Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/22 in all areas

-

Thank you for saying this, because it is exactly my mindset. It does look like it's twisted right where it connects to the clamp on the balance cock. I have practiced hairspring manipulation on several other movements with good success, and I'm quite confident I can fix it. I'm just demoralized that I can be so careful, and still accidentally bend it. I suppose it's a normal part of the process, but still tremendously frustrating. Not to mention embarrassing. I almost didn't post it, but I figured we're all on this journey together, so might as well share.3 points

-

I have been watching the videos that Dr John C Taylor has made showing the very best of some of the top makers we ever had. Here is the link and you can them pick out what you would like to watch. https://www.youtube.com/c/DrJohnCTaylor I have to say he is not in my family tree but having the same surname at some point there is a connection2 points

-

2 points

-

Hey Ross, the big problem with all these type of digital microscopes is the working distance beneath the lens. They are fine for inspection and pics for recording what you have done and posting on the forum. You can’t really beat a trinocular optical scope with ring light, camera and Barlow lens. Tom2 points

-

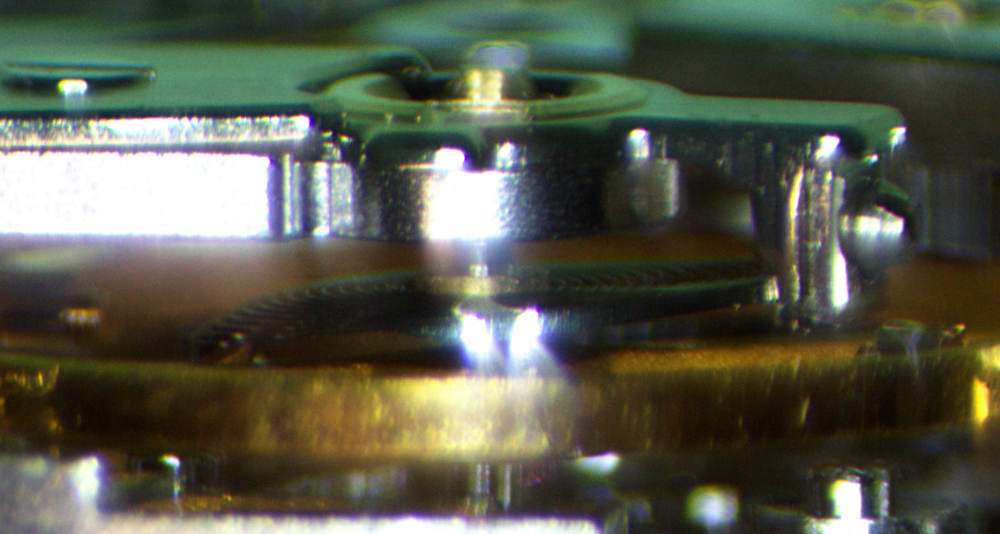

I believe it’s gummed up reverser wheels in the automatic works. Same issue on the 2824 that the sw200 is based on. Those reverser wheels should generally be replaced at every service. According to the tech sheets they shouldn’t ever be cleaned but they end up being cleaned and not lubricated correctly, which should be a dip in Lubeta V105. Depending on the state of yours, they might need to be replaced. That being said, how bad is the spinning when you manually wind? Rotor will move slightly when winding and keeping the watch at a 30deg angle, but s stiff winding stem and spinning of the rotor means seized reversers.2 points

-

I'm happy to hear even practicing because hobbyist typically like to practice on live subjects and don't like the practice on stuff just to be practicing. Unlike people who go to school who have to do the same thing over and over and over again until I get really really good at it. as I said with a watch like this there isn't too many places where it can get bent.. unfortunately this is watch repair everybody has accidents. At least everybody that's paying attention often times people don't pay attention and don't realize who caused the accident. then it's definitely nice if you share. I feel annoyed a lot of times when you help somebody and they never get back to you as to whether the fix the problem or not because they don't realize somebody else is going to go down this path at a later date and this information to helpful. I was going to find you a video on end shake adjustment found this website a lot of interesting information but when it gets to the balance adjustment of course it's wrong a Rolex word has a screw specifically for this purpose. But this person isn't talking about Rolex which is interesting https://nobswatchmaker.com/blog/simplifying-the-art-of-endshake-in-watchmaking oh and end shake think I might have mentioned this Rolex is obsessed with it not just for the balance wheel for the entire watch.2 points

-

1 point

-

Haha that was on tv last night, very wierd and really funny Gary . Thank you, I'm over the moon with it, i just need to re-jig the room as it blocking half the door way. I wouldn't even like to guess, my buddy that buck she'd it for me ( he is well respected at our local hospital and pulled a few strings for me ) said the new ones are garbage quality compared to this. I've said this so many times on here, think positive, be positive, be kind and do good thinks for people. Ask little favours of the universe and when the time is right and it wants to reward you, you shall receive. . And no I'm still not religious in any way shape or form, just genuine.1 point

-

Good one NEW. The cosmos is shining down on you for sure, that would have cost a ton in the day Tom1 point

-

as you don't have a location in your profile I wasn't sure where you are located. The reason I bring this up is even though most the people order from cousins most the people in this group are in Europe and I'm pretty sure in the US there are material houses you can order from. then for hairspring work everybody has their favorite tweezers I like number five. but once I finish with my hairspring tweezers put them safely back in the bench because using them for general watch work screws have a habit of flying away the good for hairsprings bad for general repair.1 point

-

Kinda like that scene in CROCODILE DUNDEE where he goes: "That's not a knife, this is a knife" That's a big one alright! May it serve you well.1 point

-

Hmmmm, for something that has so much friction/movement I'm curious why you'd suggest running them dry? Granted, overlubrication is a bad idea, but no lubrication? Genuine question. V105 is probably expensive for what it is (and we can't even get it locally), but a mix of 1 part 9010 to 33 parts IPA is a good substitute and works very well.1 point

-

I’ve never worked on a Rolex before, but I would check to make sure if one has the correct tool for the job: not sure what screw driver to use for the hair spring clamp, and the balance wheel screws. Also, if you have to adjust the hairspring on the Rolex, make sure you have the correct tweezers for the job. You may also have to remove the hairspring(and collet) from the balance wheel to adjust the hairspring flatness, but that is also a risky procedure. Do take some (a lot) of time to consider what you should do, and ask here before attempting.1 point

-

Aw mate sorry about that dont panic, you are in good hands with John, anything he doesnt know isn't worth knowing. Theres always a way around issues and always a fix. You really do need to take break and reset yourself maybe for a day or two if its more than just bugging you. Dont battle through it while you are in this mindset. Good for you matey, you have the right sort of attitude for watch repair and for a forum. To pass on any experience and anything you learn does help others. I try not to consider too much a watche's value, sentimental or monetary when repairing, it can affect nerves and ultimately how you work. Finding the right balance between confidence and complacency is key. You are in no rush to fix this watch, a week , a month, six months, its doesnt matter. Do some h/s practice on some cheap movements if you need to while you are taking a break, even if you have to buy a couple of crappy watches to do that. Then when you are ready, take up your mission again with the Rolex. And before you start,tell it that you are going to fix it. To get through everything in life we need a positive confident mindset, trust me i know what I'm talking about, I've been in some very dark places. So the order of the day will be " Oy Rolex you're getting fixed whether you like it or not "1 point

-

love it. great work! over here we call your framework Alstrut. Don't know what yours might be but i can tell you-stuff is expensive! nice shop BTW.1 point

-

you need to take a very long break now which is really hard because you really want to work on it and then come back and evaluate the situation. fortunately you don't have regulator pins so the only place that you could then they hairspring would be normally at the stud but you don't have a stud. Instead you have a clamp that's holding the hairspring. There's a tiny possibility that the screw is loose and it's just twisted. One unlikely you bet it at the clamp and this is a relatively simple fix if you been practicing on other balance wheels integrated hairspring work. Typically people like to practice as they go in other words they don't like the practice and Rolex balance wheels are really expensive and you really don't want to practice on that. So if you haven't practiced bending up hairsprings and fixing them need to find something disposable out there to practice on. Words you can bend a hairspring at the stud and see what it does then bend it back and see how easy it is to fix that is once you do a proper evaluation make sure it actually is bent and not something else that we can't see.1 point

-

Thank you for doing that. My plan was to not change a thing. So I took the balance off to remove the pallet fork so the balance would be free spinning while I set the end shake. When I reinstalled it, this is what I was greeted with. I have absolutely no idea how or when it happened, but I'm so upset right now I can't even see straight. I've been beyond careful and delicate with the balance, and still I ruined it. I'm so frustrated. It's not a digital, it's an Amscope 7x-45x trinocular scope with an old Canon EOS Rebel DSLR on the trinocular port.1 point

-

there is something about the hairspring that was bothering me is looking at balance completes on eBay and yours looks different but? I emailed the photograph to somebody who works on Rolex watches an answer back was this "This looks exactly the way it is supposed to. Don’t change a thing." I had to find what you are quoting from. If you do not lubricate the reverser wheels correctly worst-case is they will not work. I remember doing an Omega watch for somebody and the Omega reversers are supposed to come apart at least the service manual so is that. At the time I couldn't take them apart and put oil in them the best I could watch what out watch came back and fortunately that was long ago when Omega parts are available I just bought a new reverser wheel and basically it was solely a lubrication issue I couldn't get the lubrication where supposed to be. Now there's a solution you dip it into and it will take care of that but you really wouldn't want to have a service like a Rolex have an issue because lubrication got on the clicks and things didn't work people to spend a lot of money to get a Rolex service to expect them to be perfect oh and then even disassembling the reverser wheels later in my life I worked at a shop that was authorized to service Omega watches. In the good old days when they didn't have their own shops they had independent agents all over the place and did he take them apart didn't have the tools. He used a dual lube cleaning product to lubricate them. So basically all the reversers require different lubrication's and can have issues if the lubrication is wrong. And having an unhappy customer because of that isn't good although my customer wasn't happy he just brought it back and I had to replace them. Because I didn't know how you are supposed to lubricate them back them other than what I shown in school that didn't work1 point

-

1 point

-

1 point

-

Here is a page where you can find an incredible amount of synchronous motor clocks. If you are patient and lucky you might find your specific movement. Clockdoc1 point

-

1 point

-

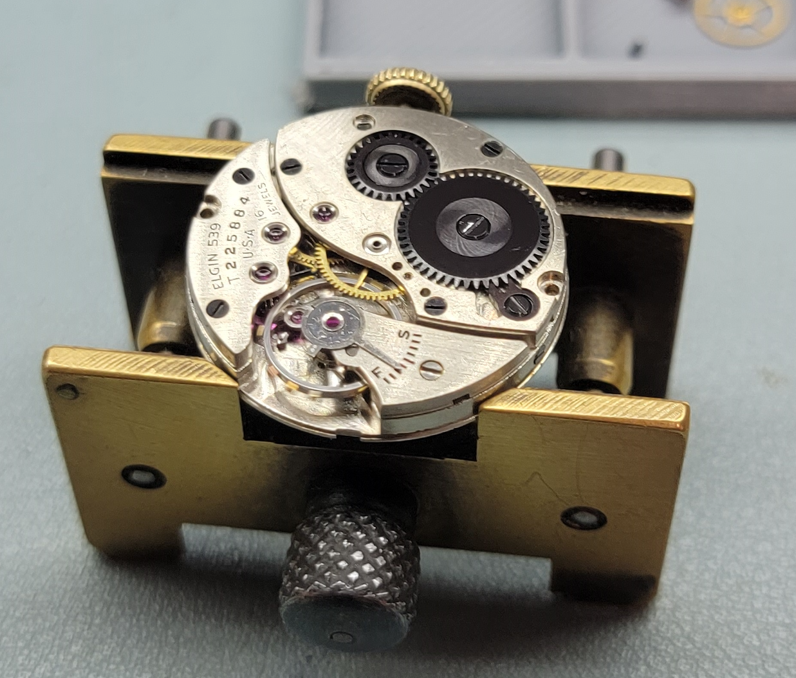

He guaranteed his work for one year, which for that time was standard practice, so there. I think he recommended yearly service. Again, I am an amateur and I work for free. I use vintage Elgin oil, Molykote, and Yamalube...a super light oil for escapement. Let the bullets fly.1 point

-

Yeah, a little Pro Micro. I must admit that it being fun was half the reason I did it. Now I must just finish it properly lol. Thanks bud. Haha it’s a common term used here, us being an ex Brit colony and all. But no, I’m 45% Dutch, 40% German and apparently there’s a Spanish Prostitute and a little Indian in the mix as well.1 point

-

I had a little time to work on the machine again and this is where I'm at. Very much still prototyping but key elements of the design is working. I've just shortened the cycles to 5 seconds each, as opposed to probably the 5 minutes that it should be - I'll have to go soil up a watch movement to get an idea how much time it needs in practice. It turns out that it's a lot more stable now at 900rpm than I initially thought it was going to be. Now I just need to work on the wavebreakers and make things a little more permanent.1 point

-

Steiner was Steiner. Bergeon put tbeir nameplates on the boxes though. Steiner is now made by Horia.1 point

-

UPDATE: Well, I gave it a shot. I did manage to get the major kink out, but I'm not ready to do much more than that, at least on such a small and thin hairspring. I was able to do as much damage as I could undo at any stage but at least I got it to be pretty round and almost flat. I did have a chance to work on a more manageable hairspring today too. I made my first attempt at oiling the cap jewel on a non-shock protected pocket watch, which meant removing the stud and taking it off the balance cock. I had a spare movement and practiced on that one first with perfect results. When I then did the one I wanted to use, its overcoil became tangled in the next coil, and untangling it caused some deformation. I did get the overcoil back into shape but the balance doesn't quite run yet (fine because i have the spare). This one does feel like it will be manageable when I have the patience to try again. The 10s pocket watch hairspring is definitely sturdier than the tiny ladies' movement mangled as the subject of this thread.1 point

-

To remove the cock-balance assembly, loosen the cock screw about 80% of its thread, do not remove the screw so it keeps the cock assembly from flying as you try to unpin the cock. Regds1 point

-

The Elgin Watchmaker's College PDF has a bunch of tool projects in it, including a different version of a screw polishing tripod. I've attached a copy for you to peruse. ELGIN-Watchmakers-College.pdf1 point

-

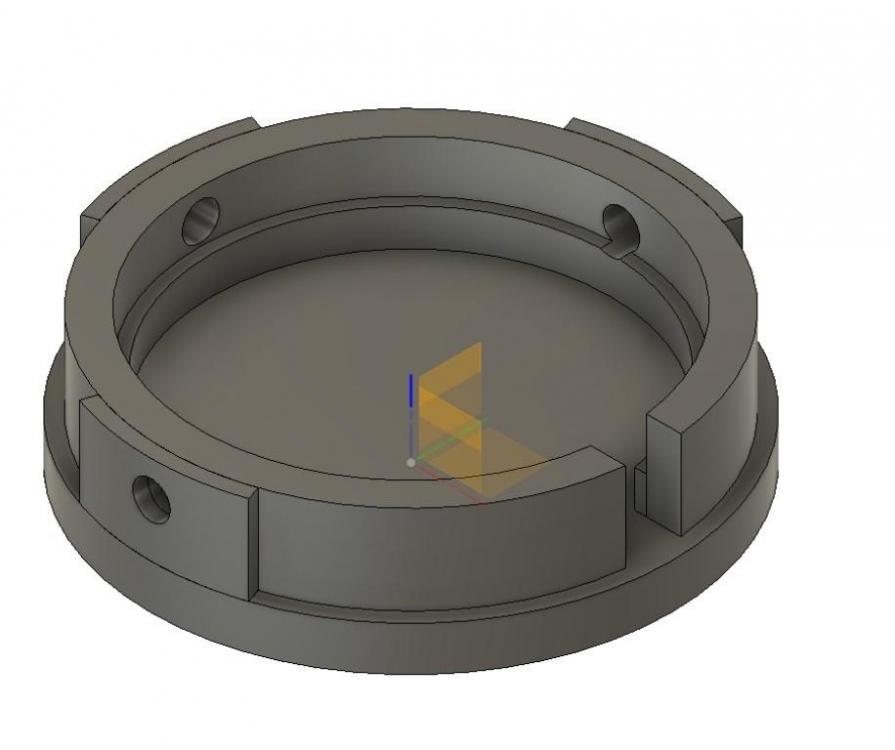

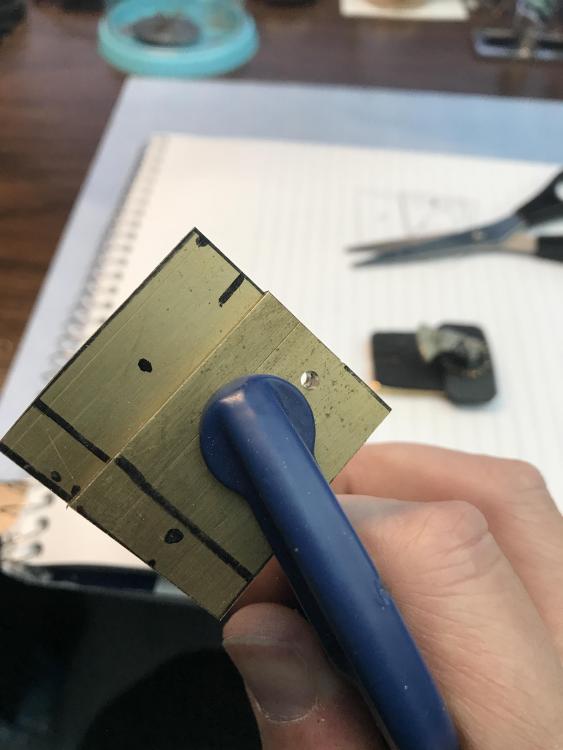

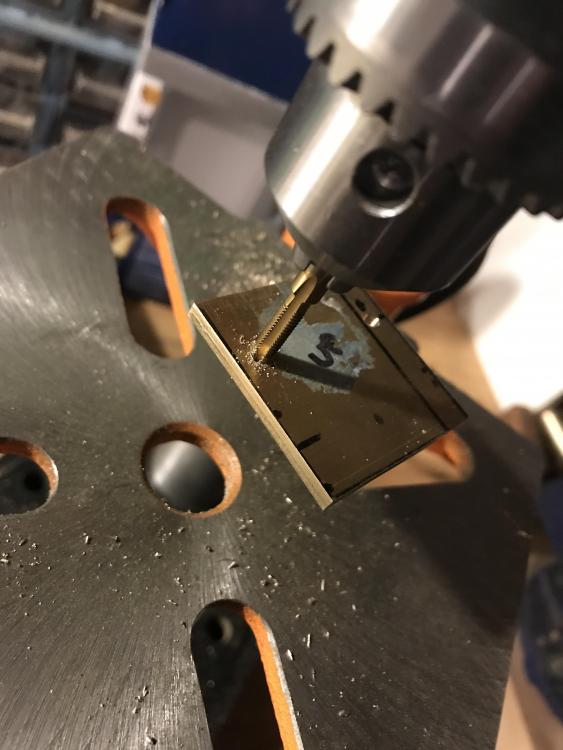

I searched movement holder in this forum and saw that they do come up in discussion so I thought I'd share my 3D printed and aluminium machined holders. I've tried a few different cheap (Ebay) movement holders and yes they do work to a point but the movement can - and always at the wrong moment - jump out or move in the holder so I tried a few 3D printed holders, I found that estimating the amount of shrinkage was a bit hit and miss, allow too much for shrinkage and the movement tends to move around in the holder - reduce the shrinkage allowance and the movement doesn't fit, a 3d printed one that was ok and a good fit is shown next to the aluminium holder, time taken to design and print is about 60-75 minutes. I also designed a slightly different one in Fusion360, the idea is that the 3 sections where there is a boss will be tapped 3mm and a 3mm plastic screw used to hold the movement steady, plastic/nylon screws available from electronics stores are used to fasten circuit boards down, I haven't printed this one yet I still need to decide if a 3mm screw will cause any damage if tightened at the wrong spot, that's the reason I provided 3 postions for the screw one should be in the right place. I also made one from aluminium it works very well, like the 3D printed one it supports the movement all the way around the edges a 4mm thumb screw presses an aluminium 'jaw' against the movement, the jaw is just a 1/4" length of aluminium rod cut out to suit the curve, there is enough slop in the hole that the 1/4" rod fits into provide firm grip on the movement. Part of this was made by hand the whole process taking about 2 hrs but since then I've worked out a way to machine the complete thing. If I end up making any more aluminium holders, I'm going to 3D print a cap/cover so I can cover the movement while taking a break for the day or lunch - what ever.1 point

-

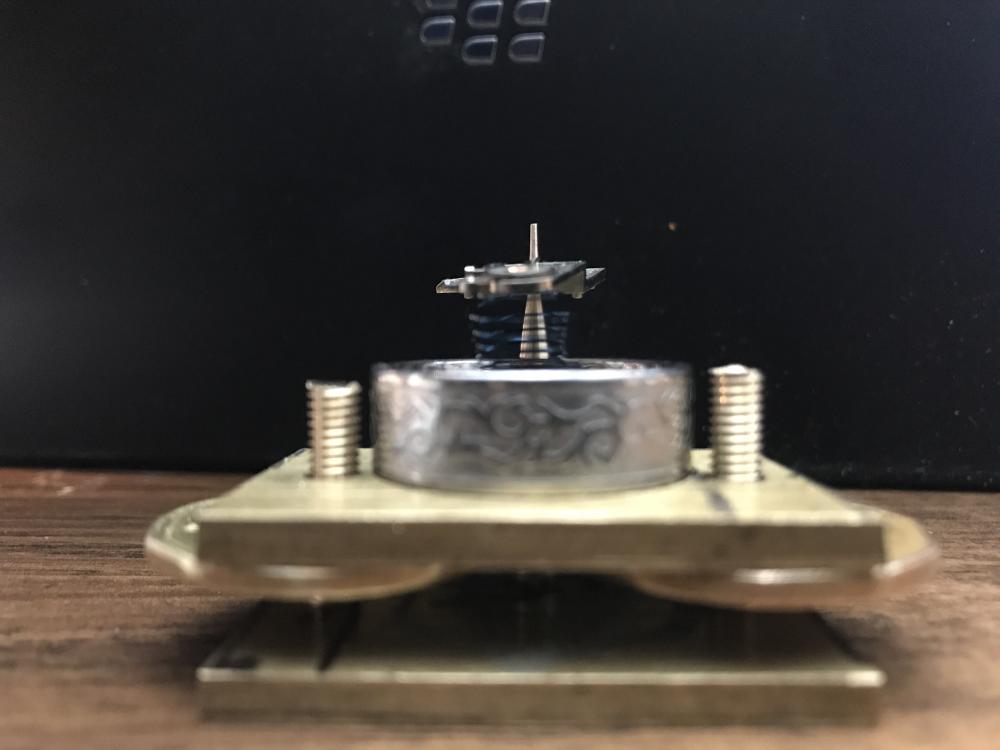

So have you ever dipped a balance with hairspring into lighter fluid to clean it...old school. Well I do this occasionally and most often remove the spring for cleaning. However, sometimes it is nice to just clean the balance and hairspring will still on the balance cock. Soooooo, I invented and made this little elevator that has a small cap filled with lighter fluid, and the Balance is hanging on a tack. You simply lift the fluid up to the balance. This is so so safe with no chance of snagging the hairspring or dropping the balance cock and leaving the hairspring elongated. It has not been completely finished yet and is still in rough form. Plus, I need to make a brass bowl vs using the cap of a cigar tube (it actually worked) with a spot of lock tight on the bottom. Really fun little adventure. And “IT WORKS”.1 point