Leaderboard

Popular Content

Showing content with the highest reputation on 10/05/22 in Posts

-

A quality of life upgrade for the machine. 3D printed a handle for the knob cause my knob HURTS! Just snaps on and makes it easier to tighten and loosen the knob without ripping my hand. Part file below. https://www.thingiverse.com/thing:55486705 points

-

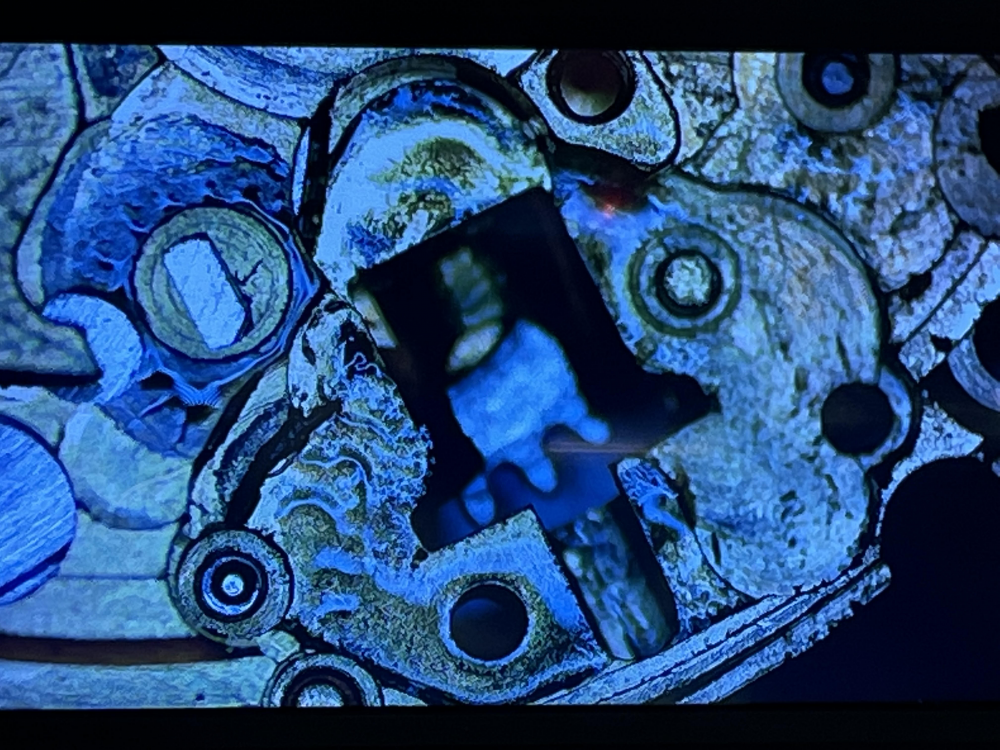

The worn through area won't hurt anything, and a repair would be extremely difficult and almost certainly resort to soldering metal and remachining, which is kind of hokey (soldering) and a lot of work (machining). What has happened is the stem has worn the bearing area* at the edge of the bridge and quite certainly on the mainplate as well. That's the play you've noticed. The solution is to make a new stem with a larger diameter there so that it has minimal play. Not a big job for someone accustomed to it. *When installing a crown most folks will hold the stem in a pinvice on this portion (the bearing nearest the thread). If the pinvise has hard steel jaws and they are of the pointy type, it will likely dig in and raise up 4 little teeth which will certainly eat away at these areas over the coming years of winding. It's important to make sure the pinvice does not damage the stem (I always hold the stem in the lathe or in a pinvice that takes lathe collets). But a regular old stem with no damage can eventually wear these parts too. The solution is still the same.3 points

-

3 points

-

Here is one of the three machines I acquired. It is labeled "L&R Special" which is not something I have seen. The motor works! I took it apart and cleaned it up. I have ordered a rheostat and knob (old school). It appears to me that the heater is a light bulb retrofit as opposed to a 200 ohm resistor as in my working L&R. Anybody seen a light bulb heater in one of these? I have all of the jars and lids as well. I found a 60W heater that fits an Edison socket. I think it will work fine. I am guessing that the tube on the left is some kind of aftermarket retrofit...does not look or feel factory.2 points

-

Incredible, I am in awe of machinists full stop as it is the essence of engineering being able to make and shape things from metal, but on such a tiny scale as watch parts usually are is just another level. sometimes I look at watch screws in my microscope (I rarely use loupes) and think how can someone have made this tiny thing with so much accuracy...2 points

-

I remember posting in FB about working on a friend's pendant watch, which had survived her house fire, only to be ejected from her car during an accident which happened while she was transporting the last of her worldly goods. It had landed in soupy mud with the cover open. So, silly me, I commented that it was the filthiest watch I'd ever worked upon. Not more than a month or two later, my brother brings me an Elgin grade 241 that he picked up at some kind of flea market. It had been in a cloth sack and was listed as non-running. I open it up...and every square millimeter of every part of the movement was coated in Cosmoline. I almost cried. It took me forever to get it all clean. So I've become wary of saying that a watch is "the dirtiest I've ever seen" for fear of the universe being tempted to show me one that's even dirtier.2 points

-

Thanks for this link! But if you look closer, you find that the topic stays difficult: - gaps between his CGS numbers are huge. You cannot be sure you'll find what is needed. - no mention about the spring metal. Looks like Nivarox or similar? Then it is usable for modern watches, not for vintage pocket- and wristwatches with cut balance. - colleted springs are nice, but then there is no more chance to choose the needed pinning angle - what would distinguish serious hairspringing from tinkering. Frank2 points

-

Daniels is talking about getting a raw spring that has been properly heat treated and such ready to be vibrated. I do vibrate springs, but seldom. It's a price issue mostly (for the customer). I have a stock of dozens of CGS numbers and thousands of springs in different qualities of Nivarox and in steel, the Luthy tool, and an electronic machine for vibrating from Greiner, etc. For all the effort of finding the springs and equipment it's barely worth it for the few I do, not counting the cost of buying up all that stuff, but I like having the capacity. It also comes in handy doing prototyping work for sure.2 points

-

I think you already know this, but anyway... Steady hands are the effect of being completely relaxed. The more difficult something is purely motorically, the more we tend to tense up. It's paradox and it needs to be practised continually as it is one of the most difficult things to do when working in the world of micromechanics. Being tense also poisons the joy of working with watches. I have never fitted a balance in my Jacot but just trying to imagine it I can feel how my muscles start to tense up. Anyway, well done, you got it in there!2 points

-

2 points

-

2 points

-

2 points

-

Eyup muckers hope you all well. So into my first endeavour of using the Jacot. Last week i had two new tool arrivals in the the post. A DL PP make and a WIT Jacot. The WIT is in the better condition so i tnought i would start there. Been fiddling around with an old well knackered Osco movement back and forth for a ages, basically just abusing it for practising things i haven’t tried before inbetween some repair. Trashing bits and pieces and seeing if i could bring them back to life as you do. Its basically become my whipping boy movement. So he's down for another session, balance assembly out, collet off and ready to fit the staff and wheel into the Jacot after a measure of the staff pivot which came out at 0.7mm. Relatively small for my first attempt. Aannndd man what a bartender to set up, talk about bloody hard to fit the staff. I'm doing this with a x10 loupe attached to some +3 reading glasses, so magnification is not the best but its ok i can see reasonably well what im doing. Now i thought i had steady hands i can manipulate hs to a good standard if i had to blow my own trombone. But this is another level, using a loop and with my hands in the air, in the gym this free hand completely unassisted exercise is what Bros call doing it RAW. Yep this is pretty raw, I've nearly trashed the pivot 3 times already, but its holding out to my abuse. Any tips anyone ? As cool as i am , I'm starting to feel a little stressed. Its in. Over half an hour and 2 cuppas later. Man tell you what, all respect to anyone that can get a small balance staff set up in a jacot tool straight off the bat. Tbh i will be surprised if i havent trashed at least one of the pivots., though the balance wheel is spinning very well with a blower. I may be lucky.1 point

-

I am "somewhat" **BLEEP** about some things, but I probably have several thousand. My plan now is to separate them by the non-franctional number, so 17 1/16 will be stored with 17 15/16...etc. I am not going to break it down by profile except for the ones that have a graded height (1-8). Do I plan to sell them, or for personal use? Personal use, for sure...that gets maybe 10 out of the inventory. The others I will probably give away to my watchmaking buddies. The amount of effort to put them on ebay relative to the amount of money I would make is a bit insane, really. BUT, I want to store them in a way that keeps them from breaking, and with some order.1 point

-

I ended up just placing another order to cousins. They seem to be the only place at least with an easily searchable site that has such a huge selection of generic gaskets that i could actually find ones that were exact matches for everything i need and then i ended up going with oem crystal gaskets, took the opportunity to get the etachron twisting tool and some new sapphire glass for the two watches and a proper oil pot with individual lids to avoid dust contamination. While i'm a little annoyed this will delay everything for another month or so i should be good on tools and equipment now.1 point

-

I once tried to turn a piece of this stuff, into some spinning tops for my children . It was as hard as iron, i had to use a sharpened masonry drill bit in the end. Hardest wood on the planet. Your confirmation is confirmed mike Under a scope first attempt one min, second attempt 20 seconds, third attempt about 10 seconds. I found the easiest and safest method is to forget using tweezers and use a rolled up piece of rodico, put a small bend at one end of it , hook it through the balance wheel up against one of the arms. Bring the lantern fully in on the right side, using your right steady hand to drop that side pivot in first , then bring up the pulley side with your left hand and wind in the pulley. Dressing the pivot another story, x20 mag only just gives you enough visual anx i dont think my scope optics are clear enough. Update, no rodico use a bent acupuncture needle to hang the balance wheel from and folded paper to catch the wheel. Literally a few seconds to fit it in place.1 point

-

Well we have our own local superstar of clock and watchmaking in John Harrison. the machines he made were world beating both literally and insofar as he cracked the problem of seaborne timekeeping and won the longitude prize. the movie of his story is well worth a watch... you could even clock it... this ones better that one is some serialised netflix version of the Harrison story... https://ww0.123-movies.bz/longitude/ I thought it particularly interesting that his early clocks had no jeweling but used lignum vitae as these oily woods are incredibly hard wearing and are self oiling...1 point

-

I can confirm that using the scope makes all the difference ! I was trying to polish a pivot - using a loupe puts your head in too close. Trying to get the wheel to sit in place while you get the string, burnisher etc in to place takes 3 hands and 5 goes. BTW instead of a bow, I use one of these things (don't know what they're called) - has a retractable string to hold your pass card. Fasten the end down, wrap it round the pulley wheel, pull it out, then let in wind back in, and repeat1 point

-

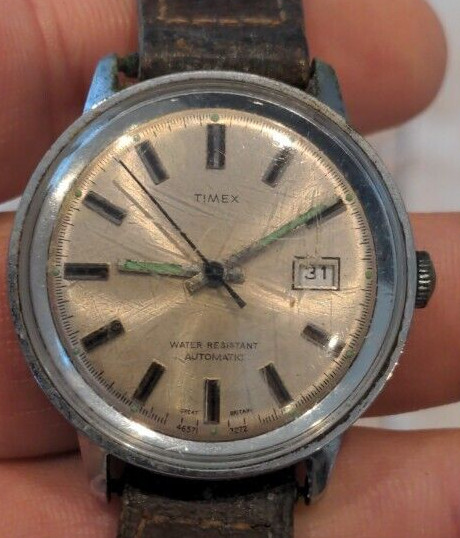

I started work tonight on a Rado Purple Horse with an ETA 2782 movement. Winding felt a bit rough, and the quick set date felt like it was sticking at times. I finally got the movement torn down, and I must say that this is the dirtiest watch I've come across yet. It looks like someone just decided to dip it in oil without cleaning it last time. It was an absolute mess. I spent the better part of 90 minutes pre-cleaning. It's in the main cleaner now, and hopefully it'll shine up a bit! I should've taken more pics, but this will give you an idea. Basically take the level of dirt and oil shown in this photo, and apply it to nearly the entire movement!1 point

-

1 point

-

Not bad! looks good enough to me. Cool innovation, I was thinking of drilling thru and tapping the existing shaft and have a shaft and round knob like the original Elma.1 point

-

I was starting to get a tad frustrated towards the end. There is a knack to it, having the balance wheel hanging from the wheel's driver on the pulley and then lifting the pivots into the pivot holes on the lantern did eventually get me there.It was more of a visual problem to be honest, my hands are pretty steady which is why I'm not bad with hairsprings. I was using very cheap +3 glasses and a very cheap x5 loupe. It was about getting close enough to see and then being to close to work, i had to find that right balance. Which i dont think there is for me with loupes. Under a scope i dont think i would have an issue. I have an adjustable bench poising tool, setting a balance in that is the same principle. Under a scope that takes me seconds.1 point

-

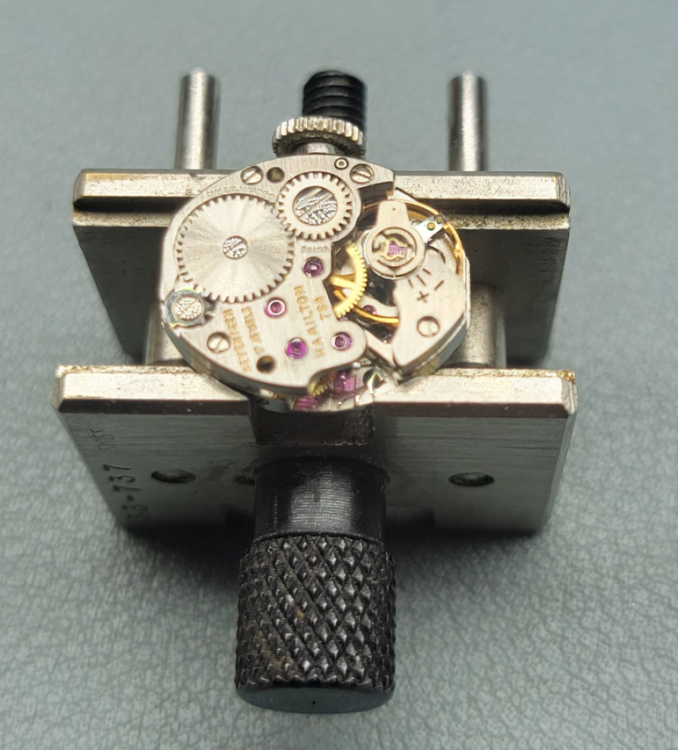

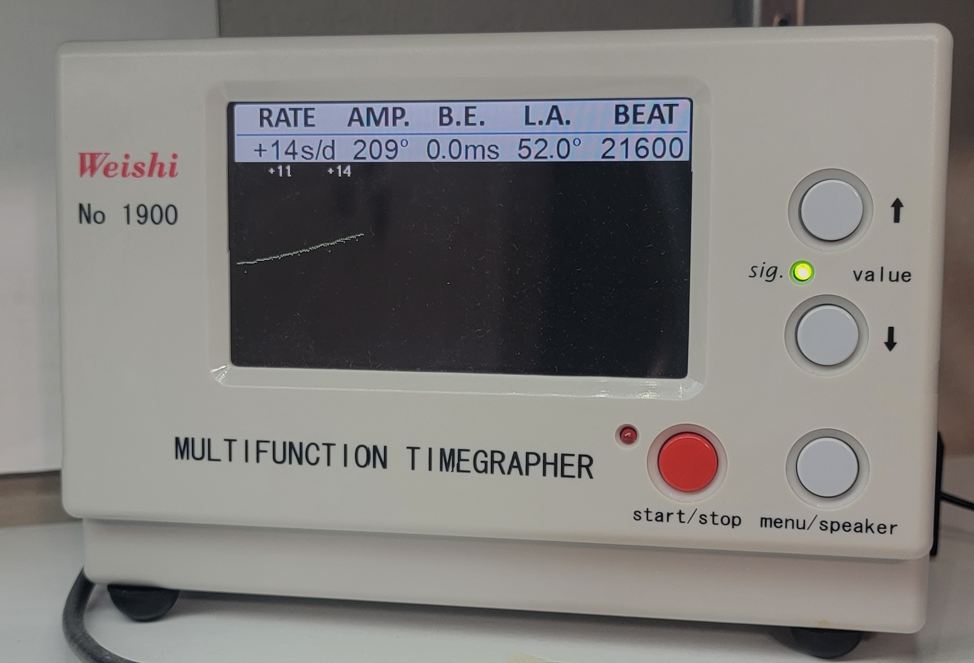

I hate working on ladies watches, but this belonged to my aunt and the family asked me to service it. She was a wonderful lady, so I made an exception. All of the train wheels are covered with one plate. I thought it was going to be a royal pain to assemble, but surprisingly it went together without a hitch. When I dropped in the balance assembly, it ran really goofy and stopped and when running it was at 28,800. What was going on. Geez...the hairspring was sitting on top of the center wheel. Well...everything is so small...so tight. Anyway, I made it right and it is running fine.1 point

-

The hardest part of assembling or disassembling these movements is the balance cock: it’s very easy to get the hairspring out of flat when putting or removing the balance cock. If the hairspring gets even slightly out of flat, it will rub against the Center wheel, and cause snow on the timegrapher. Manipulating such a small hairspring is very difficult to get it back flat. The lower price to service ladies movements in the past has always puzzled me as well. If anything, they require more work… Nowadays, if you bring a ladies movement in for servicing at an independent watchmaker, either he will refuse to service it, or charge you a lot more for a ladies movement.1 point

-

Yes mate completely agree with you. I've been discussing hairspring vibrating with John . Fascinating subject, i think hes trying to put me off trying lol. I was under the assumption that raw hs are unavailable. Apparently not, whatever size and spec you require at the click of a button. and far cheaper than i imagined. Success can't come with some failure its inevitable, i embrace it with positivity. Its a good way to learn, you know that as well as i do Watchie . Maybe easy for me to say, i grew up doing things i shouldn't lol. Also the work i do and did from being 18 does make you quite fearless. Being ultimately responsible for removing the entire back of two houses with the threat of loss to finance also to life for that matter. You just have to be very sure in what you are doing in this case. Also good public liability helps . So a transition to watch repair was a different learning curve for me that doesnt involve any apprehension at all. The small scale is tough for me though. My post a few days ago, trying to mount a balance wheel in a jacot made me feel rather inferior haha.1 point

-

all I've done is pointed you in a direction now you need to go there. Yes reading the book will be interesting experience for you as it covers more than just vibrating hairsprings. Basically everything you want to know of why your watch doesn't keep time is sort of is in their. then here's an interesting story the quest to get a few hairsprings and the outcome.1 point

-

Jendritski . Thanks john . Looks like a good read. As its said, with knowledge comes understanding and power then responsibility. My what have you done ? I did read somewhere ages ago , a reporter with a passion for watches and repair visited an old lass that used to vibrate and attach hairsprings in a factory when that was the norm. Apparently she demonstrated the proceedure for him while on his visit. By the time she had described what she was doing, the task was practically completed. Within a few minutes, the reporter was left with his jaw hanging apparently . If you believe the story, it did sound genuine as i read it. Send them to me1 point

-

What caliber are you working on ? mark, Their CGS No is surely printed on the package they came in, otherwise they must be identified which is very time consuming at the least. What caliber are you working on Murks?1 point

-

1 point

-

1 point

-

Interesting that Daniels says (on page 345 of his 2011 updated "Watchmaking"): "Whenever possible the springs should be purchased ready for fitting." I guess he decided that others were better equipped to the task.1 point

-

Haha. Good ohm, i mean good one. You are feeling better matey. I've researched it , an Italian made device.1 point

-

Definitely, jump in at the deep end, thats how I've got through life. How you doing mate ? you feeling better ?1 point

-

I have a link that talks a little about dial refinishing and a problem. I would've recommended international dial because I've heard that they do really good work but notice he said it were sold and moved to someplace else. Dial refinishing is interesting in that as far as I know there's no schools teach how to refinished dials so I assume it's a handed down trade to have no idea how these people learn how to refinished dials which means some of her going to be good and some of them are going to be bad obviously. Oh and notice on his recommendations he doesn't actually say how to reach out to these people. you do a search like I did for international dial I found the yelp page but anything that supposedly their website is either nonfunctional or not exactly what it's supposed to be obviously they do not like Internet business. http://www.thewatchguy.com/pages/DIAL.html okay the other name he mentioned at least they have a decent website if that's worth anything https://krdial.com/ so it basically looks like tile refinishing companies don't like online repair business. It is kind of a specialized field and Norm whether only servicing people in the watch trade which may be why they're not online. Like I know a lot of material houses are not online which means if you're relying on online well you screwed.1 point

-

1 point

-

considering how common stopwatches are it seems like there should be more servicing information out there but it doesn't seem to exist. Did get you a picture of the factory where you can see some pictures of movements https://www.watchuseek.com/threads/flieger-friday-visit-to-hanhart-factory-and-museum.5210908/ oh and apparently some parts are available we get a parts listing which suggests that there must be technical information out there somewhere. seeing as how the company is still in existence you could always ask the company for service guide it should be worth a laugh though as usually watch companies want you send the watch back to them they don't trust you http://cgi.julesborel.com/cgi-bin/matcgi2?begin=HAN_&end=HAN_&label=Calibres_Manufactured_by_HANHART1 point

-

I just use a heat gun. The method works every time. I learned of it somewhere on this forum early last year. I have the big Bulova case holder...I don't think you could break it with a tank!1 point

-

@Bearman "Very skeptical of the superglue and nut technique..." Ha. I actually once had a bigger problem removing the glue and the bold off the lid.1 point

-

We might be able to use the Greiner Record Time Machine to make this real once it is fixed.1 point

-

1 point

-

Lol same nostalgic thoughts here Karl1 point

-

I used to deal with them back in the 70's and 80's they were in Orpington Kent.1 point

-

Here is a video of the ABS rotor running from start, a bit of bubbles at 2-3 minutes, and a photo of when it finished. Feel like the video makes it seem like there was a bit more bubbles then there actually was. I think if I increased the level of the fluid a bit it might help resolve it. But nothing that seemed to be concerned about.1 point

-

Well, I can tell you this much: being that the case is most likely plated brass, it probably goes without saying that you wouldn't want to try bending it cold. I think it should work to remove the works and the crystal - basically strip it down to just the case frame - and then use maybe a butane torch to heat it before bending. Something tells me if you try to bend it cold, it will either crack or break off.1 point