Leaderboard

Popular Content

Showing content with the highest reputation on 09/13/22 in Posts

-

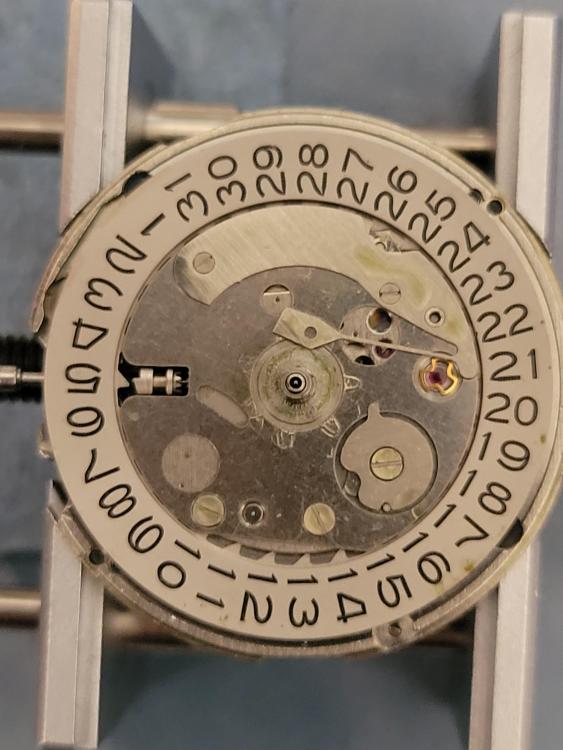

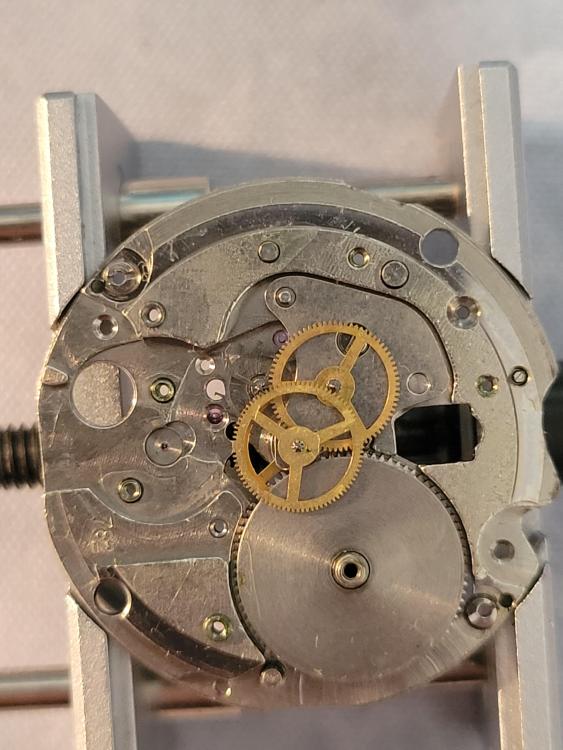

Introduction This service walkthrough is not a tutorial on how to service a watch movement. I made it for myself because I think it's fun and because it will make it easier the next time I service a Vostok 2431. I also think it feels nice to be able to share this walkthrough considering all the valuable information that many very talented members on WRT freely share. Many, many thanks! There is a lot to learn when servicing a watch movement that is not covered in this walkthrough. Therefore, I recommend, for example, watchfix.com, learnwatchmaking.com, or timezonewatchschool.com. I feel like I got the most bang for my buck at watchfix.com (I'm not sponsored in any way) but I've also had a lot of fun and benefited from the other online schools. Links to photos on my OneDrive Vostok calibre 2431 disassembly walkthrough. Please sort the images by name in ascending order. Vostok calibre 2431 assembly walkthrough. Please sort the images by name in ascending order. Curiosities I think it was in 2014 or possibly 2015 that I bought my Sturmanskie Open Space. I had just discovered that there were watches where the hour hand only rotates one revolution per day and at that time I knew absolutely nothing about watch movements, service and repair. The idea that the hour hand of a watch only rotates one revolution per day seemed not only completely logical but also different and fascinating. The earth rotates one revolution around its axis per day, so it should be obvious that the hour hands of our watches do so too. The fact that the letters on the watch were also Cyrillic did not make the whole thing any less exciting. I just couldn’t resist it and I’m happy I didn’t! Vostok claims that their movements only need a service every 10 years, and I think that's true because the tolerances are pretty rough and therefore large amounts of dirt are needed to stop a Russian movement or even cause it to run badly. It has been said that the amount of dirt required to stop a Vostok movement is enough to stop a hundred Patek Philippe movements However, the price for this endurance is a movement that doesn't come close to the precision offered by high-quality Swiss and Japanese movements, but it's still quite easy to get these Russian movements to run accurately as long as they're worn and used consistently. About the movement Russian watch brands such as Vostok, Raketa, and Poljot, to name a few, are known for using their in-house movements, but not this Sturmanskie which is instead powered by a Vostok calibre 2431, which is a 24-hour movement. However, it is not a true 24-hour movement. That is, the movement is not originally designed as a 24-hour movement. Instead, Vostok has modified the movement in its calibre 2416B so that the hour hand only rotates one revolution per day. Calibre 2431 is otherwise identical to Vostok automatic calibres 2416B and 2415. The motion work(/dial train) in Vostok 2431 The way that Vostok modified the movement so that the hour hand only rotates one revolution per day is by modifying a) the minute wheel, b) the bearing for the minute wheel in the main plate, and c), adding an intermediate date indicator wheel. The minute wheel has been modified so that it has two pinions that lie on top of each other. The lower pinion drives what I call the first intermediate date indicator wheel while the upper pinion drives the hour wheel and has been adjusted so that the hour wheel only rotates one revolution per day. The number of teeth on the hour wheel itself may have also been adapted, but this is not something that I have investigated. Normally the minute wheel is mounted on a regular metal post on the main plate, but in this case, Vostok has replaced the post with a beefy, jewelled bearing. I assume that this has been necessary to get the minute wheel, with its two pinions on top of each other, to rotate sufficiently smoothly and stably. The added first intermediate date indicator wheel drives the second intermediate date indicator wheel which is part of Vostok's regular (non-modified) calendar complication. And this is what it looks like with the hour wheel mounted. Cleaning I have found that it is all too easy to underestimate the importance of cleanliness when servicing a movement, perhaps because the parts are microscopic and therefore it takes time to get used to thinking microscopically, even though I have been doing this now for five years. Cleaning of pinions and pivots A type of watch movement part that is particularly important but also difficult to get completely clean is pinions, but @nickelsilver advised me quite recently that in its pre-cleaning you can dip and rub the pinions in pith wood that you have impregnated with an effective degreasing agent, for example, Horosolv. I've done it several times now and it works amazingly well. Speaking of pinions, independent American watchmaker Josh Shapiro mentioned in a podcast that he considered pinions to be the most difficult part of a watch movement to make perfectly. Whether it's true or not I don't know but I think it's likely. To get the pivots clinically clean, I have also started using EVEFLEX, but you have to be careful because the material has an abrasive effect. It is important to choose the right polisher and to be careful. I have summarized my experiences with EVEFLEX in this post and I mention it because EVEFLEX is easy and quick to work with and gives me very good results. End-shake If there's one thing I've learned this time around, it is that a Russian movement cannot be converted to a Swiss movement because the tolerances in Russian movements are generally much coarser. Experimentally, I adjusted the end-shake to 2/100mm on everything from the pallet fork to the centre wheel, with the result that the amplitude and rate became extremely erratic. I created a thread about this: "Can end-shake and or side-shake ever be too small?" As you will see if you follow the thread, once again @nickelsilver, @Shane, and @JohnR725came to my rescue. Many thanks! My recommendation is to let the end-shake be slightly wider on Russian movements. After I increased the end-shake to approx. 4/100 mm, the amplitude and rate returned to typical, i.e., still somewhat irregular but perfectly normal for a Russian movement. Side-shake In this video, Kalle Slaap from Chronoglide shows an amazingly simple and effective way to determine if the side shake is correct. Since there was a crack in the third wheel jewel in the train wheel bridge, I replaced it, and when I then used Kalle Slaap's method, I could clearly see the 3rd wheel pivot jumping back and forth in the jewel hole. So, I replaced the jewel with a hole that was 1/100mm smaller and the visual difference, just changing it by 1/100 mm, was nothing less than dramatic. I am incredibly happy that I got to learn this simple and exceptionally clear method. Many thanks to Kalle Slaap at Chronoglide! Vostok reverser wheels If you Google “Vostok reverser wheels”, there is a lot of whining going on. I don't think there are any major problems with Vostok's reverser wheels, but they are unfortunately easy to damage during service or modification of the movement, and I think that is the real reason for the whining. Next to Seiko watches, Vostok watches are immensely popular to modify in terms of dials and hands, and in addition, many people want to fix the seconds hand that sometimes stutters on these movements. The latter is done by bending the second-hand pinion spring illustrated in this thread. To make these modifications, the oscillating weight/rotor must be removed and when it is to be screwed back on, it is easy for the rotor pinion to end up on top of the teeth of the reverser wheels. If you tighten the rotor screw in that position, even just a little, the reverser wheels will inevitably be damaged. The result is that the automatic winding stops working or only works intermittently. An easy way to check if the reverser wheels are working as they should is to manually rotate the oscillating weight alternately about 20 degrees in both directions with a piece of peg wood while looking at the 1st reduction wheel which is large and easy to see. If the 1st reduction wheel continuously rotates in the same direction (counterclockwise, if I remember correctly), no matter which way you rotate the oscillating weight, you can be sure that the reverser wheels are working as they should. If, on the other hand, the 1st reduction wheel rotates alternately in both directions when you rotate the oscillating weight alternately, then you can be sure that the reverser wheels are damaged and need to be replaced. Servicing the automatic mainspring I find it difficult to service the mainspring on automatic movements. It is, in my opinion, a construction that leaves room for improvement and that is why I generally prefer manually wound movements. If the mainspring in an automatic movement slips too soon, it reduces the amplitude and the power reserve, and if the mainspring slips too late, there is the risk of re-banking and that the movement runs much too fast when you are physically active, especially when you take a brisk walk swinging your arms, and the oscillating weight rotates constantly. The effect is like continuously turning the crown of a manual movement with high pressure when the mainspring is already fully wound. Not good! What I learned this time anyway, long story short is that you can be quite generous with braking grease on the rim on the inside of the mainspring barrel. Even if some of the braking grease ends up where it really shouldn't be, I don't think it will destroy or affect anything negatively. Also, and again from Kalle Slaap at Chronoglide, I learned that you should press at the end of the spring at the bridle when it is mounted in a spacer, and you are about to push it into the mainspring barrel. In this way, the rest of the spring automatically follows down into the mainspring barrel. You can see it in this clip. Very smooth, especially in combination with my highly rated Master Craft mainspring winder which I wrote about in this post. Lubrication of cap jewels For a long time, I have had trouble getting the oil to stay in the centre of the cap jewels and not flow out after I oiled them and installed them, despite treating them with epilame (Fixodrop). I think it's because (and now I'm going by gut feeling) that I previously always installed the shock assembly in the main plate before installing the balance and that I didn't treat the jewel housing (chaton) with epilame. After several failures in servicing this movement, I decided to treat both the cap jewels and jewel housings with epilame and mount the shock assembly after having replaced the balance. It did the trick and also made fitting the three-legged anti-shock spring much easier. My theory is that the balance staff pivots stabilize the oil in the centre of the cap jewels when the jewel housing (chaton) is dropped into place, and better hold the jewel housing in place, which will otherwise slide around while installing the three-legged anti-shock springs. Have I just written the longest post in the history of WRT? Anyway, hope you enjoyed it!7 points

-

I bought a 1975 Seiko automatic with a really nice emerald green and gold dial, and the entire watch was so sticky with old oil that I almost wonder if whoever serviced it last just dunked it in oil to try to get it working. I thought at first that the hairspring was kinked, but removing the balance and a close inspection under the microscope revealed that it was just caked with old sticky oil, and most of the coils were sticking to each other. I tried cleaning it in lighter fluid three times before I ultimately gave up and ordered some L&R 556 fluid and an ultrasonic cleaner. With the movement given an actual proper cleaning, the balance swung free and clear and I had high hopes that I would get a usable watch in the end. On the plus side, I have an ultrasonic cleaner now, and it made cleaning up the watch case much easier. The crystal was completely destroyed so I had to source a new one along with a new band, but the dial only had a few spots where oil seemed to have seeped through from behind. I didn't want to touch it much, but was able to gently dab up most of it with some rodico. Unfortunately there was one spot where a small drop of oil had gotten under the clear coat and destroyed the paint underneath. As soon as I touched that part it all came away leaving a spot of bare metal. The rest of the watch looks good enough though that I can ignore this small blemish, and with everything cleaned up and a bit of regulating it's running really nicely. Here are a couple of shots I took for reference before the cleaning (didn't take any of the sticky balance, sorry)6 points

-

3 points

-

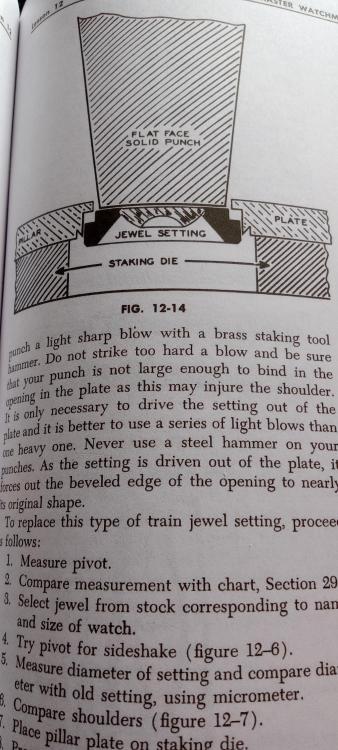

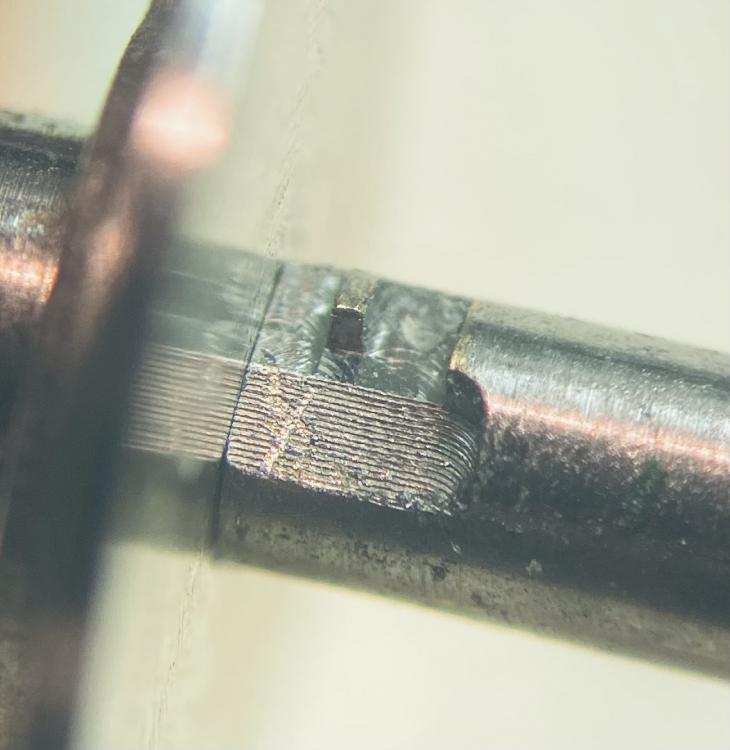

Thank you oldhippy, Kalanag, and dadistic for your information and taking the time to reply! I watched Mark's video and part of J.D.'s video. I previously had watched a few others. Here's where i am currently. I used my Seitz tool to attempt to push out the jewel. That turned out to be only partly successful. The edges of the jewel remained stuck in the setting. Then, right or wrong, i decided to push out the entire setting. Since my original post, i found this information on the Pocket Watch database. I believe i need part 1472 (Pallet jewel, Lower, in Composition Setting, Type F, shown in the aforementioned digitized manual. Now i have to find one. Thanks again!2 points

-

2 points

-

One thing with the Chinese winders with Brass Arbours, I have had both sets one brass and one steel, but it's often said don't get the brass ones as they could wear out because brass is softer that the steel used in the spring. Two takes from this, firstly so is the steel used in the steel Arbours so they also could wear. Secondly the spring is only being pulled by the hook on the Arbours for one or two revolutions, it's then gripping the pin and being pulled around by the pin not the hook. Lastly everyone who says the brass will wear already own the expensive Bergeon set so they would say the cheap set is inferior wouldn't they. In every post claiming the brass will wear I have seen not one image of a worn Arbour or pin. Yes steel is better but for occasional use brass will be fine for quite some time, especially now the steel Arbour Chinese sets have arrived, the brass sets have tumbled in price to around £50 to £60 which only get you one Bergeon winder.2 points

-

The vintage pin pallet ( in-house) Oris is collectable, it'll eventually run but refuses to show accurate time, case looks good, they mostly are worn down to the brass, you might get the dial look a bit cleaner, should you decide to sell it can fetch aprox $130. The bucherer can be a daily wearer, eta 2824 parts are increasingly getting hard to find. Best of the bunch is obviously the Universal Geneve. Good luck getting it completed with 100% Genuine parts and case, definately a keeper. Regds2 points

-

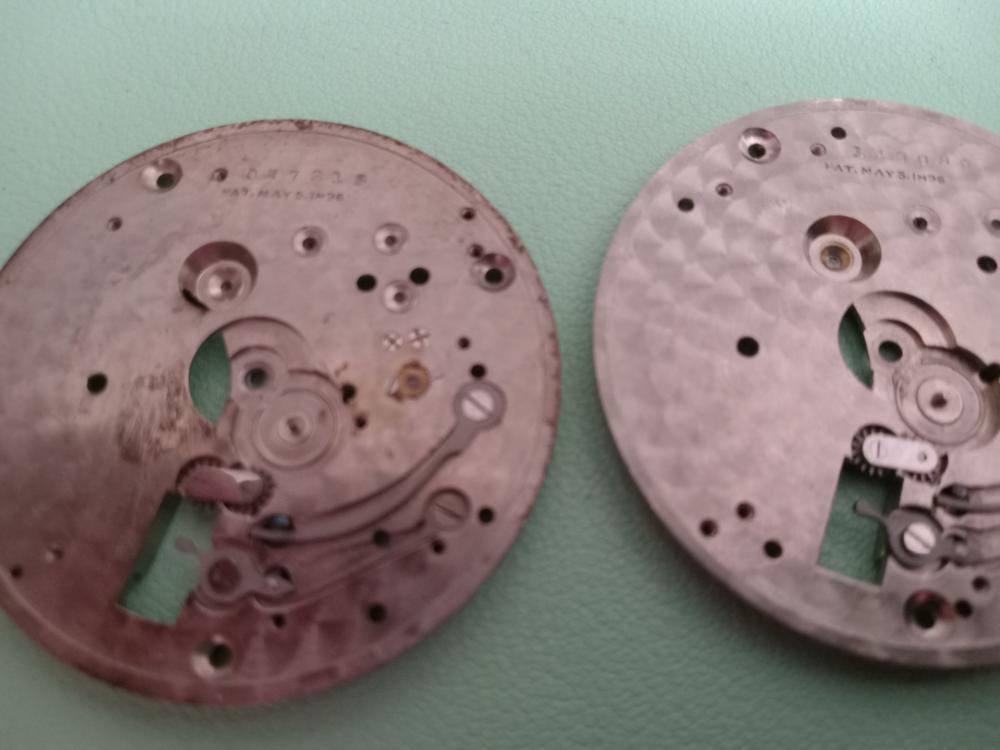

hi all I have a Hamilton gr 974 size 16s that needs a new center wheel jewel in the pillar plate. This is my first encounter of this type and so far what I've read is this type of jewel setting is one of the most difficult, if not the most difficult to repair due to its hybrid friction setting. it seems it's a two part setting to include the jewel, set into an either steel or bronze hub, then the beveled edge in peened over to hold the jewel, and then another beveled edge on the opposite side is peened over to affix the entire setting into the pillar plate. Anyone have any experience or advice before I attempt this one? below are the sorry excuses for pictures showing the plates side by side. the one on the left contains the donor jewel, and the one on the right is the missing center jewel. the third and second to the last is the donor jewel and the last is Section 300 out of the book, The Chicago School of Watchmaking that shows a cross sectional view of the procedure. Again, advice needed! i have to do some running but will check back later. apologies on the late wish: to our friends across the pond-my sincerest sympathies on the passing of Her Majesty, Queen Elizabeth. A great, remarkable and very special lady indeed.1 point

-

did the entire setting come out cleanly? Then as nice as the pocket watch database is sometimes it's nice to have your own catalogs. Here's a older version of a parts catalog https://archive.org/details/catalogueofwalth00walt/mode/2up1 point

-

Thanks for your kind words @gbyleveldt! Absolutely, go ahead, these Vostok movements are so much fun, and when you lose or damage a part, just pick up a bag of used Vostok movements on eBay for next to nothing compared to Swiss and Japanese movements.1 point

-

Some time ago, I picked up a small nurse's watch with a nun's name engraved on the back. A cute piece with the same dial & red seconds hand found on lots of 1940's & 1950's military watches. It has a pristine AS 1287 that already ran well. Reassembling it today, I hastily tried to get the setting lever spring on before the yoke spring popped out and lost BOTH of the tiny screws that hold it down out of my tweezers. I ordered some huge magnets I'd been meaning to get anyway and hopefully I can turn them up. It's the only carpeted room iny house. What's my point? I think I'm just here to complain. This movement is abundant and I'm sure I can get a donor under $25, but with the shame that comes with waiting. My "achievement" was to take a superb little movement that's been running for 70 years and mess it up. I'm guessing this is a rite of passage1 point

-

Man, your enthusiasm for working on these Vostoks makes me want to rip one of mine apart and play. Some real good tips there sir, thank you!1 point

-

You may find that the easiest way to get another will be to find another Waltham 1883 movement and CAREFULLY extract the lower pallet setting.1 point

-

1 point

-

This looks like high dome crystal, the crystal lifts are good for replacing these. Use a vernier gauge to measure the diameter and take a few measurements around to get an average of the size. Its normally good practice to order a size above and below to compensate for inaccuracies.1 point

-

This video is even more useful for the issue discussed in this thread:1 point

-

Mark has a short tutorial about dealing with rubbed in jewels.1 point

-

You need to replace the jewel. Good luck in finding one.1 point

-

Unless you can pressure test the watch after you did the work on it, it's not suitable for diving use (or even casual swimming) - especially after it's been opened.1 point

-

1 point

-

IMO if a diver watch is going to be used whilst diving then it’s essential that it has been regularly serviced including having the seals changed and also the watch was pressure tested.1 point

-

1 point

-

If it is stopping because of the escapement check all the pivot holes for the escapement, pivots and burr on the escape wheel and the angle of escapement the pallets also need to be smooth with no marks or signs of wear. I can't tell by the photos but many clocks with this type of escapement the crutch is friction tight, so it has to be tight enough for it to work, too lose and it will stop, to tight and it won't set its self in beat.1 point

-

Yes: Fabrique d'Horlogerie de Fontainemelon (FHF) was set up in 1793 to supply the Swiss watch industry with ébauches (bare movements) to reduce reliance on the supply of ébauches from France. Show us a photo of the case.1 point

-

Here is all about winder data: https://bhi.co.uk/wp-content/uploads/2021/05/HJ-Mainspring-Winders.pdf1 point

-

The big problem is, for an absolute beginner that has never completely taken apart a watch, let apart putting it back, it's extremely difficult to correctly diagnose and correct a positional problem, and even more on a Seiko watch. The issue is with the escapement, it can be the hairspring rubbing or out of perfect shape, there can be other more subtle causes. even the diagnostic part is difficult, without a timegrapher, without the experience needed to examine both visually and aurally. Then, there is about 100 more chances for a beginner to damage an hairspring when touching it, than making it better. Even removing and refitting the balance is a risky operation for a beginner, even after watching tens of videos. Your question repeats very often here, which is expected being Seiko watches very popular and accessible. Yet despite all warnings, many new members tried, failed, and disappeared without even saying goodbye. Watch repair is not an easy hobby, it has a steep and costly learning curve. Your best approach is either to find which night resting position makes an acceptable timekeeping, or get a replacement NH36 mov.t that adds manual winding and seconds hacking for about $40. But, As it happens, you can probably get a good complete SNK watch for about the same money.1 point

-

Lol i thought it pretty cool to have your name on a watch dial. 30 quid though not a bad price for 7 play watches. I have a very unusual surname, in fact me and my son are now the only ones in the blood line to have it in our town of 300 thousand people. And very few in the whole of the Uk. I have found 2 fusee pocket watches both made and marked by a close decendant one of them even has the name on the dial. I have to have them for sure.1 point

-

How to choose a new mainspring - watch repair tutorial https://youtu.be/CZfFkv0FLX41 point

-

1 point

-

1 point

-

I'm sorry: https://www.youtube.com/watch?v=viq9-V1sv7M1 point

-

would've been nice to have a serial number for this watch so we can look up something. did you look at the pivots on the balance wheel to make sure they're still there? Then regarding the serial number notice how most of the parts have a partial of the same serial number on the main plate? Usually the balance wheels have the serial number scribed on it sometimes is hard to see so you'll have to look carefully1 point

-

Hi willow, just be careful when moving the adjuster they are usually very tight primarily because they are factory, set use a good well fitting screwdriver to avoid slippage. As you see the screw adjuster is circular and the bearing is on the side any adjustment will go up/down in an arc. If as we suspect its been moved the lateral and vertical positions have been compromised. put a small dot in the position it is now and when refitted check the action and adjust accordingly. all the best. Hi willow have a look at this bit of reading might be of some help. https://r.search.yahoo.com/_ylt=AwrIAX8ZKx9jqRAApUF3Bwx.;_ylu=Y29sbwMEcG9zAzYEdnRpZAMEc2VjA3Ny/RV=2/RE=1663015834/RO=10/RU=http%3a%2f%2fwww.abbeyclock.com%2faeb7.html/RK=2/RS=jZ9ZEnYKNW2O2x8OI7jRBYPbnOU-1 point

-

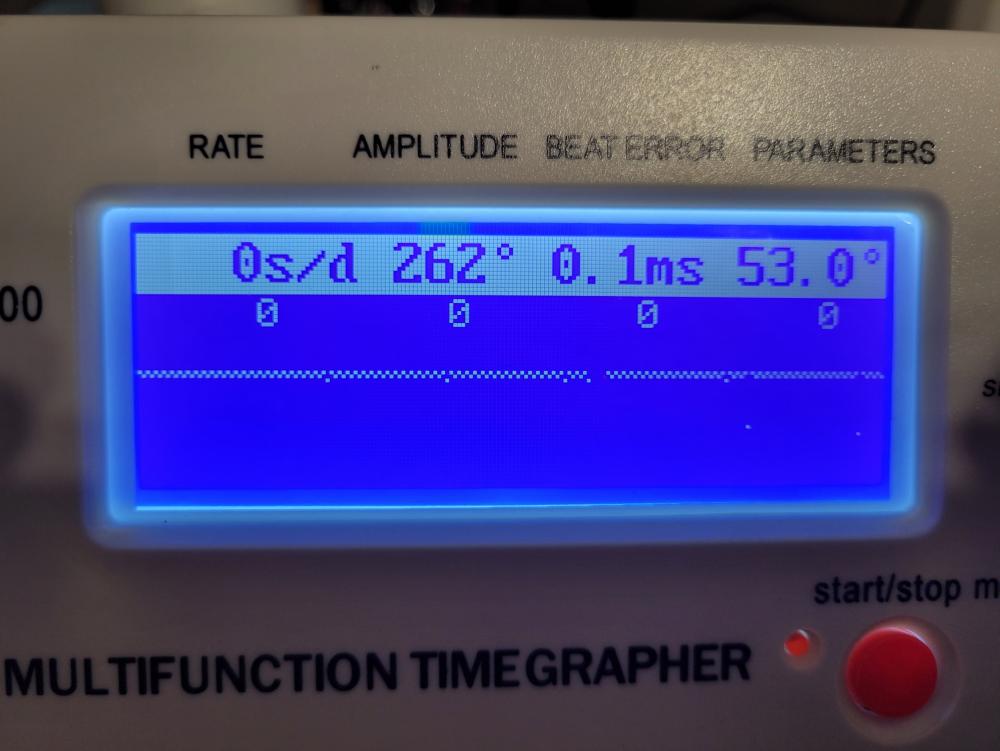

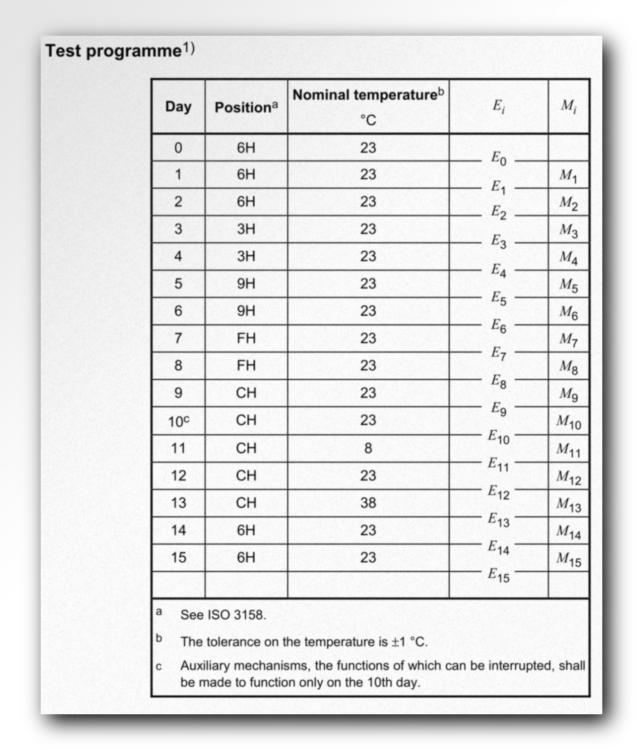

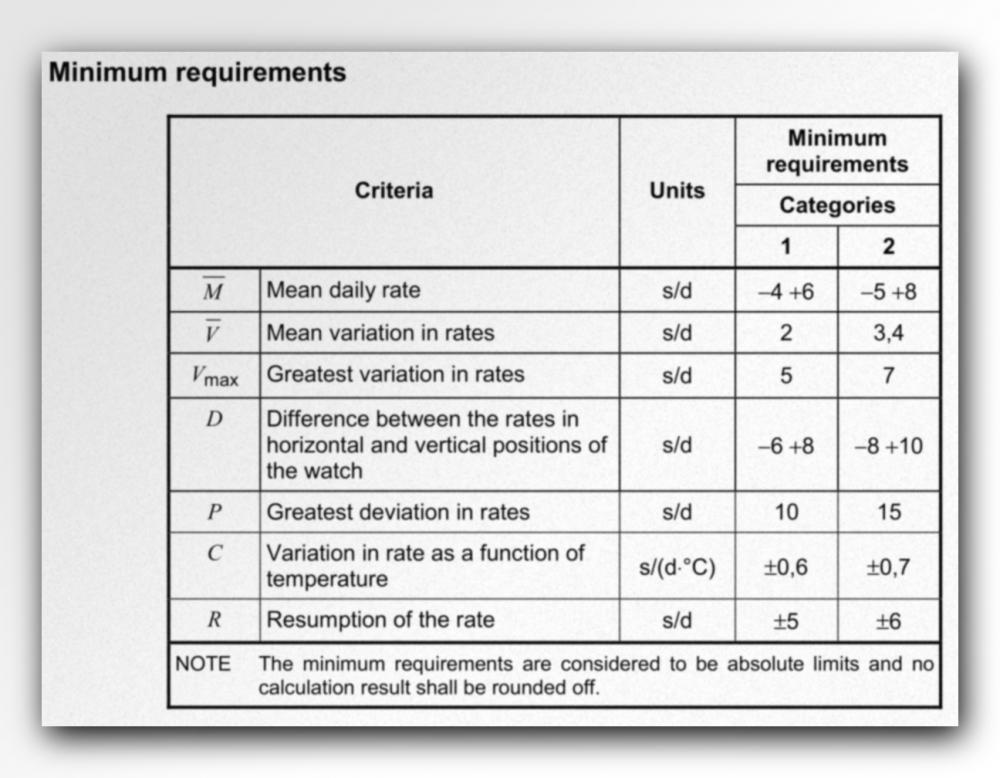

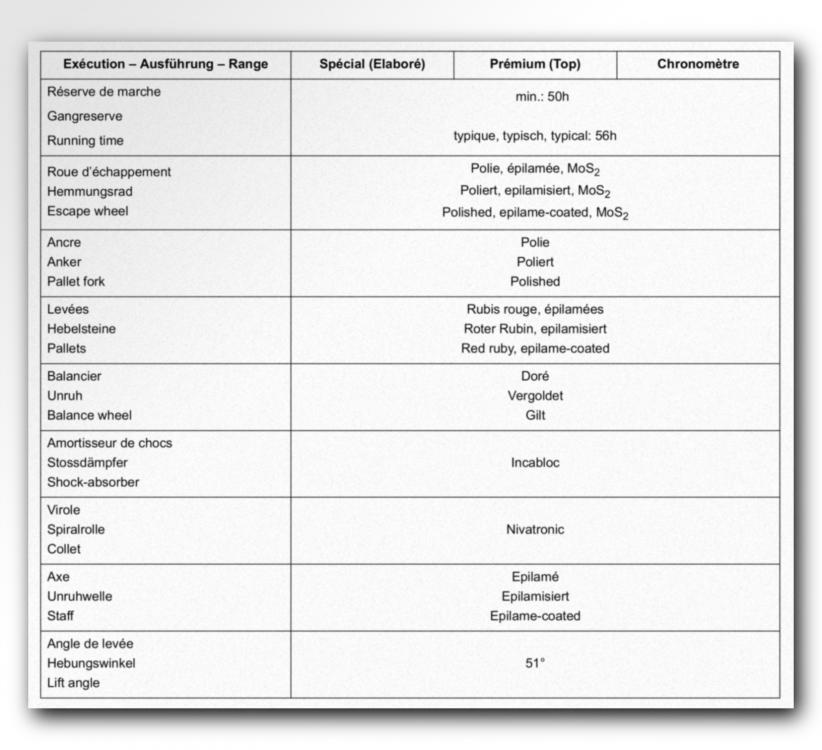

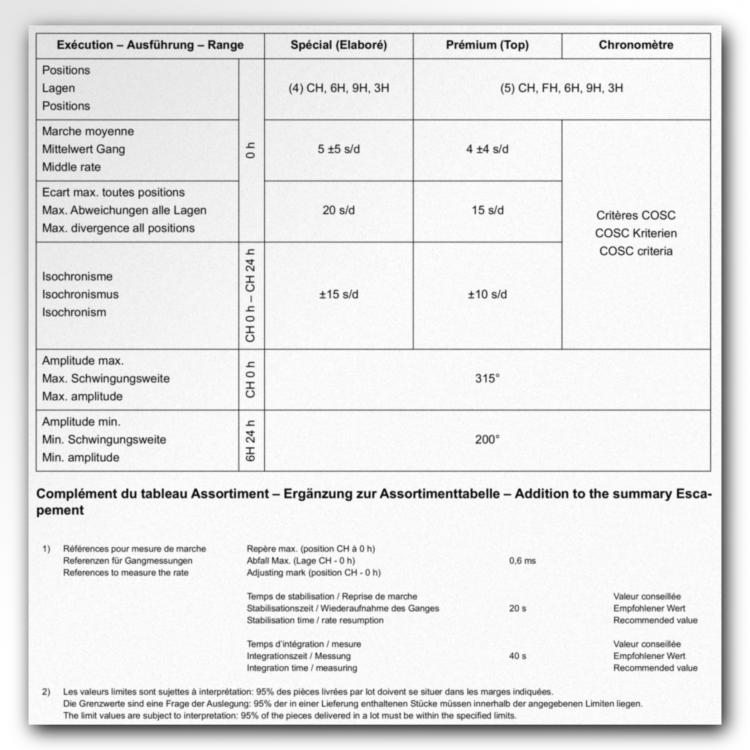

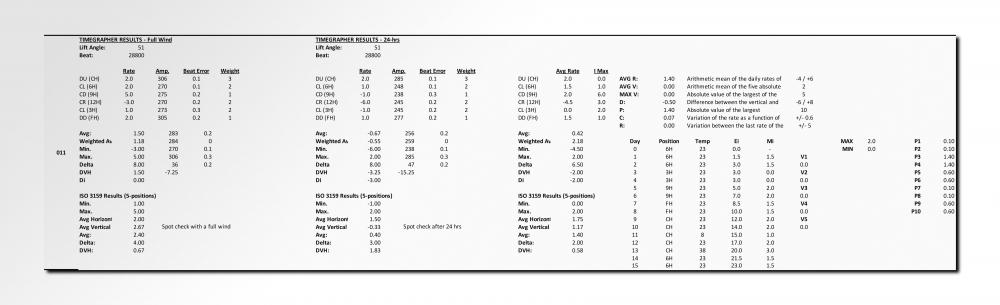

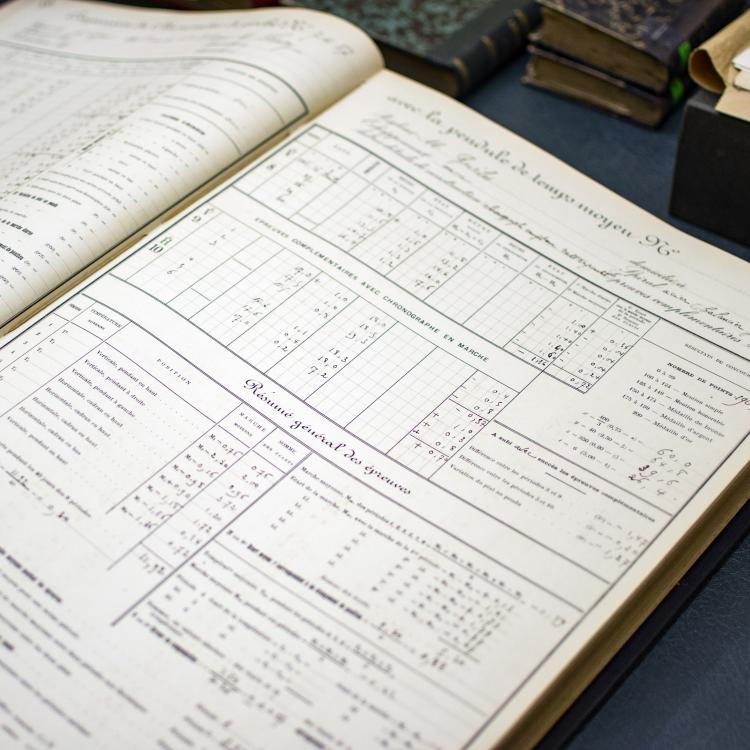

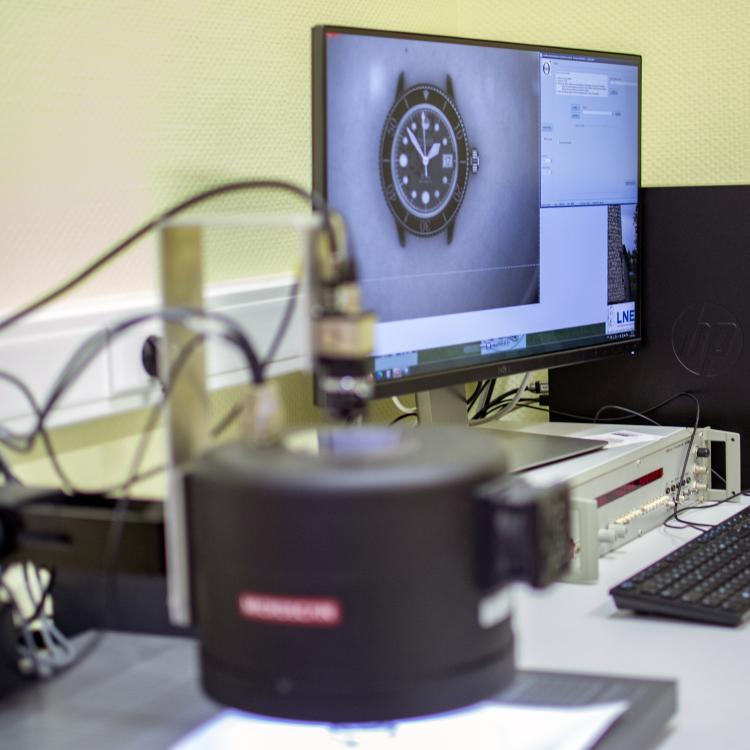

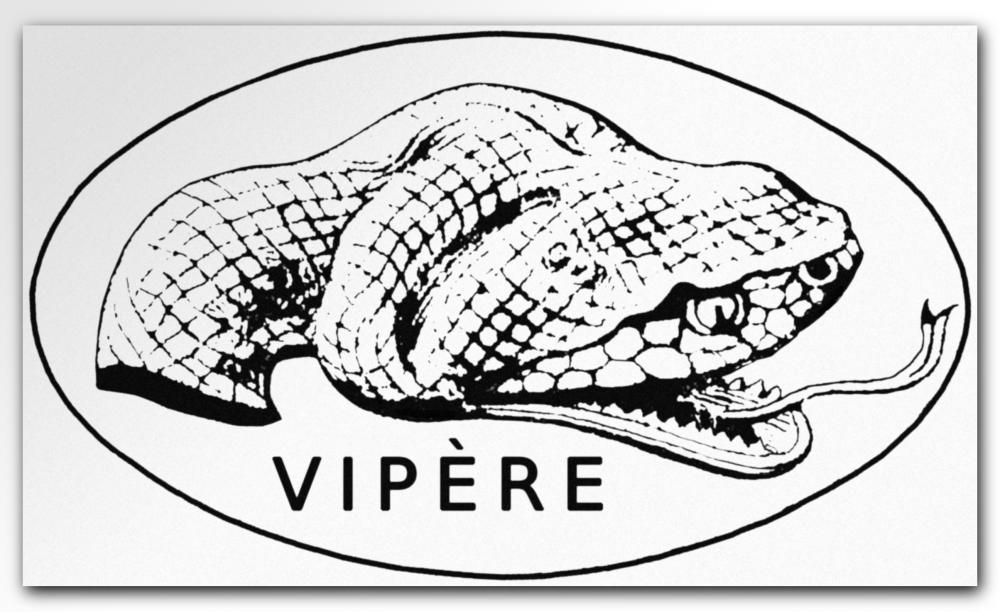

Introduction Before I jump in to sharing my story I will introduce myself. I’m Matt. I’m the founder, designer, and watchmaker of Typsim Watches. Typsim is a small, independent watch company based out of Seattle, WA, USA. This is my experience with chronometer certification of the Typsim 200M-C. I chose to have some of the Typsim watches chronometer certified out of my desire to produce the high-quality, accurate watches. For me, chronometers represent watches that use the highest quality materials, are put together with great care, and are rigorously adjusted and tested. But further, they connect a timepiece to the history and pursuit of precision timekeeping Typsim is a USA-based company, registered in the United States. The watch components come from Hong Kong, China, Canada, USA, and Switzerland. The watches are designed, assembled, and regulated in the United States. Because of this, Typsim watches or movements cannot be tested by COSC, Contrôle Officiel Suisse des Chronométres. The Typsim 200M-C is designed with a Sellita SW300-1 movement. This is Sellita’s comparative movement to an ETA 2892-A2 or Omega 1120: Diameter: 11.5”’ (25.6mm) Height: 3.6mm Frequency: 28,800vph (4hz) Jewels: 25 Power Reserve: 56hrs Features: Center Second Hand, Quickset Date Sellita offers their movements in several grades, Special (Elabore), Premium (Top), and Chronometre. The primary difference between Premium and Chronometre is the precision in which the movement is regulated for the average rate, max positional rate difference, and isochronism tolerance. The Typsim movements were ordered as rhodium-plated, diamond-snailing decoration, blued screws, custom logo engraved oscillating weight, custom date disc, with Premium regulation and Chronometre grade components (balance, pallet fork, escape wheel). What’s required of chronometer certification? The chronometer test program is defined by ISO (the International Organization for Standardization). ISO also accredits the testing laboratories that perform the tests. For reference, COSC follows ISO standards and is accredited as a testing agency by Swiss Accreditation Service. There are several other testing agencies around the world that can test and certify chronometers which include Besançon Observatory in France, Glashütte Observatory in Germany, and very recently the Horological Society of New York in the United States. A certification is provided to a wristwatch that successfully meets the requirements of the testing program defined by ISO 3159:2009. Test testing protocol lasts 15 days, tests 5-positions and 3-temperatures. The minimum requirements are: I selected to have the Typsim watches tested and certified by Observatoire de Besançon in Besançon, France Besançon, the historical watchmaking capital of France, is located in the eastern part of the country near to the Swiss border. It’s history as a watchmaking place began shortly after the French Revolution and culminated in the mid-twentieth century. Unfortunately, the 1970’s rise of quartz-based watches create a sharp downturn in mechanical watchmaking and shuttered much of this city’s watchmaking companies. The city’s expertise in precision work pivoted toward micro technologies. Since the 90’s the watchmaking industry has slowly recovered with a focus on high-end and custom watches. In 2002 the Observatoire de Besançon reopened for chronometer testing. Since then, they test several hundred watches a year, mostly from independent companies like Laurant Ferrier and Voutilainen. The typical success rate hovers around 70% with even the best companies averaging 80% success rate. Testing at the Observatoire de Besançon differs from COSC in that the Observatoire de Besançon only accepts fully assembled, complete watches with all components engaged for testing. COSC on the other hand tests bare movements with the automatic device (if a part of the movement) disengaged. This means testing with the Observatoire de Besançon accounts for more complexities faced by assembling and having an assembled watch. Preparations Understanding the testing requirements and average failure rates, I felt immense pressure to submit the very best performing watches I could. The first step was identifying the best movements out of the batch of movements provided by Sellita. Sellita provided movements conforming to their Premium regulation standards: Adjusted in 5-positions Average rate of +/- 4 s/d Maximum difference between positions of 15 s/d Isochronism of +/- 10 s/d Per terms with Sellita, up to 5% of the movements are allowed to be delivered outside of Premium regulation specifications. I created a preliminary, bare movement testing protocol to identify the best movements out of the box. I tested each movement in 6-positions with 20-seconds of stabilization and 40-seconds of measurement per position at both full wind and -24hrs wind. I was able to discover the number of winds to achieve the full wind and -24hr wind thru crown rotations, not waiting 24hrs. I measured the number of winds it took to wind up a watch to full wind after 24hrs. That number was subtracted from the number of winds it took to fully wind a movement to determine how many winds to wind to -24hrs. The instantaneous values from the timegrapher were inputted into a spreadsheet which calculated: Average Rate Weight Average Rate Minimum Rate Maximum Rate Delta DVH Di Isochronism Hypothetical Chronometer Testing Results based on the average between 0hr and 24hr rates From this information, the best performing movements were selected for assembly. Movements were selected for the amplitude, min/max rate delta, isochronism, and their apparent aptitude for passing the hypothetical chronometer test. These values gave me an idea of how well the movement was fabricated, lubricated, assembled, and regulated from the factory. Serial numbers were engraved on to these movements. One anomaly that bothered me at first, but I eventually let go, was the rate in the 12H (crown right) position. This is a position not tested under ISO 3159:2009 nor as a part of the Sellita specifications. Frequently, this position presented beat rates 5 – 7 s/d slower than the minimum beat rate in the other 5-positions. The selected movements were selected in part because they did not demonstrate this beat rate delta. With movements selected, the Typsim 200M-C watches were fully assembled and retested all over again using my pretest protocol. This was done to verify the assembly process was executed without causing issue. The watches were all adjusted based on the pretesting protocol. The beat error was reduced to 0.0 or 0.1 in CH (dial up) position. The rate was adjusted based on the average beat rate between 0hr and 24hr instantaneous rates. The Etachron pins were adjusted to narrow the isochronism down as close to 0 as possible. I would soon find out this was not the best route to make adjustments for this test. With the watches adjusted I set about testing them in accordance with the ISO 3159:2009 testing protocol. I planned to take measurements every 24hrs and adjust as required. The watches were set against www.time.gov and measured against the same online atomic clock after 24hrs to determine their actual, daily positional rate. I quickly discovered the movements were not demonstrating a rate that averaged between 0hrs and 24hrs rates but instead represented the instantaneous rate taken at full wind. Said differently, in real world timing condition, the rate was what a timegrapher said it would be at full wind. If the full wind timegrapher results for CH (dial up) indicated +1 s/d, the 24hrs wind timegrapher result indicated -4 s/d, the watch would demonstrate +1 s/d when measured against the online atomic clock after 24hrs. This was true of all positions. From the point of this discovery onwards, my adjustments were made only considering full wind timegrapher results and actual timing results. Each movement was tested for actual timing results for two weeks in CH (dial up) and 6H (crown left) positions. These two positions were prioritized for two reasons. First, ISO 3159:2009 emphasizes the rates and differences between these positions in the minimum requirement calculations and number of days tested in these positions compared with the other positions. This meant these positions needed to be as close as possible in their rate. Second, when CH and 6H rates are adjusted to be equal the other 3-positions were reined in to be within +/- 2 s/d, having a 5-position rate delta of around 4 s/d. Confirmation of 5-postiion average rate and rate delta was performed every 4-5 days during this process using the pretest protocol. Achieving a 4 s/d tolerance provided for a daily average rate that was well within ISO 3159:2009 requirements. My methodology for equalizing the rates between CH (dial up) and 6H (crown left) was to measure the instantaneous rate at full wind for each position. Depending on the results, the Etachron regulator pins were rotated further opened or closed. If vertical position had a faster rate than the horizontal position, the pins were opened. If the vertical position had a slower rate the pins were closed. I adjusted the pins with the movement running at full wind, testing for the results after each adjustment. I found, minor rotation of the pins would increase or decrease the beat rate in CH (dial up) position. The smallest rotation I could make would affect the CH (dial up) beat rate by +/- 10 s/d. I discovered that amount of rotation would bring the rates between CH and 6H together by about 1 s/d. If my CH (dial up) rate was +1 s/d and my 6H (crown left) rate was +4 s/d I would need to open the regulator pins just enough to reduce the vertical rate by 3 s/d. I would rotate the regulator pins until the CH (dial up) rate was approximately +31 s/d. I would then adjust the regulator arm to +1 s/d and measure the resulting rate for 6H (crown left). The resulting rate would typically measure +1 s/d. I would not call this scientific, but the results were consistent enough that I could rely on the action and corresponding results. I have a suspicion the instances that didn’t work out this way were due to my inadvertently moving the regulator arm, hence changing the rate more than the pin rotation alone. At the end of the 14 days the watches were performing at +0 s/d to +1 s/d in both positions – both as shown on the instantaneous timegrapher results and with 24hr timing. The Test Historically, the Observatoire de Besaçon used a Lunette Meridienne instrument to measure elapsed time through precise observation of solar bodies passing through the meridian. This one axis instrument sits on a dedicated, three-story, solid foundation – as do the reference piers outside the building – to maintain instrument stability. Comparing the elapsed time on the watch with the movement of solar bodies allowed the observatory to calculate the rate to the tenth of a second. Today, Observatoire de Besaçon uses three interrelated atomic clocks located in a thermally and seismically isolated room to synchronize the various clocks throughout the laboratory. These clocks are a part of the French national and international atomic clock organizations, setting the most precise time around the world. The watches are provided a QR code, and the hands are digitally synchronized to their timing software with a high resolution, macro camera. Each watch is held in position by holders and placed in a temperature and humidity-controlled vault each day after measurements and winding. I decided to fly the watches from Seattle to Besançon myself, hand delivering them to the Observatoire de Besançon. Due to the sheer value of the watches being shipped from the United States to France and back again, the shipment needed to be processed through customs with a Carnet. This is a special, temporary export/import procedure allowing for products to be shipped between countries without duty. The caveat to this procedure is the shipment needs to be hand carried or couriered (basically not shipped with FedEx, DHL, etc). I also had concerns that the vibrations of a cargo plane or handling of a courier could displace the precision adjustments in the watches. Finally, I personally wanted to see the historical observatory, meet the staff, and understand every part of the process. The watches safely made it to France with me in mid-August 2022 and I was notified of their success rate in early September. The 95% of the watches successfully passed the test and were certified chronometers. 70% of the movements had an average daily rate of -0.5 s/d to +2.0 s/d, aligning with what the preparations and pretesting indicated. The remaining successful results were just barely outside that range at -2.0 s/d or +3.0 s/d. The failing results were not far off at around +6.5 s/d, just outside of minimum requirements. Each movement will now receive a Tete de Vipere, symbol of the viper, the historic marking used by the Observatoire de Besançon that the movements were certified chronometers in Besançon.1 point

-

I never bought a full set of winders until I got the vintage K&D set for pocket watches. I've bought the Bergeon left and right handles, but you can actually do without them if you want. I buy the right hand winders with the arbor in the size that I need, and then if I want left in that size I just get the left handed arbor to use with the winder. Still expensive, but not eye wateringly so like buying a set would be. I get the numbered sizes that are not caliber specific. If I found myself working on a lot of ETA's, for instance, I might get a caliber specific winder, but so far no need.1 point

-

1 point

-

I use the same jewel picker all the time. It's really handy, and not too expensive. Got mine at Cousins. I've found the red one (smallest) the most usefull.1 point

-

Regarding the cap jewel tool,I didn't tried the sugested design , but I recently bought a jewel picker, it is pretty good, at least safer than tweezers. Jewel Picker1 point

-

Hi Its par for the course, dropping bits and loosing screws. Watch repairers spend as much tine on their knees as the Clergy.1 point

-

1 point

-

I clean anything with shellac by hand (Horosolv degreaser). For the cleaning machine I use IPA (isopropanol) in the final rinse. I (and my wife!) just can't take the smell of naphtha or suprol pro and IPA works extremely well. The smell of Suprol pro is absolutely horrendous, like death, and has a narcotic effect warning. Stay away from it! It will probably shorten your life by quite a bit.1 point

-

in a reason why you are not using suprol pro for the rinse? then 10 L are you sure that's going to be enough? if you look at the user manual for the Elma Super Elite they don't seem to be concerned about fire at all? although they make a couple references to the heated chamber at the bottom can reach temperatures in excess of 90°C. They appear to be more worried about you burning up something wherever you set the machine I don't see any of fears of the machine catching fire because of the fluids? it's interesting with the users manual for the cleaning machine is they don't seem to grasp that the user might get creative on their choice of fluids in the machine that apparently never crossed their mind. then I'm being confused? I'm looking at the material safety sheets for the suprol pro rinse and I'm looking for anything that would resemble flammability so that appears to be this "Flash point 23 - 25 °C". then for the rinsing your using naphtha "Flash Point : -20° C to -50° C ( Exists in the form of Vapor at ambient Temperature) ". This means the troubling aspect for your rinse is it's going to be a vapor even in the jar probably on the surface. And of course when you're spin drying it it's going to be a vapor. On the other hand if you look at this group naphtha or the other name it goes by lighter fluid is very popular as a cleaning fluid and of course as the rinse and I don't recall yet anyone burning the house down. on the other hand I don't know of how many people at have 10 L of it I would keep that some place separate from the machine. I suppose you might want to pick up a another fire extinguisher just to keep handy near the cannon of the stuff itself.1 point

-

Here's a few pictures of my home made watch cleaning machine. It uses a bathroom vent fan motor, ceiling fan speed control, and a digital timer. I've since added a 12v cooling fan above the motor as running an induction motor at lower speeds (voltage) increases the heat produced by the coil. I turned a 10mm shaft extension to mount the L&R cleaning basket, and the "lid" has a groove that has high temp RTV silicone in it to create the seal. The square post indexes the basket and lid to each jar, and I'm using old school (read: DANGEROUS!) solutions, but they are quite effective. I raise the head after each cycle and spin off the extra solution before going to the next one.1 point