Leaderboard

Popular Content

Showing content with the highest reputation on 01/29/16 in all areas

-

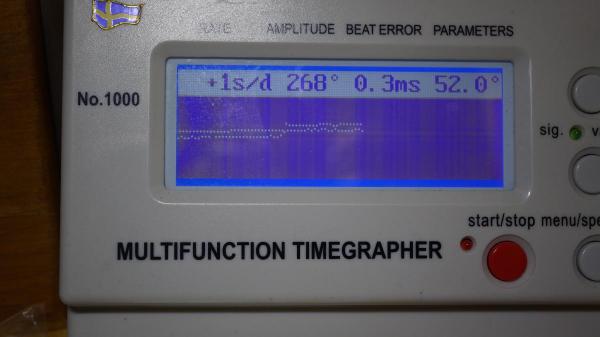

This two watches are ready. Promised to report back when the watches was assembled. It's a Seiko 7005 and a Omega 165.024 with a 552. Timegrapher is not perfect as i happen to knock the table. And that upset the line. What do you think of the lume on the hands? Did i do alright with the color matching.3 points

-

So happened to receive this watch with a broken stem today. Just want to show how to remove the dummy top plate to access the movement under it. Remove this center plate by unscrewing the two screws. Unscrew the three screws to remove the automatic rotor. The dummy top plate is secured to the movement ring by three screws and the movement by two screws. The positions of the five screws are as aligned in the pic. All the others are dummy screws. Underside of the dummy plate. The movement exposed but I have no idea which Chinese movement it is yet. There's a "ZE" mark near the balance wheel. Now have to source for a new stem. Don't know where to find one yet. Any suggestions? Sent from my Lenovo S650 using Tapatalk3 points

-

This very nice Seiko Presmatic was delivered today . Super clean case , case back , and movement . The only blemish I found was a touch up on the black of the dial under the "r" of Presmatic that I saw with my loupe , but the color match is spot on . This 5106 movement hacks and hand winds , this is unusual for a vintage Seiko . For those that may not be familiar with the Presmatic , a particular feature of them is the internal push-button for date change in the head of the crown . The pleather watchband that came on it is not long for this world . http://www.ebay.com/itm/GREAT-FIND-33J-SEIKO-PRESMATIC-37MM-5106-9000-MENS-WRIST-WATCH-RUNS-/351632420816?_trksid=p2047675.l2557&ssPageName=STRK:MEBIDX:IT&nma=true&si=f50BRCyQVjUJykzt89lIG2JArRk%3D&orig_cvip=true&rt=nc1 point

-

You got it right! I had an hint when, in despair I poked the stud arm a little and it started behaving, just to go crazy again after few moments. I was puzzled. Then with the balance removed again I found the hairspring was moving freely in the end stud. Pressed it and it's good so far.1 point

-

1 point

-

I shall start it tomorrow. I have some circular Click springs, the broken one fell out so I know the sort of shape. I shall start from the top and work down to the Barrel Bridge, then it will all become plain and simple....... I hope. The watch has had little use so I expect it was either a faulty spring or they are prone to this. If I remember I shall take some photo's, for anyone interested in seeing what is there............1 point

-

I got a headache with my cheap loupe. The cheap chinese oilers broke the first time i used them. The cheap screwdrivers worked okay but looked very worn an ugly after a while. And i have to replace the screwdriver bits with Bergeon bits. The cheap movement holder didn't work and the movement keep falling of and breaking something in the fall to the floor. The cheap tweezers didn't hold the screws and they where flying all over the place. Everything took twice as long to do and causing grey hair in the process.1 point

-

1 point

-

Hi Steven, The movement underneath reminds me of a copy of an ETA 2824 or its derivatives. I'm not saying it is, but there are two directions I'd explore: 1. compare the stem with one from an ETA of that type 2. If convenient to your location, check ofrei, the mechanical movements section has a Chinese/Asian entry and at the end a whole bunch of Chinese stems...I bought one of each once and that's how I compare when the movement can't be identifiable. I'm not that much experienced in those watches but at least I'm able to suggest something. I hope it is useful. Cheers, Bob1 point

-

I use cheap tools like Indian screwdrivers, Jaxa tool, presto tool, cheap Swiss tweezers, hand setting, oilers, movement holder, case holder, case cushion, work mat and probably few more. All that works fine, doesn't break (when used correctly) and doesn't mark anything. In fact I'm proud to achieve the identical results than with overpriced tools, even if I could have afforded them without any problem. I have learnt (even before watchmaking) that the only tool where quality can't be sacrificed is one's skills and dedication. All the rest is secondary. That being said there is stuff for which one needs the real thing, example forked end spring bar tool. I have also opened a thread abut laughable cheap tools to stimulate sensible discussion without preconceptions.1 point

-

1 point

-

Superb Roger i especially like the Omega it's a beauty and the lume looks perfectly matched to me well done1 point

-

That's a really nice couple of watches and an excellent job Roger. Your lume job looks great to me, well done!1 point

-

Difficult to make any judgments without pictures, but Speidel is a long-standing manufacturer of expanding metal watch wrist bands (among other things), and the case makers, Dennison used sun, moon and stars as case marks for different grades of gold-filled cases. Just a thought, Will1 point

-

Hi guys, IMHO, I think that cheap tools only achieve one thing: waste of money and time. There is a bonus to that though, blotched work and not showing your true skills and/or develop them. Wait that's not one thing but many things! In any case, I'm talking by experience. If I were to get back all the money I've spent on cheap tools I could buy twice the quality tools that matter and that I had to buy in the end...and I've tried everything: from cheapo screwdrivers to cheapo screwdrivers with adapted expensive tips to top of the line screwdrivers...tweezers is another one! Dumont are what you want, never settle for less. When you use good, professional tools, you have more control, tools work as they should and the result is "unmarked" work, professional work. They also last a long time with the proper maintenance and proper use, a lifetime in most cases. There is always the learning curve and that might be an issue but if you train with mediocre tools you will never know how good you can be since your work will, most of the time be mediocre. Again, all this I learned the hard way. I'd listen to oldhippy, he knows what he is talking about...forget cheapo tools, I can't stress it enough. BTW, material houses have to carry cheapo inventory. That's where they actually make killer money! They, depending on who and many other factors, choose the "less" bad of the lot...and some don't even choose, just pass them along to the unaware buyer. Just my 2 cents on the matter. Cheers, Bob1 point

-

1 point

-

1 point

-

Hello John, First things first, never adjust the pallets, their set from the factory, maybe polish the impulse faces slightly. Also check to see that the pin lever has not worked loose in the verge/anchor. Should only be checked when its removed from the plates, the pivots will break like glass. Like OldHippy says, the suspension spring must be the exact thickness and length, and the fork must be positioned perfectly according to the horolovar book specifications, and the mainspring should be wound Setting up proper beat takes more patience then watching paint dry. Make the pend stand still, put tape on base and mark as neutral position turn pendulum horribly slowly until you see it escape a tooth, mark this position turn pend the other way until it escapes, mark this. The distance from each mark to neutral should be equal, if not, you need to turn the top Saddle assembly a microscopic amount until it is correct. Realize each adjustment will require new marks After proper adjustment, you will see that not only does the pendulum swing enough to cause escapeing, but you will also see it overswing the mark, this is very good. A total rotation of 270 degree's is great. This shows good power coming through the train to the escape wheel. Once you have it in beat, a half bottle of Wine is in order Beat Rate is adjusted with the knob on top on the pend bob. Don't be surprized if the etched arrows are in correct for Retard or Advance. In a perfect world the knob should be in the middle at the correct beat rate according to horolover specs If the beat is too fast and you can't slow down with the pend knob, you can sand the suspension spring length below the fork with Crocus Cloth, polishing cloth. If you didn't put in the correct suspension spring to begin with, don't expect Crocus Cloth to fix it. If the beat is too slow, you put in the wrong suspension spring Finish off the rest of the Wine Forks that flutter are usually adjusted too low on the suspension spring a micro amount If the fork is too high it will reduce the total swing of the pendulum, but not flutter, you need to find the sweet spot in between. Any adjustment to the fork or spring throws out the above adjustments, do it again, and again. Also as the mainspring and oil ages along with dirty pivots, this reduces tolal swing of the pendulum until the swing cannot cause escapement any longer If you've gotten this far, you might be wondering if the clock will run an entire year. To test this, let down the mainspring and put 1.5 winds on it. It should barely be escaping. If it does, pat yourself on your back, your done. Now you know why most clocksmiths will not touch anniversary clocks, too much labor, not enough money I think its time for my nape Al Takatsch Jefferson ClockWorks1 point

-

Not the easiest of clocks to get in beat. In fact many clock repairers won't touch them. Its hard without seeing the action, but I will do my best. There shouldn't be hardly any distance or play between the suspension pallet forks and the long stem from the pallets, to stop the jerking put a very tiny drop of oil both sides of the long stem, this will stop the jerking. A little oil on both pallet faces. I know you said you fitted a new suspension spring, are you sure you have the correct one and that it isn't bent in any way and it is the right length. You need to have the forks at the right height There is a book which I highly recommend about these clocks. I think it's called The Horolovar 400-day clock repair guide. Also a very good tool for getting the clock in beat link https://www.cousinsuk.com/product/horolovar-beat-setting-tool. How did you go about cleaning it? Try this first and let me know.1 point