. There's something else going on.2 points

-

2 points

-

As alluded to in my introductory post my current victim is a Raketa 2603. Disassembly and assembly is complete, and it's still running. phew! Haven't purchased a timegrapher yet, but it's still satisfying! I'm about to do a second run through but clean and oil this pass. A couple of lessons learned. I lost the yoke spring (440), it has gone home to its family. Also, one of the two screws on the settings lever spring (445) is stripped. After reviewing my initial images it appears there may have been damage to start with. Any tips to avoid stripping? My gut instinct is to use the largest screw driver possible that fits without fouling the case. Luckily, these movements are affordable and plentiful. I was able to find a set of four 2603's for around 12 dollars. So I'll have spare parts and practice movements. Also, I purchased the Burgeon 4039 after struggling with the 4040 for this movement. Below are pictures of my journey. I thought I took a ton of pictures and afterward was surprised how few I had!? Definitely more pictures on new movements from now on. Will take more images of the train of wheel orientation and keyless works configurations on this teardown because those appear to be the interesting bits IMO. To Be Continued... Realized, I didn't have an after!1 point

-

1 point

-

Welcome @clepal Take a look at this web page for an interesting look at what makes a watch tick.1 point

-

Not especially Gert but i do take care of myself. I thinks its more to do with being a sickly child, i had every illness going and known to man, and now apparently unknown to man . Its more likely that that has made me bullit proof, after all i am Suprman . Haha1 point

-

1 point

-

1 point

-

When I replaced my seiko solar watch, I removed one of those tags and then put the correct tag on it and that turned out fine (but that was the correct cell anyway, just the wrong tag). If I make progress with the Bular Solar I'll let you know.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. I don't have T V in my house haven't had one in about 13 years. I can't stand the bloody BBC.1 point

-

I know but think of all things you could fix and make with it . Oh and tools that you need to buy to go with it , and the maintenance of it , and the things that could go wrong with it , and the watchparts that could get broken on it . Yeah mate forget it dont buy one.1 point

-

Hi Having read whats going on and the pictures supplied I would agree with Gert that the balance is "stuffed". The only way to check it out is to remove it from the watch lay it on its back with the top pivot in its jewel hole and check the concentrticity of the coils because as Gert said sticky or magnetised or both.1 point

-

1 point

-

Please leave the mainspring barrel alone without even opening it. That is the way that Seiko designed it, and is not the cause of the problem. I understand that you will probably think that I am wrong, and this or that video shows how it's opened and dealt with, but I am talking from direct experience, and the one of very many beginners that had to come to the same conclusion. I also recommend not to use lighter fluid which is made to burn not to clean, and use professional lubricant of which you will need is at least 3 types, and are expensive. Finally, if you have never taken apart a watch mov.t, a Seiko is not the recommended one, simply becuase returning it to the original performance is not so easy as one can think.1 point

-

That last pic looks real suspicious, although you might have caught the balance as it was winding up, not down. But if it looks similar the whole time then that's your issue. Would be great to have a pic of the timegrapher as well though.1 point

-

you know what one of my favorite diagnostic tools is other then using your eyes? Is something that lets you see the invisible the thing that sees the invisible is the timing machine. But I'm guessing the original posting person doesn't have a timing machine. multiple discussions here it leads to my mental confusion especially today. Seiko is supposed to be using synthetic oils at least that's what it says in the tech sheets but? Does Seiko actually use what they recommend on their service and tech sheets?. a for instance in the shop today work at the boss offers a service. He tells his customers who regulate the watch any watch to Rolex timekeeping. Yes I know what Rolex timekeeping is and he is the boss so he can say whatever he wants. So I get to be entertained with what he's doing. The case of the Seiko watches they usually running pathetic. Of course Seiko is tend to be low amplitude anyway that's not an issue that's a Seiko but at times the really low amplitudes. That means the balance wheel comes out pallet fork comes out it's rinsed off and it's nice and clean again fresh oil fresh oil on the balance jewels to running better and then he regulates them he's got really really good at that. Customers happy their watches keeping time for now but it does bring up the problem of why does fresh will make it better if the oil synthetic and it's supposed to last forever oh since I went back to read the original message I see a timing machine is in somebody's future just not fast enough for this discussion but it looks like at least he grasps that that be a good thing to have. Hopefully it's a real timing machine and not a app. either way I've attached the tech sheet for the Seiko in question. As others have noticed it's unlikely somebody is seen the decrease in speed ads in amplitude variation in other words the amplitude sucks. The regulator position becomes interesting in that wasn't always there? It's back to my fussing about timing machine it be nice to see what it has to say oh and then there's the other little problem of how do you wind this watch up? Wind it up the crown and how many times do shake this watch to wind it up? If you really want to have fun put a little mark on the ratchet wheel in and start shaking I believe JDM would probably know better I think about 11 turns the ratchet wheel and it's considered fully wound up. In other words if your hand shaking the watch the wind it because you're not using a screwdriver to do it the fast way it takes quite a while to line that watch back up again and it's not wound up your aptitudes going to be pathetic then as far as being seven years old may be did you purchase it at the factory? It depends upon a variety of factors watches made at the factory and then it shipped and did a distributor or sales agent sends it off to its final destination and then you purchase of their it's conceivable your brand-new shiny watch might've been sitting for several years somewhere so I know the watches at least seven years old conceivably older then the watch was sitting doing nothing for a whole year. Then the amplitude sucks it's always possible the oil is migrated is no longer properly on the pivots plus maybe the lubrication just isn't doing the job anymore either then the demagnetizer I would ask for a picture but I'm not only get one. Is it a proper demagnetizer for watch repair and do you actually know how to use it? Is a lot of times people don't understand the demagnetizer how it works and instead actually magnetizing watch. oh and why did I want pictures? For the same reason JDM wanted pictures we wanted know where they hairspring is and we just want to look at it and see if there's something that we see and grass that the original posting person didn't see you grasp. Especially if they hairspring isn't quite where it's supposed to be amazing what interesting are bad things happen if they hairspring is not where it's supposed to be. 7S26B_36B.pdf1 point

-

1 point

-

1 point

-

As said, that's called reduced amplitude, it's the most common problem after "watch stops". It happens with any watch but often reported with Seiko because 1st there are very many more of these, and 2nd, their design construction is more optimized and tight. If you search with the term in quotes, or with Google site search, you will find many discussions on the subject. There is no direct and sure solution, maybe that's why the talk sometime takes tangentially, or remains conjectural and not resolutive. Anyway, you should really post a good picture of the hairspring taken from dead above, and one by the side. You can also take the regulator back into the middle as that won't make things worse.1 point

-

Lol. trust you Gary, do you have cookies on the brain. Hint at your missus to get the baking gear out and crank up the oven . Now I'm hungry lol. I like you shane. You think exactly like me.1 point

-

Hi Dan, I didn't intend to imply that your "tinkering" wasn't good enough to perform a good service, only that there may be more needed. For example, I "tinkered" with a junk set of screw drivers and a case opener but once I got "serious" I realized that I needed a lot more. Some folks show up and make an introduction and have worked on all sorts of mechanical things over their lives but the size of a watch makes everything you do pretty critical. There's quite a lot of information "out there" as well as "in here" and I think that as long as your Hamilton wasn't rusting on a junk heap for the last 70 years, you'll find a lot of help. My first foray into this was via a grade 313 Elgin. Have you opened up the Hamilton yet? Do you have a serial number? Have you visited the https://pocketwatchdatabase.com/ to determine the details of your Hamilton? Once you start down this road and begin to ask questions people here will want to see photographs of both sides of the movement and if the watch has a beautiful case, we'll want to see that too... Again welcome and hopefully I didn't come across as a jerk? - Gary1 point

-

Someone saved it (in this condition), It must have ment something to them. In my opinion, the custodianship of our collective history should not be limited to just the valuable or perfect. What does it hurt if I show it some kindness? I try not to purchase new parts for a totally lost cause but I won't know how bad it is until I take it apart. If all I wind up doing is cleaning it up and putting the parts in a bag and the bag in a box of unfinished watches, I'm not much different than the watchmaker I got it from. It will just be clean for the next guy to find when I'm gone. Shane1 point

-

One other thing about the MT621 - it is smaller than the LR41, so it may, or my not make good contact. The spring battery contact may make up for the difference in height though. Also all of the MT621 cells I found online have a spot welded tab of one form or another that you would need to carefully remove before fitting the cell to the Buler. Let me know if you decide to go down this line as I am curious to see if it works, and if it charges correctly.1 point

-

1 point

-

Usualy screws that get ruined are the ones which don't want to come out peacefully ( often due to rust and the like). A 48hr soak in Coca-Cola gets rid of the rust. Please don't ask suger free or regulare coke. Regs1 point

-

1 point

-

1 point

-

The "P" logo on the dial side would seem to suggest a Peseux movement. Ranfft shows 200+/- Peseux movements. You'll want the diameter before you go looking there. I don't see enough detail in the keyless works to look through Bestfit. Are those mini OREO cookies ?1 point

-

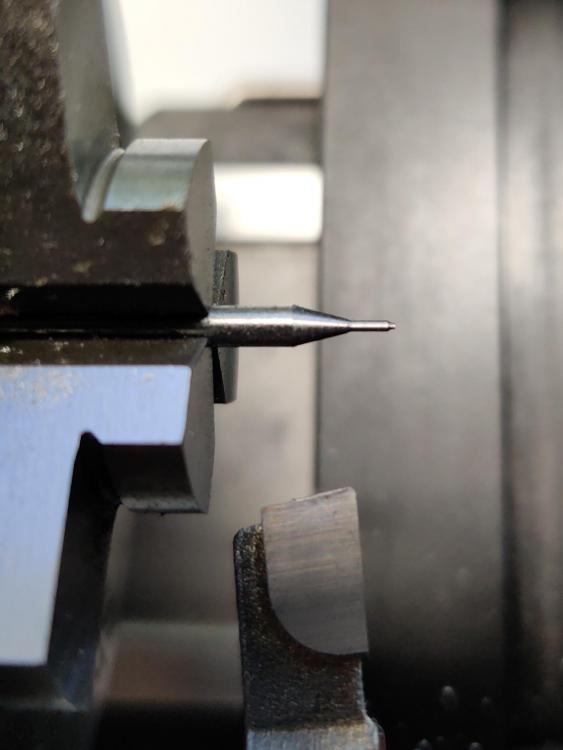

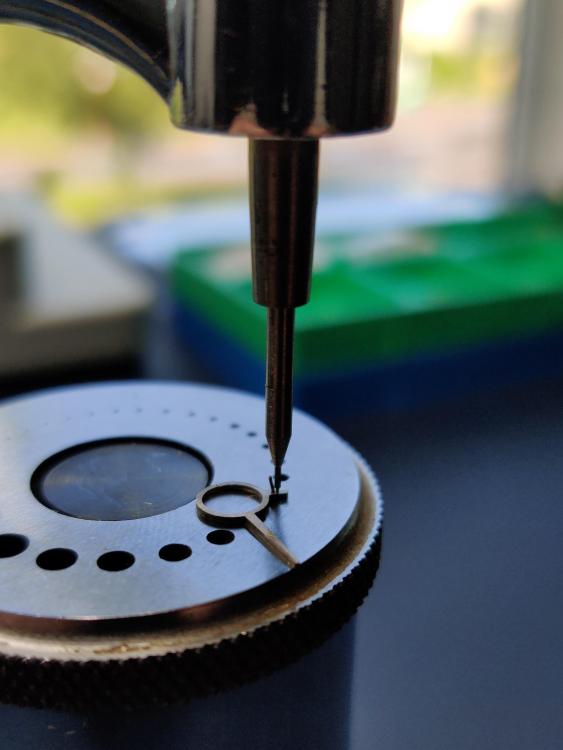

I have successfully removed the regulator pin. It turns out that I have a flat faced punch with a 2mm hole in it, and my 2mm A2 rod stock fits nicely without requiring adjustment of the diameter. Lucky me! So, based on the idea from@praezis, I turned a little insert. The tip is 0.25mm, and with the tooling I have I can't make a square shoulder at that scale, so it should have been longer. The step keeps the tool from going to far and impacting the other pin. A couple of taps, and the old pin was mostly out. Now to replace the pin and straighten things up. I hope the other one doesn't break when it's straightened, but now I can replace that one too if I need too. Thanks everyone for all your help!1 point

-

Today I'm wearing my 404 club 9ct solid gold Rotary Quartz. It too is sporting a natty new Moralleto band, and I have to say these straps are extremely comfortable. Its a bit of a favourite of mine. In fact I'd worn this watch so often over the last couple of years that the old strap was starting to fall apart.1 point

-

Most of what I've acquired have been non-runners from eBay. The Felsa 4023 that I spoke of in this thread is immediately to the right of the penny. The two Elgin grade 313's are lower right. These were my first victims. The Seagull ST36 that I managed to dissolve the glue on the hairspring is in the petri dish (upper right) with a second (untouched) copy to its left. The petri dish on the left holds the 1st Buren Grand Prix with the broken setting spring lever that I discussed here on 6/10 with a second copy of a Buren Grand Prix (untouched) sitting around 4 o'clock from the petri dish. The Pobeda sits below the untouched Seagull and to the right of the Omega 620. Above the Omega is another Elgin pocket watch (grade 409) with a dial and hands (also as yet untouched). Immediately surrounding the penny are 7 movements from the recently purchased job lot that have shock mounted balances. There were another 9 movements in that lot that were too shy to make the photo (and which had no shock springs - which was the reason I purchased the lot).1 point

-

I use a hand blower to remove most of the cleaner from the parts before the rinse. I believe one rinse is adequate. I dispose of the solutions after each watch. Make sure your oven is not too hot to melt the shellac !1 point

-

To ensure all the cleaning fluid has been removed. The first rinse becomes contaminated with the cleaning solution quite quickly. It's all about dilution. I used to use a hand blower to dry but about 3 months ago I had a little accident on the farm and now my right wrist clicks and using the blower constantly hurts quite a bit so I moved over to a fruit drying oven. I find the rinse on say a flat plate does dry quickly but anywhere that it can pool like the inside of the barrel or inside a chain cone can take a very long time without encouragement.1 point

-

Can recommend L&R UF Watch Cleaner followed by L&R Ultrasonic Watch Rinse in glass jars in an ultrasonic. I usually put everything in apart from the face. clean for 60sec, remove and peg out jewels followed by another 30sec clean. Then 30sec in rinse 1, 30sec in rinse 2 and dried at 45c in a desktop drying oven. For the face I place it in a denture cleaning pot with a little warm water and a Steradent tablet and gently wipe with a cotton bud and dry in the drying oven.1 point

-

https://vintagewatchinc.com/using-watch-timegrapher/ I'm not sure that you can infer anything about jewel count from a freshly serviced watch that has no jewels. Jewels are going to minimize metal-to-metal wear as well as providing a surface harder than steel for the steel pivot. I would assume that a freshly serviced watch that had just been lubricated ought to give better readings than shown but I don't know if a lift angle of 36° is correct for the watch shown or if 133° is a reasonable amplitude for the watch. Neither would be close for a modern watch. All that said, who cares if a so-called "dollar" pocket watch is gaining 38 seconds a day? The watch was never sold as or intended to compete with a chronometer1 point

-

Hi all, It's taken a year or so (time just gets away from you) but the rusted, beaten up, non working Super Elite is now 95% completely restored. Powder coated in "Marigold", it will look good in the study. However that 5% remaining is bugging me. One thing I wasn't able to do is find a red lens for the bulb holder or a clear photograph of an original Elma decal (the gold and blue one from the older machines). If anyone can provide one, sell one or flick over an image that would be magic. Cheers and thanks to everyone on this site. Other restorations and general data makes life so much easier than doing everything oneself. Better outcomes to. Thanks, John PS. I still need to polish the heater cover.... next weeks chore.1 point

-

If looking for an authoritative 2824-2 servicing video check the one by our Host Mark Lovick1 point