Leaderboard

Popular Content

Showing content with the highest reputation on 05/16/22 in all areas

-

I'm with Doc. The cheap tweezers and screw drivers certainly don't stay sharp and crisp as long as the expensive ones. Even the best tools are going to need a tune up at some point. The cheap stuff gives me the chance to improve my skill before I have to work on the expensive stuff. Never let a crisis go to waste. I did send one set of tweezers to the first aid drawer. I just couldn't get them the way I wanted. They work better for splinters than any splinter tweezers I ever had.2 points

-

It's not like you really have a choice here? Hairsprings are usually not replaceable usually come with the balance wheel. Then as others have pointed out just because it's blue in color doesn't mean that it's steel.2 points

-

In 1968 Omega would have used a Nivarox spring and monometalic balance. Nivarox supplied springs either white or blue, in various grades as Joe mentioned, but still an alloy very different than carbon steel.2 points

-

I find it's always a good procedure after or when you're cleaning the watch that you clean your bench. Then you start the nice clean bench for reassembly of the watch. But yes it is troubling when there are extra parts floating around as to why is this here? But don't worry it happens to all of us currently I have a plate screw on my bench not quite sure where it came from I'm sure I'll figure it out eventually1 point

-

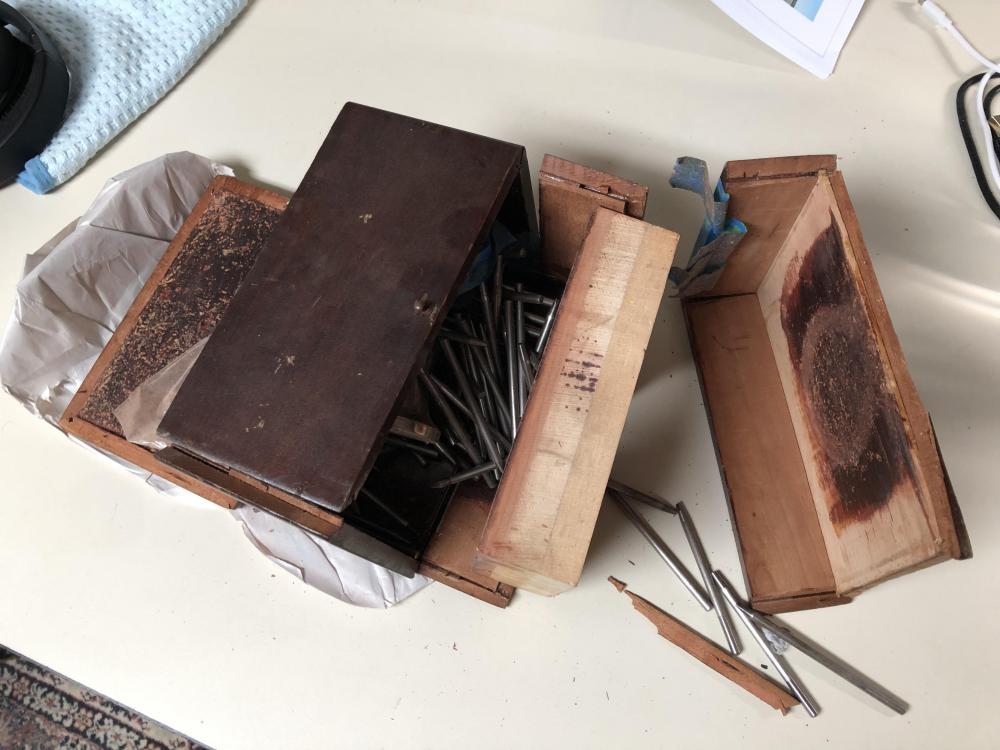

Hi all. Its been awhile but now time to introduce the next tool in this series. This time I introduce my Watherproof Watch Case opener, which is clearly based on the much more expensive Bergeon 5700. I went with this one https://www.aliexpress.com/item/4000394753607.html?spm=a2g0o.order_list.0.0.7c8018028gGu7h Which at £63 was quite a bit less than the £535 the Bergeon version is Comparing the two side by side, there are a few differences most being cosmetic, like the measurement scale on the adjustable tool on the Bergeon version, on this version there a no scale markings, but in reality they are not needed, the only other difference is possibly the support spring, on the photos of the Bergeon one it appeares to be a little longer. The Chinese one had one issue out of the box but it only took a few seconds to correct, out of the box the two raws (for want of a better word) were not quite the same difference from the center line of the tool, so with one lug in its slot in a case the other lug was out by about a millimeter. This only took a few seconds to cottect by unscrewing the two locking grub screws in the Alluminium adjusters and sliding the threaded rod a millimeter to the correct position thenlock the screws gives an accurate possition. One other difference that is first seen is the use of black plastic for the base were its wood on the bergeon tool, well it was wood on the Bergeon tool, as can be seen in the picture below even bergeon now sell their tool with a Plastic base. Is this tool made in the same factory that Bergeon use for theirs but with less QC applied to keep the costs down, I would not be surprised, I worked in production engineering for years and seen the practice of having stuff made in China but boxed in their country and then claiming on the box to be made in the the boxing country before so would not be surprised if the reason so many Bergeon and Horotec tools look identical to some of the Chinese tools is because they all came of the same production line just with different finishing touches. Still if its the same or not it does exactly waht it says it does on the tin (as they say) I comes with a useful selection of tools and adaptors to hold the case with or without a stap and different size and shape lugs in the case back. If you only encounter a few divers watches with a super tight back this tool will pay for itself in no time at all. pictures below, first is the current version of theBergeon tool, then a couple of the Chinese one I got from the link above.1 point

-

Problem is I went back and looked at the pictures and it's really hard to tell what were seeing. Although if it was a plastic crystal it would have a tension ring. If it was some form of glass or worst-case sapphire because Sapphire would be astronomically expensive then there would be an outer Polly propylene ring holding the crystal in place typically. But the best way to do an evaluation is to take the back off the size we would get the case back number from the inside. But taking the watch apart does bring up a minor problem like? Recently acquired was it expensive? Casually one is looking for a crystal the seems to be an expensive watch I wouldn't really recommend it for your first watch repair. Even taking the movement out could be interesting if you've never done it before and Omega watches the parts are astronomically expensive if you can find them. As they have restrictions on who can purchase those parts.1 point

-

1 point

-

I'm not sure I've ever seen a broken tension ring? Now it could be a broken poly propylene or whatever the plastic gaskets are that holds the crystal in place they can disintegrate. The normal tension rings: the inside their metal and I don't think I've ever seen one go bad but this is watch repair everything is possible. Then I didn't see any back pictures like a picture of the backside where we can get a serial number or a case number although usually case numbers inside the back but serial number would work I can look up how the crystal holes in place but I can't do it without a number.1 point

-

From the second photo does look like a broken tension ring. Does the crystal feel secure ?1 point

-

You can get different size Eclipse Eclipse that is one of the types I had. Here is another one I had you can get it from here its a double ended type. I also had various other old types. The one I've shown I would say was the popular ones I used https://www.aliexpress.com/i/4000160194293.html1 point

-

Well, it's not that weird - men and women who are in the military are "deployed" on assignments around the world. It wouldn't be all that strange for someone in the military on deployment to take an interest in watch repair. The Elgin Watch Company trained military personnel to fix watches under field conditions. In any event, welcome to the forum! Are you currently working on a watch or thinking about one in particular? If you've already posted something elsewhere I've not yet seen it.1 point

-

Hairspring's grade is what matters, I am not sure if the color indicates the grade. Traditionally hairsprings in Omega are high grade I think grade or No 1 , there are No2 up to five I believe.1 point

-

My dad gave me this pocket watch, it was a gift to ware at my sisters wedding, I was 12 years old, I'm now 60. At some point I dropped it too many times and it stopped working, so it got stuffed into a drawer and forgotten...until now. I took it apart and found the escarpment wheel had a broken pivot. I was able to source a new escapement wheel and proceeded to clean and rebuild the watch. At one point I thought I had failed as the balance wheel would not rotate correctly, but I then found that I had installed the wrong screw into the pallet cock bridge and the balance was just barley rubbing on it, but enough to mess it up. Once I figured that out it started to run...and too my absolute joy, it works great now!!! Really a great and fun rebuild / fix, especially because it was a gift from my late dad.1 point

-

My next "project" will be the Buren 410 "Grand Prix". I've already cleaned it (although I wasn't able to completely disassemble it). Thanks for watching my progress1 point

-

But from 40 micron to 9 micron, they both overlap in grit. One thinks 3M wouldn't make two different products that were exactly the same, but every published spec seems identical. To sand a fair surface for paint, you don't use a random orbit sander or anything like a buffing wheel. Instead blocks or longboards are used. These are flexible yet stiff backers for sandpaper. They bend to a curve but make a fair curve. The high spots that are smaller than the curve get sanded down. If you sand with something soft, like say sandpaper in your hand, it sands the high spots and the low spots. So while the surface is smooth vs the grit you sanded at, i.e. at the micron scale, it's still lumpy at a much larger scale. For sanding a flat surface, I use a glass plate as a backer. Something like a zinc or brass plate with a paste is a more traditional method, but I don't have that. But for the the sides of a watch case that should be curved lengthwise but flat across the short dimension I think there might be a better way. I'd like to put some adhesive backed sandpaper on a plastic backer of the appropriate stiffness and try to longboard the sides.1 point

-

I was going to suggest "Eclipse" pin vices as I have a number of them and they are very good indeed. However I have just had a look at them on Amazon and I don't think that they are what they used to be. Mine are all vintage, I would say 1950's to 1970's, and made in England. They are very well made and look almost identical to the Starrett set. The new ones on Amazon look a little different and not so well finished. I'm wondering if they are now a cheaper product altogether that is just trading on a previously quality name. If you can track down the vintage Starrett styles ones on eBay though then provided they haven't been abused they are a good buy.1 point

-

I thought it was a lack of money was the mother of invention, well it has been for me over the years with some of the gagets I have made1 point

-

I suspect that it may only be decoration as Karl says here: This is after all a $24 Chinese copy of an Unitas 6498 which does not have the swan neck adjust. So, it was added by somebody in China. After looking at mine, I don't think that the adjustment as implemented is doing anything as you rightly noticed in the first place. I only purchased the one I have to practice on.1 point

-

1 point

-

I never throw away anything. I'm a hoarder. I'll probably grind off the tips and reshape them. If the tips are too soft, I'll try hardening them. If that doesn't work, I'll still keep the metal in my scrap drawer. You never know when it may come in handy.1 point

-

0 points