Leaderboard

Popular Content

Showing content with the highest reputation on 10/05/24 in Posts

-

4 points

-

1971 Bulova Oceanographer 'R'. The friction pinion was rusted to the large driving wheel arbor and after cleaning off the rust it was a little loose, so I tightened it but after assembly the hands didn't move. I stripped it down again, tightened the $#!! out of it, re-cleaned and still had the same issue. I think maybe the rust just ate enough away that tightening wasn't gonna do the trick. A donor part saved the day (along with a NOS dial, crystal and minute hand).4 points

-

It's not so much old vs new, as weaker vs stronger. A 0.01mm increase on a 0.10mm thick spring is significant. I have worked on many older, vintage, antique watches- for the factory. In most cases they wanted me to reuse the mainspring. I have compared new to old many times though, same dimensions, including steel to modern alloy, and most of the time the results were close enough to be considered identical. This is true also for steel springs that most would consider "set"- if it opens up to at least the movement diameter, it's really fine. I know there's a push to always replace the mainspring, but there's a good argument for keeping the old/original one: the fact that it has lasted for years (perhaps decades) proves it's reliable. I have dealt with far more broken mainsprings post-repair where it was a new one I installed than repairs where I reused the original. I'm quite sure this is the thinking from the Factory I did work for; in many cases the cost of the repair was well over 1k, so 10-20 bucks for a spring is nothing in the mix.3 points

-

The vast majority of vintage watches use common, lentile round acrylic crystals. These should be sized to be about 0.1mm larger than the measured opening they are installed in. These are best installed with a press with an upper die sized to fit over the outer edge of the crystal, bearing down on the sloping section towards the outer diameter. The die will tend to compress the diameter slightly (depending upon the shape) as it is being pressed downwards. You can also use a smaller diameter die (or a convex rubber or Bakelite die) on the bottom to accentuate the deformation of the crystal by pushing upwards in the middle. Then the case or bezel is lifted upwards so that the crystal fits within the bezel. Then the tension is released on the press and the crystal expands again and wedges itself into the bezel. Tension ring (or armoured) crystals are typically fitted to water resistant watches (or at least those with that prentention like compressor cased watches) These are installed with a press in similar way to the lentile crytals but they will deform less due to the tension ring being present. These are basically just man-handled into the opening with force from your press, so make sure that the case is well supported and not holding on lugs or the crown (it’s best to remove the movement while installing). These often install with a crack as they are pushed into place, so you get to slowly remove the press and check it has been correctly pressed in or you have broken it! Flat mineral glasses are the easiest of the lot. Check you have a gasket present (it might be worth replacing it anyway). Measure the inside diameter of the gasket and get the same or next biggest size of crystal. Measure the depth of the opening (or the old crystal ) to set the thickness of the glass. This is then pressed in with a die just slightly smaller than the OD of the crystal and with the case well supported underneath. Press it into position and periodically release the pressure and rotate the watch in the press and reapply pressure so that the crystal is pressed in consistently all around the diameter. This will do you for the vast majority of vintage watches you will encounter. There are more complicated pieces such as ‘top glass’ crystals that fit over the case and then have a bezel pushed down over them like an external tension ring. These are tackled in a similar approach to the others with a combination of techniques but measuring and getting the correct crystal is a lot harder. it’s definitely tricky to get the right size crystal, so I will typically buy additional crystals in the next bigger and smaller sizes. They are usually cheap and don’t impact on shipping costs if you have a few others thrown in an order so getting some ‘spares’ isn’t a bad idea. I am going to buy a boxed assortment from Cousins which has 10 of each size for the typical size crystals that I work with. That way, I will have one on hand for any typical project watch with a standard crystal.3 points

-

This community needs to vote on and then pin the post on what is the agreed definition of overbanking and what is rebanking because this thread is talking about 2 different problems. What Chronoglide calls overbanking in that video is not what H.B. Fried calls it and not what De Carle calls it. They agree on it meaning the escapement is locked with the impulse pin on the wrong side of the fork, and not about excessive amplitude causing knocking.3 points

-

Guys, if we talk about the situation when the watch has stopped with the impulse jewel outside the fork notch in zero position and it is needed to take the balance out and put it back correctly for making the watch work again, then it has nothing to do with the mainspring. The strong mainspring may be provoking the fault more frequently, but if it is able to happen, then it will happen again and again, until the real reason is rectified. And, the real reason is that the guard mechanism of the balance, which consists of the guard roller and the guard pin, for some reason and in some situation, doesn't work.3 points

-

OK, I see You advance with the project. It will be no surprise to me if You will perfectly adjust the escapement from the first attempt, I have such feeling. Yes, the pallets stones angles are pretty standard and even if the replacement pallet angle is not exact mach, usually good enough compromise is possible to do in adjustment that will give good result at the end. First, You need to correctly adjust the banking pins, and for making this You will need to be sure that the guard pin is with correct length and well centered. If You need guidance, ask. My advice is to use banking pins for reference when adjusting the pallets position. Just adjust pallets by leaving small 'run to the banking' on both sides and check what the drop lock will be. As the drop lock may differ on entry and exit pallet, especially if they are not 'pair', evaluation of the drop lock must be done on the pallet where the drop lock is smaller. Usually the result that this way of adjustment gives is good and no additional corrections are needed, but this will get clear in the process. Clean the shellac from the slots of the fork. Adjustment is easy when the pallets fit in the slots tight and stay there firm enough for the movement to be able to work for awhile with no need of shellacking. Use brass tweezers to put the pallets in slots and correct their position2 points

-

2 points

-

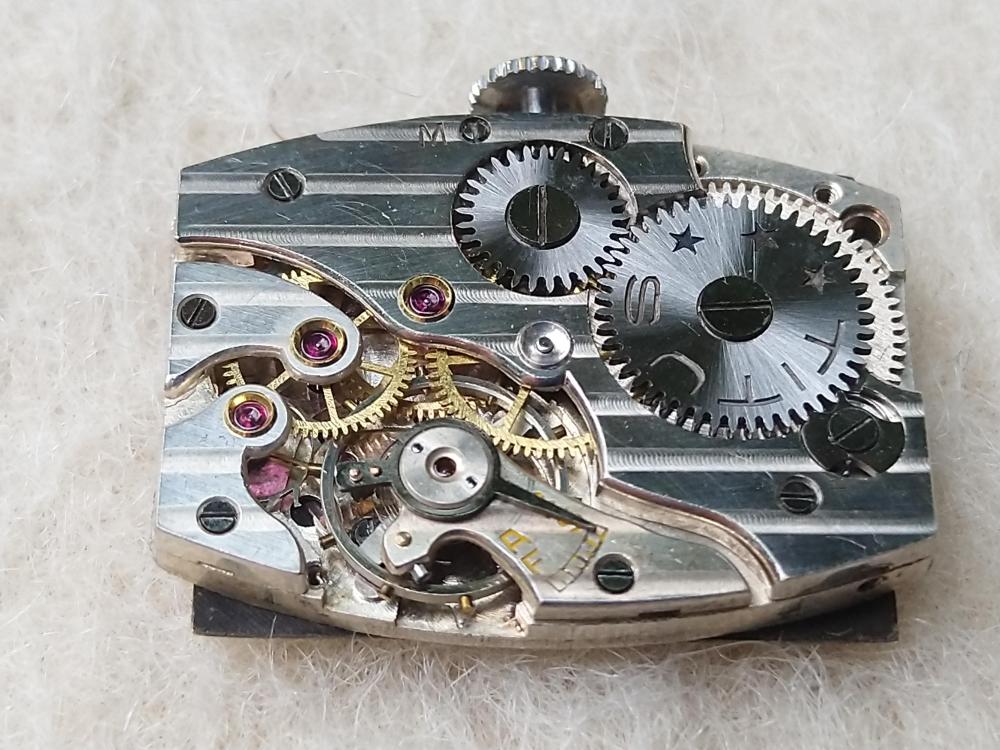

Following on with another Citizen, this example from 1972. I purchased this for the case from Bulgaria. I have a square custom movement and dial that have been waiting for a case for quite a while now, but when it arrived was too good to just swap out. I haven't seen many of these in the uk market. This one has the 5204 movement 25J while the square custom has the 5203 movement 27J. I was assuming the movements were pretty similar so I could use the split stem, but the stems are not the same. The other main difference is that the 5204 also has hacking. I have now got another case from Italy this time, but now I need the correct split stem for the 5203. The stem adapters available from Cousins are not an option, not enough space. Have been wearing this for the last 2 weeks and it has only lost around 30 seconds.2 points

-

2 points

-

What do you get from testing the movement on your TG if you don't lubricate the pallets?2 points

-

Which lift angle did you choose? If the default 52 then your real amplitude is 240 - if no other measurement errors apply. You should do the tests that John recommends, before any advice can be given. Frank2 points

-

2 points

-

sometimes I have a lack of reading skills because today I'm not seeing a number attached to just how fast you're going? Then 300° amplitude for a vintage watch how did you achieve that? then I was like to see pictures the timing machine results. Plus is dial-up and dial down identical for timekeeping and what happens if you put the watch new one of the crown positions like crown down. Then as it's a mechanical not an automatic watch we wind it up nice and tight you getting at 300° amplitude digital at the watch settle for about 15 minutes before you looked at the timekeeping? Because you usually want the watch settle a little before you time it.2 points

-

I have a degree in chemistry and words like "naphtha" and "ligroin" would cause us fits in school when we were trying to figure out what they were. We used them in organic chemistry as solvents. Most things in organic chemistry are named so clearly that you would know exactly what atoms were in the compound and often how the atoms were oriented. In any case, it's my understanding that naphtha and ligroin are created by fractional distillation of petroleum. You get molecules with a specific range of carbon atoms in the distillate, and then you desulphur the distillate. The name comes from people who are making industrial fuels and solvents and are chemical engineers and not "chemists" and so the terms are a little more squishy. And historic. That's just the perspective of someone who had to deal with those solvents in chemistry lab. I liked reading through this and wondered how to see if my solvent was too dirty. I don't want to switch it out for every watch, especially since I'm working on broken watches from ebay. Just putting a drop on a mirror is much easier than the optical scattering device I was thinking of building. I really need to find a real watch cleaner though.1 point

-

Thanks for all the responses. The movement is an Valjoux 7750 clone. The shock spring is Incabloc.1 point

-

Hi I doubt it’s a hawthorn, as the name suggests it has thorns . Well loved by shrikes for impaling its food for later like a larder. The flowers can be white or pink. The berries appear in clusters. Favourite food of starlings, thrushes and blackbirds. It is possible it’s a modern cultivar bred without thorns like some roses.1 point

-

1 point

-

I had to look this up: https://en.wikipedia.org/wiki/Crataegus_monogyna Never knew its name and I never knew that "The fruit of hawthorn, called haws, are edible raw, but commonly made into jellies, jams, syrups, or wine, or to add flavour to brandy." I only hope that I identified it correctly, I identified its name by reading the plant description, based on the shape of its leaves and compared the pictures I found about it to the actual plant. Placed two pics about one of the branch of our tree.1 point

-

1 point

-

How did you clean the fork pallets? Shellac dissolves in zippo fluid and gets washed away in ultrasonic, so you are likely to have lost enough shellac, which has let fork pallets loose thus misaligned. CHECK IF FORK PALLETS ARE MISALIGNED. Or show a top view close up of pallets in the watch. Check end shake on balance staff , fork arbour and escape wheel, in case of excessive end shakes they can be unlevel to each other and disengage in some positions. Rgds1 point

-

Hello and welcome to the rabbit hole known as watch repair, you will in time develope a (Tool) addiction. Every job needs a special tool……. Enjoy1 point

-

1 point

-

How difficult was it to put together? Have you published any of the construction details like 3d printing files? Thanks.1 point

-

There's no such thing as an X002 movement so need photos to help.1 point

-

On vintage stuff Seitz replacement pallet jewels are fine. I just measured a couple and got 102 for entry and 114 for exit, pretty close to what Fried wrote. Sometimes the length is an issue, too long and it can be trimmed on the back side, too short and they can still work but are unsightly with a large gap at the back of the slot. On rare occasions I have lapped the face to change the angle slightly, but only on really nice pieces that merited it. Practical Benchwork for Horologists by Samuel and Louis Levin shows a nice way to accurately lap the face on page 196 (link is to an archive.org copy of this awesome book).1 point

-

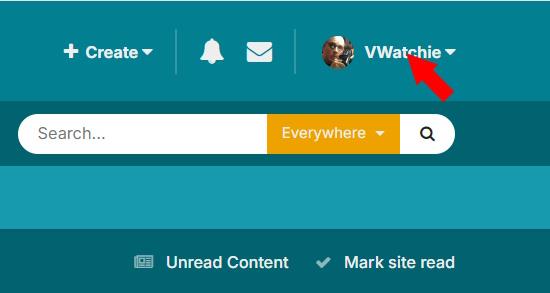

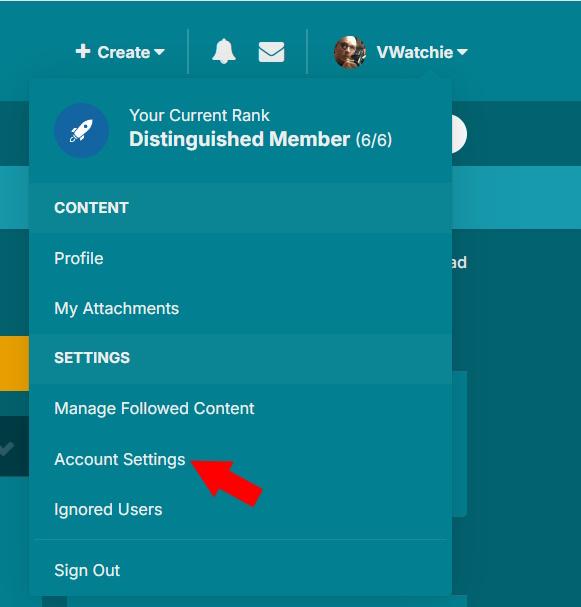

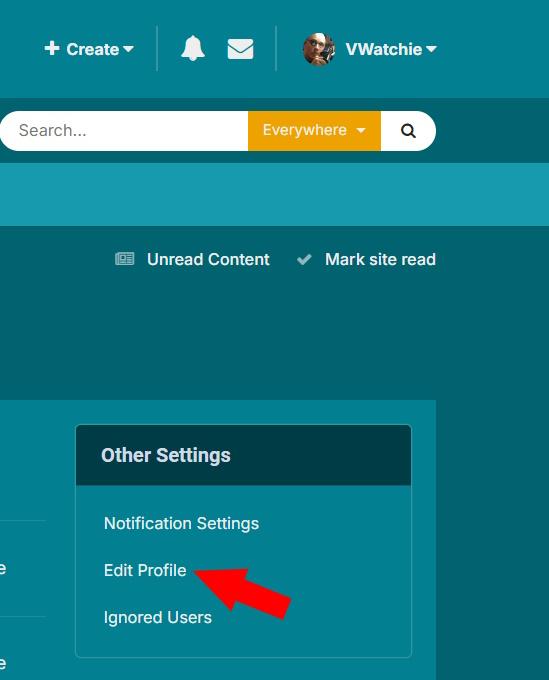

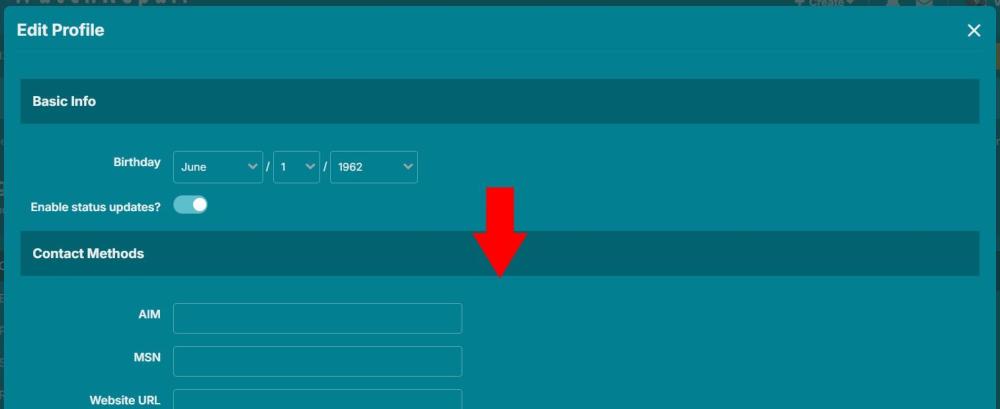

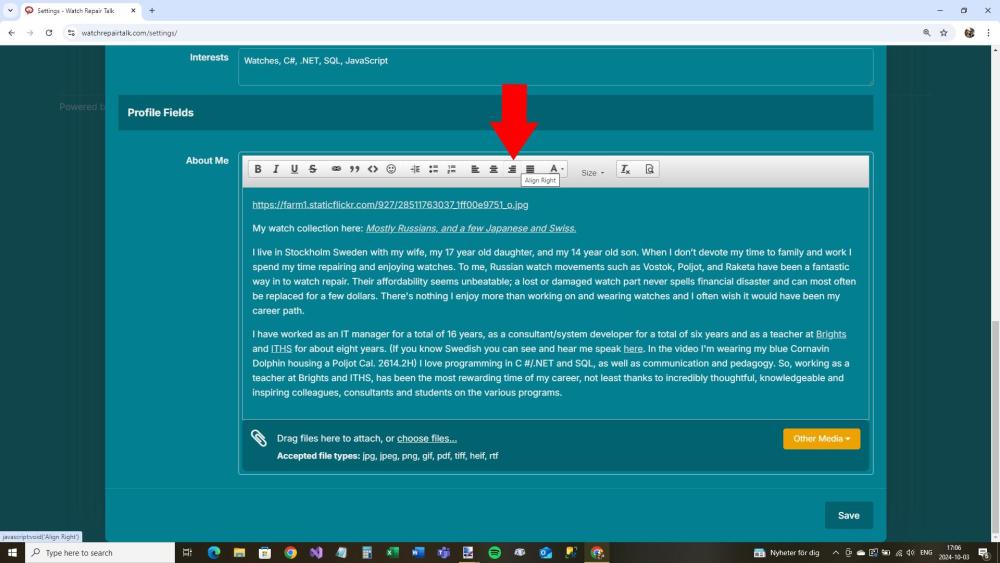

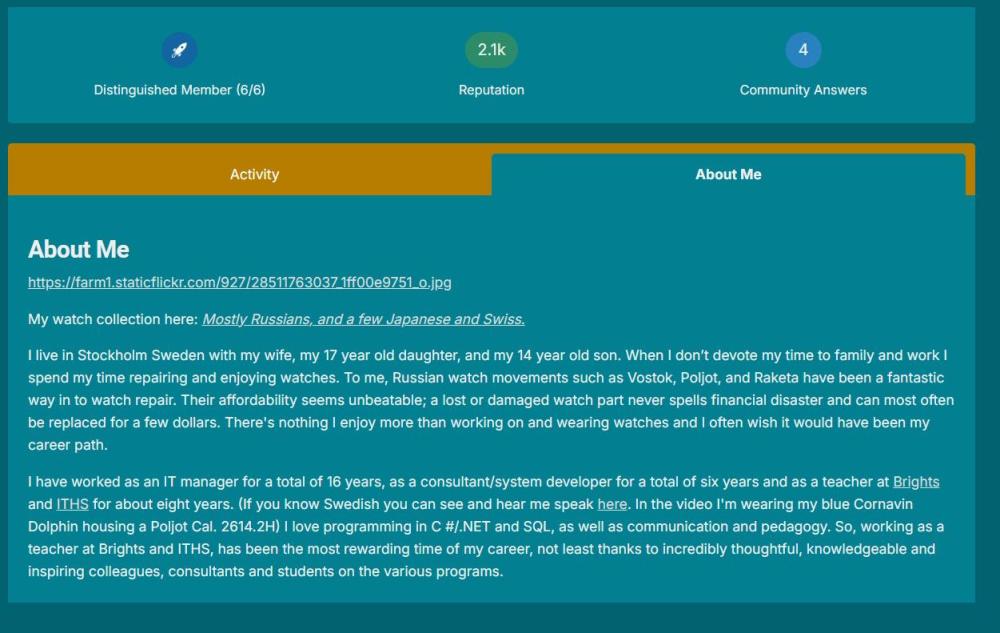

What I really appreciate is when members take the time to introduce themselves on the "About me" tab of their profile. All you need to do to write an "About Me" is to follow these steps: 1. click on your member name at the top right of the page. 2. then click on "Account Settings". 3. click on "Edit Profile". 4. Scroll down the page until you see... 5. ... "About Me" Now all you have to do is write something about yourself and then click the "Save" button. You can always go back and update when you wish to change something. Now other members can click on your icon or name anytime, anywhere, and get some information about you, which is both nice and useful. For example, you can tell others that you are a beginner, which allows other members to customise their answers for you. And once you've warmed up, just update the "About me" section. If I could make a wish, I would like all members to write an "About Me"!1 point

-

That wasn't why I did it. The train was running free with limited friction after service.i was not trying to overcome any deficiency in the train with a stronger mainspring. I did it because I thought that the mainspring was probably done for after sitting fully wound for decades and also not wanting to have to wind the mainspring back into the barrel with my Chinese mainspring winders (or more likely by hand since the winders are only suitable for maybe 1 in 4 mainsprings). Swapping out the mainspring seemed better practice than messing around with an ancient mainspring, unfortunately I chose the wrong one.1 point

-

I realised this and came to the same conclusion earlier this year,( all by myself may i add ) swapped a stronger spring for the original one that i was convinced was set ( looked worse than the OPs ) in a little old Oris. The stronger spring caused high amplitude and rebanking, easy to hear in the mic and the tg trace and readings showed a regular step in the rate happening. Despite the high amplitude it still had low power reserve. Decided to go back inside and see if i could find some friction somewhere, found it in an incorrect cannon pinion fitted, rubbing on the plate, solve this then re-fiited the original spring. Touted power reserve is about 40 hours, this is getting 35ish now . Amplitude is 260ish after an hour of full wind, then down to 210ish after 24hrs. This could be from the original factory spring.1 point

-

Yes, the lift angle should be 42 on this piece. Check that the regulating pins have a visible gap with the hairspring, between 1/2 to 1 hairspring thickness, and, importantly, that the spring is centered well between them. With no power on the watch, just a little movement of the balance should cause the spring to bounce from one to the other. If the spring wants to stay in contact with one pin, this can cause an increase in rate. But- once the amplitude goes above a certain amount, the spring may begin to come away from the pin. This can cause all sorts of timing issues. If all is well, and you want to reduce the overall rate, the easiest and best solution would be to add a pair of timing washers under opposing balance screws.1 point

-

You could look at just getting a GR4484 or GR4485 from Cousins which are just shorter versions of your GR4486.1 point

-

I mentioned this about a week ago OH and also posted this video......Kalle had the terminology backwards. Overbanking is the situation of the impulse pin trapped on the outside of opposite fork horm unable to release the escapement. Rebanking is the situation of too high an amplitude causing knocking of the impulse pin on the outside of the fork horn from too strong a mainspring. But I'm sure you know this, Just Kalle terminology as we understand was incorrect maybe in that area of the world that is the term they use. If we look at again at the OPs description of the issue " the pallet fork gets locked on the wrong side of the escape wheel" . This is where the confusion begins......what is OP actually meaning here ? With overbanking the impulse pin is locked on the wrong side of fork........is this what the OP actually means ? As Nev tells it, either the safety feature of the fork's gaurd pin ( dart ,finger ) is malfunctioning and slipping past the safety roller possibly from movement of the watch ( a shake , a jar an impact) or an unsafe lock with the pallet stones allowing the lever to switch banking pin sides, so 2 issues maybe happening.......an unsafe lock and a bent or short fork pin that doesn't tap back from the safety roller..........or the impulse pin and fork heights are poor and are not fully engaged when they meet every time. Easy to determine a fork pin issue....release all the power.....leave just the lever and the balance fitted.....make sure both palllets are unlocked so the lever is free to move from the escape wheel now carefully test to see if the gaurd finger will pass by the safety roller so an overbanked scenario can take place......it may not quite......but just how close is it to bypassing the safety roller's circumference?1 point

-

for an alternative number you go to eBay and search for this mainspring 711K. then you may find the numbers a bit confusing because they typically and Dennison numbers not metric so I've attached a conversion chart. In any case you get a mainspring for between 10 and $20 Mainspring - DennisonChart.pdf1 point

-

1 point

-

1 point

-

See, The idea to take balance out to check and look at is wrong. Actually, You need the balance and the pallet fork IN the movement to do the checks needed. It is better to put ONLY the balance and the pallet fork (with their cocks) on the main plate. Then You need to turn the balance in some direction and try to force the pallet fork to the other side. You should try this in different manners, like balance up - fork down and vise versa. Then You should repeat the same when balance is turned to the other direction. Generally, the fork must NOT be able to go to the other side. This should be the same as to lock a drawer so fast that to throw the key inside before it is fully closed. And, if the fork is able to go to the other side, then investigate how, when and why this happens. Generally, it happens if the guard pin is short and passes thru the roller or it passes above or under the roller. Or, the roller doesn't rotate true and there is certain balance position where the roller gets far enough from the pin and lets it pass. The other reason for rebanking is that the impulse jewel is short or it stays up and in certain situation can pass above the fork's horns1 point

-

the banking pins are safety feature of the watch adjusting of them for other reasons will probably have other consequences. I don't suppose you remember the mainspring number? Then it would be preferred to replace the mainspring was something slightly lighter rather than modifying the watch to work with your overpowered mainspring. but it would be nice to have the mainspring number so I can know the actual spring to compare what I perceive the watch is supposed to have.1 point

-

Is this a confusion between Klassiker's and OH's use of the term "overbanking"? ... Exactly the confusion described in the Terminology section of the PWD blog article Klassiker linked above?1 point

-

Hatch things up is a term used for telling porky pies. Don't tell me you don't know what that is.1 point

-

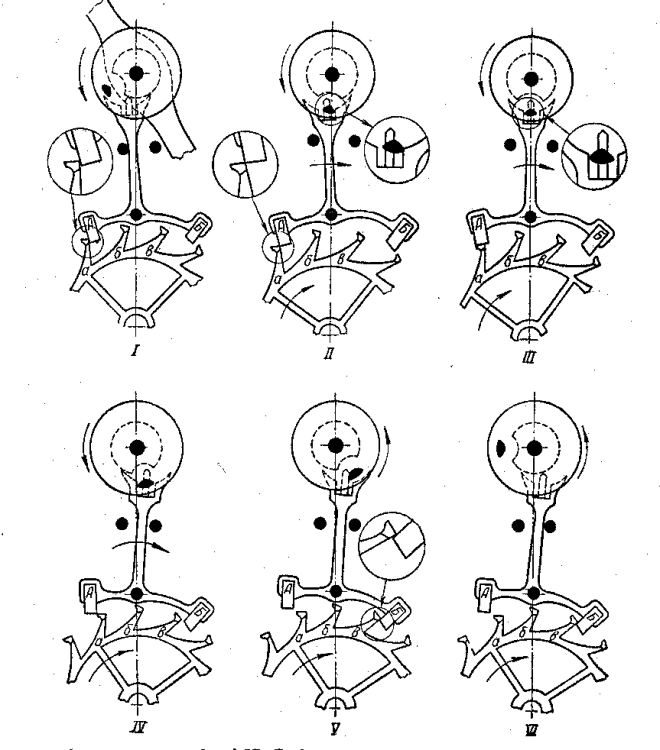

there's all sorts of information on escapement adjusting for instance here's a peculiar handout. Peculiar in that it's basically a whole bunch a handouts that were combined together into one. Including a handout that came from a lecture that is on YouTube although it's a little hard to follow with the audio. then as reading backwards through the discussion seeing all sorts of interesting suggestions including moving the banking pins and the jewels of the escapement and I get the original message what I'm quoting something above. The watch was working fine and then one day it stopped working. Which means the banking pins probably didn't get moved along the stuff probably didn't get moved unless you that creative in your repair process? one of the thing is always helpful in a discussion like this would be to show a picture of the timepiece. Because a sizable percentage of the people fortunately have never seen this thing before. this comes back to the problem that I quoted above of not actually seeing which version this is. I'd have to go look in the parts book but I think the basic version is seven jewels and there may have been some versions with more jewels. But a seven jewel version will have unfortunate issues of things wearing out. Where basically cleaning will not fix the problem Escapement handout wostep nscc.pdf1 point

-

Yes that i how its usually done, once the movement is out then you can access the dial retaining screws, tabs or however it is fixed. The hands can then also be removed safely, try not to lay the movement face down until they've been taken off or you could bend them or scratch the dial if they press up against it. Most of us use hand levers and a thin plastic film cover over the dial and hands to protect it from the levers, i prefer to use paper with a slit in it slipped under the hands, this way the hands can be picked up from the paper without fear of dial damage. But as John suggests begin a new thread regarding your watch as there are a few methods for removing movements that are specific to the case style.1 point

-

always best to start a new discussion as I regard each watch as unique. Then which watch the same as in this discussion or some other watch? We always need a little more information but typically not always on wristwatches you can usually remove the stem and of course the back possibly a movement ring and the movement will come out. Typically you would never take the dial and hands off to get a watch out of the case.1 point

-

What you are seeing is usually called overbanking, and it isn't a result of too much power from the mainspring. The pallet fork is jumping to the wrong position mid oscillation, without interaction with the impulse jewel, or the impulse jewel is bypassing the fork somehow, then can't get back. Most likely the guard pin on the pallet fork is bent or missing, or the balance or pallet fork has a bent pivot, or too much end shake. Here's a nice article, with a discussion of the terminology too. https://blog.pocketwatchdatabase.com/2022/08/22/overbanking-in-watches-failure-of-the-safety-action/1 point

-

I agree, skill level and location would be really helpful. I think an introduction should be compulsory.1 point

-

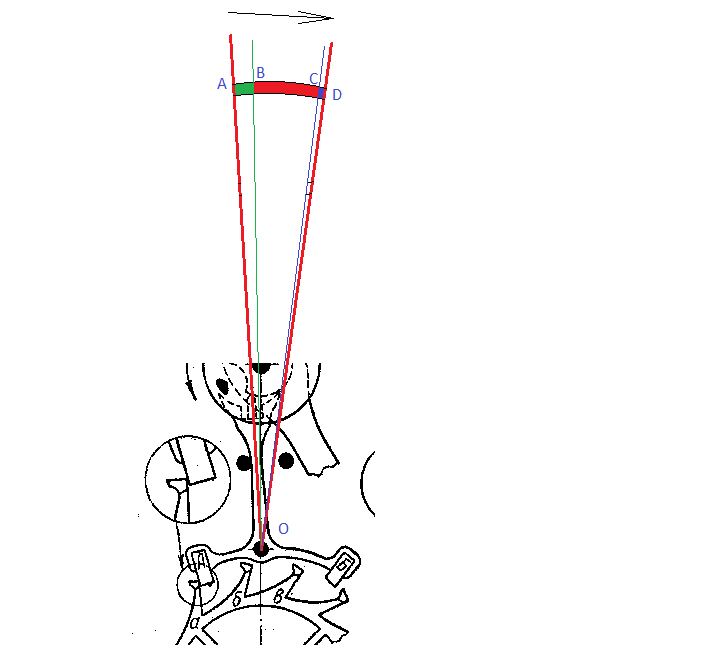

Hi Dmitry, First, a little theory needed here. I will try to present the theory in a little different way, hoping this way is easier to understand it. Look at this drawings: The angle AOD on the first one represents the whole angular movement of pallet fork tail from one banking pin to the other. In the beginning, the tail is in point A, which is shown as "I" on the second drawing. Angle AOB is the rest angle. If moved to the green area, before point B, and then released, the tail will return to A by itself. If the tail is moved past point B to the red area (point B is corresponding to "II" in second drawing) and released, it will snap to the other banking pin by itself. The red area (angle BOC) is impulse angle. The important moment here now is the point C, corresponding to "IV". You will see on "IV" that the tail is not touching the banking pin. This is very important. In the moment when the tail leaves point C and enters the thinny blue area, the tooth "a" leaves the pallet "A" and the tooth "в" falls on pallet "Б" as shown in "V". The movement of the tail from points C to D is RUN TO THE BANKING. Movement C-D and the thinny blue area MUST exist and this is very important. What happens in You case is that 'Run to the banking' in the exit pallet is close to 0. If we look at the second drawing, this is like IV and VI to coincider and in the first drawing - the blue area to not exist. The tail to be already rested on the banking pin, but the tip of the tooth а can't leave the edge of pallet A and there for tooth в can't fall on pallet Б. Of course, this happens only on one or two teeth of the escape wheel, which are higher than the others. And, the drawing is for the entrance pallet, but the problem in You case is with the exit pallet. As I already said, the easiest way to make the watch work is to open a little the banking pin as to allow some healthful 'run to the banking'. I understand that You don't want to bodge with the escapement, but You have to understand that this is what is needed here. What i saw on the last video... See, You show actually nothing helpful. Just endless jerking the brass table of the escape wheel with steel tweezers. This can only hurt the escape wheel teeth, which is something not wanted. The correct and simple way to look for wear of a bearing is to give some force to the wheels repeatedly in forward/reverse direction and see if the pivot moves. Then, the bearing that is actually interesting is not seen in the video, this is the main plate bearing.1 point

-

1 point

-

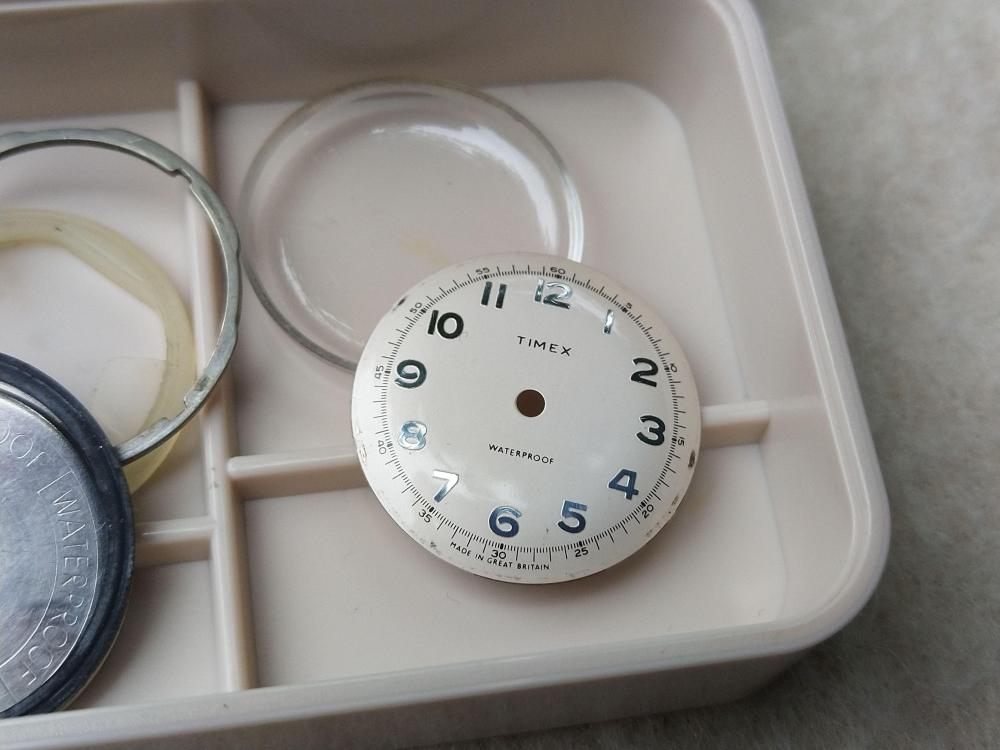

1966 Timex field watch 1158 2466, 30.5mm just got cased with a new crystal today. This m24 movement had all sorts of problems revealing themselves each time I solved one. Bent wheels, bent fork slot, bent pallet pins, somehow the lower balance v-conic pivot getting pushed out of its friction fit hole (I never gave these any thought before as to their installation on the plate). Luckily I have a sackful of Timex spares and all the parts are interchangeable. I was glad to get this around $20 since they're not all that common.1 point

-

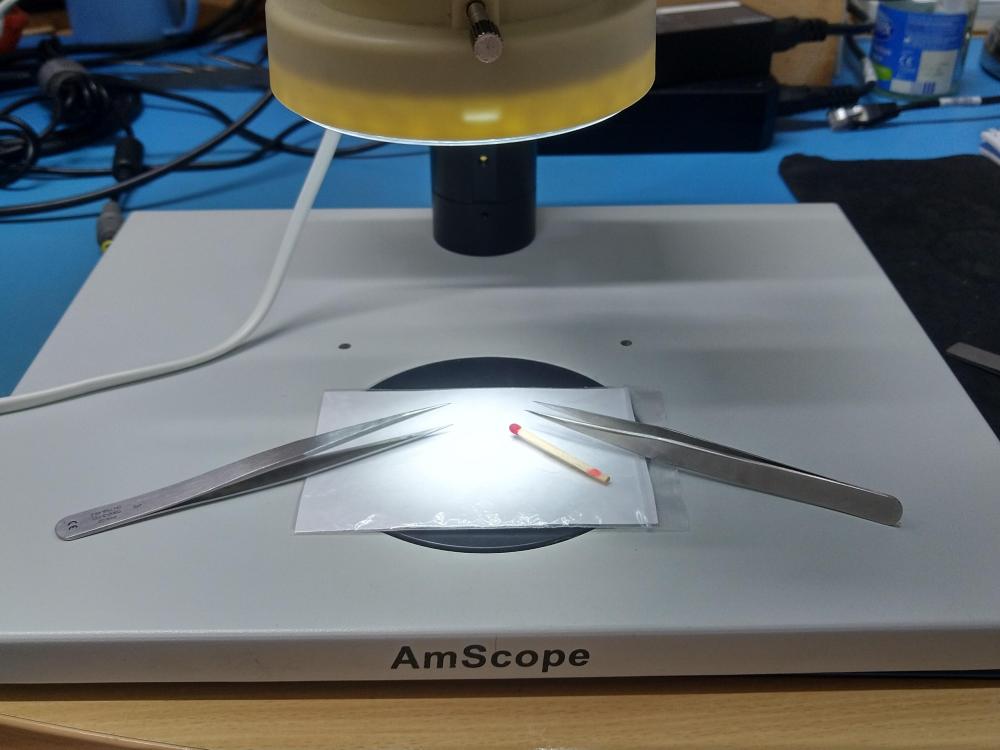

HWGIKE#22 Timex M22/23? Started as a full service.. ended up like a disaster! A 100 quest would not be complete without a Timex would it? when I started my watchmaker carrier I started with some of these (I thought it was a good idea... it wasn't) so I had already some ideas as how to deal with these old Timex movements. This one is like the mixture of the M22 and M23? US made. I put the main plate back with relative ease after cleaning but then it was non runner... went on for a bit but then stopped... one of the pin was bent... wanted to straighten it in situ with a suitable staking tool, but the hole of the tool was jammed with dirt... did not check it beforehand so i pushed the pin to the other side of the pallet... ohh dear.. i took it out then.. the pin.. started to straighten it with tweezers... jumped... what a luck stayed on the table.... jumped again... ~ 30 mins magnet fishing on the carpet.... what a miracle, found it... built a barricade around my microscope... jumped again... penetrated my defense lines... long long search... no result... then I lifted that plastic plate on the microscope to see if it went there into the small space between the plate and the base... there it was... what a miracle again... then I asked a friend who is an experienced watchmaker what to do and carried on following his advice.... in a plastic bag this time i straightened the pin completely by rolling it on a glass sheet... then with great difficulties I tightened the hole for the pin on the pallet using my staking tool.. and I managed again with great difficulty to place the pallet flat on the staking tool anvil and put the pin back in place... but then I bent the ping again with the staking tool... not even using the hammer just by lightly tapping the pin with the tool bit itself.... i took it out again and started straightening again rolling it again on the glass sheet pressing a plastic bag on top of the operation.... but the pin was not in the bag.... it was just on the top... pinged again... managed to escape somehow... started looking for it.... magnet fishing on the carpet, cleaning the desk....searching searching searching and a bit more searching.... lost forever... I am still happy I now understand the difficulties and developed a bit of sense what to do and what not to do... what is the force required etc.. i cannot say that the next time I will be more successful, but it will be a lot easier so start the operation... I now also have two staking sets organized... i never spent the time to organize my 2nd hand staking sets so far. HWGIKE#23 Titus Unknow movement Full service, swiss level. New mainspring, new glass. Hole for the main spring arbor tightened. Nice performance with the renewed bearing and new mainspring. It was a bit dirty because somebody in the past could not find the right crystal for it and instead of a rectangular crystal a hexagon was used. The movement itself is beautiful. These 15/17 jeweled swiss lever movements without the complications are my favorites. Nice to work on them, they are reliable and they are a beauty in my opinion.1 point

-

Next up is a Basic Staking set again found on Aliexpress https://www.aliexpress.com/item/4000394566891.html?spm=a2g0o.order_list.0.0.21ef1802wHIXpx A well made tool with 50 Stakes and 10 Anvils, all machines to a high standard with size code etched on each stake, codes seem to match those supplied by Bergeon etc. Only used it a few times sofar but it did everything expected without any issues. The only thing to note is that the Stakes cannot be used inverted, if that is an issue than something from Bergeon etc may be your only option. Another Chinese tool I am happy to recomend.1 point

-

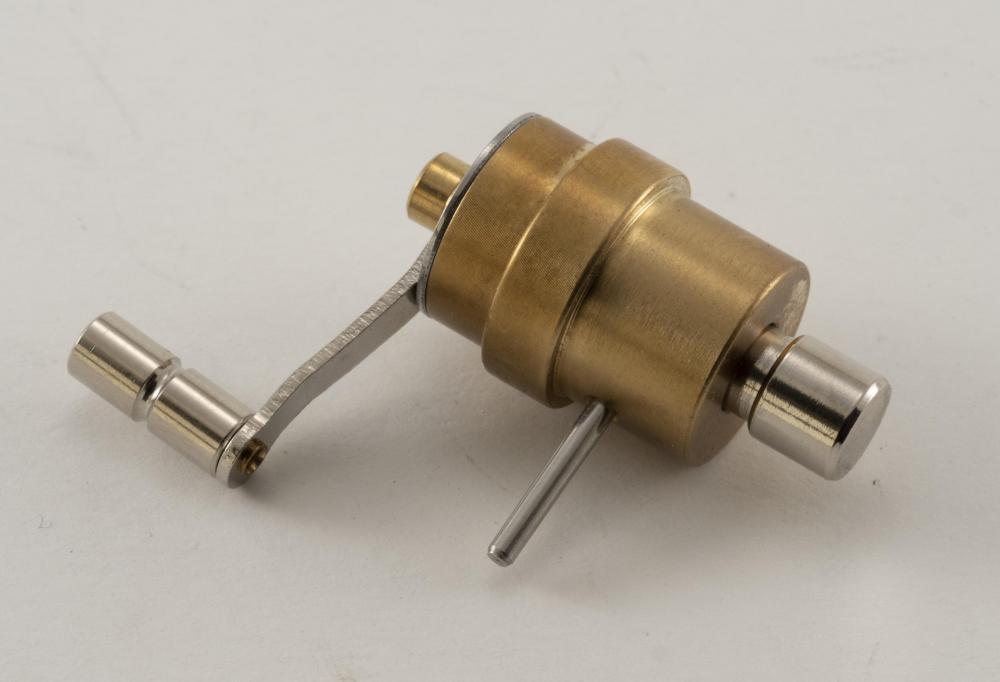

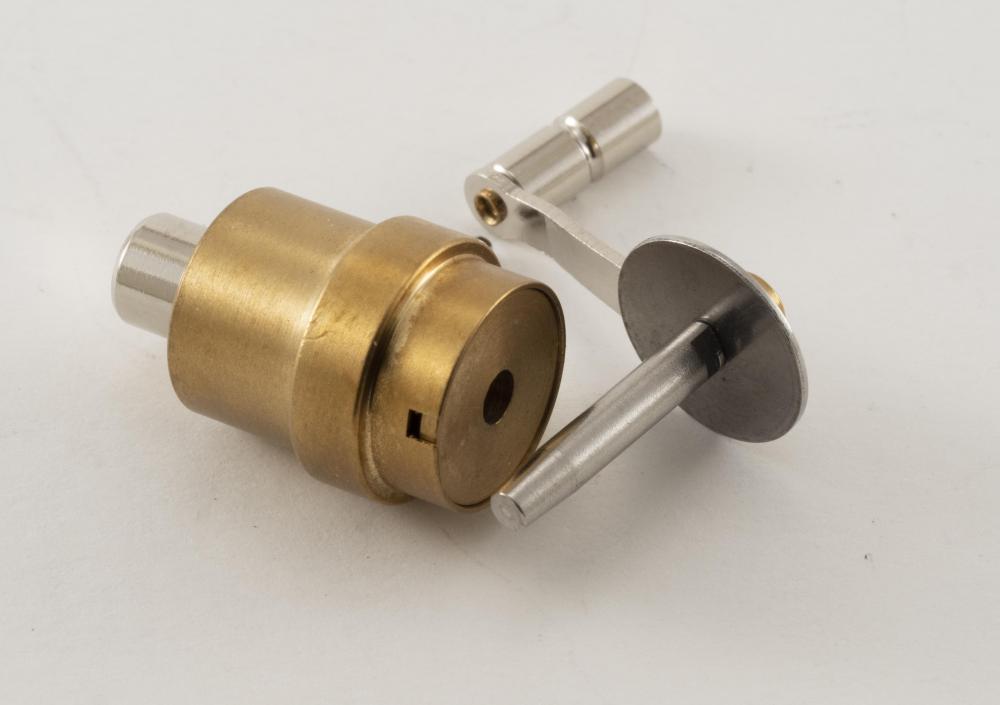

So here we go with the first tool in this series The obquous mainspring winder ser. This set came from Aliexpress and the price seems to fluctuate around £150 https://www.aliexpress.com/item/1005002838742309.html?spm=a2g0o.order_list.0.0.21ef1802uk2ABx A set of 20 winders with lrft and right hand sizes plus one handle. With this set the important Arburs are all steel and they are sold steel throught the range even some of the bergeon ones use a brass core with steel sleeve on the larger sizes, these are all steel. Construction and machining is all to a high standard Now to the handle which is often a point of critisism in these Chinese sets as there is often only a right handed handle included which can make using the left handed winders a trifle fiddly which is why Bergeon supply two handle in their kits. The handle in this kit is actually cut for both left and right hand use so only one is needed. So on the whole a high quality tool that works well and well worth the average asking price of around £150. Photos below, more tools to follow.1 point