Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/22 in all areas

-

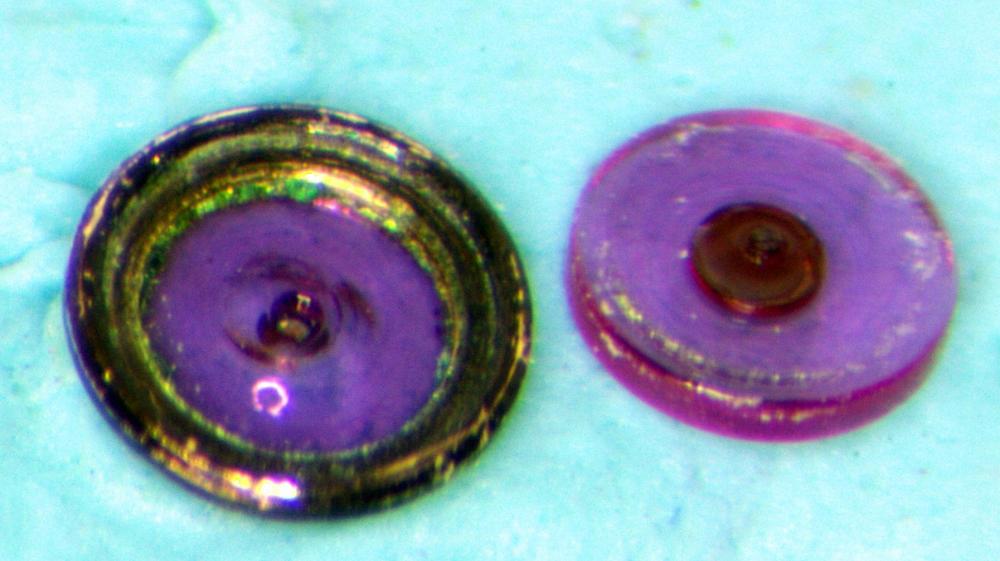

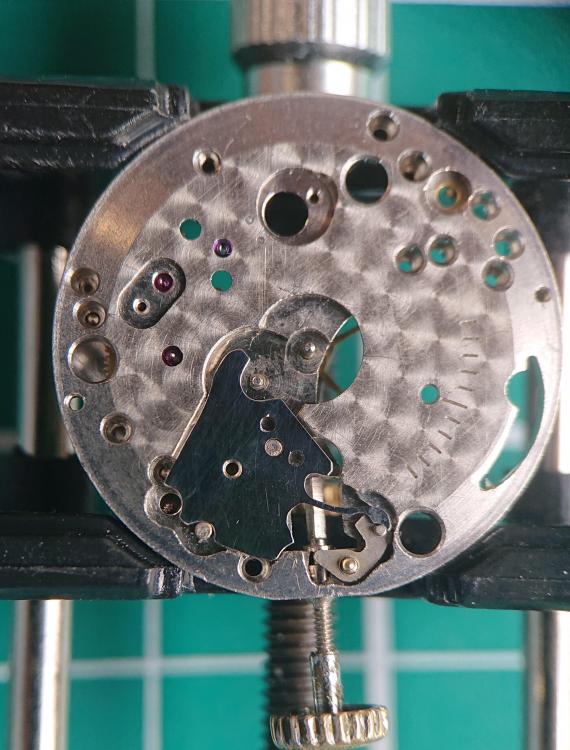

Got this interesting guy off eBay as a non-runner. It was fully wound to the point that I couldn't even disengage the click to let down the mainspring. I noticed the balance turned, but not easily, like it was glued in place. Not wanting to force anything, I took it off, then noted the pallet fork snapped back and forth briskly, so I knew there was power through the train. Took off the balance jewels, and found out they were stuck together with goo, both top and bottom. You may have seen the photo in the "Stuck cap jewel" thread. It must have sat in a drawer for a reaaaaaaaaaally long time for the oil to turn to shellac like that. I got the dried gunk off, put the jewels back in, and it sprung to life! What a fun feeling. It still needs a full service, and the hairspring looks a little suspect, but we're off to a good start. I really love the face and case, even though it's a little small on my wrist. The movement is really slim, too. I dig it. Ready for cleaning. Such a nice, simple movement.5 points

-

Hi peeps hope you all well. So here it is, I've been after a new bigger better scope to replace my pre Amscope ( Swift ) which has been ok but lacking on magnification and field of view. Asked around here for a little while and thought I'd be getting the same one Alex from About f______ time suggested. Also a few good guys here said similar. Did i listen ? Er yeah i did but then this baby fell into my hands today. I say fell which is not actually possible because its huge and and its heavy, veeerry heavy. It took two very strong boys to get it upstairs and into my watch room, me and my lad and hes 6 ' 5" and built like a brick shitter and I'm freakishly strong for a 5' 9" old fart. Bigger and better doesn't begin to describe it, its the biggest and the best lol, well i think so, I'm very happy. So what is it ? . Its a surgeons microscope, I'd guess around 50 years old, kept in a hospital's storage for god knows how many years finally released to make way for new old microscopes to fill the hospital storage. Made in West Germany, solid and stable as hell fully adjustable in every way possible. It has 3 light luminosity settings, 4 colour filters 2 camera mounts and the best bit is a Carl Zeiss 5 fixed magnification lens. Working distance of around 10 inch for all magnifications. The price ? I hate talking about prices, to me its priceless like my brother from another mother that aquired it for me gratis.4 points

-

I like the suction cup idea. I found one from my aquarium which was just the right size. Push fitted an electrical connector in to the hole, then mounted in the cordless drill. Spinning at low speed, and using 400 grit wet and dry. It only takes a little pressure, so you don't need a strong fixture. And it works !3 points

-

I've had some success simply blue-tacking the case back to the chuck of my battery drill. Open the chuck first so you have a flat face to work with. Use a relatively generous blob of blue tack. Once you have it centred, which is a matter of squishing the casback into the blue tack till it rotates without any chatter, simply attack with whatever abrasive is appropriate. 500 grit emery paper seems to do a good soft circular pattern. Coarser grit gives a coarse pattern, and you can polish almost mirror smooth with finer grit and polishing pads or something like T-Cut. You may need to re-centre from time to time, but the blue-tack keeps things surprisingly well centred. It probably helps that the drill in question has a good speed controller to keep things relatively slow and stop me launching the thing into space.2 points

-

Eyup delk. Both case back and bezel may come off. Look for a slight nick somewhere around the edge of both of them. It can be quite often opposite the crown, as long as a previous repairer has thought to replace it that way. Its can be something or barely anything so you may need a x10 loupe to find it. Go around and around both the back and bezel a few times it can be easily missed. If no nick then you may need something sharp to work your way in. Generally speaking if the watch has a bezel and it removes then the watch will come out that way after you have removed the movement's case screws that are at the back. But again this is not a given, there are always exceptions. As far as i know westclox are not like that, but not the name on this dial anyway delk ???2 points

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Any clock problems just ask.2 points

-

Thanks Gert, its amazing. I class myself as very lucky to have it and to have some incredible friends. He had been planning it for a while and then dropped the surprise on me yesterday the day after me and the missus got back from Rome. An anniversary gift he said, but now I'm worried about what he got the missus . Thanks Hector, thats exactly what it is. I've not searched it for a manufacturing date yet but I'm very curious as to how old it is. The optics are extremely sharp, inside the head is a 6 fixed lens block that runs from 6 to 10 to 16 to 40 to 25 to 10 then back to 6. The focus and working height remains the same for each magnification. The light source also runs through some optics in the last arm these optics connect up with the barlow lens . So wherever the light is aimed that is your viewing area, with 3 light intensities but also with 4 color filters. The main swing arm is counterbalanced from inside the arm post and then an additional weight block can be added to reduce its upwards counter pull to zero. Its a serious piece of kit, the friend that got it for me said they're just not made like this anymore. I am very lucky to have it and such good friends.2 points

-

10 month in Hello again to all. Just an update on progress of a beginner. And a few observations. I began in December 2021. My wife has 3 old pocket watches. That are dead. “I know!” I said to myself. “I’ll fix them”. I’ll look up on the Internet, and it will show me what do do. I’ll buy one of those watch sets and Bob’s your uncle (English saying). All will be well. The set arrived. I pulled the watches apart. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Some Internet sites are doing repairs. I’ll buy a cheap watch that I can repair. Did so. I was not running. Now I have 12 watches and movement. None working. What goes where.? My weekly spends of £10 was going every week and nothing to show. Nothing was ever fixed. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Looking on the Internet I found YouTube. There is a plethora of sites where people show you what do. Not! In actual fact there a very few who are into showing their skills at the teaching level. Less that 2 dozen. That’s not many. All bar two are amateurs. There are many who show off. “I started last week, and this is how I have worked on a Chronograph, and it is now pristine”. Wow! I can learn from him. Not. But as you begin to understand you realise why you can’t. Their skill level they portray is way beyond even my level after 10 months. The ability to use tweezers correctly to remove and turn jewels over for cleaning for example. What did I do right. Well, I can say in my favour, I typed the words ‘watch forums’. I found ‘Watch Repair Talk’, and information about Mark Lovick. Wow! Cant afford that. Look elsewhere, Buy a cheap course. Did so. The video was made in 1987 and was converted from a 16mm Cine camera and it was about pocket watches. They did give me a refund. It took me over 3 months to save and buy Marks course. Should have done it in the first week. What he offered me was information and guidance. Learn the principles. Practice. Repeat, repeat, repeat. It won’t work first time. Redo. Practice. Where am I now. What would I do differently. In actual fact. Not much. Working my way forward has given me hours of pleasure. I subscribe to 22 YouTubers and eagerly open each. They are great to learn from. I spend almost the same time practising. Can I disassemble safely? Yes. Very rarely screwdriver slip or ‘ping’. Can I clean? Yes. Hand clean then Ultrasonic to degrease and wash twice. Can I assemble? Oh yes. Do they work? Yes.. ish. Need to practice to overcome low amplitude. Am I getting there. Oh yes. One of the things that I have been told by a number of people is quite correct, but as beginner it is totally impracticable to practice. Don’t start on movements, or dead watches. Trying to find the parts for movements means that you have to buy another movement, or more than one because the donor is just as bad. The dead watch is just as bad. Why is is bad? Because it is broken and needs a part. Buy a movement for the part. Back to square one. In hind site, it is the correct thing to do. But where would I now be? Most running watches are in excess of my months saving. I would never have started. But I have. And I have to say it is great fun. What information would I have helped me? None really, as this is voyage of discovery and you can only discover by error – practice. The best thing I have learned is, system. Have every tool in its place. Put everything away each time. Have a label on each box that contains the watches and note on it details what you have done or need. Where will I go from here? Deeper into the hobby. I’ve given myself two years to learn enough to service my own very expensive watch. I bought it in 1968 for my 18th birthday. Regards to all. Ross2 points

-

I have been watching the videos that Dr John C Taylor has made showing the very best of some of the top makers we ever had. Here is the link and you can them pick out what you would like to watch. https://www.youtube.com/c/DrJohnCTaylor I have to say he is not in my family tree but having the same surname at some point there is a connection1 point

-

Interesting Andy, only 3 have a running balance .The only real solid potential is labelled meyer and studelisa on the movement, solomax inside the caseback and Medana on the dial. Was a quality watch in its day looking at it with some toughness. All quite old , one has a 1942 service mark inside. There is an awful lot of work between them needing hairsprings staffs regulator pins, stems, escape wheels etc etc. Its all good practice and learning to be had from them regardless of their outcomes1 point

-

Hi all . So here we have a bunch of 175s thats 12 watches for 21 quid. This is the new Dirty Dozen, very dirty and pretty sad. All art deco , love that style and eranot checked any of them as yet but 4 have stems missing and 3 without a crystal but i have a shed load of fancies so fingers crossed. It's going to be an interesting evening and I'll be happy if just one has some life. Good test for tge new scope as well.1 point

-

Hello, I just stumbled onto your site. I was looking for info on cleaning pallet forks & balance. I found the very good information here! My name is Benjamin. I am retired and live in San Marcos, California. I enjoy American pocket watches (mostly Hampden Watch Co.), just a small collection, I have. Also, many French clocks are in my home.1 point

-

Hi LWS If one was to pick up the watch for the first time without knowing the work done they would be had placed to spot any mods at all, Once cased and a new crystal fitted a first class job well done. cheers1 point

-

During assembly, the hour and minute hands were too small. I had taken them from a donor. I measured the hour wheel and the cannon pinion of the original, and then the same for the donor. The donor was smaller by 10um in both cases. I did not want to modify the hands, so I put the hour wheel and cannon pinion from the donor on the serviced watch. That worked just fine. I am waiting on a crystal, so the watch is running in a holder on the bench. BTW, I glued the markers on using GS Hypo cement.1 point

-

Yes its sometimes the case that the dial name is irrelevant to some degree.what is more important is the makers name on the movement itself and that name is not always the movements maker either if its an èbauche supplied to be assembled by a watch factory. Other letters and logos may be present to indicate the true maker.1 point

-

Very nice, I'm a big fan of Bulova's of that era. This one looks to be a 1967 Banker 'K'.1 point

-

The little that I have discovered about this is that LaSalle was the suburb of Chicago where Westclox had its plant. It used this label on watches and clocks. I suspect the name on the dial means less than the name on the back. And thanks for the hints on back and bezel. Time to get out the loupe! Best, Del1 point

-

1 point

-

1 point

-

I picked up this watch as part of a group from an auction site. Originally I thought it might be a cal. 292 which was (I believe) produced exclusively in the 40's. After opening the case, it turns out to be a cal. 452. I can't find a lot online about these particular movements. Does anyone know the history? I'm planning to make a thread for this watch with more images and info as I start working on getting it back into good working order. I'm a complete novice, but I know it's a pin-lever escapement, and the lume is almost definitely radium, so I know it will a) be annoying to service and b) also be somewhat hazardous. I'm not planning to start restoring/repairing this watch for my first attempt, I've got some cheaper modern movements on the way that I'll be practising on first. But eventually the plan is to tackle this watch when I have more experience.1 point

-

1 point

-

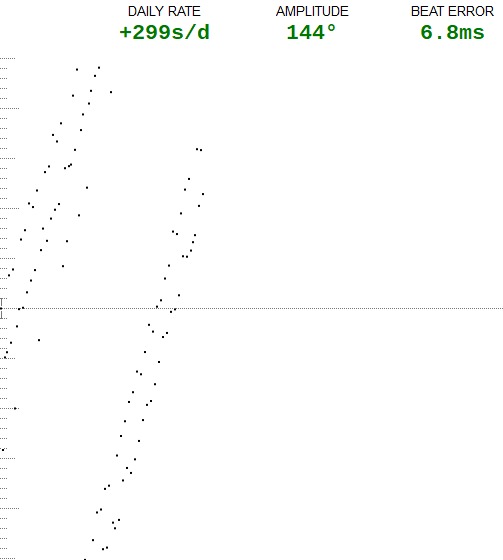

Fantastic, thanks for the info! With the bundstrap and leather band it really looked like a pilots watch from factory, so I was kinda hoping it might be a WWII era timepiece. Good to know that might still be the case. The back cover is in near immaculate condition which lends some credence to the idea that the bundstrap was an original accessory. It sure does! It's a bit of a basketcase on the timegrapher, about 200-300s a day slow, but then I'm not sure what to do about lift angle for a pin-pallet escapement. It's running non-stop but has some pretty severe jitters. I'm hoping it just needs a decent clean and lubrication and it will come back to life. Fingers crossed no issues with the balance, but I've seen some parts out and about. Will definitely go balance complete, the bank account is a bit drained after getting set up, so no staking set for me for some time. Great advice, thanks! I'm definitely planning to take as many macro pictures and probably video of the disassembly so I can reassemble in the correct order. I've watched at least one 292 disassembly video on youtube so I'm hoping that will provide assistance for the 452 if I need it. I hadn't thought to disassemle and then reassemble the cogs and spring a couple of times like that, but I'll definitely be doing that. Oh, I have no plans to clean the dial, I love the way it looks. I'm going to store it away safely until it's time to reassemble, that's about it. I'll definitely be replacing the crystal though, just hoping I can get it out without obliterating it, it's obviously not in great condition. Full PPE is the plan for sure. I really hope the lume stays in the hands, for safety reasons but also I'd like the watch to stay as original as possible. But if it does come out I'll look at re-luming with something less... radioactive. Oh yeah I've read up about that guy. I've been eyeballing the Bergeon presto 5-spoke wheel removers, but I don't want to buy a single tool for a single task if I can avoid it. I may be able to fabricate something that will do the trick, but if I go down that route I'll definitely be running it past the experts! Thanks again for your help!1 point

-

If you are interested I could provide the 3135 service manual as a pdf. There are a lot of similarities.1 point

-

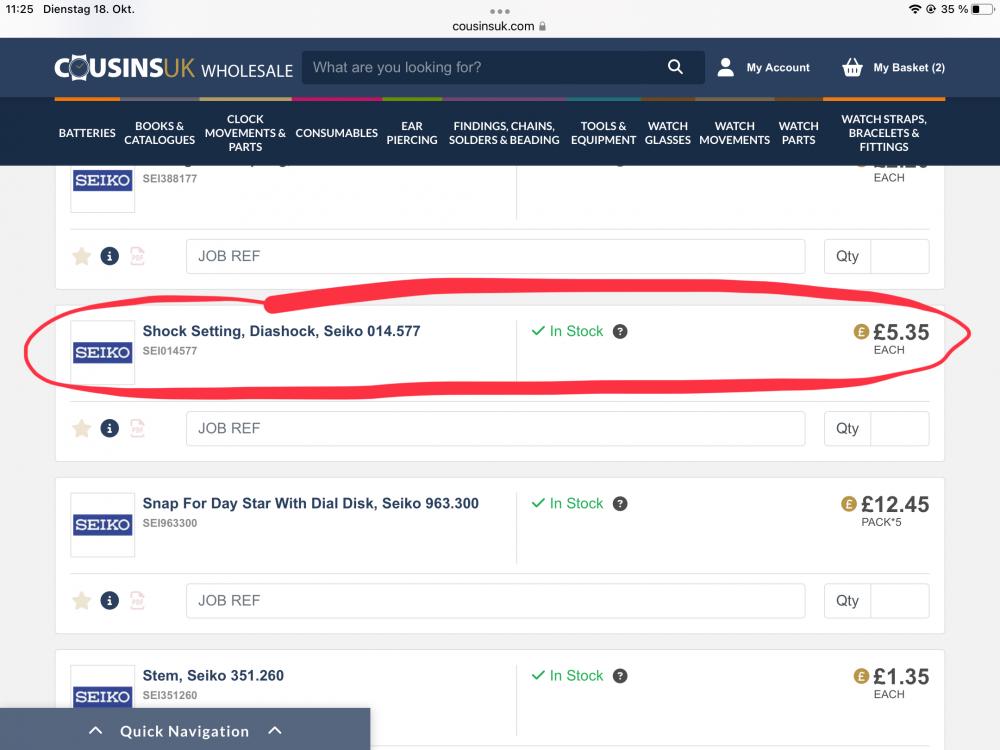

material houses for watch parts are interesting things in their histories are very interesting. I had never looked at cousins history until now it's at this link. as I read through the history what I find interesting is they embraced technology early on. When they realized that at one point most of business was with telephone and that fill the orders in the afternoon they grasped technology and embraced it early on. Plus they did not fear quartz watches like a lot of others did what makes the history of the company interesting is is exactly why you like to do business with them basically everything is online. this is where a lot of material houses in this country their histories are very different we still have material houses local material houses don't even show up online. The remaining two Seattle material houses do not have an online presence for instance and I'm sure there's others sprinkled across the country. I also know that a lot of material houses in this country do not have everything online just because the inventory things would be complicated so basically they will have to go into their warehouse and find it for you if you ask nicely. So this explains why cousins has so much they embrace technology early and the don't think they quite grasp thing is the way cousins did which explains a lot. https://www.cousinsuk.com/history1 point

-

Eyup lex. A good choice Oris is my favourite maker and were my first repairs. I have quite a few of these. The 292 is a fraction bigger but both made around the same time 40s and 50s . As far as i know the 26x and 29x were a little earlier but they overlapped for a while with the 45x . 451 is the sub dial the 452 sweep second and 453 is the famous oris date pointer, some of the dials on the pointers are just gorgeous. I have a lovely beige grooved dial with bronze raised numerals with an old style date cresent pointer, waiting to be repaired. The 45x jewel count did eventually go to 15 . Not bad to work on, does it tick ? The balance staff is often broken or worn so watch out for this when buying as not an easy fix for a beginner and requiring a staking set. An option would be a balance complete. The time set and winding mechanisms is quite dated with a rocker plate and 3 meshing cogs. But still not bad to work on, make sure you replace them the correct way up, one side has a bevel. And the return spring is a little fiddly, you have to work on both sides of the dial to have it interact with the rocker plate. My advice when you strip that part down take plenty of photos and do a few short reassemblies of the cogs and spring to imprint it in your memory how they go. Yes it is so no breathing in any dust or using your puffer to clear the dial, if you intend to try clean the dial ( personally I wouldn't for one it will ruin the patina here which has a nice tropical look going on ) then wear a mask and work well away from the numerals. Really just wear your mask, finger cots and roll a fresh piece of rodico over any loose debris. Then dispose of the rodico responsibly. ( not in the mother in-laws tea, now there's an idea ) The lume on the hands may well fall out when you remove them ( so thats a little more to dissolve in her cuppa , stop it Richard STOP you're being bad, you had a lovely gift yesterday lets not spoil it . Yeah wierd day coming up I'm affraid , I'm talking to myself already ) . Hi yeah sorry, back to advice er. The wheel on the top plate you can see drives the pinion on the sweep ( second ) hand. The pinion is under that little pressure strip. So that 5 spoked wheel needs come off before the plate comes off really, its friction fitted ( pressed on ) . It can be a real 'son of a' to get off for a beginner without the correct tool. So take your time plan what you are going to do and ask here before you even attempt it. A few members have some little hacks to try, if you break it you've lost the use of the second hand, er yes i have one those that has my swear words etched onto the bridge plate from my vocal blast .1 point

-

Welcome Dave! You'll probably want to review some material on the guts of a watch (I know nothing about clocks @oldhippy is our "go to" clock guy). Here is a good animated web page that describes the internals of a watch. You'll probably want/need tools as getting to the insides of pocket watches will require smaller screwdrivers than you likely have. Mark has a good list of domestic suppliers here: https://www.watchfix.com/category/watch-parts-tools-suppliers/watch-parts-tools-suppliers-us/ He also has several online courses that will give you more than you'll likely find on YouTube. Ask questions and provide photos and you'll usually get help from somebody here. - Gary1 point

-

When you are working on the movement side (1st picture), put the stem in. At least then the movement won't turn in the holder when you are turning the screws.1 point

-

1 point

-

Geesh Rich, nice score my man. That’s certainly an impressive piece of kit and have it fully articulate is a bonus!1 point

-

Ludwig and Fries was a wholesaler in Frankfurt/M. like Flume, Jacob etc. Frank1 point

-

You're right. I'm just asking for trouble! The good news is that it cleaned up pretty well in the end and has been running on the timegrapher overnight. Slightly lower amplitude than what I'd like to see, but I did re-use the original mainspring. Pivots looked pretty good after cleaning and treatment with pithwood. This was the first watch I got to use my new automatic oiler on for the cap jewels. I wish I would have bought one sooner. It made the process so much easier.1 point

-

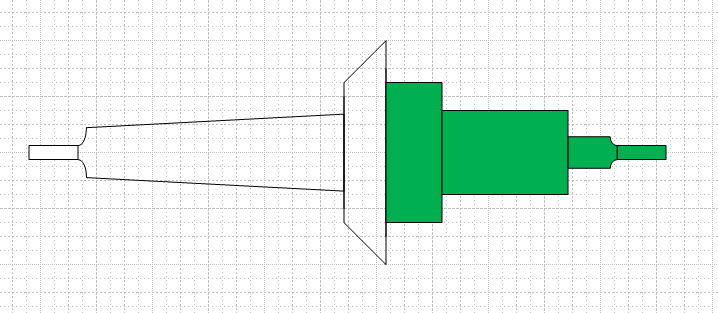

Thanks for the tips everyone. I went with the feeler gauge option as it was to hand. Rather than risking the temper I used a mini angle grinder (plus constant cooling) to cut a rough blank, then carbide drills and diamond files to drill and shape the part. I tried scribing the shape on to the part but eventually having scribed a copy as a template I glued it to the blank and worked on that: I changed the design of the detent spring slightly as the original obviously had a stress riser at its root. I couldn't match the exact shape of the detents but their positions are identical to the original. Time to check for functionality and fit: I bent the spring slightly (about 0.3mm at the tip) down towards the setting lever. It functions perfectly and feels smooth with a distinct click from one detent to the other, so I'll polish it ready to fit to the watch when it is cleaned: Thinking of stress riders I polished the cut edges of the spring with metal polish on the tip of a toothpick . It will be interesting to see if it lasts.1 point

-

Well...it is about the journey, not the destination. I show the progress here in this figure, but there is a problem. The dimension for the balance beam hole specified did not work for my balance. Probably been wallered out over the years of repairs. Instead of 120, I get 133. Discovered that AFTER the cut. I can save it by going back to the pivot and working inward.1 point