Leaderboard

Popular Content

Showing content with the highest reputation on 06/06/18 in all areas

-

A quick look on ebay. I have found these clocks. Made in china and extremely poor in every way. Do not waste your money. A genuine French carriage clock would never have holes drilled in the bell. Hardly ever do they have a sweep second hand. The platforms are normally made of brass some are silvered. I can only assume the Chinese platforms are of a metal to look like it is silvered, they are very poor. If you are considering on purchasing a French carriage clock you can ask me for advice and I will whiling advice. I expect these links to disappear when there time is up on ebay. https://www.ebay.co.uk/itm/Vintage-Cloisonne-Enamel-Carriage-Clock-with-Twin-Bell-Chiming-Repeater/273257850972?hash=item3f9f6fe85c:g:2IAAAOSwJiJbFC2Y I have no idea who made this. It is very poor quilty https://www.ebay.co.uk/itm/Antique-Carriage-Alarm-Clock-Brass-Complete-Working/392052641707?hash=item5b48288fab:g:5OMAAOSwhHJbCq3s https://www.ebay.co.uk/itm/Vintage-Brass-Repeating-Carriage-Alarm-Clock-M-D-Ger/273257911846?hash=item3f9f70d626:g:CjIAAOSwSlRa7y8N https://www.ebay.co.uk/itm/Vintage-Cloisonne-Enamel-Carriage-Clock-Twin-Bell-Chiming-Repeater/182932078625?hash=item2a979a0021:g:F74AAOSwUwFaEvpc https://www.ebay.co.uk/itm/VINTAGE-REPRODUCTION-SOLID-BRASS-CARRIAGE-CLOCK-PLATFORM-MOVEMENT/202102035369?hash=item2f0e3853a9:g:V6oAAOSws6ZZ-3ff2 points

-

The biggest give a ways are very poor finish to the parts if you look at many of these Chinese fakes there is no attempt to polish surfaces that should be if you look at the edges of the plates or any of the escapement edges they should be highley polished the Chinese ones are rough just as they have been cut, the quality of screws used is always poor french ones again are highly polished and blued the Chinese ones lack finish they are blued to black which is wrong but look dull and lifeless compared to french ones, screws are often mismatched on Chinese copys. Ratchet wheels at the back are almost always unpolished on the Chinese copys they should be polished the casting of the case parts is rough at best, made in france on the dial would never appear on a french carriage clock. Since I have started working on french carriage clocks even one's that would have been considered rather cheap in the 1900's basic time only with cylinder escapements and plain style of case even these are far superior and the quality can be seen.2 points

-

2 points

-

Chinese carriage clocks main plates are a lot thinner. The striking works tend to be showing on the back plate, the bell will normally have holes in them. French carriage clocks will usually have the striking works between the dial and front plate with a solid bell on the back plate. Chinese will age there cases to make them look old or as many describe them as antique. As the law goes antique does not mean a specific amount of time. Everything about these Chinese clocks compared to the French ones is poor. I am wondering how long it will be for them to come out with copies of English carriage clocks. wis1971 has given you good details of what to look out for.1 point

-

Here is a genuine French carriage clock that has enamelling. https://www.ebay.co.uk/itm/french-brass-and-enamelled-carriage-clock-alarm-timpeiece/382479426558?hash=item590d8ce3fe:g:~xcAAOSw9V5bEiNs Here is the one I have already posted; this is the poor Chinese one. See the difference in movement quality and the enamelling. If you have a painted dial Chinese carriage clock it has been painted by a child who works in one of those sweatshops for very little. https://www.ebay.co.uk/itm/Vintage-Cloisonne-Enamel-Carriage-Clock-with-Twin-Bell-Chiming-Repeater/273257850972?hash=item3f9f6fe85c:g:2IAAAOSwJiJbFC2Y&clk_rvr_id=1556090534609&rmvSB=true1 point

-

Thank you Tmuir for the info. I would buy the complete unit, it will save you having to sort the blocks out. You will be able to just fit the unit in.1 point

-

That looks like plate 1407H Kundo 4 ball midget clock circa 1965 Use 0.0022" (0.056mm) Horolovar you want. Page 133 in the 10th edition if someone else wants to double check. It should do 10 beats a minute when set correctly. Make sure you mark out the exact dimensions and the placement of the parts on the spring, or you can buy a complete replacement unit '5F' https://www.cousinsuk.com/product/kundo1 point

-

Hi and thanks for the supportive chatter. Makes this hobby so much more rewarding. Right now the hs seems pretty demagnetized, can’t see any sticking tendencies as it lies on the table. And I agree, this is most likely not the original hs. There are too many signs of tampering with the stud pin etc. for that to be the case. Will definitely give it another clean before assembly, it does look grubby towards the stud. Rogart63, I think you are correct pointing towards FEF 130+. The bridge design differs slightly but the key less stuff appears identical and from what I hear that’s the true identifier. I found a supplier with a FEF 130 hs in stock for decent money and may go for that if this one doesn’t work out. Will be away next week, so if I appear quiet, that’s why. Sent from my iPad using Tapatalk1 point

-

This is the most difficult thing to teach. When you have a critical job to do, step away and come back to it when you're rested and fresh. There have been many occasions when I have been trying to do a fiddly task and getting frustrated. Coming back to it fresh on another day and it goes well 1st time! Anilv1 point

-

So far so good... got the hs pinned back in the stud and the collet reasonably centered after a bit of tweaking. Found that holding the pin with a piece of rodico was a lot safer than using a pincette. I hate that ”ping” sound I hear when realizing I held the part too hard and it’s off to some distant place. Still plenty of opportunity to blow this completely so time for a break [emoji3] Sent from my iPhone using Tapatalk1 point

-

Maybe I can help but I don't fully understand what you're asking- Do you want to know how to close a collet in the headstock, or one in the tailstock? For the former, it appears the drawbar is there- with the large reddish-brown (bakelite?) hand wheel on it. For the latter, I don't know. My experience is that the tailstock will have a Morse taper internally. Your third photo appears to be the index for the tailstock- so it can be moved toward the headstock a known distance. (my guess anyway) My first-hand experience is on larger lathes, but the Hardinge Super-Precision is generally used with headstock collets and in that case a similar drawbar draws the collets into the headstock. (they also have a hand-lever option so the collet tension is set for performing operations on multiple parts, and the collets quickly opened and closed with a known force every time.) Also on the Hardinge, the tailstock has graduations on the handwheel so the depth of (drilling typically) can be accurately monitored and reproduced (graduated in 0.001" increments on that). I love those Super-Precision lathes... They will hold and repeat within 0.0005" all day long. A pleasure to operate.1 point

-

This is WAY above my pay grade but I appreciate it! I also like the link to Raul Horology. I enjoy absorbing this info even if I have no plans to get that deep. Knowing the implications of other actions can help me make smarter decisions in other areas of a project.1 point

-

This is a follow up comment on my earlier question about my watch that was running fast. I had many great answers, most directed toward the hairspring. As suggested, I demagnitized the watch and all the tools to be used in the repair. Then I removed the balance wheel, hairspring, and the plate holding the mechanism in the watch and soaked them in Naptha overnight. Then I reassembled the watch, wound it and let it run for 24 hours. A dramatic change had occurred. It gained, not three hours, but three minutes! Thanks to all who gave me such good advise and helped put this watch back in service. Bill in Augusta, Georgia, USA1 point

-

An almost broken hs can cause all sorts of unexpected behaviour. Before going hunting for a new hs, you should try repinning this one as close as you can to where it broke. If you can do this carefully you should still be able to adjust the timing by moving the regulator to the slow end. You can, if necessary, tweak the mean time screws on the balance (the ones closest to the arm) 1/4 to 1/2 a turn out to compensate for this. You must remove the balance form the watch to do this or you risk breaking pivots, and you must adjust equally on each side. You will need to remove the hs from the balance and reform the terminal curve so the collet is centred over the jewel hole and the regulator pin / boot moves freely round the full range of adjustment without moving the spring off centre. There is a special tool for holding the stud, but your balance cock here will suffice. You may want to move the stud down a ting fraction to help in pinning the spring perpendicular to the stud. You should be able to re-use the old pin. You will find some info on all this here... http://raulhorology.com/2012/12/the-mark-of-a-true-watchmaker-forming-hairsprings-part-4-pinning-to-the-stud-final-adjustments/1 point

-

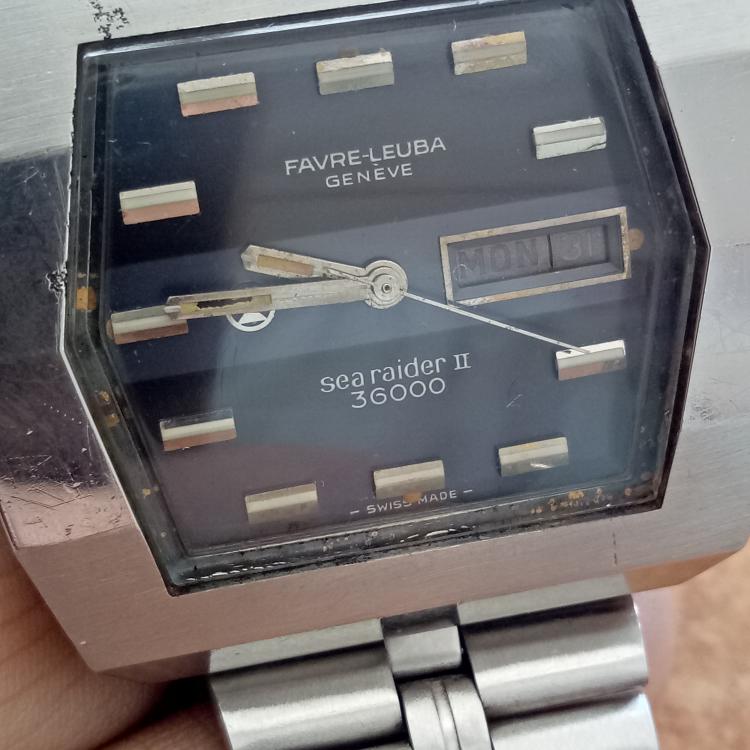

Just bought a Favre-Leuba Sea Raider 2 from a local seller (in Malaysia), cost was approx USD100 incl shipping. I've been a fan of Favre-Leuba for a long time and I've been looking out for a Sea Raider but they usually fetch a high price (for me). This one was advertised on a local facebook group and I didn't waste time grabbing it. It's a very chunky design that screams 70s... The dial is in good condition, there is some marks along the edge... this could be some lume material from the hands or wear caused by the dial rubbing against the case/crystal revealing the brass dial material. If it's wear it can be masked by colouring the visible brass with some black paint or even a sharpie. The day and date wheels have faded to the point that they're barely legible. Case is really big.. Look at how low the crown is! Case back is pretty low-relief. I imagine having a deeply embossed case back would probably give you a mark on your wrist! Did I mention the case was big? It won't fit comfortably under your sleeve. The case originally had contrasting polished and brushed finish.. Someone has tries to re-do it but it's still not perfect, if you look at the dial closeup above, you can see some pitting around the 11 and 9-10 markers. It's powered by a FL 1164 hi beat calibre.. Which is based on the AS1167/1168. Well that's one more ticked off my list. Anilv1 point

-

1 point

-

Here's a picture of my Bulova Snorkel. I had to do a screenshot off my photobucket as it doesn't let you save your own photos. Bad job Photobucket.. The actual watch is in storage somewhere. I've had it around 25 years now and its still working fine. I can't really remember what movement is inside but its probably similar to the 11BLACD above. I believe this is the first model Snorkel.. the later ones had the raised lume-filled cylinder hour markers. Anilv1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)