Leaderboard

Popular Content

Showing content with the highest reputation on 10/06/22 in Posts

-

10 month in Hello again to all. Just an update on progress of a beginner. And a few observations. I began in December 2021. My wife has 3 old pocket watches. That are dead. “I know!” I said to myself. “I’ll fix them”. I’ll look up on the Internet, and it will show me what do do. I’ll buy one of those watch sets and Bob’s your uncle (English saying). All will be well. The set arrived. I pulled the watches apart. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Some Internet sites are doing repairs. I’ll buy a cheap watch that I can repair. Did so. I was not running. Now I have 12 watches and movement. None working. What goes where.? My weekly spends of £10 was going every week and nothing to show. Nothing was ever fixed. What am I looking at? Don’t know. What do I do? Don’t know. How do I do it? Don’t know. Looking on the Internet I found YouTube. There is a plethora of sites where people show you what do. Not! In actual fact there a very few who are into showing their skills at the teaching level. Less that 2 dozen. That’s not many. All bar two are amateurs. There are many who show off. “I started last week, and this is how I have worked on a Chronograph, and it is now pristine”. Wow! I can learn from him. Not. But as you begin to understand you realise why you can’t. Their skill level they portray is way beyond even my level after 10 months. The ability to use tweezers correctly to remove and turn jewels over for cleaning for example. What did I do right. Well, I can say in my favour, I typed the words ‘watch forums’. I found ‘Watch Repair Talk’, and information about Mark Lovick. Wow! Cant afford that. Look elsewhere, Buy a cheap course. Did so. The video was made in 1987 and was converted from a 16mm Cine camera and it was about pocket watches. They did give me a refund. It took me over 3 months to save and buy Marks course. Should have done it in the first week. What he offered me was information and guidance. Learn the principles. Practice. Repeat, repeat, repeat. It won’t work first time. Redo. Practice. Where am I now. What would I do differently. In actual fact. Not much. Working my way forward has given me hours of pleasure. I subscribe to 22 YouTubers and eagerly open each. They are great to learn from. I spend almost the same time practising. Can I disassemble safely? Yes. Very rarely screwdriver slip or ‘ping’. Can I clean? Yes. Hand clean then Ultrasonic to degrease and wash twice. Can I assemble? Oh yes. Do they work? Yes.. ish. Need to practice to overcome low amplitude. Am I getting there. Oh yes. One of the things that I have been told by a number of people is quite correct, but as beginner it is totally impracticable to practice. Don’t start on movements, or dead watches. Trying to find the parts for movements means that you have to buy another movement, or more than one because the donor is just as bad. The dead watch is just as bad. Why is is bad? Because it is broken and needs a part. Buy a movement for the part. Back to square one. In hind site, it is the correct thing to do. But where would I now be? Most running watches are in excess of my months saving. I would never have started. But I have. And I have to say it is great fun. What information would I have helped me? None really, as this is voyage of discovery and you can only discover by error – practice. The best thing I have learned is, system. Have every tool in its place. Put everything away each time. Have a label on each box that contains the watches and note on it details what you have done or need. Where will I go from here? Deeper into the hobby. I’ve given myself two years to learn enough to service my own very expensive watch. I bought it in 1968 for my 18th birthday. Regards to all. Ross5 points

-

3 points

-

I did make above the reference to the Bulova book. Before videos there were books that's how people learn things ideally even with a video I would find a scrap balance wheel and practice to avoid complications. But if you want a video here's a video and you will note that he referenced reading a book and he's not an expert but here's a video of somebody's journey with the truing caliper3 points

-

Thanks for the reply @HectorLooi, it makes me feel better about what I just did! I was reading and found an article where it said the same thing, that they aren't really serviceable and must be replaced if they get too loose. Well, I figured there wouldn't be any harm in trying to fix it because I'd just order a replacement if I damaged my current part. Looking at mine under high magnification, I saw where the 3 brass prongs sat inside that gap just behind the roll crimp on the back side of the cannon pinion. There was a lot of vertical play, which I believe contributed a lot to how loose it was, along with the brass prongs not seating fully in that groove any longer. I slightly adjusted the prongs inward. Afterwards I used my recently acquired antique staking set to basically press down a bit more on the old roll crimp with a curved stake, lowering that crimp closer to the brass prongs. It still has movement, but wasn't as free spinning as it was previously. It seemed to do the trick and the watch is up and running now! I feel the slightest resistance when setting the hands, and the minute & hour wheels are moving nicely. I'm pretty happy about it. I felt like a bit of a 'watchmaker', fixing the part rather than just replacing it. I saved a bit of money and probably a lot of time trying to source a replacement part as well.3 points

-

Bloody brilliant post Ross, it reflects what practically every beginner here has experienced. I'm so pleased to see you still at it and staying with us. You're a bloody star and an inspiration mate2 points

-

Well done Ross and keep at it you are learning all the time, After 10 years you will still be learning.2 points

-

Thanks all your your advice on this. It was good practice using the Jacot tool on less fiddly pivots, and the replacement jewels were simple to fit in pressed in brass mountings. There is no significant change in the appearance of the escapement except the slight change of colour from the old jewels to the new synthetic ones such as the lower jewel in the picture below. The movement works perfectly.2 points

-

2 points

-

This 404 club candidate just arrived. A Star cased 10K RGP Vintage 15 jewel Wittnauer rectangular mens dress watch for £1.99 The listing didn't show the mechanism, but the star on the case back piqued my curiosity. It is admittedly a non runner. It needs a main spring and a second hand, and obviously a service. Here are a couple of images of what is inside (following a quick scrub of the case and crystal, but not a strip down of he mechanism). I'm not sure who made the mechanism. Longines or Tissot are possibilities, but then again so are AS and ETA. Does anybody have any information in this regard? EDIT: The AXA mark according to www.mikrolisk.de is a registered mark of Albert Wittnauer & Cie. SA designating a US-Importcode for Wittnauer & Cie. Uhrenteile; Genf, Montreux, Carouge, Schweiz; New York, Montreal, Chicago, USA. So there is a good chance this watch was originally sold in the USA, most probably around the 1940s I'll post more pictures once I have it fully restored and running.2 points

-

Ok so another crazy post. Only joking . Most watches that we are aquiring via ebay are tending to suffer from one of three things. Three things that stop beginners in their tracks. And these are the things i most want to learn even in my short learning span. No. 1 issue- a broken balance staff pivot. No. 2 a missing or broken stem and No. 3 a shafted hairspring. So 1 and 2 is going to require a lathe, not a cheap item . But i managed a good one fully kitted out for 180 Betties, a very lucky find but patience paid off. And lastly No. 3 a hairspring vibrator required possibly, a more expensive item, harder to find and not something the missus should be toying with either. Pun unintended but hey it just came out that way so deal with it. This post is to ask a couple of questions regarding repivoting. Ive watched a few you vids on it so i have a general idea what to do. The questioning is aimed mostly towards pros and their opinions on how well it works ? how easy is it to do ? and what sort of equipment and material is required ? Or is it just better to buy and fit a new staff, bearing in mind a staking set will be needed and thats providing a replacement staff is available. A full staff turning is almost definitely out of the question for the beginner, but I'm game after a few months of lathe practice and a new scope acquisition. I will be asking about the stem manufacturing and the hairspring replacement in the future if thats ok. Thank you for any comments and advice in advance. ( Nickelsilver )1 point

-

1 point

-

yes i've never had cause to use it (i build guitars also) but that was part of harrisons genius, his use of materials. He would use all kinds of metals with each other that expanded at different rates that was way ahead of his time and also use of exotic woods like lignum vitae that are self oiling and super hardwearing... https://en.wikipedia.org/wiki/John_Harrison1 point

-

anybody hobbyist or professional if there's some problems it's usually best to think about it rather than jumping in. I find often times people what make quick decisions basically end up painting themselves in the corner of the room before they grasp what exactly they're doing. out of curiosity is this the way the balance wheel came?1 point

-

with modern watches they typically don't like to remove the balance wheels from the balance bridge especially of it has a etachron system of holding the balance wheel hairspring in place. So just easier to remove the balance jewels and clean the balance safely mounted to the main plate. But with vintage you're cleaning fluid isn't going to touch the pivots or the jewels if they're all sealed up in other words the balance is in place. So it's better to entirely remove the balance wheel from the watch and put it in its own separate compartments in the baskets or in a separate smaller basket. You don't want anything bumping into the balance wheel and hairspring when you're cleaning1 point

-

1 point

-

Lift angle should be 42 degrees. Looks like an issue with the escapement (if you're sure the hairspring isn't rubbing somewhere). What that issue is is pretty hard to say without more investigation.1 point

-

Wittnauer, predecessor/part of Record ? Nope got that wrong. It was Longines that had a connection with Wittnauer. From my reading, Wittnauer was a big importer of Longines watches along with some other high end brands. The Wittnauer house brand was their next best thing to offer America against their more expensive import watches that they sold. Their business dealings with Longines lasted decades and when Wittnauer finally sold in 1936 the buying company kept the same arrangement with Longines. That business changed its name to become Longines-Wittnauer, probably a generous agreement with Longines to promote both brands. But apparently neither owned by each other, just a shared name to benefit both parties. Or so it seems. Been after one of these for a while but they dont come cheap. I was lucky not much interest in it. Great retro 70s feel, i read somewhere that they were given away at petrol stations if buying a full tank of fuel, i wonder how true this is. Good condition and runs, but the alarm is not working. It coes look like the alarm set stem has been swapped as it has a logo on it. Lets have a look at that. hmmm Tissot ? I was under the impression Secura ( This guy bought Breitling, nice when you can just go out and buy yourself a major watch brand on a whim eh ) made these.1 point

-

Have a really good close inspection of that lug to see if there are any fracture lines around it against the case. If so i would be temped to leave as is as any straightening is going to stress that area more so. A full break is going to cost you the price of a jeweller to micro weld it, probably more than the watch is worth.I will post you some photos when i get home, i have the equipment but not got into the whole process of it as yet. Also a little diy gadget to make as well to help with accurate and even plating. I ruled out gold plating from the start too expensive and I have an idea that the chemicals are pretty toxic. I will be concentrating on just nickel plating1 point

-

1 point

-

1 point

-

Good advice from @nickelsilver - I have a Hamilton 992 Railway watch, nothing complicated about it, but it's not worth the risk of damaging yours before you become more skilled I started on pocket watches, and I always advise beginners to do the same. It's easier to learn the necessary skills on the larger parts before moving on to wrist watches. If you want them to run well, buy watches with at least 15 jewels. I have a collection of 16s Waltham's which I learned on. Nice quality and not too hard to find parts. And they look wonderful1 point

-

Hamilton was the cream of the crop in the U.S., and the envy of many Swiss makers. You'll want to get some cheaper watches to practice on before getting into this piece.1 point

-

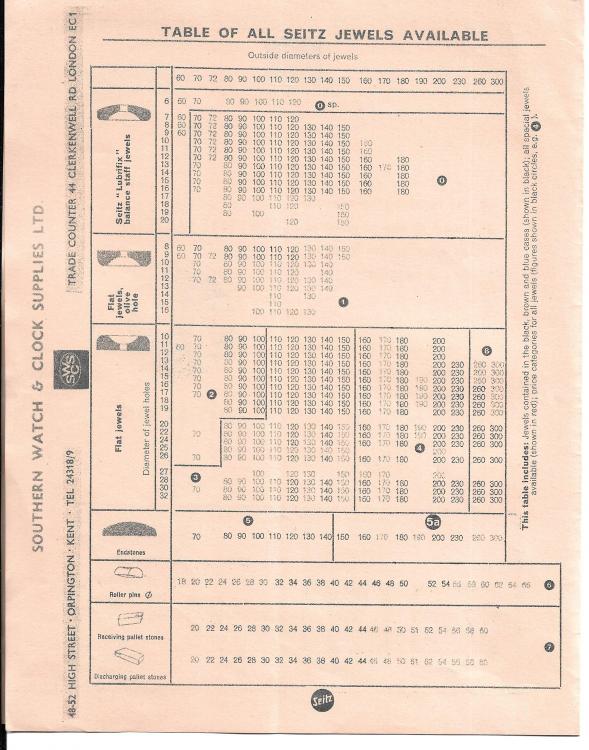

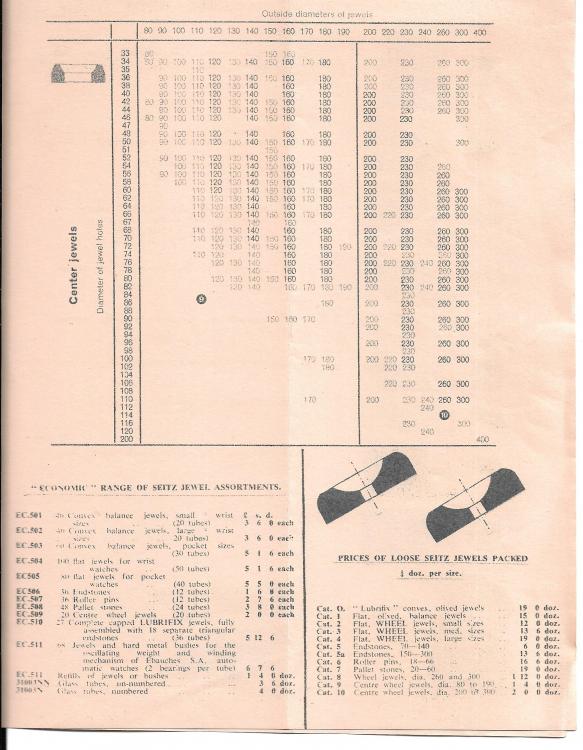

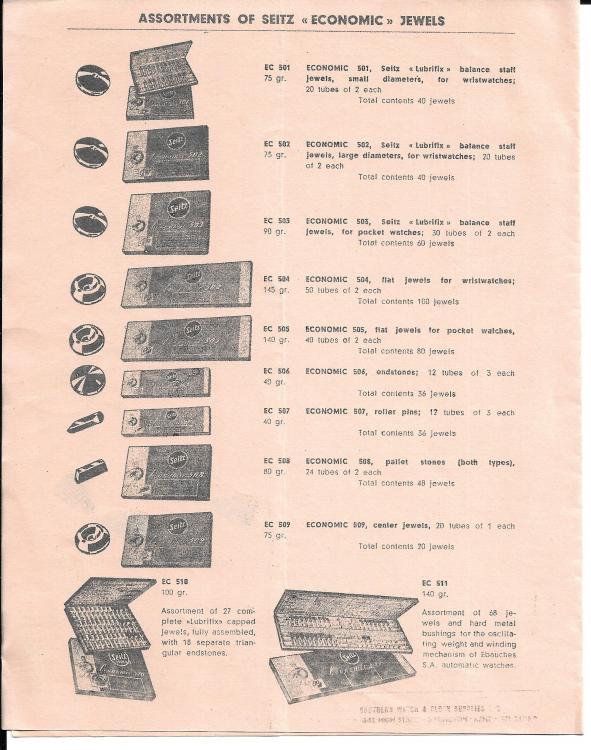

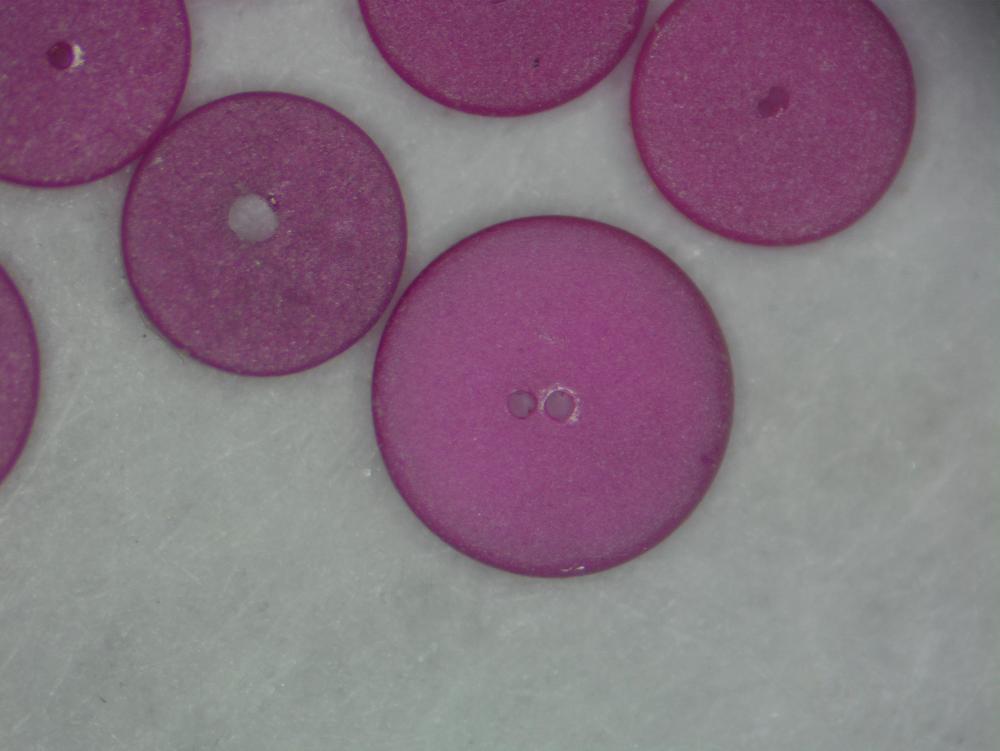

It wasn't fair from me to place that pic there, it might explain why to insist on Seitz though. The pic I took was about some of the jewels came from this assortment: https://www.cousinsuk.com/product/jewel-holes-end-stones?code=J47732 First it seemed to be a good buy, but turned out that these are the jewels which were discarded and swept from the floor after the shifts in the jewel factory.1 point

-

1 point

-

When reassembling, try and see if you can support the stem at the edge of the movement, where the stem enters the movement. This will help to stabilise the stem and avoid further damage. A bit of copper/brass is easy to work into a tube and you can probably epoxy it in place. Hell, even a piece of plastic sheathing like the bit around an electrical wire will be better than nothing as I don't think this watch will be worn on a daily basis. The idea is to avoid further damage. Also the case may need a crown tube as that also helps stabilise the stem/case/movement interface. Anilv1 point

-

It's not advisable but I've done it before. You need to remove the centre tube first, then use a screwdriver blade to wedge the prongs on the wheel to tighten it. Good luck.1 point

-

I ended up just placing another order to cousins. They seem to be the only place at least with an easily searchable site that has such a huge selection of generic gaskets that i could actually find ones that were exact matches for everything i need and then i ended up going with oem crystal gaskets, took the opportunity to get the etachron twisting tool and some new sapphire glass for the two watches and a proper oil pot with individual lids to avoid dust contamination. While i'm a little annoyed this will delay everything for another month or so i should be good on tools and equipment now.1 point

-

I once tried to turn a piece of this stuff, into some spinning tops for my children . It was as hard as iron, i had to use a sharpened masonry drill bit in the end. Hardest wood on the planet. Your confirmation is confirmed mike Under a scope first attempt one min, second attempt 20 seconds, third attempt about 10 seconds. I found the easiest and safest method is to forget using tweezers and use a rolled up piece of rodico, put a small bend at one end of it , hook it through the balance wheel up against one of the arms. Bring the lantern fully in on the right side, using your right steady hand to drop that side pivot in first , then bring up the pulley side with your left hand and wind in the pulley. Dressing the pivot another story, x20 mag only just gives you enough visual anx i dont think my scope optics are clear enough. Update, no rodico use a bent acupuncture needle to hang the balance wheel from and folded paper to catch the wheel. Literally a few seconds to fit it in place.1 point

-

You're right. I'm just asking for trouble! The good news is that it cleaned up pretty well in the end and has been running on the timegrapher overnight. Slightly lower amplitude than what I'd like to see, but I did re-use the original mainspring. Pivots looked pretty good after cleaning and treatment with pithwood. This was the first watch I got to use my new automatic oiler on for the cap jewels. I wish I would have bought one sooner. It made the process so much easier.1 point

-

Daniels is talking about getting a raw spring that has been properly heat treated and such ready to be vibrated. I do vibrate springs, but seldom. It's a price issue mostly (for the customer). I have a stock of dozens of CGS numbers and thousands of springs in different qualities of Nivarox and in steel, the Luthy tool, and an electronic machine for vibrating from Greiner, etc. For all the effort of finding the springs and equipment it's barely worth it for the few I do, not counting the cost of buying up all that stuff, but I like having the capacity. It also comes in handy doing prototyping work for sure.1 point

-

Here are some additional threads that you might find useful (especially the excellent illustrations made by @HSL).1 point

-

1 point

-

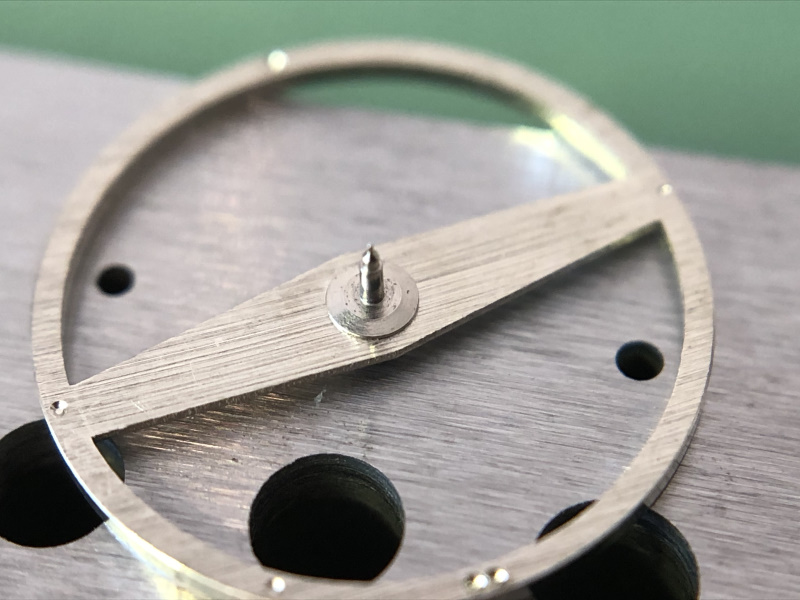

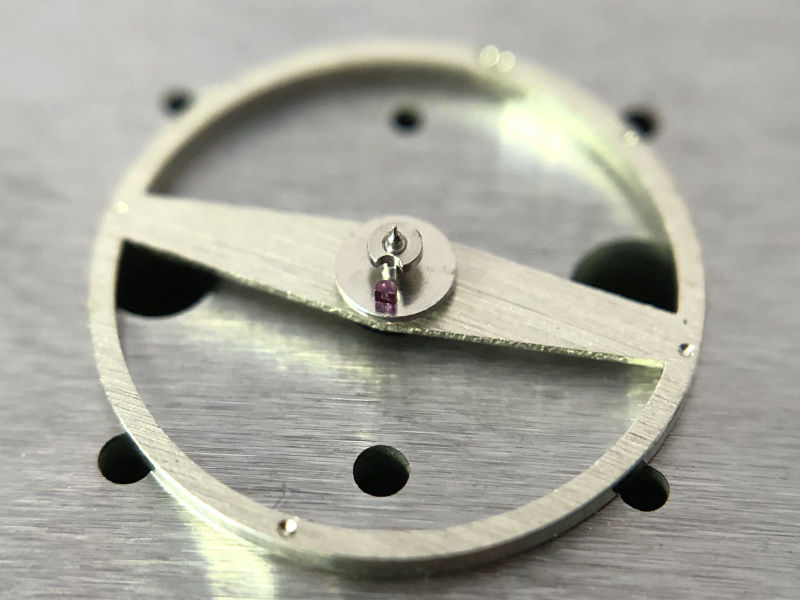

So, I've reached another major milestone on my journey in watch repair. I have now replaced my very first balance staff (Tissot calibre 781), and I feel pretty good about myself! ? Replacing a balance staff is likely not the first thing you do when you start servicing and repairing watches as you need some expensive tools. Of course, you should also have developed some skill in handling small parts with tweezers. You also need the know-how, and that was mainly provided to me by my fellow Swede @HSL in my own language (Thank you very, very much!). There's also an excellent video on the watch repair channel which demonstrates in detail how to replace a balance staff. The video can be seen here. Anyway, as you can see in the following video, the balance wheel wobbles: I don't know if the wheel wobbled before I replaced the balance staff. The reason for the replacement was that one of the pivots on the original staff had broken off. I should mention that end shake and side shake look pretty perfect. So, I have some questions: 1. Is the wobble severe enough to affect timekeeping? If so, how much and in what way? 2. Would a truing caliper like this one be the tool of choice to rectify the wobble? I do not yet own a truing caliper and it is a pretty expensive tool. 3. I intend to poise the balance statically on my poising tool, but will it be worthwhile as long as the balance wheel wobbles?1 point

-

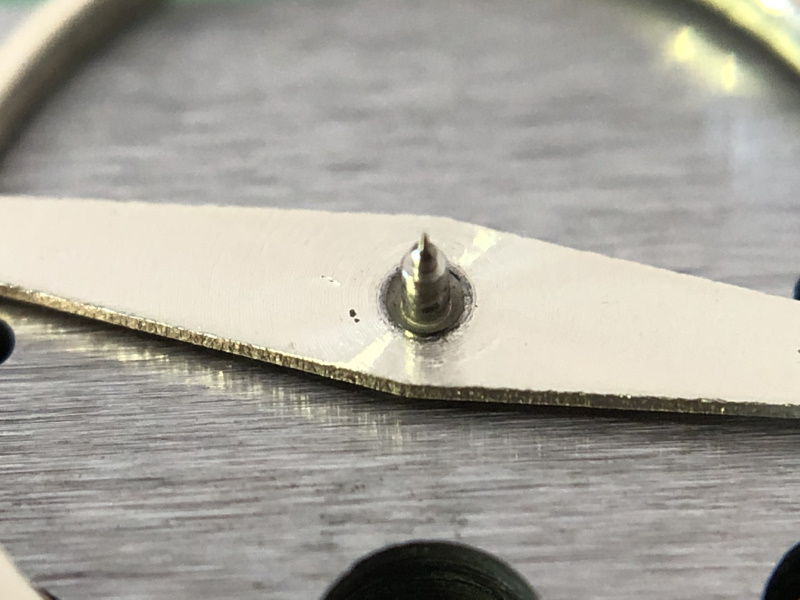

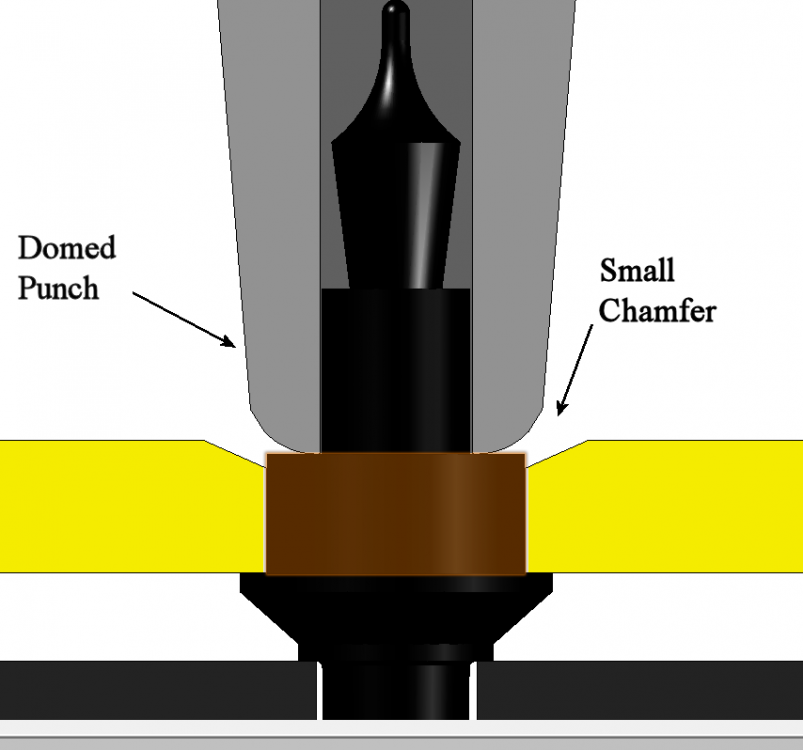

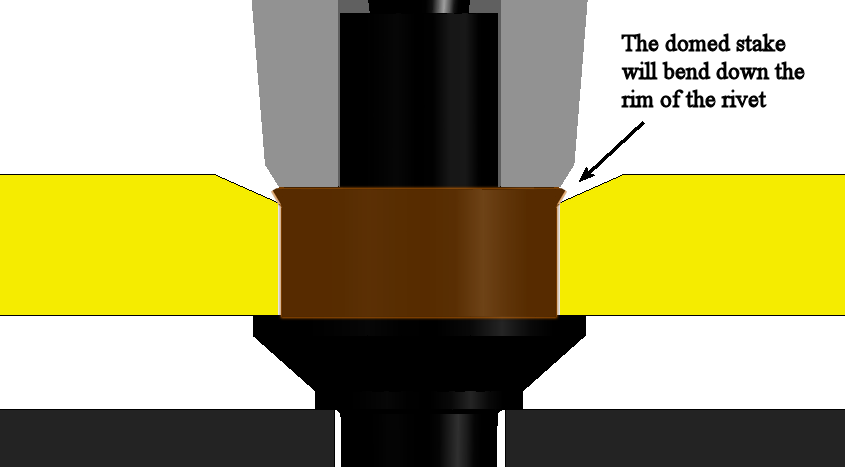

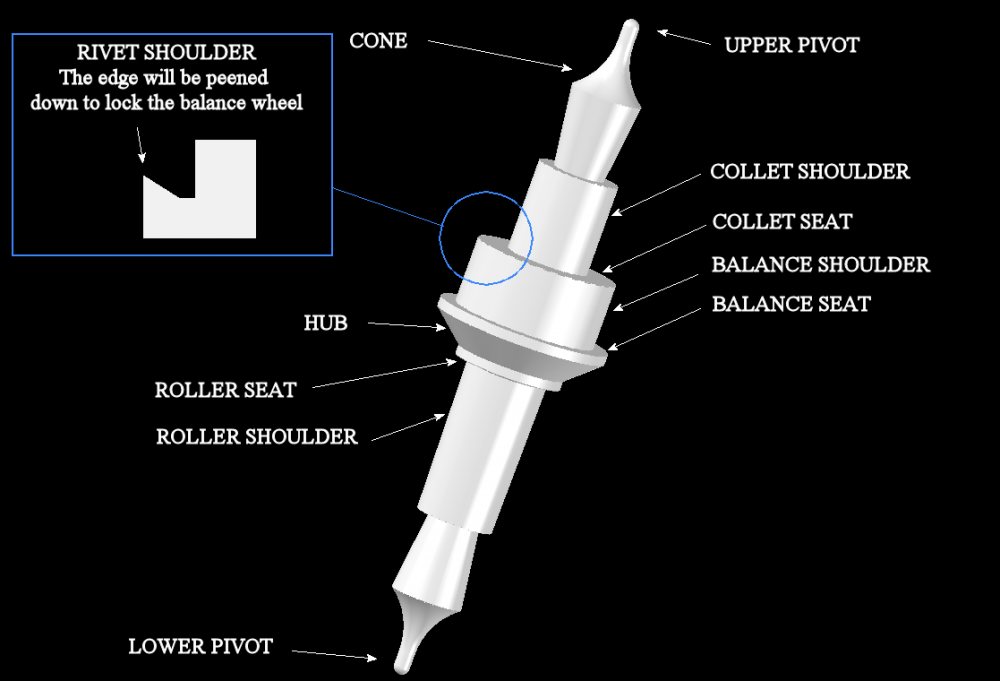

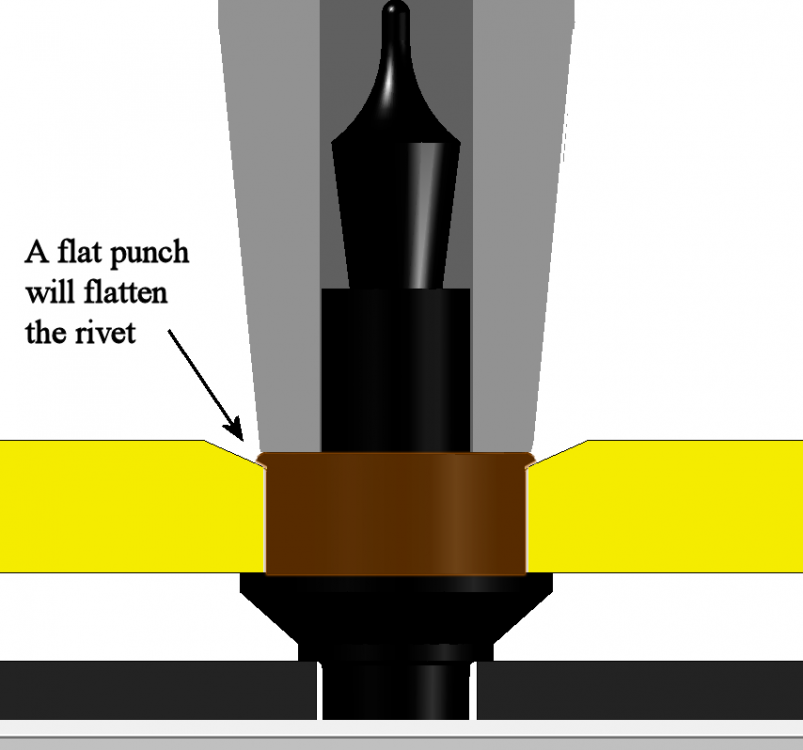

I think you are the only who can see if the rivet made a good and even spread. I mostly only use two stakes, I see you say narrow and wide. I guess the black art of this staking business is like taking your driver’s license, in the beginning you do all by the book but thirty years later you picked up some bad habits. With the risk of getting bombs sent to me by mail I try to show with some illustrations, which don’t need any focus set, and which shows approximately what should happen with the rivet. A too wide flat punch is not any good thing as you might end up hitting the balance instead.if the stake hits the spoke it might turn it slightly upwards. The tip of the stake should go inside the small chamfer on the hole. I intentionally have a different color on the balance shoulder so one know which part of the balance to concentrate on. After giving it a bunch of gentle but firm taps the doomed stake should have begun to spred the rivet shoulder. If not the stake is just a bit to small. But it should be a snugg fit. Rotate the balance to get a even spred and tension. Finish of with a nice and snugg flat stake. You still have to rotate it around. When done you will be able to see the rivet shoulder bent down with a close fit to the chamfer of the hole. I hope these illustrations gives you an idea what to look for. And just in case my vocabulary differs from your or someone’s else’s I attach a drawing of a generic balance with some definitions on here too. Now I think I go back to my 3D printer..... Lol well saw John answered at the same time too.1 point

-

Wow, thanks for the additional input! ?? I've been looking at that rivet repeatedly, but not really knowing what to look for I thought some additional pictures from different angles might help determine if more "banging" needs to be done. When getting this close with the macro lens it's difficult to get perfect focus with the equipment that I've got, and lighting can play a prank on us. Anyway, here they are... When I did the hammering, @Mark's words from the video were ringing in my ears: "As you can see, I'm not going to town on hammering away". He also speaks about the risk of splitting the staff. Good advice, but all this made me pretty nervous so I only used as much force as I dared while continually rotating the balance. Anyway, I ordered two staffs just in case I would fail on my first attempt. So, if the pictures help to determine if more work needs to be done, which punches should I be using (narrow flat, wide flat, narrow domed, wide domed) and in what order? As I have that extra staff I'm ready sacrifice this one to learn more about how much force is required. As always, the input from you guys is just invaluable to me! ?1 point

-

This is interesting, the original 0.9 mm in diameter cap jewels were quite excavated. More so than I've ever seen before so I have replaced them. Perhaps the explanation for the pits in the cap jewels (except for being perfectly dry and dirty) is that the balance was already wobbling before I replaced the balance staff!? Anyway, that's what I'd like to think, meaning I made an excellent job replacing that staff! ? I think I will do that and meanwhile research the market for truing calipers and read the "Unit 2 - Truing Balance Wheels" that you linked to. EDIT: The pits in the cap jewels were somewhat wider in diameter than the pivots.1 point