Leaderboard

Popular Content

Showing content with the highest reputation on 07/17/23 in all areas

-

It's easy @Neverenoughwatches, glue a bit of soft leather/suede to a lolly stick (best not use 'Zoom' or 'Orbit' sticks ). When you press down the jewel gets embedded in the leather and you can't lose it.3 points

-

3 points

-

The cap jewels go into my cleaning machine (70-year-old ELMA w/o US) and usually come out visually clean. Even so, I always clean the cap jewels manually using the method shown in the below video. However, these days I also place a few drops of IPA in the centre of the watch tissue paper and then once I've cleaned the cap jewel in the IPA-soaked section of the paper I drag it out to the dry section of the paper to get rid of any IPA residue. I'm very satisfied with this method.3 points

-

That sure sounds a lot more convenient and efficient. However, don't know if you saw my video to the end where I mention I also tried my method with printing paper. The problem with printing paper IMO is that it is too rough. When looking at the flat side of the cap jewel under 40x magnification I could clearly see the surface had been scratched by the printing paper. Not much, maybe even acceptable, but still. Christian Lass cleaning a cap jewel using a piece of peg wood shaped like a screwdriver blade I say "IMO", because Christan Lass (Former Master watchmaker of the Patek Philippe Museum in Geneva) shows a similar method in one of his video tutorials (Watchmaking 101, Beginner Course) but is using common printing paper. I guess it could be that we only need to apply very little pressure on the stone. Thinking a bit more about it, it makes sense that printing paper is designed like emery paper. The roughness is there to scrape off enough black lead from the pencil for easy writing. Anyway, perhaps a sticky note pad + a light hand (whatever method) is the way to go!?2 points

-

........Unless you are an inveterate nose picker, like me. I'm going to have dreams now about the possibility of synthetic rubies traversing the cribriform plate and into my frontal lobes. Might make me more decisive or even know WTF a toothpick condom is!2 points

-

This watch has a 1956 date on the caseback which is before Bulova started using case numbers so it won't be in the case parts catalog. I don't have this watch but I have a handful that are somewhat similar. None of them have a moveable ring like on yours. When the movements are in the case they are somewhat difficult to get out, I have to pry them up to get them to pop out.2 points

-

I'm very sure you are right watchie, when i wasn't being careful enough the jewel could escape. This was just a case of finding something that worked better for me. Its something that I've always strived for in my day job for over 30 years , time is money for me and that habit never leaves you. This way made me a bit quicker and a bit safer, the pegwood didn't give me the same confidence, maybe i could have made the hollow a bit deeper which may have improved the slip but i didn't persist with refining that method. I just tried something else straight away and liked it better.2 points

-

It could be that you didn't hold the piece of peg wood perfectly perpendicular to the cap jewel and perhaps in combination with pressing too hard on the jewel. Same principle with screwdrivers. If not held (near) perfectly perpendicular to the screw head the blade can slip, especially if not properly dressed.2 points

-

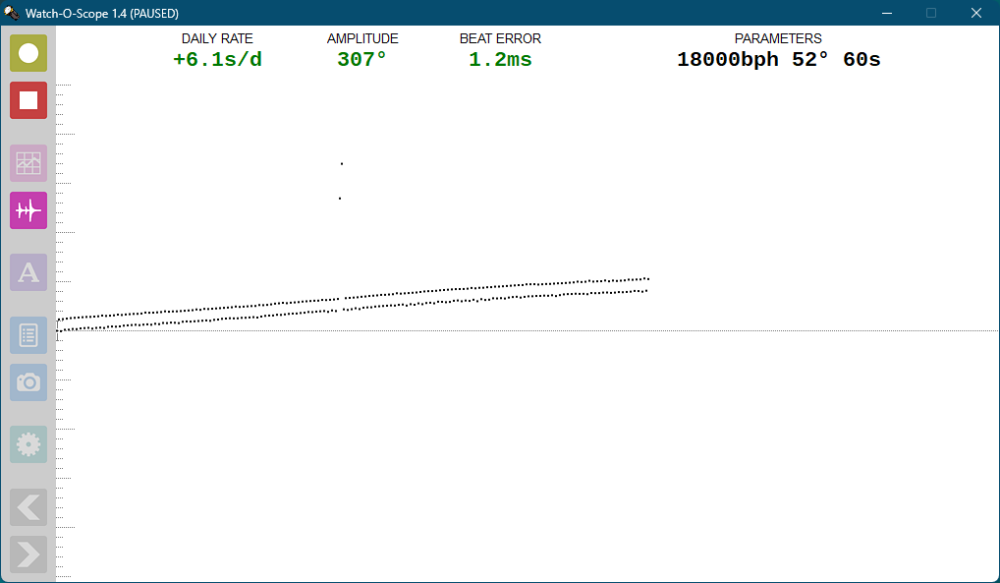

I would start with a full disassembly, clean and lubrication, pay attention to the mainspring as any damage or kinks etc will kill the amplitude. I would also check all the pivots and jewels to make sure the pivots are not broken/bent and the jewels are not damaged (cracked/chipped). The hole in the mainspring bridge should also be checked, this often becomes worn resulting in too much play, causing the spring to tilt and bind up... See YouTube chronoglide hammer time to diagnose and fix this. As a caveat I would advise against going for a specific number, the amplitude depends upon a number of interrelated factors and a specific gold standard may just not be possible. For example it is reasonable to expect a new good quality movement to get an amplitude around 300, but it is unreasonable to expect such a high value from a 100 year old middle-of-the-road movement. I would instead look at a before and after values to see how much improvement there was.2 points

-

Haha an original Lyons Maid Mivvi in its 70s heyday. It has its uses Doc when the lube is fluid. Both chucked in few drops of your chosen dissolver will sort out their years of mating. I tried this some time back when i started but couldn't get to grips with it. The paper would crinkle up and move around so had to be taped down as you've shown. And most times the jewel would flip out from under the pegwood if i wasn't careful. The sticky note pad works great ( i figured paper is paper and watch paper is so ridiculously light and unpredictable the culprit of lost jewels and springs I'm sure ) tear the top page off and away you go with a fresh clean page. And using my finger ontop of the jewel it cant escape to anywhere, i do find it best to use a bare finger as it slides better on the paper. A quick wipe with alcohol first to clean the finger pad and if I'm in a belt and braces mood i dot the cap with rodico before i insert the shock spring. You can always wear a cot if you prefer ( i hate wearing them and have taught myself to use them in a minimal way) if you have confidence while using any method then i think that plays a major roll in avoiding mishaps.2 points

-

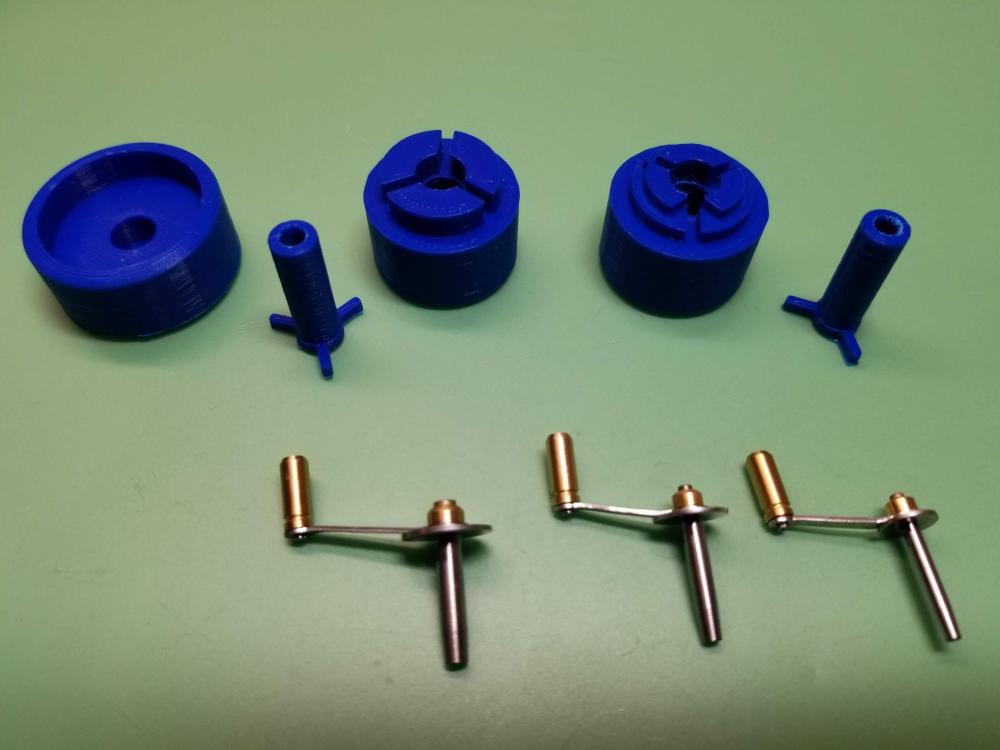

I struggled with the staples, trying to hook them to the mainsprings. So, I thought that I would test out a hybrid approach. Using the Bergeon generic arbors with the 3D printed winder barrels. I've been able to wind several mainsprings without too much trouble. For me, this approach is much easier than with the staple and winder base. I got the Bergeon #4, 6, and 8 right hand arbors. That gave me arbors of 2.5, 3.0 and 3.5 mm with the largest diameter end washer available for the arbor size (Mainspring winder sizes). The right hand arbors were less expensive than the left hand, for some reason and, of course, are far cheaper than getting the full Bergeon mainspring winder and arbor combos. I modified the pushers to be able to accept up to the 3.5mm arbor. For when I need a left hand arbor, I wind up the mainspring with the right hand arbor and then transfer it into a modified winder body, that I call a "reverser". I made a base to hold the reverser and its pusher while I push the mainspring into the reverser. These parts are shown on the left side of the photo. Maybe eventually, I will get the left hand winder and arbor combos, but for now, this is workable for me.2 points

-

I made a quick video to show how the movement fits in mine, and so you can see the rotating inner movement ring.1 point

-

Interesting? It actually seems to be a relatively common Electric movement as it was very inexpensive when it came out. Of course the problem with electric wristwatches is you never quite know what's inside Until you open the case up. Although quite a few of these came with transparent backs where you can see the movement Yes that's definitely what it looks like. Fortunately somebody already partially answer the question I would get a service manual if you've never done one of these before. Too many mysteries if you're not familiar with what you're looking at While I'm sure somewhere around here I have a physical manual if you have a PDF yes it be nice if you uploaded it. Why limit yourself to the Hamilton? For instance on this website look at the movement gallery look at all those electric watches you could try to acquire. https://electric-watches.co.uk/movement-gallery/1 point

-

I'm going to have to give this a try. Thank you for the amazingly detailed advice. I suspect you need a light touch when applying the downwards pressure and a good sense of vertical to avoid Pingu, so I need to practice (a lot!) For my hamfisted self, thats one of the advantages that attracted me. It was pretty much downwards pressure independent, allowing me to eat the Mivvi with my other hand!1 point

-

Electronic watch. Battery powered oscillator. Common ones are made by Timex and Benrus. If memory serves HectorLooi has worked on them.1 point

-

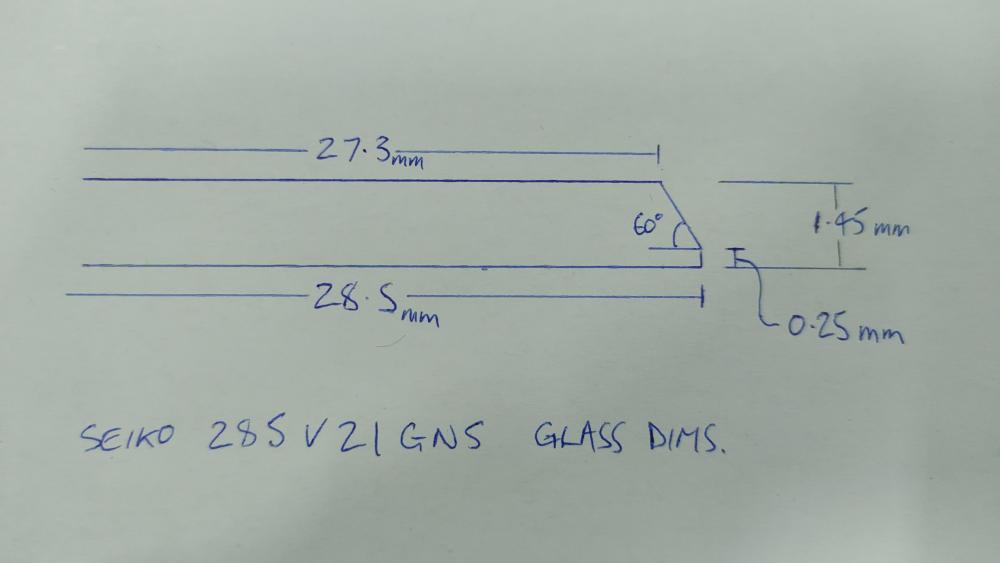

For future reference. Glass dimensions: 285V21GNS Diameter 28.5mm Thickness 1.45mm Height of polished beveled part approx 1.2mm Diameter of the flat face of the glass 27.3mm Polished bevel angle approx. 60 degrees. I have looked through Sternkreuz catalogue and don't see anything close. Does anyone know of any other crystal suppliers?1 point

-

I always like to see a picture of the watch somebody's working on it answers a lot of questions that we would have. In the absence of your picture is this the watch at the link below you're working on? Then the lift angle would be close enough to 52° I wouldn't worry about it. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Lip_R25 We really need the background history of the watch to properly diagnose the watch. Because without a background history it's basically a guess and educated guess based on parameters. Like this is what a watch would look like if it hasn't ever been serviced for instance. Yes on this group amplitude is an amusing problem. If you look at watch companies specifications which is typically for newer watches where they have specifications. All they really care about is don't go over 300 because that's bad. then they care about it at 24 hours and that will vary with the quality of the watch. The big thing watch companies are concerned about is timekeeping. Then yes it's always nice to evaluate a watch incoming to see what it looks like. Then reevaluate after it's been serviced and preferably do that when it's wound up and 24 hours later. 24 hours later is a nice test because it does show all sorts of interesting problems That can come up especially if somebody didn't do a complete servicing.1 point

-

@rossjackson01 I agree, sometimes just tapping the arm with peg wood moving it less than the eye can detect will change the beat error from 0.5 to 0.0 ms, and the same with the rate. Sometimes you can go back and forwards for half an hour before you hit that sweet spot, and sometimes (during an eclipse on a leap year) lady luck smiles at you and you get it first time. Even if you need to make a big change, its best to do it in small steps. If you get too heavy handed and move the arm too much the delicate hair spring may not have time to slip to its new position and kink.... Then its game over, unless you are a black-belt hair spring ninja.... which I am not1 point

-

Not 100% sure what you are asking, but below is how I would interpret it Rate = +189: this means that the watch will be about 3 mins fast per day, ideally you should aim to get this down to single digits by moving the balance arm making the spring longer. When the rate is too fast the lines on the graph slope up, too slow and the slope down and are horizontal with no error Amplitude = 166° : this means that your spring is delivering power at a low efficiency, ideally this should be greater than 200, and even better as you get closer to 300. The low efficiency could be due to a poor spring or friction in the gear train or dirt or...... This reading would indicate to me that the movement needs a good clean and lubrication as a starting point, then if still below par you can start to troubleshoot other problems Beat Error = 1.9ms indicates that the balance jewel is out of alignment with the centre position of the pallet fork. On some balances you can adjust this by moving the second (lower) arm. You should be aiming for less than 0.5ms, and a good value is under 0.3ms. The distance between the parallel lines you see on the graph represents the 1.9ms error (in your case) when the error is reduced the lines get closer together, until they completely overlap at 0ms and look like a single line. The lines look a little wavy which could be down to a few things, but aren't too bad so I wouldn't be overly concerned. A crazy mass of dots (not in your case) usually indicates that your moment and specifically the balance spring may be magnetised, a quick fix if you have a demagnetising tool. Hope this helps.1 point

-

Well said @Waggy, however, it was @JohnR725 who provided that good advice, not me.1 point

-

1 point

-

To be honest I have rarely come across this, but I use naphtha and not IPA to clean the cap jewels, so maybe this is why? When I drop it in the naphtha they separate almost on contact.1 point

-

Contact lens cases sounds like a safer solution. Do Bergeon make lollies? The last lolly I ate was a Mivvi, so that'll give you an idea of how temporally impaired I am!1 point

-

Actually this one is a Mumbi Montres. @AB23 I suggest a preowmed King Seiko, a Chronometer grade movement cal 5625 , well worth the money. Good luck pal1 point

-

I was going to suggest a Tissot Seastar as this is a quality brand and value for money - another thing is that they don't cost the earth, so even if you are unfortunate enough to receive a fake (lightning can strike twice) it wont be the end of the world. It's sad that buying watches as become such a mine field, bizarrely, even relatively inexpensive watches such as a Seiko are sold on eBay for $10 and are obvious fakes or watches that are cobbled together from spare parts from several watches (Frankenstein's) with 'after market' dials etc. One wonders how they can make any profit bearing in mind the cost of the parts and labor etc. to make such a fake/frankenstein??? I agree with @VWatchie that one way to avoid this is to buy from reputable sellers, but even this isn't fool proof, as even these guys are only human and can be caught out by the super fakes. It's an interesting point @VWatchie raises that popular and commonly faked watches (such as Rolex) will elicit a response by most people who will automatically assume it's a fake, so if it is the wow factor someone is looking for, then wearing a Rolex will backfire even if the watch you have is genuine. Bearing this in mind it may be a better tactic to look for a quality watch that is not plastered on every magazine or airport departure lounge... dare to be different @AB23 I'm glad the forum responded quickly and prevented you making a costly mistake with that 'Rolex", it's in everyone's interest that such fakes are not sold. I know saving one person is just a drop in the ocean..... but its like the saying "how do you eat an elephant?....... One bite at a time" hopefully this was just such a bite!1 point

-

Yes, you are correct. Beeswax is hard, like a bar of soap. But wood finishing beeswax is dissolved in a solvent like orange oil, mineral oil, etc. The solvent will evaporate and leave a thin film behind. Some elbow grease will work it into the wood and give a nice lustre.1 point

-

Such calipers were common in many trades. In dentistry, we used the Iwanson gauge, which measured in 0.1 mm increments. There is quite a bit of spring tension in the jaws when measuring an object. So when there is nothing between the jaws and the indicator arm is hitting its backstop, it's impossible to tell if the zero point is accurate. Hence we test for zero by measuring an object of known thickness. For example, a 1.0 mm feeler gauge. The indicator arm can be bent to adjust to the correct reading. Hope this makes sense.1 point

-

Make sure the clock is away from central heating you don't want it near gas or electric radiators because they will not only dry out the wood but dry the oil from the movement. Never use that so called muck they call polish in an aerosol. A good clear beeswax is best, apply with a clean cloth and rub off with a clean cloth. Do this about every 6 weeks.1 point

-

Thanks for this. The movement is in the case atm but I might have an opportunity to try this on Tuesday. If not I’ll have to wait until September time. I’m not going to be here over the summer. But at least I have a plan. Thanks for your help … I’ll keep you posted.1 point

-

I use old contact lens cases - two compartments so I can keep top and bottom jewels separate. I use a drop of Elma WF Pro or naphtha, and 5 mins in the ultrasonic. Then IPA rinse. If not spotless, I dip in IPA and rub them on some watch tissue using a lolly stick with a bit of leather glued on - buggr spending £££ on Bergeon stuff1 point

-

I like to apply lube with a manual oiler i can then see exactly how good a job i have made. Jewel flat side up and held so the oiler doesn't lift it up . And that would be the chaton placed on top, the oil grabs the cap jewel and both parts can be turned over and placed into the setting easily.1 point

-

I've been using almost from my start a similar method. I didnt like the ipa clean at all and the risk of handling wet cap stones is too high. I started by rubbing the flat side on watchpaper but that crinkles up too much so i just rub the flat side dry on a sticky note pad. I also just use my finger on the stone to rub then pick the stone off my pinky with tweezers. With complete confidence in this method i never lose a stone and it cleans it perfectly.1 point

-

Both chemical and mechanical and simultaneously. I use cardborad instead of leather and spread some lighter fluid on the cardboard " trap " the capstone with my thumb and rub. Once the stone surface shines, I give it a rinse as tiny bits of cardboard/ leather are inevitably aggreagated around the circumference of capstone. Even IPA leaves little residue on the capstone which wont bother the new lubricants.1 point

-

Look at the case together the hole isn't round. Ether a tube is missing or someone has filed part of the case away. No way would you have a hole that big for the stem and button, there is a part or parts missing. The amount of dirt that would get in is crazy. Even a dust proof button would be useless.1 point

-

Looks like someone has been playing about with needle files. That is why the tube is missing.1 point

-

1 point

-

I've been playing with big beers lately. I don't drink much or often, so when I do, I like to do it all the way. I mentioned above brewing a 150% stout recipe. My whole famn damily is in town this week, and my siblings are interested in homebrewing. I set up an educational brew day for them. We're opening/trying the 150% bottles, brewing a 175% stout, and bottling a 200% stout tomorrow (a non-linear full process minus waiting for fermentation to occur and waiting for bottles to condition). With my process/equipment, I am getting about 85% brewhouse efficiency with a 100% recipe, 85% with a 150% recipe, but only 65% with a 200% recipe. I'm hoping to find the point at which my efficiency starts to drop, and then I'll do a two-step mash to see how high I can get. I've been intentionally mashing at a high temperature in order to get a fairly high percentage of non-fermentable sugars (to get that big beer maltiness and mouthfeel without the high ABV), but depending on how these 150%, 200%, and 175% beers taste, I'll likely attenuate that somewhat and let the fermentable sugars convert a bit more (if I can get an 18% beer, why not do so every once in a while?). I also haven't changed the hops at all, and that will likely need to be addressed (as its own variable of course). Eventually, I'll likely end up with a true big beer recipe, and a small big beer recipe. Then... I start playing with adjuncts!1 point

-

Joao Magueijo's version of VSL cosmology is the one I'm thinking of. There are books and even a documentary about it. It's been a while since I read anything about VSL, but I recall it was pretty sudden. It would have to be to result in the physical reality we see in the universe (the evidence of the big bang is pretty incontrovertible, it's the interpretation of that evidence that's in question). That it might be happening as we speak is my little brainwave that caused me to resurrect this thread. If the observed redshift is not the universe expanding via dark energy, but C gradually increasing, that aspect at least would be internally consistent. Hubble's constant would still be a constant, but would be the rate of change of C rather than the rate of the expansion of the universe. Again, I've not had time to noodle on various implications on other established observations/laws of nature/etc. That brainwave may crash on the shore of some obvious island the second I get a breath to let it ride... Noodling while my 3yo is between whining about her pants being too short (they're not) and whatever comes next (didn't even have to wait for the end of that sentence, she managed to get her shirt inside out)... If C suddenly decreases, matter precipitates. If C suddenly increases... Does matter evaporate? (now running, screaming through the hallway and running into a wall). E = MC^2. If C gets smaller, M gets bigger. Do it quickly, you get a big bang-esque precipitation of matter. If C gets bigger, M gets smaller (in this case, slowly over billions of years), but how? Does matter evaporate? (Now something is hard about washing her hands) It took me too long to get to this point. I wake up an hour and a half before everyone else to have some quiet time to enjoy my tea and be able to think. Chaos has now erupted, and any hope of the level of thought required to advance this notion further has evaporated in a manner that matter might if C were to increase.... I'll try to keep fleshing the idea out as I find moments throughout the day... No one publish without me.1 point

-

Finally got back to work on this one, and boy did it clean up nicely. Only part replaced was the mainspring. It could probably use a new stem, and I lost the little spring on the stem during cleaning, but otherwise just cleaned and lubricated. I polished the crystal with red rouge, then automotive plastic polish, and the results are nothing short of stunning. Despite the dial being a disaster up close, it really looks great on the wrist.1 point

-

All, Whilst I find the discussion on IPA/shellac highly valuable and it is related to general cleaning it is not specifically related to Alternative cleaning machine chemicals, therefore, could we port this particular topic to another thread - I would like to retain the focus of this thread on the Alternative cleaning machine chemicals. I don't mean to be bossy, I just don't want the core discussion wandering down a well trodden rabbit hole.1 point