Leaderboard

Popular Content

Showing content with the highest reputation on 01/25/23 in all areas

-

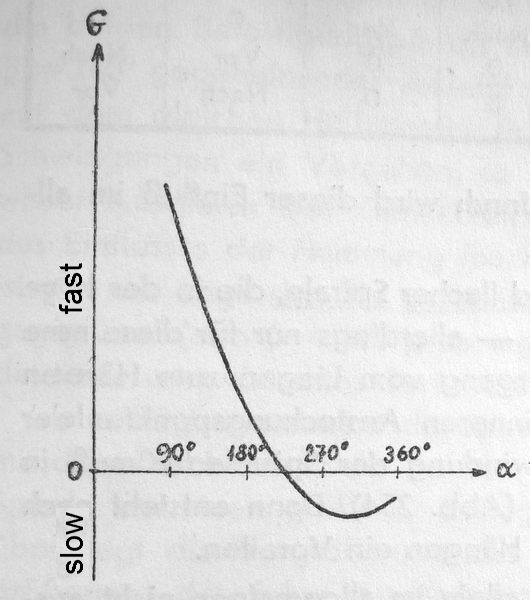

The higher the amplitude, the more stable is the swing regarding timing. Shocks have less influence on timing, and escapement action is a series of pos. and neg. shocks, too. With standard value 270° flat you will get near 220° vertical, at least after some hours. This is a magical number, as poise errors have zero influence at 220. So choosing 270/220 was quite clever. Frank6 points

-

I've been busy making a few two stitch leather straps. Would you like to see a tutorial on those?4 points

-

I would be curious as to whose sheet that is. Yes I'm all sorts of interesting technical documentation but just trying to find it all in one place can be a challenge. Witschi will take up to 330° but watch companies tend to get nervous if he gets too high and usually are more concerned about at 24 hours. Then of course the big thing most companies are concerned about is his timekeeping. I'll just attach a few interesting things slightly different version of the above chart Posted by praezis. With this chart shows is amplitude and poising errors is a concerns of the higher the amplitude the less effect poise is. Something from Seiko 4006 service instructions actually gives you a numeric number for amplitude. Eta Is interesting because typically you don't Get timing specifications in the service information. For that you need to manufacturing information sheets that's for all the nifty specifications are. Then there is sort of consistency and then sort of non-consistency in the various manufactures sheets. Universally 200 is the minimum I've snipped out an image of one of them but the maximum seems to very 304 one 324 another so that seems to very As to what the maximums going to be. That Omega has interesting for their amplitude specifications typically they would only give you a minimum mom. But I noticed something right now that I hadn't seen before they actually do specify the maximum so I snipped that out. The minimum depends upon the particular watch and the lowest I'm seeing is 160°. Also have an image of timing specifications for watches that aren't listed anywhere else the rest of the document. Of course at these low amplitudes the watch still has to keep time.3 points

-

Then buy a cheap watch from a branded manufacturer that looks like a Rolex, there are plenty out there. Or better yet, build an homage. I wouldn't knowingly buy a counterfeit purely because I don't want to put money into the hands of counterfeiters. Not that Rolex is struggling for money. But if you're trying to get unsuspecting people to buy something that isn't what they expect it to be and making them pay more than the sum of its parts just because you put someone else's logo on it, that's criminal, and I don't want to be part of encouraging that.3 points

-

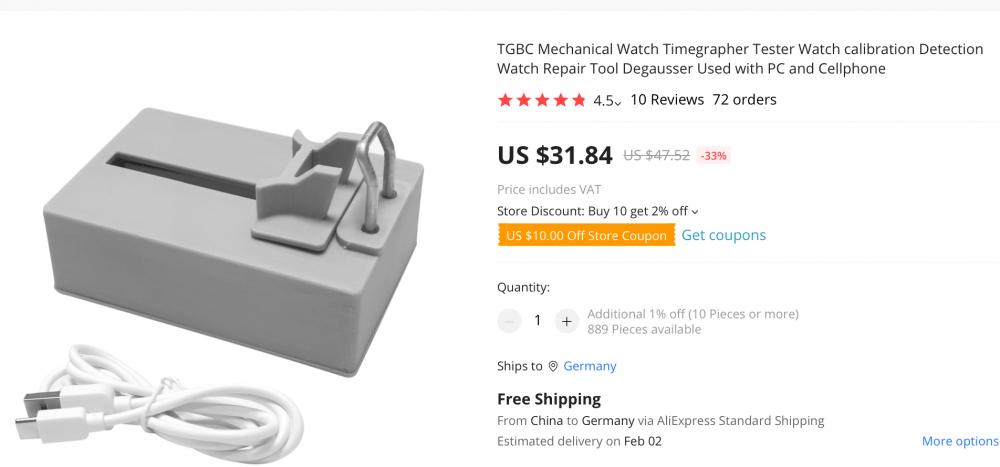

I finished my first (second really) complete disassembly, cleaning, reassembly, and oiling of a mechanical watch last night! The Unitas 6376 movement. In a Caravell pocket watch that was not working but the balance was in perfect shape. A little fumbling around and some minor scratches on a screw or 2, but otherwise pretty decent for a first timer. The other pocket watch I completed a first run on was a Ward Co. with no jewels. Brass plates including a palate for that was not a fork really. The Unitas was pretty easy to work on and a great first run at a Swiss movement, I think. Got it pretty close on the adjustment. Need a Weishi so I can get an amplitude reading, I think.3 points

-

2 points

-

2 points

-

ETA? They like to run 300-320°. I read somewhere that Rolex do not like more than 280° - I think it was because, if you run at higher amplitudes, you get a bigger drop after 24 hours. At 270-280° the idea is that a lower drop over 24 hours gives better timekeeping.2 points

-

What's high amplitude? I like to see (and companies I do work for) a healthy 270 flat at full wind. Drop in vertical amp hopefully not much more than 30 degrees. This helps ensure that the rate will still be good at 24h. John has more technical documentation he can quote, but looking at a sheet from one company they spec 300 to 320 max amplitude (but no minimum) horizontal at 0h, and generally around 200 minimum in vertical at 24h. Some watches are very stable though; for example the Lemania 5100 chronograph might only lose 10 degrees in 24h. On one of those I don't mind if I have 250 at full wind, as it will still rate terrifically at 24h.2 points

-

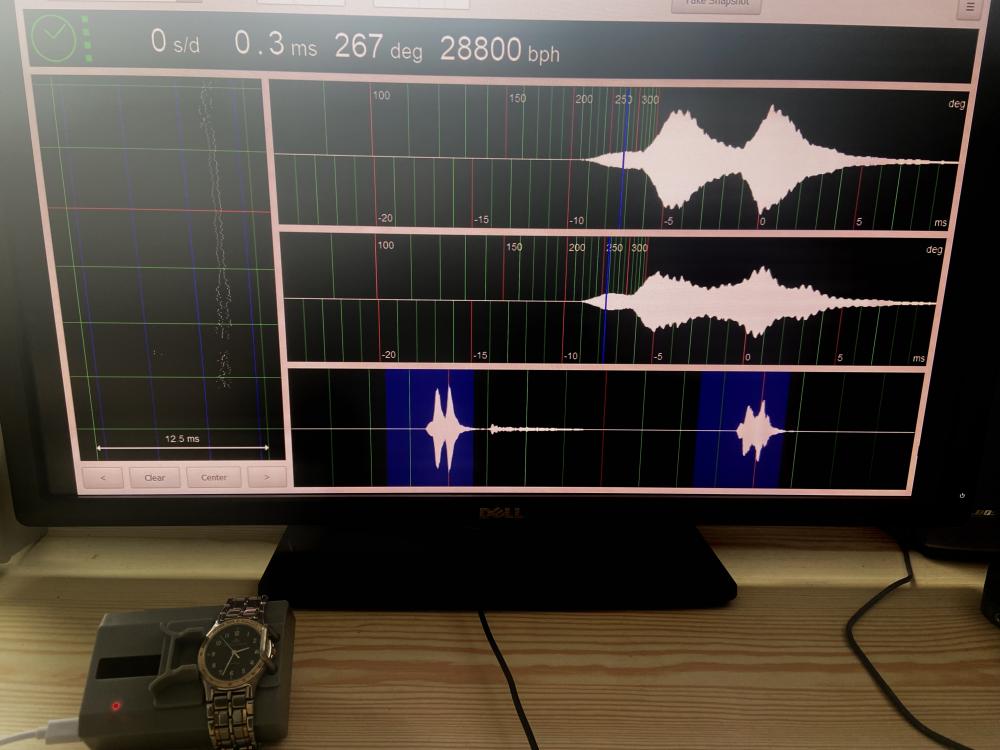

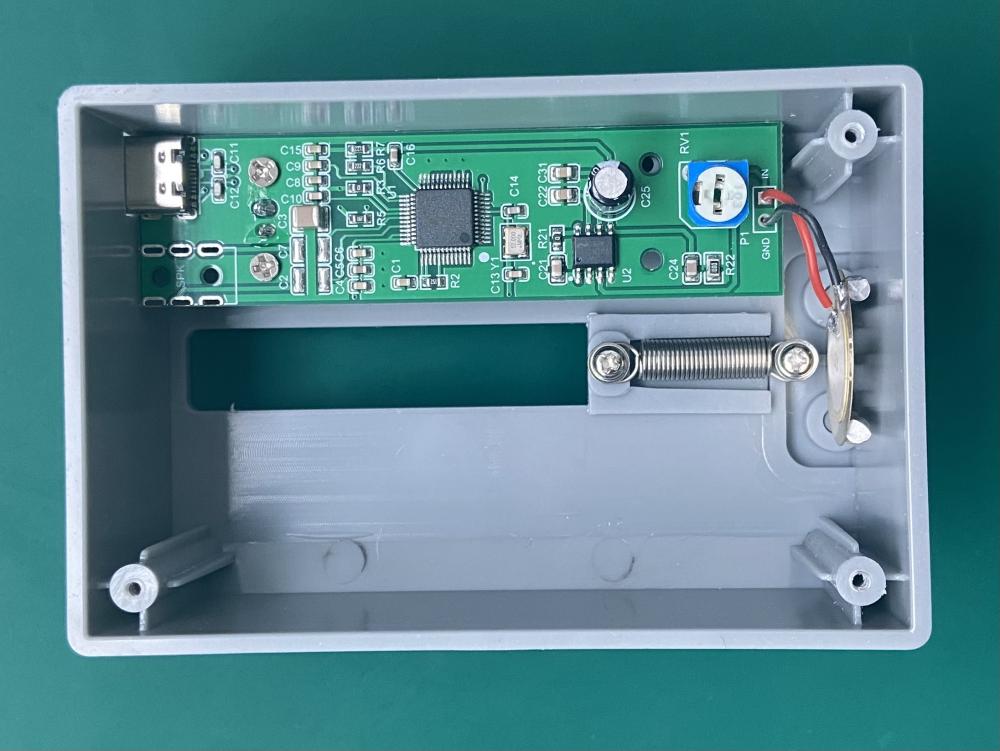

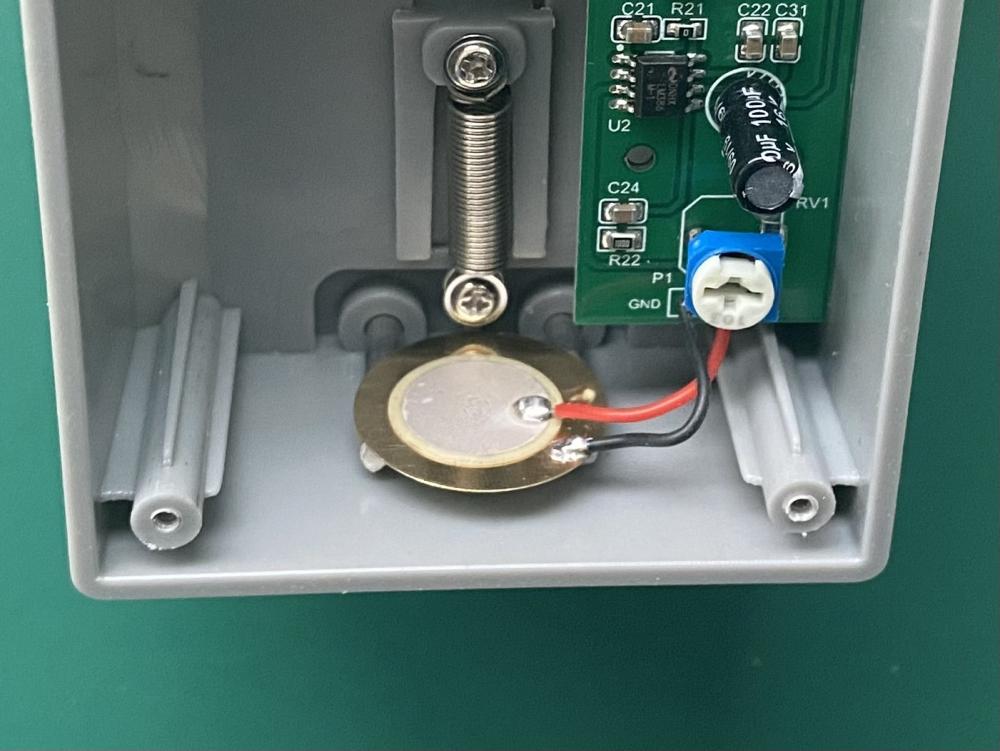

At the risk of inspiring you guys who have to have one of everything (like me) to spend money on one of these, I thought I'd show a photo of a Chinese-made tool I jut bought. It's not a watchmaker tool but rather a tool to make tools which can easily include many watchmaker things. The first applicable thing that comes to mind is... screwdriver blades. My back story here is that I have some 3/16" and 1/4" titanium rod that's been sitting around for forever, and I got to thinking that since I could use some really nice screwdrivers, rather than blow a bunch of money on a set, I'll just make my own... out of titanium. The blades can be made from whatever, and though you can easily enough just hone some stock into good tips by hand, this machine could dang quick whip out a set. The titanium shafts and delrin knobs are another project, but also another whole story. Just an idea I had and plan to implement coming up. I'm a machinist by trade so my newly accepted tangent into watchmaking is adjacent. Anyways, I wonder what you other guys can dream up that this machine might be handy for in the watchmaking realm. Behold, the cutter grinder: These run around a grand delivered, give or take. A full complement of decent wheels is another half that, but you can get by with what it comes with for a fair while. Anyways, any thoughts?2 points

-

One of the things that amplitude means is the greater the amplitude the less affect the escapement has on timekeeping. Escapement's always produce a loss and will interfere with timekeeping. So the greater the amplitude the smaller the effect the escapement will have. That is a reason to have a higher amplitude. Thinking of the inertia of the balance wheel I have a PDF attached. This is where the physics of the balance wheel isn't necessarily just simply increasing the amplitude is good there may be other things that also affect that. Like the diameter the balance wheel or even how heavy it is. So the attached document Omega's talking about changing their balance wheels. On the second page we see where it says greater rating stability. Explained because of the inertia because the larger balance rim. Omega-have-adopted-the-screwless-balance.pdf1 point

-

It's more of a power issue. Higher beat rates need more power, but there's only so much room for the barrel, so the inertia of the balance is reduced. The distance the balance travels from perspective of a point on the rim is the same for a given balance diameter at a given amplitude; it just travels that distance more quickly at a higher beat. So for a given time, yes, it travels more distance, which means a higher power input required.1 point

-

Considering something like a standard 18,000 beat watch, it's very hard to get a smaller balance to perform as well as a larger one. I mean like an 11 or 13 ligne movement compared to a 5x7 ligne. Generally the proportions of the balance pivots doesn't quite scale; the larger watch might have 0.09 or 0.08 pivots, while the smaller balance might have the same or in a high grade piece maybe a hundredth less- but a far smaller balance and inertia. Another big factor is the hairspring- again, proportions. You can have a proportionally smaller hairspring collet on the larger balance, which gets the spring end closer to the balance center. This is a big deal for timing. Then there's the escapement; on something like an AS 1012, the escape wheel and fork and pretty much the same size as the escapement in a larger 11 or so ligne watch, so more effort for the tiny balance to unlock, more mass in the parts, etc. etc. There are some very high grade small movements that perform very well, but they are relatively rare. An example, while not super small in diameter but ultra thin is the JLC 838; these can give surprisingly good rates, stably, while having a very light balance and tiny escapement (and suspended barrel too!). JLC also made some really impossible to rate small movements... In higher beat watches the balance does become smaller than a similar size movement at 18K. These do tend to rate very well, as the higher beat is a huge help, it's a different escapement geometry that's suited to the higher beat, and by and large the hairspring collet is a Greiner or similar which are poised and also help with the rate.1 point

-

1 point

-

1 point

-

The hole end Springs by Waltham are a problem if you do not use A original Waltham factory spring. Especially if you have a small size like yours I would definitely try to find an original spring probably off of eBay. I have a picture below the original spring as a little bit of a Bend and a little bit of a file paper. The modern spring is just a square punched hole it's missing the band and it's missing the taper. Typically these will never catch and some of them the square hole isn't even the right size that definitely will not catch. If it's a bigger size spring you can usually file the little bit of the taper part in may be banned just very carefully get a little and maybe it will catch usually want to catch as it's fine but if it doesn't catch because it's not the right end it will never catch.1 point

-

1 point

-

Quite a number of them are in display boxes, or on watch stands, however since my wife is somewhat less enthusiastic about cluttering the place up with them, a lot of them are stored in the drawers of my writing desk. I rotate the ones on display from time to time. Some others have ben donated to a friend of mine who runs a charity to help the blind, and he is in the process of flogging them off to make the charity a little money. I'm just hoping the government doesn't have any plans to reintroduce the Duties on Clocks and Watches Act 1797 otherwise at whatever the modern equivalent of two shillings and sixpence per watch, I suspect I'm going to end up in the poor house.1 point

-

Just closing the loop on this one- the mainspring slipped off the arbor, and in the process of re-shaping it to catch it broke- so I got an entirely new mainspring/arbor/barrel assembly (only a couple dollars more than just a mainspring, surprisingly) and after installation and reassembly, I'm getting 290 degrees right away. It appears the mainspring was probably not correct for this watch (boo, watchmaterial!).1 point

-

That is most likely to be battery juice, sodium or potassium hydroxide. I would rinse it in distilled water and brush it gentle with an artist's brush. The jittering is not likely to be a pcb fault. It's probably to electrolyte crystals in the movement train or corrosion caused by the electrolyte. If you have a quartz watch tester, use the "line release" function to see if the hands can move freely. If not, a complete disassembly and clean is needed. Also, the quartz watch tester can test if the pcb is producing a pulse. Good luck.1 point

-

1 point

-

Try moving the minute finger on the chrono runner a bit forward (counter clockwise looking at the movement side). When the sliding gear comes down it's catching it and moving it backwards, then the finger trips a minute in the first few seconds.1 point

-

1 point

-

1 point

-

We all would like to see how this is done. If like me i like to consider every aspect of watch repair. I'm also interested to try leather strap making. Haha and yes the beard mate, I've tried and couldnt get on with it, as soon as it reaches half an inch its itching, getting caught and tugged in my clothes fibres and my missus wont let me anywhere near her . Affraid its not for me. I can still appreciate someone else's effort though, my lad has one1 point

-

There is a rule of thumb for this which is that with everything dismantled, stand the wheel in question upright in it's pivot hole and observe how far it is able to lean from the vertical. Ideally you are looking for about 5 degrees of lean. Now although you can't put a protractor into the system to measure this, you can draw two lines on a piece of paper that intersect at 5 degrees to give yourself a bench mark with which to compare. Believe it or not the human eye is usually pretty good at comparing angles.1 point