Leaderboard

Popular Content

Showing content with the highest reputation on 04/17/23 in all areas

-

3 points

-

Different profiles will come into their own, what is being removed will usually dictate that. My thoughts are you need to push into and create a gap to have something to lift off, an over thick profiled or steep edged case knife could make that difficult. Then forcing comes into play and control is out of the window. I'm sure other folk have different ideas, ive seen kalle of chronoglide use something that looked like a sharp bladed auto punch. He said it worked well. Here are the ones i use, all but one have a bevel on both sides, not by my doing just as they came. My favourite is the old bone handled one, its very thin and sharp but still has good stiffness to lift off, it fits into almost any gap. Ideally a prying action shouldn't be used as that will tend to cause damage, but who doesnt resort to that when things aren't shifting. The bevel edge of the caseknife should pop the bezel up, but thats not always the case if its tight. Thats usually when we feel the need to work our way around the edge lifting bit by bit. And has been mentioned lifting one edge can make the bezel and case bind against each other. Same with everything in watchreapair, its about finding which way works for you and practising that technique to get better.3 points

-

Hi there, you are bound to get many opinions on this subject, so I'll kick off with my 2 cents: Height: this is a showstopper and you need to have it the same or very close to the original or the barrel lid may not close if it is too high or the spring may produce "waves" (AKA sinusoidal buckling) if height is not enough. Type: this is another showstopper, the end of the spring needs to match the original, for example you need an automatic bridal for an automatic watch The thickness of the spring (strength): you can play with this a little but try to keep as close as you can to the original. Length: my experience is that you can be fairly liberal with this, maybe if you have a shorter length than the original having a slightly stringer spring can make up for this if you have to pick one that is not the same as the original and vice versa Barrel diameter: To be honest this is the dimension I pay least attention to, because as long as you have the above right this will automatically be correct or as close as possible I am sure there will be lots of people who disagree with the above - but if I were in your shoes I would go with the 1.45 x 0.105 x 300 x 9 assuming the bridal type is compatible of course.2 points

-

up until recently oils and I'm going to pick on moebius because they have a nicer website is more technical literature did not have anything resembling an expiring date. If you look at older bottles you will find that there's no date at all. So conceivably to buy a partially use bottle off of eBay that's been sitting around for 50 years because there's no date. then at some point in time that changed they now have dates on the bottle. Of course watch companies also have recommendations for when the bottle is opened how long you should use it before you toss the thing. Some of that has to do with contamination of getting the oil out of the bottle. which is why some watch companies that supply lubrication to the watchmakers used syringes to avoid the contamination issue. so for instance if you look at the website below if we pick 9010 almost everyone's favorite not mine as I preferred 9020 but let's look at what it says in the tech sheet. then look at the tech sheets you find that there are two separate time intervals six years shelflife and that on the very bottom of the page one year from the time it's opened. Then let's look at something popular 8000 as a comparison a popular oil probably for cost reasons. On the bottom of the page it has a similar note of open the bottle it's good for one year. but because it's a natural oil it now has a shelf life of two years much much shorter than the synthetic. Oh then we get more fun things here Omega they recommend when you open up a bottle of oil that you should write it dates on it and you can keep your bottle for six years which is as we know the shelf life of a synthetic oil. So now live a conflict between the lubrication company would like us to purchase a brand-new bottle every year versus omega and they're both part of Swatch group. then you run into the other issue of how long does that fresh bottle or six-year-old bottle of oil last in the watch. For that I have a link to a video below it is a Q&A with Sellita at 18 minutes and three seconds someone asks an interesting question of basically how long does a watch last if it's run daily. The question is really changed to how often should you service the watch and then what is the life of the watch. You'll notice it's five years but there's a hinting as long as 10 years. the real question of what I would be concerned about is what about the keyless works. Can't test out on the timing machine and there's a lot of metal on metal. As long as the rest of the watches made decently polished pivots jewels probably not a big of problem of lubrication as opposed to metal on metal. just a reminder for the future looking at a watch with the dial positions will always look nicer then like a crown position. So what have been nice to see a crown down position. Then for the real test wait 24 hours look at it again in both positions. https://www.moebius-lubricants.ch/en tinf_9010_en_1.pdf tinf_8000_en_0.pdf2 points

-

1 point

-

1 point

-

1 point

-

The last (4th) figure is the diameter of the retaining ring, no property of the spring. For easy mounting, it should be equal or smaller than the inner barrel diameter . Both lengths will produce no noticeable difference of running time. Frank1 point

-

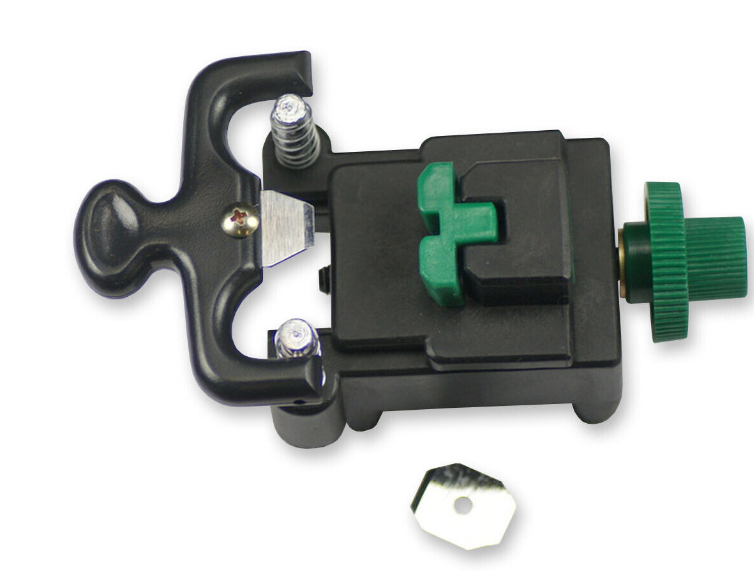

You should not "lever" but just push the blade in. That's the theory, but I gave up with case knifes as I found them too difficult to use in some cases, and it's easy to scratch the movements and dials (or draw blood ) I use one of these on bezels and case backs, works easily and no danger of slipping and damaging something. For tight bezels, if there is very little gap to get the blade in, I sometimes work round with a razor blade just to start it.1 point

-

1 point

-

To start with you cannot overwind a clock or a watch. When someone doesn't know what they are doing this sort of thing can happen. These anniversary clocks can be very temperamental to repair. The pivot has been broken off, so a new pivot would have to be made and fitted or a complete new wheel would have to be found. We need to see the complete back plate to I D the clock. It might be possible to find an old movement or the part on ebay. It will cost a lot of money to get this clock working again this will depend on the repair and parts, The suspension spring will need to be replaced (that is the very thin spring with a block at each end and a fork part way down from the top block. In the end It probably won't be worth repairing. I hope you have good insurance that covers you for this type of thing. A new clock will cost over £100 here in the UK with that type of movement.1 point

-

the unfortunate problem in the universe is there's not a service guide for every single watch in existence. Then typically for cousins there in the spare parts business they only have stuff that has spare parts. There is some documentation where I know there's a service part to it but they just scanned in the parts cross reference and didn't scan in the rest of the manual. Or basically you're lucky to find anything we find it all.1 point

-

According to Ranfft it is the same movement as the ETA 2360 - http://www.ranfft.de/cgi-bin/bidfun-db.cgi?11&ranfft&201&2uswk&ETA_2360 There is no document for the 715 on the Cousins site, but there is one for the 2360. However, this is a parts list not a service document. https://www.cousinsuk.com/document/search?SearchString=eta+23601 point

-

Okay some success here. Resetting the jewel more like DeCarle's diagram has worked and the movement is now ticking. It won't run dial-up though, and that appears to be due to excessive end shake. I'll have to see if I can correct that - it is also possible I fitted the wrong staff since the ebay seller was a little ambiguous. This was meant to be a practice watch anyway so I'll keep practicing. I had thought the roller table was just not a tight fit on the staff as it wanted to rotate a little too easily, but ultimately discovered I didn't have a good enough rivet on the staff (and that my staking set is missing the exact rounded stake I needed). I did get the rivet set in more solidly and assembled the thing, got the roller aligned between the banking pins, and am pleased that it is at least kind of running since this started out with 2 broken staff pivots.1 point

-

1 point

-

Lubricants (oils) are made from standard base-stocks of given viscosity. This applies to both natural mineral oils and synthetic (POA) oils, (not chemicals) These base stocks are then blended to get to the required viscosity. Normally a thinner oil is added to a thicker oil to get a lower viscosity than the thicker oil. All oils have a range of molecules and the lesser/greater sizes are referred to as light ends or heavy ends. To 'evaporate' an oil would require temps well in excess of normal temps (even tropical areas). However some evaporation can occur with the very light ends and the heavy ends will tend to oxidise more, particularly at higher ambient temps. Both these effects will tend to thicken the oil. The more blended an oil the greater the effect would be, but still miniscule in the realm of things. This is why the sticky residues are found in bearings etc in old watches and non-serviced watches. Synthetic oils (PAO and not 'chemicals') have much better control of the molecule size and therefore have much fewer light and heavy ends. They therefore tend to degrade less noticeably (ie oil thickening). Some oils (both types) have 'addtives' incorporated to control other factors (extreme pressure EP, ant-iwear, metal pacification etc). These additives will do their job whether the oil is active or not and some will be 'consumed' doing that job, so a further age related degradation occurs. If the oil has stayed in place, then it will probably still lubricate ok. If it has spread, then the part it should be lubricating will be starved of oil and will therefore wear more rapidly. Obviously the comments above re servicing make sense if the watch is to be worn regularly again1 point

-

I've heard that as well, though I still haven't worked on anything Russian yet. Jealous of your micrometer there... And yes, I used two tiny strips of basic aluminium foil for this. I did play around with adding some D5 to the pivots which seems to reduce amplitude by around 30 degrees after a short test. This might be a viable solution, but I'll have to let it run for a week or so to be sure.1 point

-

Since you have been provided with two notches diametrically opposite each other you might want to try using two case knives simultaneously, one in each notch. This should result in a more vertical lift without canting the bezel off axis. If tolerances are really tight, which they seem to be, the axial tilt of a one sided lift may be all that is needed to bind the thing solid.1 point

-

The bezel remover does work for some types of bezels, but others are just a sod to get off. For some you need to remove the bezel insert then remove the retaining spring, others, like the Squale I've been working on, need 3 hands and the patience of the pope. The bezel remover would not work on either of these bezels.1 point

-

Looking at the photos Col, the case knife just doesn't seem sharp enough, the honed angle looks too steep. The bezel removers can be a safer and more accurate option for some people, some better than others depending on your budget. Case knifes can be hit and miss tools, some casebacks will require a sharper edge than others. Handy to have a few kicking around with different edges or is often the case of having to sharpen one up to make it fit better. Most folk's go to with a tight case back and particularly a bezel where damage is so visual is a single sided razor blade. They will fit into almost any gap to make a start but not stiff enough to do any real damage if the bezel isn't shifting as long as you dont slip with them.1 point

-

one of the first shops I worked at the owner recommended or his suggestion was tight against one of the regulator pins which makes logical sense unless something happens. Like too much amplitude. this is the rule for flat hairsprings. They need a little bit of breathing room. If it's in over coil spring then the pins have to be as tight as possible but still allow the hairspring the slide. then I have an image for you the effect of the regulator pins a necessary evil if you would like to regulate the watch conveniently but beyond after a pain in the ass and be nice if we could just break them off and not have them at. Because as because plainly obvious timekeeping is affected by amplitude with the regulator pins.so if your hairspring is between the regulator pins which is where it's supposed to be ill have even timekeeping at least above a specific amplitude. The farther the pins are a part the worse this effect becomes. Then for whatever reason flat hairsprings need their breathing room so closing a really tight will have some unknown consequence. Yes everything has a consequence. In the case of an over coil hairspring those pins are just a little bit apart you can dramatically see the effect of going from a dial position to a pendant position the watch will slow down. And that's where is mostly all my pins are too far apart and that I tighten them and in the problem goes away hopefully. Then what if you're touching one of the pins as you can see it has a very different type of timing curve. This example if you are regulated for zero seconds resting on a pin everything would be fine until amplitude picks up enough that it lifts it off the pin.then the exact nature the curve will depend upon the pins spacing. Initially as you lift off you'll be slow very slow because the regulation point is now at the stud. Providing the other pin was within distance of the hairspring finally able to touch that then you end up with some point in time with the flat average at the higher amplitudes. theoretically I suppose anything is possible but I'm going to say no. But you can get some interesting beat error changes by going to crown/pendant positions. This is because as the hairspring sags because the effect of gravity it rotates the balance wheel and that causes a beat error. Also things like hairspring is not centered can cause beat errors. oh and if you're into this kind of thing is a video where it talks about a really interesting book. Plus if you find the book interesting the second link is where it can be purchased. https://youtu.be/op68gwVvsCo https://www.booksimonin.ch/home.php1 point

-

As you rightly say fellerts the spring should sit inbetween the pins with a half a spring width either side. With the spring breathing spending equal amounts of time on either of the pins rather than mostly centered which would allow its active length to run back to the stud and slow time keeping. If the pins were too tight then i guess the beat would alter as the spring's active length and held length becomes the same, eliminating the stud's effect on beat. Wouldn't that push the balance and roller jewel more over to one side ?. So important to have that pin spacing correct so that the spring sits center of them as it reaches its neutral point of rest as the roller jewel lands center of the pallet fork. Too much thinking has made my head a bit fuzzy now lol.1 point

-

Good point. I've tended to adjust the spring so that it just rests against the inner pin. That might explain why I sometimes get a big variation between horizontal and vertical rates.1 point

-

I should imagine so! In this scenario, I believe you should see significant rate differences between low and high amplitude as well, which I guess is one way to detect this particular fault. Let's imagine the outer regulator pin having broken off or being bent way out of shape. If the spring rests on the inner pin at low amplitudes, it will spend a lot of time in "free air" when the amplitude increases, effectively increasing its length, slowing down the rate. This problem would perhaps even be exacerbated in some vertical positions, because gravity will help pull the spring out from the inner regulator pin. This is why the literature is so adamant that the balance spring should rest perfectly between the regulator pins and have very little "slop" to move about between the pins (the gap should be around 2x the thickness of the spring if I remember correctly). It's also important that the spring follows the arc of the regulator pins as perfectly as possible.1 point

-

Some excellent tips in this post, thanks guy's! I've started a notebook with them so I don't forget them. Something I've had some luck with in retrieving small parts from a carpeted floor is a bit of my wife's discarded nylons rubber banded on to the end of vacuum hose, run it around where you think it may have landed and I usually find the missing surface mount component stuck to the nylons while the vac is still running. Not sure if the mesh of the nylons is too large for some of the smaller screws but you never know.1 point