Leaderboard

Popular Content

Showing content with the highest reputation on 06/17/19 in all areas

-

After receiving a watch from a WWII Veteran Uncle, I sent it out for a repair estimate.. I was shocked the price and decided I need to learn to do it myself. I didn't dare just jump in, so after watching dozens of Mark's videos I purchased a similar watch from eBay for practice.... it was a real learning exercise.. I learned what tools were good, best, and better. Which vendors to call for parts, and what was really needed to do a proper service and repair... Needless to say, I got my Uncle's watch running and wear it with pride. It was a long cold winter and I kept myself busy with all of that new gained knowledge and growing experience... I have attached a few photos of where I have gotten... I have cleaned, oiled and timed every single one... taken off the old straps and found original new old stock, or period correct straps to make them authentic. Some I left with patina, other cleaned up to near minty condition. Out of the 50-odd watches all but 3 or 4 keep time with a few seconds a day. I had so much fun learning that I started looking for more projects by cleaning out the local swap meets and pawn shops of their WWII watches (mostly Elgin, Waltham, Bulova, and Hamilton).. now I have a few extras and I owe it all to Mark. Thanks Mark! Now if I can get my work bench cleaned off I can get started working on my Willys Jeep transmission rebuild....2 points

-

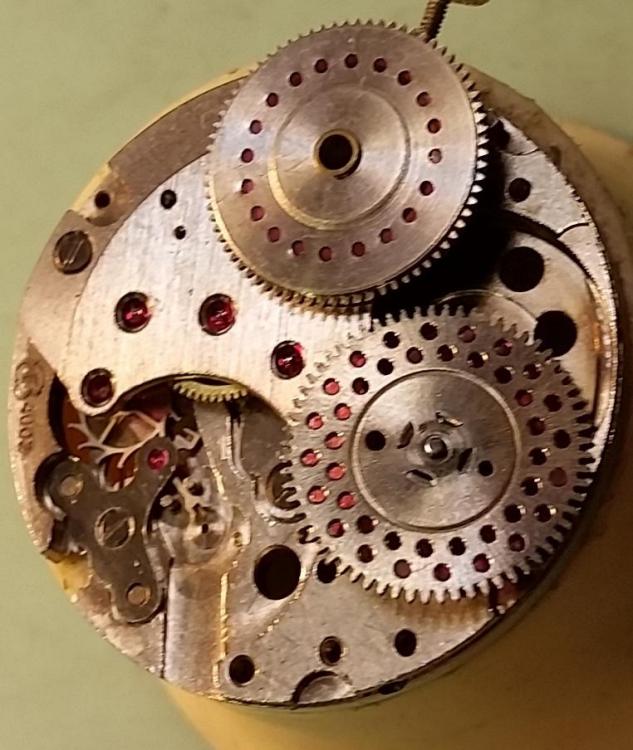

A relic of the Jewel Wars, this 35mm 1950s Mount Royal with an 80 jewels (kind of) Felsa 4002, 21 of which are broadly functional and 59 which, er, aren’t. I’ve no idea how many of these watches survive today or, indeed, were ever made but it “coulda been a contender” until the likes of Waltham, Orient, and Titoni climbed into the ring with their 100 (and more) jewelled efforts. Of the two recorded makers of a Mount Royal brand, Choisi seems to be the most likely candidate for today’s curiosity, it being a product of the original company founded in 1929 before its demise, date unknown. The company name was seemingly reactivated in 2013 by a Singapore-owned enterprise which, from what I can see, is largely producing retro-style watches along with homages based on the old company’s vintage models. Regards.2 points

-

Hi! Since long I did try to bring this tiny movement back to life: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&2&2uswk&Bulova_5AP I got two other movements for parts and I had to refit a balance wheel with his own cock from another movement The problem I am having is that if I tight the screw of the cock, the balance wheel stops. If I loose the screw and push up the cock from the mainplete, the balance wheels starts spinning itself for a several minutes, until the gravity pushes down the cock, then pushing it up it again from mainplate makes it spinning again. I did try to lube but it appears it mate things worse and not better. Any suggestion about what problem I may be facing? Thank you!1 point

-

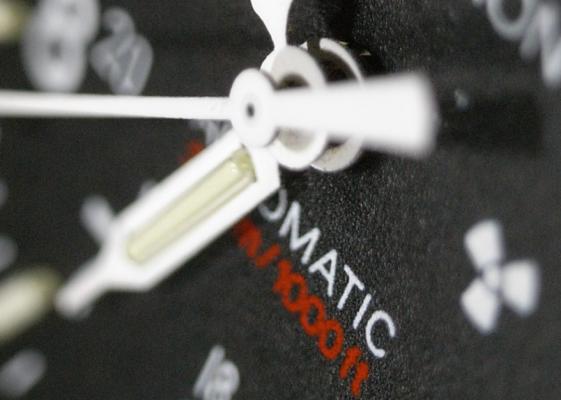

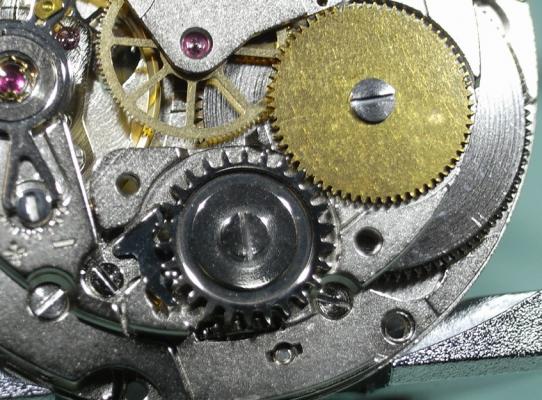

ETA2824 Service - The Radioactive Watch! Yes this watch is Radioactive ... so to speak :P It contains H3 Tritium Tubes to illuminate the dial at night. This watch belongs to my brother, and he has owned it for many years. I have to say that Marathon Watches are great "bang for buck", as this watch has served him well over those years, and he rarely takes it off his wrist. Unfortunately, on one of the rare occasions that he did (to wash his hands after work) he dropped it on the ground, and it stopped dead ... right at his quitting time 3:30pm. He was very angry with himself, and asked if I could found out what damage had been done by the drop, and repair it ... of course I was happy to help my bro :) While he was with me, I pulled the Caseback off and could instantly see the problem. The Hairspring was jammed up and the Balance was seized. I told him there also could be broken pivots, and I'd have to dig further to assess the total damage; but not to panic, as all parts for this movement are readily available (at the moment) ... so he left the watch with me. So I removed the movement from the case, pulled the Hands, and the Dial off to inspect the Calendar Works ... everything looked good. Next I removed the Oscillating Weight, and checked that the bearing hadn't been damaged by the impact ... it was fine too. Next I pulled the Automatic Work off the movement, so I could gain access to the main body of the watch. Here's a reference photo of the Automatic Work for ya Next I undid the screw of the Balance Cock and began to gently lift it ... and hey presto, and Hairspring dropped back into place, and the movement started tickin away ... these are a solid movement indeed! I carefully watched the movement ticking away, noting to see that the Pallet was working properly, and that the Train Gears ran smoothly ... all seemed fine, and the problem with this movement was resolved. I could have just stopped there, but this movement hadn't seen a service in over 8 years, and was already out of the case and 1/4 stripped, so I deiced to burn the midnight oil and do a complete service on the watch. And yes, that is a real radiation dosimeter, as I wanted to be sure nothing from those glass vials had leaked into the movement I was handling ... I'm glad to say it was clean B) Continuing with the strip down. All mainspring tension was removed from the unit. Notice with this movement too, that the click is on the Crown Wheel; instead of the Ratchet Wheel. Balance and Pallet was removed Crown Wheel, Ratchet Wheel and Barrel Bridge was removed. This is a reference photo of the Click Spring sitting on the Barrel Bridge. Under the Barrel Bridge there is a small Balance Hack to be removed as well. Next I flipped the movement and removed the Calendar Work. Then the Keyless Work Back the to other side and Train Gear was removed. Here is a reference of the Gear Train. Lastly the Automatic Work was stripped. Back from a bath, and all parts clean and ready for inspection and assembly. All pivots where intact and unburred, no damaged teeth or pallet stones, and no wrapped gears ... GOOD NEWS!! Ready to be put back together! :woohoo-jumping-smiley-emoticon: Nice clean and shiny Gear Train, Train Bridge and Barrel back in place and oiled Back on with the Barrel Bridge, Ratchet Wheel, Crown Wheel and Click Keyless Work clean, oiled and working smooooooth Automatic Work back together as well The rest of the re-assembly wasn't photographed ... sorry guys, it was VERY late, or should I say EARLY, in the wee hours of the morning, and I just got carried away with the build :huh: But it all went smoothly and as per the reference photos early. After the Dial was attached, the hands where next. Let me tell ya, these are NOT easy to fit correctly! With those glass tubes of H3, there is NO room for error fitting them. You literally have a couple of thousands of an inch to play with ... here's the photos to scare ya :o. This type of watch will really test your hand setting abilities. Here's she is all back in the case with the Automatic Work and Oscillating Weight fitted, purring like a kitten! Job Complete!! And as you can see, it now is showing my quittin time of 4:11am OUCH!! :hot: Hope you enjoyed this post as much as I enjoyed working on this movement. It was really nice to finally work on a watch that hasn't been molested, with nice clean screwheads, and no rust to deal with.1 point

-

1 point

-

Have a Sternkreuz press i use for most glasses. Love it. I bought a second one on tradera some month ago for spares. Also have an other which looks like a Robur but not 100% sure it's a Robur. Was thinking i could make an adapter so i could use some other dies as the Robur ones cost a lot of money. Maybe i can part with that as i have to many presses anyway.1 point

-

That is the Indian copy of an MKS 46610 (famous Japanese brand), I got one as clearance from Germany and paid maybe less than that. If you use the search function you should find my posting.1 point

-

I haven't pulled the trigger on a watch cleaning machine, yet, but if/when I do, I suspect I would go for something vintage, 'cos half the fun for me, is in restoring it. I've still to bring home a colour laser printer I picked up on ebay, which is currently in my office, and which is no doubt larger than my wife expects, so I may need to wait for a suitable diplomatic cooling off period before I introduce any more junk useful items in to the mix.1 point

-

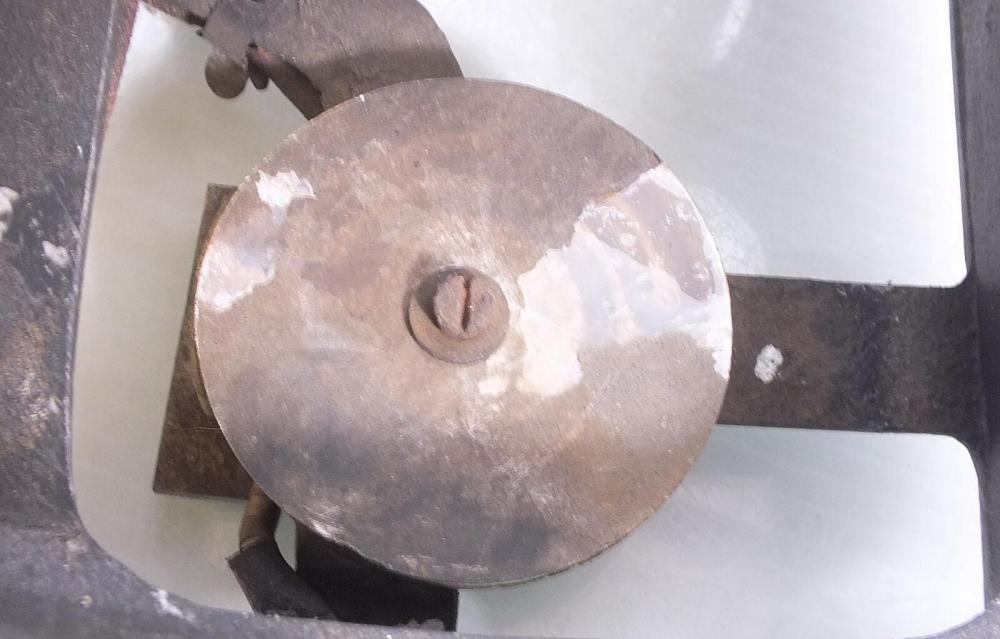

I forgot to actually show the original heating element. So in the interests of full explanations and detail, here are some photos. The first shows the heater in the base of the front right corner. It is normally covered by an alloy copy of the glass jars used for cleaning, but with no bottom. (You can see this in an earlier photograph.) The heater is a circular, pot-ceramic element, typical of its age, and contains a long 'nichrome' wire element to provide the heat. It is simply switched across the mains input to provide whatever it's rated output was. (I have not been able to find this out, but guessed when looking at this machine's descendants, for it to be around 150W to 250W heat output.) There was a simple protective mica disk over the element, once again something of a give-away as to the age of this design, and also again, not particularly safe, as the Mylar is quite flexible and it would be easy enough to lift up at the side of the disk and touch the element whilst at mains potential. After disassembly. you can see the channel where the heating wire fits. As can also be seen, is the reason for the auction listing describing the heater as non-functioning. The coil was broken in many places and sections were missing. Replacing this to get the National Electric Watch Machine's drying capability back in action, was seen as essential during my restoration/repair/refurbishment of this fine antique! (Slightly tongue in cheek there... )1 point

-

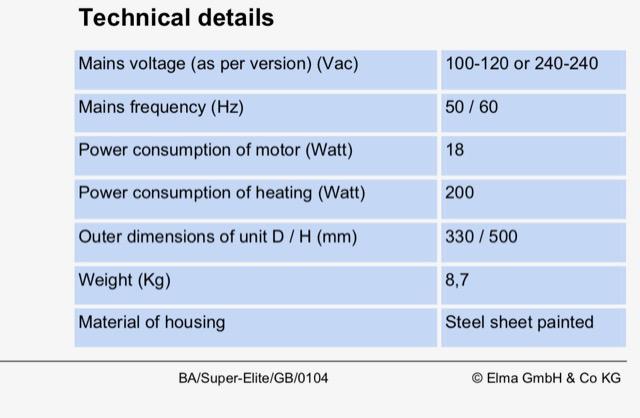

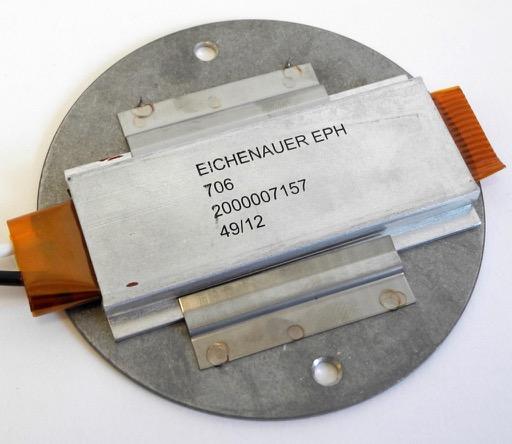

No suppression in sight. Again, typical of its age I guess. I am also a licensed Radio Amateur so well aware of looking out for and solving interference problems. As well as not annoying the neighbours, I have no intention of wiping out my HAM radios either. All those plates you see on the rheostat almost certainly contain asbestos as mentioned, but they are bonded into those plates and are in very good condition for their age. I have "fabricated" a plastic insulation shield that encloses the rheostat and provides much increased protection. Having said that - I have also, already ordered a more modern 240v motor speed controller as well which will arrive today. I'm pretty sure that even with the "new" protective cover - I still would feel uneasy putting this back into service, so will likely panel mount the new controller in the space vacated by the rheostat. I hope the measurements I took off the replacement are accurate, as it should be a straight swap (if I am lucky). I may even be able to use the original rotary control knob and maintain a bit more originality... Anyhoo... Having cleaned and painted the base (with rattle-can black Hammerite) I turned my attention to sourcing a replacement for the heater. My main design criteria was that It had to perform like the original, and fit in place of the original. Clearly finding a spare part (even if likely, which it is not, not without cannibalising another original machine and goes against the grain somewhat), would mean that I was re-introducing an old (unsafe) element, after taking away an old (unsafe) rheostat. This did not make logical sense. So something new was needed. Thee replacement heating element for the Elma Super Elite (RM80/RM90 etc.) are still available and they look like they would do the job, but are £45.00 plus postage from everywhere I could find them. This is the specification for the Elma Machine and a photo of the spare part. The spec. shows that the power consumption of the heater is 200W, which is important to know. A quick examination of the wiring diagram (found elsewhere on the forum) shows that the heater has no external temperature regulation circuitry, and therefore must regulate its temperature by itself. I recognised the heating element (the rectangular thing) as they are the sort of heater used for equipment cabinets etc. for frost protection and providing other low level heating needs. They are PTC elements, available in a variety of outputs and crucially, can be switched directly across mains voltage and self-regulate their temperature. They are easy enough to find as the likes of RS Components and Farnell (other suppliers are of course available). So - I ordered a 200W 240V element for about £23. This would provide the perfect solution for my application. Incidentally - As the Elma cleaning machines themselves are somewhat "vintage" these days, their original spare part heating elements are also likely (if they are not already) to become rare things. Therefore, knowing how to source replacements is useful to know. The Elma spare part comes with the circular metal disk (heating plate), but having a look at how the element fits onto it, looks like it just slides into those two grooves. Anyway - the solution to my National machine was sourced and the next instalment will cover fabrication and installation.1 point

-

Great tool. I have one of these for my screwdrivers which gives the blade tips a better non slip shape. Expensive but very good.1 point

-

If the cap jewels are seated correctly and you have not transposed them then the balance is not aligned correctly. Rule of thumb DON'T FALSE ANYTHING. By any chance when you removed the balance cock for cleaning was there a shim between the cock bridge and plate. Sometimes if a new balance staff is changed and it is bit tight a cheats way is to put a thin shim under the cock.1 point

-

My advice is this. Whenever you are about to start on a new mechanical watch repair, make sure all your screwdrivers and tweezers and other tools you might use are de-magnetised. It is also good practice to de-magnetise the watch movement before attempting any repair. It will also save you time.1 point

-

Anti magnetic tweezers are expensive, most people cant afford to have all their tweezers anti-magnetic. You do not want tweezers or screwdrivers magnetized, magnetism is the bain of mechanical watches and causes all sort of issues, such as causing the coils of the hairspring to stick together making the watch run fast. If your tweezers are not 100% anti magnetic they will eventually becomes slightly magnetic, whether that is from touching magnetized parts of watches, or just them passing through other magnetic fields. If you work on quartz watches you will need atleast 1set of tweezers that is 100% ant-magnetic to pick up the rotor for most people a good set of brass tweezers will do. For everything else rather than have 100% ant-magnetic tweezers having a demagnitizer is more important. You can buy cheap ones off ebay and you will need one as its quite regular to find that a watch you are working on is slightly magnetized that you will need to demagnetize and so will your tweezers or screwdrivers after touching the watch. Bottom line you don't want any of your tools magnetized and the only part of a watch you want to be magnetized is the rotor in quartz watches.1 point

-

maybe one needs a new MS, maybe the bridle lost it's hardness. Use the old MS instead, the one that works. I don't think making the MS wall more rough is a good idea (in time).... What is the amplitude of the watch when the MS slips?1 point