Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/15 in all areas

-

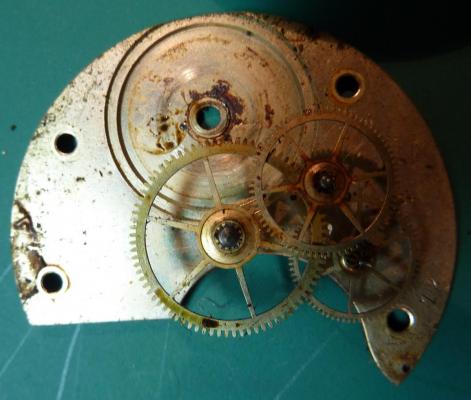

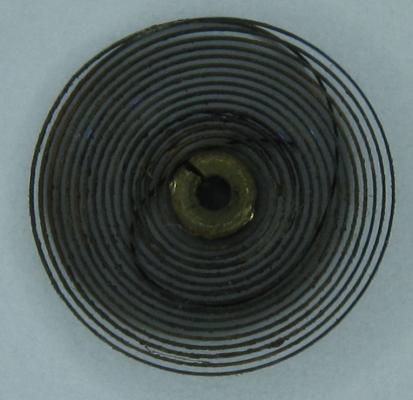

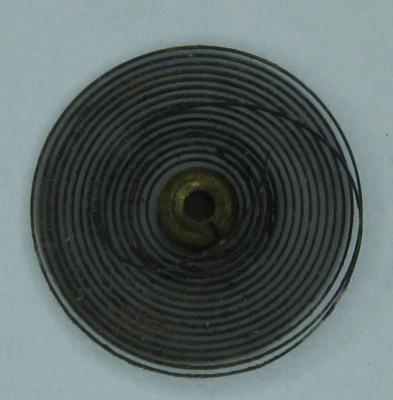

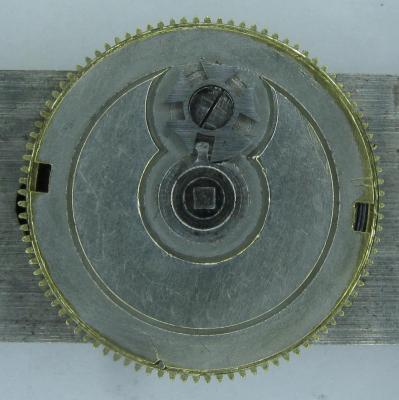

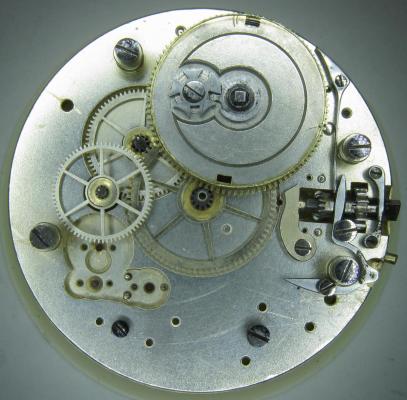

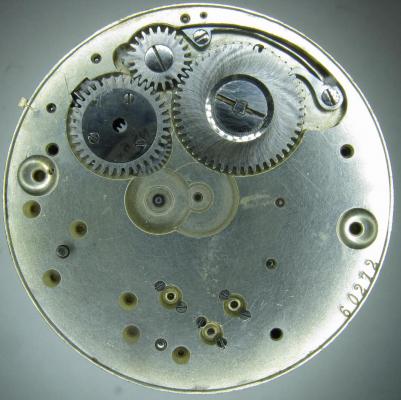

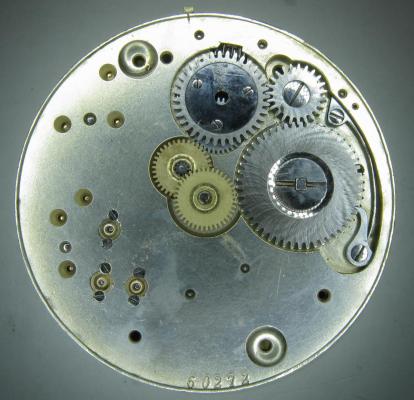

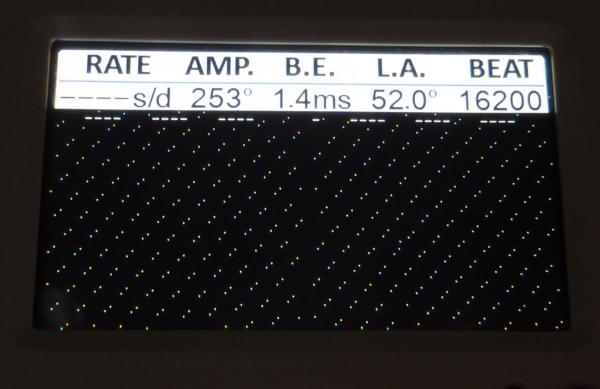

OK, so me and Mrs H did Christmas day with the family, and then we did Boxing day with the family, and then we were granted a day off so got to relax, and for me that meant I had the chance to tackle a little project that I had acquired as part of a job lot from a long retired watchmaker that had been sitting around in a shed for about 35 years (the job lot, not the watchmaker). Pocket watches are not usually my thing although I do own and use a couple. Orphaned pocket watch movements are even less my thing; but this little baby was in such a state that I couldn't resist the challenge. I don't think I have ever attempted to resurrect anything in quite such a sorry state as this before but it wasn't all bad. The balance was free and with sufficiently little end shake to hint that the pivots were not broken. However, the accumulation of dirt and dried grease obscured just about everything else. The inner coils of the hair spring also looked to be completely filled in with rust/gunk. With the balance cock and balance removed things got a little more interesting. Underneath the grime is a rather nice English Lever escapement with cap jewels on both the pallet and escape wheel pivots. A good sign, but I need to let down any power in the mainspring before I go any further, which means flipping it over and removing the dial as the keyless works are dial side. Not quite so bad under here as the dial has kept the worst of the dirt away. You can see too that both ends of the pallet and escape wheel pivots are capped, and the click spring is a proper cut steel affair, not wire. There is worrying evidence of rust on the steel work though. With the power let down the pallet and escape wheel cock is removed and you can now see the English Lever escapement in all its (rather grubby) glory. What a mess, but through the gunge there are just little hints of quality watchmaking peeping through; the thickness of the 3/4 top plate, and the cut and form of the teeth on the wheels. The top plate comes off taking the entire train and barrel with it as the pivots are seized in their bearings. The main plate is a mess. The under side of the top plate with the train still in place. The barrel has vacated its bearing revealing rust. Not a good sign but it could be worse. The train now removed from the top plate and dropped back into the main plate for a reference shot. The set lever and stem retaining bridge do not look healthy. Again though the set lever spring is cut steel, not wire. Oh yuk!!! The main plate now stripped. The barrel lid, with another nice touch; Geneva stop work, designed to only allow the central portion of the springs torque curve to be utilised thus reducing isochronism. Main plate, top plate, and escapement cock ready for cleaning. Ok, so whilst I was stripping all of this down, the hair spring, removed from the balance has been sitting in some Cola. The result is that the rust has softened and with a little careful tweezer work with a pair of Dumont #5's, most of it has been dislodged. The terminal curve of the Breguet over coil is badly out of shape due to a mishap when trying to unpin it from the rusted steel stud. I'll sort that out later. For now it's back into the pop to see if I can get those coils a little cleaner. Everything cleaned and ready for reassembly. I have a couple of spare jars for my cleaning machine and when I renew the cleaning solutions, the old stuff is kept in the spare jars. Any really heavily soiled movements get a "pre-wash" in the old chemistry so as to prolong the life of the new. With this watch everything was washed in the old gear and then very carefully gone over with peg wood, a G/F scratch brush, and tooth paste on a cotton bud in order to remove all of the staining that the bath didn't touch. All the jewels, bearings, and pinion leaves were also pegged out. Then it all went for another cycle through the old stuff before going through a normal cycle through the fresh chemistry. Main plate dial side prior to reassembly. And train side. Scrubbed up quite well I think. Stem, winding pinion, clutch, and stem retaining bridge reinstalled. Set lever and spring back in place. I haven't removed all of the rust pitting from the stem bridge and the set lever as it was too deep and to take it out would alter the shape too much, but it has been stabilised. The reassembled barrel and Geneva Stop work. I have reused the old main spring for now but made a note of its dimensions in case I choose to replace it. Another (gratuitous) shot of the Stop work as I just love it :-) Barrel and train back in place and things are starting to look fairly healthy. The top plate goes on. Quite a difference compared to the strip down shot from the same angle. The keyless works back in place dial side. And the balance, with reshaped and re-pinned hair spring goes back into place. After about half a dozen attempts to adjust the beat, removing the balance from the cock and turning the hair spring collet each time, and she comes to life!! Everything back in place dial side. And the cleaned up dial goes back on, complete with (broken) hands. And if you ignore the rate error for now (I need to re-pin the hair spring a little shorter), it's actually not a bad performance. As I said at the outset this was a challenge for challenge sake. I really enjoyed doing it and have learned a little bit about quality English watchmaking from the days when we were really rather good at it. I have absolutely no idea what to do with it now though although I want to try and find a bit more about it. Here is what I know; The name on the dial is T Donkin. There was a T Donkin watchmaker in Scarborough but I have no dates (yet) I'm guessing somewhere between about 1890 and 1910. It is a 19 ligne, 19 jewel English Lever escapement movement with capped balance, pallet, and escape wheel pivots (diamond on at least the balance top pivot). It has a screwed, split bi-metalic compensating balance, Breguet over coil hair spring, and Geneva Stop work on the barrel, and a 16200 train. A technical spec that suggests that it was of a reasonably high grade for its day. I still have a couple of issues to address though, the most problematic of which is that it has a slightly bent balance staff pivot. I decided not to tackle this on this occasion as the risk of breaking it whilst trying to straighten it was too great and I desperately wanted to see it running, but I may have a go in the future. I will re-pin the hair spring at the same time to get the rate up to where I can regulate it properly; it is currently about 25 minutes a day slow which is way beyond the range of the regulator. I also need to re-attach one of the dial feet and source some new hands. Then of course there is the question of recasing it. If you have made it this far then thank you for indulging me :-) I hope you have enjoyed it. If anyone can shed any more light on this little old lady I would be very grateful.2 points

-

I love looking and watchmakers bench's and the tools that are used, it seems to say alot about a watchmaker and his work. This is my work bench at the moment. It's a regular computer desk elevated with risers to about 35 inches, just under 3 feet. As I'm just starting out I know my tools will have to gradually change to better quality than the Chinese tools that I mostly have....what's on your bench? Sent from my SM-N920T using Tapatalk1 point

-

1 point

-

.....with a face only a mother could love. i picked this up in a lot of five watches. this watch was the reason that i bid on the lot. it's a typical seventies, conspicuous consumption, bigger than life watch. i wonder if something else goes around the face of it - an insert of some kind. i'm not sure. anyway, it is not attractive - which is why it attracted me. it has a blue dial which is pretty much perfect - as is the case. there are no large dents in it and it still has very fine brush marks on the finish. it has lead an easy life. which makes me the madder that someone messed with the caseback. i can't tell the year of manufacture because someone sterilized the case back. so i popped it open figuring that the innards would be a mess and got a pleasant surprise. this movement shined like the sun. the pics don't even do it justice. it's almost a pale gold color. very attractive. it seems to have a low beat to it - like it needs a good cleaning or something. anyway, here it is. i'll post more pics when i clean it up a bit.1 point

-

I only lube normal mainsprings not auto mainsprings. I read somewhere not to so I don,t. However I do lube the barrel rim of the auto,s. with a non slip grease. Also when fitting a new mainspring these require no lube as they already have some sort of lube on them I think I read somewhere it is a teflon coating.1 point

-

Hi I've been working or shall we say playing with pocket watches over thee last couple years. Not much choice about oils but it seems as a general oil "Clock oil" for most parts that come into contact and Möbius for pivots. Though always remember No oil is better than too much oil. Sent from my Lenovo YT3-X90F using Tapatalk1 point

-

That is very sound advise from Geo and the proper way to do front loaders! Also, check the back, from the picture it seems that there is a ring holding down the dial. There also seems to be enough room to extract the movement and dial. Sometimes, there is a ring in the back that either turns or the movement turns (rotates) and allows for removal from the back only in a certain position. In your case, that ring may be in the way of the dial so it may come out again by rotating (and unscrewing it ) completely. In any case, let us know how you fare! Cheers, Bob PS. Looked again and I think that indentation on the first picture, on top, -- looks like a semi circle,-- that is where a ring or (usually plastic) "adapter" is fit (by pressure) to hold down everything. So, there may not be any need to rotate anything. It all should come up after it is dislodged from that indentation...or maybe it is the ring we were talking about before! :)1 point

-

Nice one Joel! Quite agree CB. Mind you, some serious bunfights have broken out on other forums regarding the pros & cons AM parts, but what else can you do if the original parts are no longer available? Even Rupert Gould had to make 'AM parts' to restore Harrison's clocks back to working condition. The main point is - if you sell it make sure you are honest about the AM parts used (unlike some on fleabay).1 point

-

CW, assuming your watch is derived from the "Amphibia" the wibbly wobbly crown is perfectly normal and is a design feature aimed at isolating the movement from shock. If you Google Vostok Amphibia there are some interesting articles out there about its design and history.1 point

-

Ok, little update - I have "won" the buler century 2000 watch as posted above (massive thanks) as the crystal measurement seems bang on. Was going to attempt to change it myself but I think I'm going to find a local watch repair shop and have someone else who is somewhat more skilled than I! Just need to find somewhere now! Thanks again for all your help/pointers, much appreciated.1 point

-

Maybe, but not me, CB! :) There are also other oils out there I believe used depending on material of drum or if the spring is for an automatic or if you are putting it directly on the drum before the mainspring or if you are putting it on the mainspring after it is in the drum or... well, too many options. What CB says is the most practical way for me and it works perfectly! Cheers, Bob1 point

-

I use Moebius 8200 & it seems to work well. Many will have different ideas I expect.1 point

-

You are right Andy, 2 or 2.25 may be "general use" if you would. I use the closer magnitude they make to 4x -- I think it is No. 10 -- to do certain things...for inspection I agree with transporter, a 10x or higher loupe may be in order!1 point

-

Hi Joel, You are "The Man"! :) Never enough walkthroughs my friend! I, for instance, would be interested to know about the dial and hands procedure you used to restore them, as well as more details on the movement disassembly, lubrication and assembly itself. What you had to tackle to make it a beauty again, or I'd say a working beauty. And don't forget to comment on what you could do better next time if you had the opportunity or where/how, if applicable, you got/built the missing/useless parts? I don't know, I'd like to go along your experience and enjoy it as much as you did! OK, that's a lot to ask, just do your best and remember, whatever you can do, we really, really appreciate it! Thank you in advance and Happy New Year to you and all! Cheers, Bob1 point

-

Nice job! ...but we need more details of how you did it! :D It is a beautiful watch and the pride to wear it -- because of your efforts -- is priceless! Cheers, Bob1 point

-

Nice watch and a good job you have done Joel. It too is one of my all time favourite chronograph so. :)1 point

-

You left it next to your favorite pin vice, in that draw, you know the one.1 point

-

1 point

-

This is mine - it's a secretaire that's reasonably high. I sit on a drummer's stool which goes reasonably low. Nevertheless, my neck is screaming at me for a better solution...1 point

-

1 point

-

That bench is awesome! Those armrest look very comfortable...nice setup RCDesign.Sent from my SM-N920T using Tapatalk1 point

-

Thanks SSTEEL, you have a great setup and a great amount of tools, I can't wait til I get to that stage. I do have a bench buffer that I just got, but I'll need another table for that and more space...another table means more tools and I don't have a problem with that. I find more satisfaction in buying tools than watches! [emoji106] Sent from my SM-N920T using Tapatalk1 point

-

Looks like a great start. I too have office desks, they used to be in a L shape format, but having just moved apartment due to renovations, I was unable to set up my workspace the same as I have been accustomed to, so had to put them side by side. I do plan on raising the height of these too when we move back, I have some extender legs salvaged from an old sofa. Untitled by Micky Aldridge, on Flickr Almost set up in temporary apartment by Micky Aldridge, on Flickr1 point