Leaderboard

Popular Content

Showing content with the highest reputation on 04/22/25 in all areas

-

That’s a nice idea, But i’m committed to providing this site as a gift to the watch repair community as my thank you for my incredible life i’ve had in this business. Ive done well and unless my financial circumstances change then i’m more than happy to foot the bill. If circumstances do change then be assured that I will make an appeal. For now, I’m comfortable with the way things are and I am extremely delighted to remove Google Ads from this site and to stop Patreon, it feels like a major step forward Sorry, I missed your reply, I got blinded by another poster in this thread. Yes - I can confirm that I have always seen WRT as a not-for-profit website, and therefore - not a business as such. I’m lucky and have done well in my life due to a decision made in my teens to start a watch repairing apprenticeship which has sustained myself and my family for many years now. Consider this my small way of paying it forward. Ive been committed to keeping the site alive on a technical and financial level for over 10 years now and I have zero plans to change that. Thank you for your kind words by the way. And as for your wish - nobody can control what happens in life, if something happens to me I have things in place with my family but I’m just not comfortable talking about my personal business - I wish a certain person would respect that, but i’ve calmed down now - i’m only human10 points

-

I have only been a member for six years & I have found this a very friendly forum although I don’t have anything to do with watches not because I don’t like watches but because I have gout in both hands so my dexterity isn’t very good, I restore torsion clocks & occasionally other antique clocks also at 72 my eyes are not what they used to be, that is why I only post on the clock forum & the lathe forum mostly . As others have said Mark it is much appreciated that you are willing & able to do this. very many Thanks Dell5 points

-

WW is 50mm exactly. Levin, Derbyshire, Leinen, Boley Lorch and I'm sure most others making machines based on the WW standard are all 50mm. Marshall/Peerless are 2", or 50.8mm height. Many lathe beds are slightly relieved in the center, so it could be possible to swing something a little over 100mm. More likely is the auctioneer had measured with a tape measure and called it 4" when it's like 98mm.4 points

-

3 points

-

an investment in assortments most likely from a seller like Ebay will be a good choice, I have seen several this month already sold, or a donor if your supplier does not carry something suitable....3 points

-

This is the old/first(?) way for making a mainspring for an automatic. "Evolution-wise" it is an logical first step forward from a standard spring. Usually these are indeed replaced with a new spring with an integrated/fixed bridle. Lubrication as you would do with any automatic. Added: I can also imagine this construction was originally made to achieve some safeguard against "brute force" handwinding...?3 points

-

Thank you. I was informed it was a cheap worthless Lack watch from India. It’s in a small mens watch looks to be around 1930 odd Cleaned the movement and it’s going really well. Keeps good time. This is a great site. Mystery solved. I’m obliged.3 points

-

Wow! What a great gift! You, Mark, has been a blessing to the watch repair community and has inspired a lot of watchmakers and hobbyists, including me. More power to you!3 points

-

Hi all, I did ad the Google Adsense program to this site quite some time ago in order to attempt to reduce some of the costs of this site - which it did. I never did enjoy the look of the site clustered with ads and all sorts of tricks Google plays in order to garner clicks. In fact I hated it. Yesterday I decided to ditch Google Adsense and remove all ads from the site with immediate effect. I hope this will help to make the site more enjoyable and, hopefully, even faster loading.2 points

-

Try to get one with the centering pin. They are often missing.2 points

-

You're right. My first measurement was done using a guessometer (calipers). My 88,8mm diameter faceplate just clears a 5,6mm stack of gauge blocks. So: exacly 100mm. The relieved center might indeed give you a bit extra. But, stepping a bit: It wouldn't make sense for a faceplate manufacturer to make a faceplate that wouldn't fit most 8mm lathes. So 4" is not very likely.2 points

-

your best approach is to measure the current crystal and find a replacement at an online watch parts supply.2 points

-

I'd just use a standard case back hand tool with either some Kapton tape or the silicone paper from the back of a label as protection.2 points

-

The ones I have opened also do not have a pry point , hence the reason for the tool. The watch is clamped in the tool and a blade is screwed into the seam, the blade being chamfered lifts the back then the screw shaft is turned and the back comes off have a look on Ali express for case back removal tools2 points

-

Thanks, Mark. That's the kind of reassurance many of us wanted to hear! Yes, life is unfortunately unpredictable, and it would be a shame if the many dedicated WRT: ers became stranded if, god forbid, something happened to you and WRT stopped working.2 points

-

For me the text looks too aligned and with no obvious way to grip as a screw back.2 points

-

Yes that's the type @watchweasol is referring too but I don't like them as you don't get any feel to what's happening.1 point

-

Sorry, no sales are allowed on the forum by the rules so we do not have a classified section or similar. Tom1 point

-

1 point

-

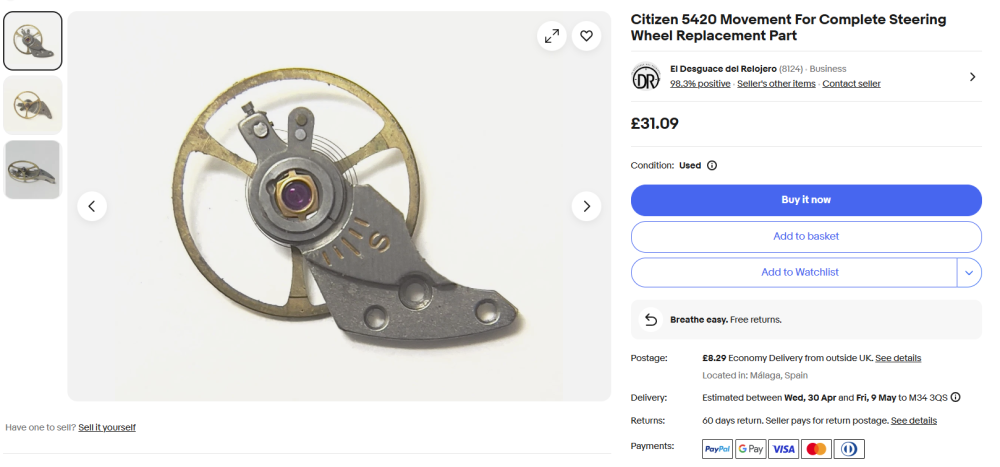

Look for Citizen 5400, 5410, 5420, 5430 & 5470 as members of a family. 5400 is likely to be the base caliber. Balance complete of any of above calibs would fit other variants. Normally most parts of the base calib interchange with all members of the family. Regs1 point

-

I measured the Reform, and yes it is >50mm; somewhere between 50.5 and 50.7mm. This is measured using pieces of bar stock resting on the flats of the bed, under the lowest point of the faceplate. Still not enough for clearance on dia. 4" though. If the axis of the headstock were centred over the bed, then the channel in the middle would allow a fraction more clearance, but it's not, not on the Reform anyway. Buy low, sell on ebay!1 point

-

1 point

-

Both my ww lathes are a tiny bit over 50mm, so I guess 4" should just work. And, if needed, using a bigger lathe to reduce the diameter is easy.. If they're cheap: go for it!1 point

-

These are quite common. I don't know how that make the groove. I always use Fixodrop on the cap jewels to keep the oil in place, so the grooves aren't needed.1 point

-

Yes - that type of jewel does exist and you will encounter it from time to time. I believe the groove cut into it provides an oil barrier, so lubrication cannot flow out away from the pivot. I have no idea where replacements could be bought if you needed one though.1 point

-

I will email them to ask for an accurate measurement; they held an in person lot viewing a few days ago that I could not attend. There is so much I don't yet know, I could not assume that no 8mm lathe exists with a spindle height >50mm.1 point

-

By the way, I opened my watch, looked under a magnifying glass, there is simply no grease, the screws are without traces, the slots are intact.I think it's just a matter of maintenance.there are no rotor marks on the body. And to remove the strap from yours, just press on the 1st side,and slightly move the strap, then on the other side and it will come off.1 point

-

Agreed, this is puzzling. Can you ask questions or inspect the lots before bidding? My Boley & Leinen Reform face plate is dia. 95mm exactly. It's possible that 4 inches is a slightly too large approximation, but why then make the distinction to 3 11/16 for the sake of 8mm? If the larger ones are truly 4" then they will clash with the bed, but then I have no idea which 8mm lathe would take them. All 8mm lathes have spindle height 50mm or less, as far as I know. The spindle height is, as you say, standard 50mm for W.W.1 point

-

In tandem with my last post regarding the removal of Google Adsense on this website - I have also decided to fully self fund this site as a gift to the watch repair community of which I’ve been a member of, and have benefited from since being extremely lucky to gain an apprenticeship back in the late 80s. Well, that means that I have also closed down my Patreon account - or, to be clear, stopped all future transactions on my Patreon account and this is with immediate and permanent effect. not to mention, but I will, I really really do appreciate the contribution all my patreon and PayPal supporters have provided over the years, you guys have been absolutely awesome and helped to keep this forum alive and available for those who might not be able to afford the payments. again, from the bottom of my heart thank you.1 point

-

Hello Vessel18 and welcome to the forum , a place to stay and enjoy. You are starting out. In the right place with Marks course. A little additional reading for you TZIllustratedGlossary.pdf TM 9-1575.pdf1 point

-

On can only concur with Joel’s comments, where else can you get such inspiration and help. A magnanimous gesture indeed. Thank you1 point

-

Hi it’s probably a snap back. I have found Tissot backs very tight and need a case back tool to clamp the movement and pry the back off. Conversely you will naad the case back press to get it back on again. Both on eBay or Ali Express.1 point

-

If the Venus 175 hands fir then hands for the sea-gull ST1901 should fit too and be available on Aliexpress. Sea-gull bought the Venus 175 tooling and rights to make the sea-gull 1963 military chronograph. Tom1 point

-

Hi @APD , welcome here. You should start your own thread for your introduction. Regs1 point

-

I’ve sent you a link to a supplier that has the hour reset hammer in stock. Hands for Breitling Venus 175 watches seem to be easy enough to find and the running seconds hand will fit the cal. 178. Mark1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

If they don't give enough movement individually then just bend a piece of wire or rod so you can depress them together.1 point

-

They are just drilled lugs, so poke one side with your pin end of the spring bar tool and you should get enough to misaligne it and if needed do the same to the other side. Tom1 point

-

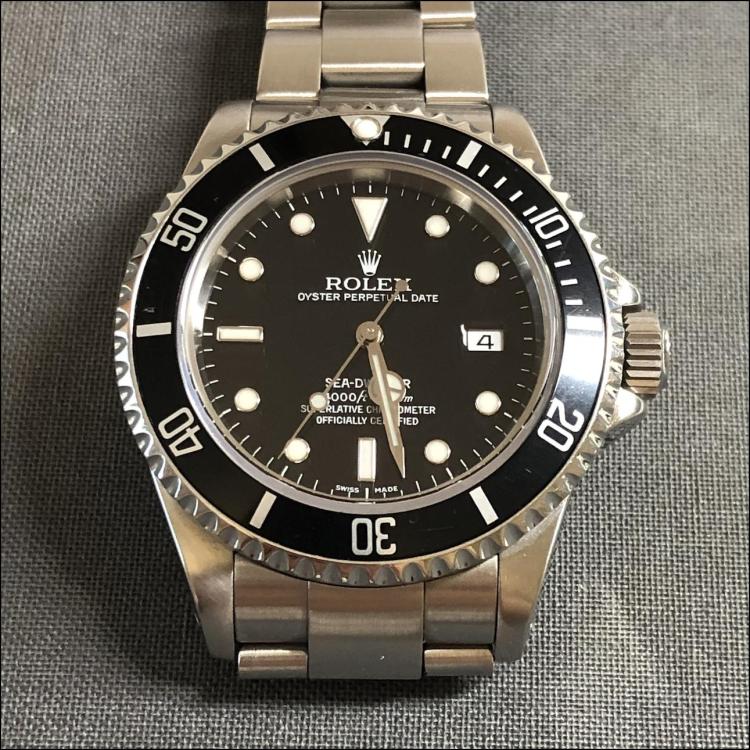

Super excited to share that yet another Rolex has landed on my bench — this time a Sea-Dweller, ref. 16600, equipped with the trusty calibre 3135, same as the last one I worked on. It seems to be running smoothly, although I haven't measured it on my TMs (PCTM/Weishi 1900) yet, but the time and date settings are completely dead. My first thought is that the yoke has slipped out of engagement with the sliding pinion. It could also be something else, of course! Haven’t had a chance to crack it open yet, but I’m itching to take a closer look sometime this week. Anyone else seen similar issues on the 3135? Would love to hear your thoughts before I dive in! Oh, while I'm at it. The lugs are drilled, but it looks like a very tight fit. Before I try it. Can the bracelet be removed w/o pressing from both sides simultaneously? If not, how can or should I go about it?1 point

-

WRT feels like a second home to me, and I’m sure I’m not the only one. That’s why we care so much about making sure it’s seen as something bigger than just Mark and us users. Companies don’t rely on one person, no matter how great they are, because life happens. You know — don’t put all your eggs in one basket. When I started my own business, I lost a lot of gigs because clients worried what would happen if I got sick. Teaming up with a competitor to cover for each other made a huge difference. Right now, WRT is the company, and Mark is our brilliant, irreplaceable consultant. It would feel a lot safer if there was someone who could step in if needed. That’s my only little wish. Otherwise? Nothing but love for WRT and everyone here.1 point

-

The screenshot was poor https://www.mikrolisk.de/show.php?site=280&suchwort=A&searchWhere=trademark&searchMode=exact&id=31 point

-

a unfortunate problem of watchmakers is watch companies not explaining why they do things. the practice of oiling the pivots is not unique to all watches. I've seen it on Seiko watches for instance a lot of the quartz watches you'll do that because you can't see the pivot on the other side there is no oil sink. Or some other watches they actually use grease rather than a oil and they do say that the grease won't flow if you oil in the jewel you have to put it on the pivot the other reason for all of this may be that if you look at the side view this is really thin module and the one side presses against the other watch movement and if you were to put oil in oil sinks they may be concerned that the oil is going to run down into the other module. So they may only want the oil sparingly placed on the pivots and not flooding all over the universe but that's a speculation1 point

-

Ahh the DD modules. I havent done one of these for about a year, but when I did it, I followed the service guide and got it within spec. Do you have this? Ive attached it for you and any others who might need it.Omega 1140.pdf1 point

-

As Hector has told you, the battery in it is a cheap unreliable one. Before you think about changing the movement, try fitting a better quality battery. Silver oxide is the norm you often find in a new watch, usually the brand Renata. If I remember correctly Energiser batteries come on top in best battery reviews.1 point