Leaderboard

Popular Content

Showing content with the highest reputation on 04/21/25 in all areas

-

WRT feels like a second home to me, and I’m sure I’m not the only one. That’s why we care so much about making sure it’s seen as something bigger than just Mark and us users. Companies don’t rely on one person, no matter how great they are, because life happens. You know — don’t put all your eggs in one basket. When I started my own business, I lost a lot of gigs because clients worried what would happen if I got sick. Teaming up with a competitor to cover for each other made a huge difference. Right now, WRT is the company, and Mark is our brilliant, irreplaceable consultant. It would feel a lot safer if there was someone who could step in if needed. That’s my only little wish. Otherwise? Nothing but love for WRT and everyone here.6 points

-

Hi all, I did ad the Google Adsense program to this site quite some time ago in order to attempt to reduce some of the costs of this site - which it did. I never did enjoy the look of the site clustered with ads and all sorts of tricks Google plays in order to garner clicks. In fact I hated it. Yesterday I decided to ditch Google Adsense and remove all ads from the site with immediate effect. I hope this will help to make the site more enjoyable and, hopefully, even faster loading.5 points

-

4 points

-

In tandem with my last post regarding the removal of Google Adsense on this website - I have also decided to fully self fund this site as a gift to the watch repair community of which I’ve been a member of, and have benefited from since being extremely lucky to gain an apprenticeship back in the late 80s. Well, that means that I have also closed down my Patreon account - or, to be clear, stopped all future transactions on my Patreon account and this is with immediate and permanent effect. not to mention, but I will, I really really do appreciate the contribution all my patreon and PayPal supporters have provided over the years, you guys have been absolutely awesome and helped to keep this forum alive and available for those who might not be able to afford the payments. again, from the bottom of my heart thank you.3 points

-

3 points

-

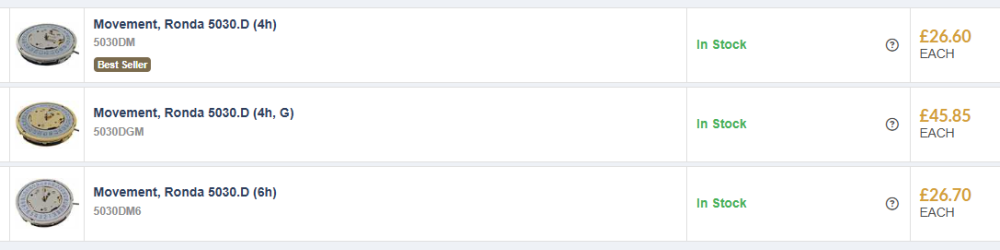

Welcome to the forum. The sticking could be corrosion of a build up of old oil. Not sure what you mean about not being able to find one with the same dial as the movements come without a dial. As with all posts, photos will help along with where in the world you are for sourcing parts. Here's the selection available from Cousins here in the UK.3 points

-

3 points

-

Good evening, introducing myself to the forum as someone currently working their way through Mark’s course and thoroughly enjoying learning stuff in this fascinating world!2 points

-

Ha! Okay, I also misread that. I had already go over to search for twenty dollar Cartier tanks on auction...2 points

-

No, I knew it wasn't a Cartier, Cerlies on the dial. Manual wind, incabloc and 17 jewels and I'll be more than satisfied.2 points

-

Looks good Richard, I really like tank watches. Oris made some decent mechanical tanks.2 points

-

I've never heard of this . I've never had a problem - but my winders aren't Ber££eon. I just checked the depth of my 10.8mm winder as 1.4mm Why not just put a washer in the winder?2 points

-

If they don't give enough movement individually then just bend a piece of wire or rod so you can depress them together.2 points

-

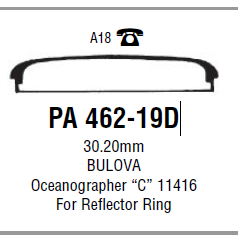

Have a look here at what parts differ from the 7J & 17J https://www.emmywatch.com/db/movement/caravelle--11do/ There's also this. Bulova Interchangeable Parts Catalog.pdf2 points

-

Books, or some sort of voucher to a material house if they do them. You can never read and learn enough and if you find a material house that could do a gift card then the person could pick things they really need. Tom2 points

-

No Mark it does not offend me. I think I have already started another thread on the matter before you replied. But since you are unwilling to discuss it with us, I will discontinue posting there. Thank you for considering it though. That's a good policy to have H , you should always safeguard yourself. Knowing who you can trust and who you can't is not a permanent thing. People's values change, people change and adapt to their situations,thats just nature stepping in and running the show. Not everyone is as genuine as you are H. The new no advertising looks much better, it never bothered me much, but it still feels cleaner. I'm pleased that your thread regarding the missing images was also returned, so thats good news as well. It appears a lot of mine have also been removed ...oh well...2 points

-

Long story short, I reinstalled OneDrive on my computer, and I suspect that's when things went south. Anyway, I have updated the first post in this thread with links to the disassembly and assembly pictures.2 points

-

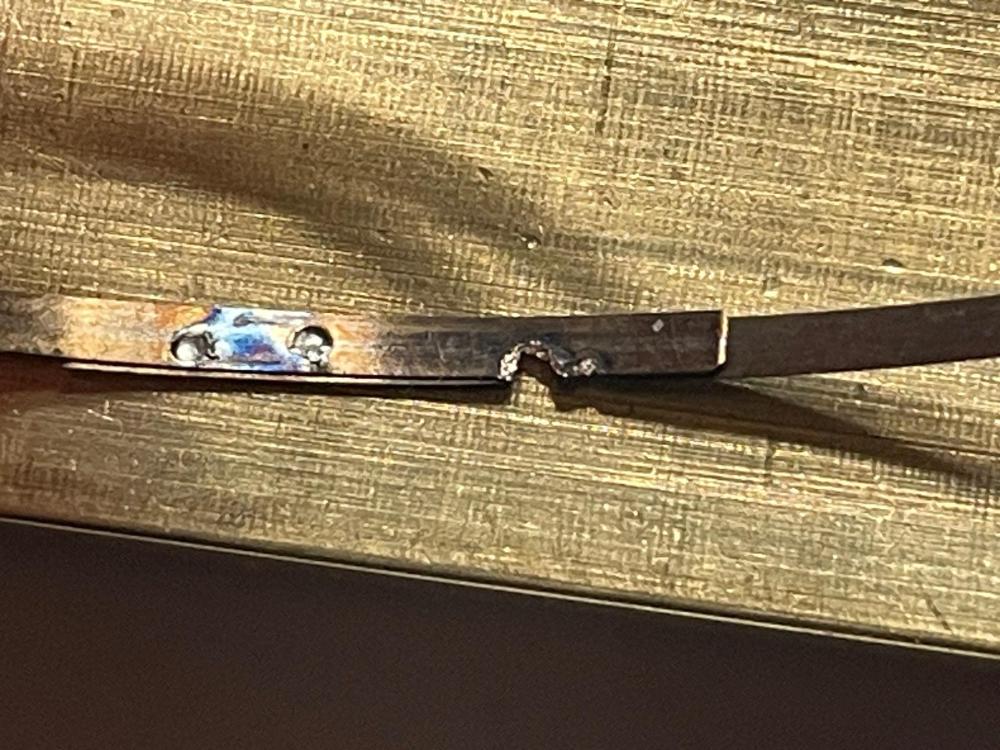

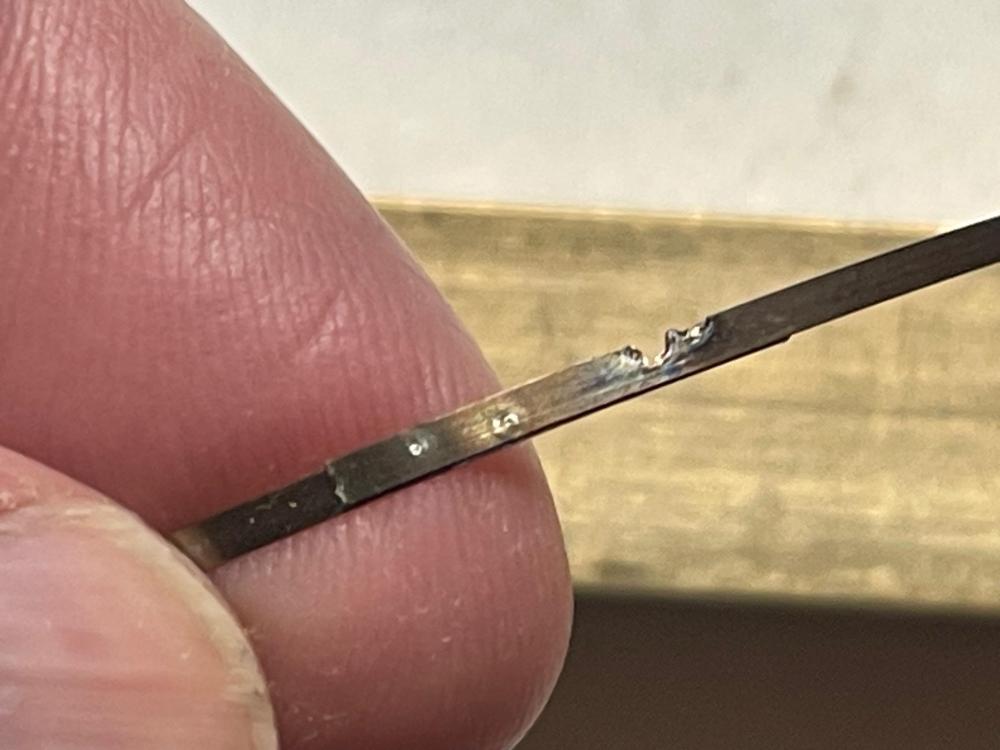

I've tried some supposedly good battery operated spot welders - the ones I had were a waste of time for anything above thin foil. I ended up with a supercapacitor based one & that does work really well on the stuff I've tries so far. I'll try it on a broken spring and see how it works on that material!2 points

-

As a result of this thread, I was able to successfully reinstall the KIF UltraFlex shock spring. As stated above, patience and a piece of Rodico are your friends. Thanks again.2 points

-

The screenshot was poor https://www.mikrolisk.de/show.php?site=280&suchwort=A&searchWhere=trademark&searchMode=exact&id=32 points

-

Hello everyone, I've been bitten by the watch repair, appreciation bug. Originally I was following Wristwatch Revival with Marshall Sutcliff, and have grown to follow Mark Lovick, Spencer Klein among others. I've tinkered a bit with watch disassembly and repair, with some luck, but mostly as a learning experience. I enjoy being able to take things apart and put them back together. I even restored a 1964 Vespa scooter. I hope that this community can help me out with some questions and resources as time goes on. I look forward to connecting with you all. Thanks, Josh1 point

-

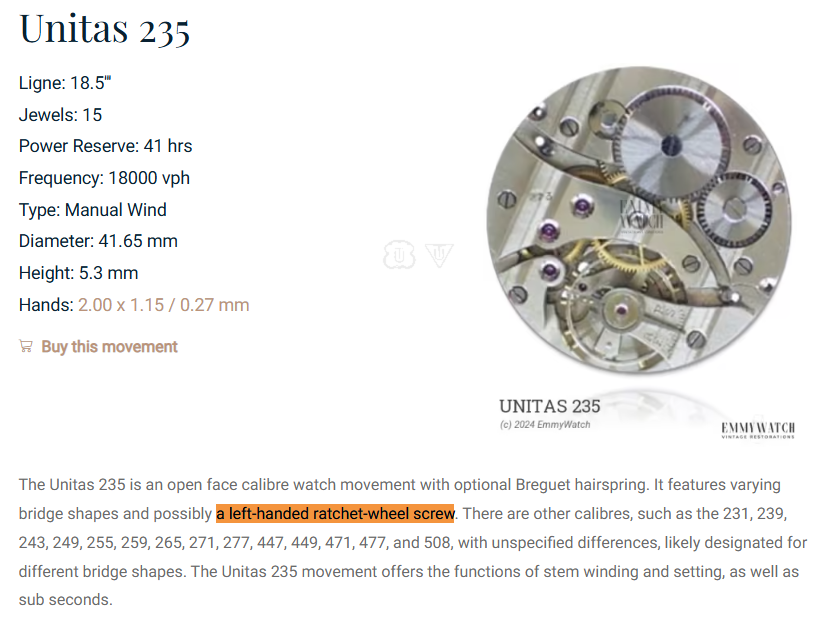

First time poster with a rookie error. I managed to shear the head off a Unitas 235 ratchet wheel screw not realising it is reverse threaded on this movement. But now I can’t source a replacement. Any ideas or pointers to sources I might not have come across? Cousins has the part listed as ‘discontinued’. Is there a suitable alternative maybe? Thanks in advance.1 point

-

Hi, My name is Alan, and I am very interested in gaining more knowledge about watch restoration. I have been cleaning and replacing movement parts for over a decade, gaining knowledge as I go along. To date I have over a hundred watches that I have purchased along the way mostly 1930s-1960s with Swiss movements and are back in working condition. However, the more I learn, the more I realize what I do not know. I am joining the forums to learn from others with more experience. My goal is to bring vintage pieces back to life as best as I can. Here is a Landeron 48 I rebuit with a NOS dial as there was extreme damage to the original dial.1 point

-

So i had heard from most of the people here that seiko mainsprings being very short in height are really a challenge to use in winders and seem to just randomly get eaten by them. I got my winder, used a worn out old test spring to practice and sure enough it got eaten. Decided to yolo it and test it on on another practice spring, it went as planned and i did it three times in a row with no issue. Since then i've serviced 3 barrels, no issue with the winder. Fast forward a year or so i'm back working on watches and i cannot for the life of me get the damn thing to work. I'm at 3 mainsprings eaten in a row now, one of them brand new. This is starting to get expensive. Mark back when he posted here would fervently say never pack a mainspring by hand as it takes it out of flat, damages the barrel yadayada. I see him and other professional youtube watchmakers with ease wind these short seiko mainspring winders by hand, what am i missing here?! The issue is of course that these mainsprings have a very short height, so once you put them in there's two directions they want to unravel in randomly, if you press hard on the top as you wind and slightly depress the plunger , it can keep it in a coil....but then you need a hand to put the bridle. If you release the plunger or turn the crank it unravels, so that's one more hand than i have that seems to be required for the job. Does anybody have any tips to use these things and avoid this? Watching him do it he's not pressing on the plunger that i can tell yet his mainspring doesn't try to uncoil itself in the winder like mine and so many people's here do.1 point

-

Sorry, by thinner I meant thinner in height. As I suggested, just put a suitable washer in the winder, and problem solved1 point

-

Hopefully, if not, it's going back. Only payed circa £23 with postage. Even so, I'll want my money back.1 point

-

1 point

-

1 point

-

@VWatchie Thanks and great pictures! Thanks to them, I have just finished my 2nd project ETA2472!1 point

-

They are just drilled lugs, so poke one side with your pin end of the spring bar tool and you should get enough to misaligne it and if needed do the same to the other side. Tom1 point

-

yes 316 stainless is what they used on these bezels. Maybe some of THESE would work, otherwise, get a 2" round bar, and turn it to your dimentions1 point

-

1 point

-

No it was ok Richard. When clicked on the picture becomes clear.1 point

-

Some links: https://www.ebay.co.uk/itm/364175859937 https://www.amazon.co.uk/Seesii-Farad-Capacitor-Spot-Welder/dp/B0DL5M2CLN/ref=sr_1_6?crid=YFXX1S2M2EV6 https://www.aliexpress.com/item/1005005736670139.html1 point

-

Half an hour later: Test done. It takes rather less power than I expected, for a fairly small watch spring at least; this measures 1.5mm wide by 0.1mm thick. The burned edge was at 20% power, through the two layers. The good weld was single sided over a brass block, at 10% power. I've been using 15% to weld terminals to lithium cells. The spot welder is one of these, bought from a UK reseller - ebay or amazon? They are also sold under other brand names. https://www.seesiius.com/collections/spot-welder/products/seesii-spot-welder-with-farad-capacitor-3000f-120-gears-adjustable It takes 20 mins or so to get up to working voltage, then a very brief time between welds - or several in a row is fine. (Around 20,000 joules [watt-seconds] energy storage; it runs from a 12V 4A PSU). WW - Simultaneous post!1 point

-

Depending on the age of the movement, the Venus 178 can be found with either a fixed or a mobile stud carrier. If the movement you’re working on has a mobile stud carrier, as seen in the image below with the blue arrow, you can move the stud carrier to adjust the beat error. It moves like a regulator arm, it rotates around the incabloc setting. Only a small movement is necessary to correct a 4.8ms beat error. You can use apiece of pegwood to make the adjustment, just be sure you don’t slip towards the hairspring. If the movement has a fixed stud carrier, indicated by the green arrow below, then of course you must move the hairspring collet on the staff to adjust the beat error. Mobile stud carrier : Fixed stud carrier : A beat error of 4.8ms isn’t a big deal. The watch will need a few extra turns of the crown to get it running, but beyond that it won’t have much impact. I would adjust the best error to <1ms, but it isn’t worth risking a damaged hairspring it if you don’t feel comfortable doing it yet I hope this helps, Mark1 point

-

Hi Mark. Thank you for all the you do for the community. I do have a question about my Patron support over the past several years and how will that effect Level 4 of the Watch Repair Course? As with other lessons, my monthly Patron contributions went towards the purchase of the next level. I believe Level 5 came out in 2022. I'm assuming that my contributions to Level 4 will have accumulated since that time and I wouldn't be charged for it when it comes out? Could you please comment on this and update us on a release date. Thank you.1 point

-

Thank you @Mark. I only became a Patreon subscriber 5 or 6 months ago, but I draw so much value here. If you come up with future contribution or support opportunities, I will be on board.1 point

-

Thanks Mark, but can we still discuss the other important matter please and not be distracted from it. Thank you.1 point

-

My pleasure. I would rather pay more than have those annoying ads ruin this site. They were a terrible idea and something I never even saw much, but I was on my iPad yesterday testing a security update for the forum software and it was impossible. I decided then - they had to go!!! Also, co-incided with this, for those who are paying for pattern in order to help fund this site - I’ve just disabled patreon. Future monthly payments will not be taken. PayPal is a little more complicated. I will try to work out how to cancel the few subscriptions but if you are a PayPal donator then please feel free to cancel the monthly sub. I will, however thank you all from the bottom of my heart for helping to contribute to this site financially - it means a lot. But going forward, I’m funding it personally from my pocket and that’s the end of it1 point

-

1 point

-

I think for the age of the watch and considering what it looked like previously I'd just leave it as is.1 point

-

Rather than rubbing with pressure, you’re far less likely to damage the dial if you use a rolling action to clean it. Wet a q-tip or similar shaped foam swab and roll it over the surface. It’s slow, but it’s very gentle. I hope that helps, Mark1 point

-

1 point

-

Can you safely detach the balance complete from the cock? Thats to keep the balance away in case of accident. 1- I usually seperate the stud & regulator arm , clean every surface involved in moving them. 2- You can just put some oil on joints then keep moving the arms ro loosen rhem , clean in ultrasonic. Either case, balance must be separated for safety . Rgds1 point

-

Often, people use the word "overwound" when referring to a broken mainspring. I.e. manually (over-)wound, until the mainspring broke. That would require a replacement of the mainspring and in most cases a disassembly of (most of) the movement. Not sure if the M24 calibre has a "shortcut" by which the mainspring barrel can be extracted without disassembling the train and escapement.1 point

-

If you've got variations occurring periodically, you can usually trace it to an issue with the wheel that rotates at that rate. This is slightly complicated in that you have a center seconds hand, so that adds a piece or two to look into. The long thin shaft of that seconds hand is where I'd start in your shoes.1 point

-

Here is how I installed one of mine. I actually found that I needed to have the jewel in the chaton or else the spring wouldn't stay level and I couldn't get it in. I use the plastic to position it and then an oiler with the force applied the long axis to snap it into place. You can see that when I first tried to apply force with the oiler perpendicular to the direction the spring needed to move, the oiler would flex. Once I came at the spring along the direction of force it snapped right in.1 point

-

I haven’t posted anything on the site for quite some time as I’ve been working very hard for the last two years. However, here is a video I made this weekend and reassembling a Hamilton pocket watch and specifically cleaning the hair spring and bounce cock jewels.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)