Leaderboard

Popular Content

Showing content with the highest reputation on 08/28/22 in all areas

-

The Waltham with the long stem at 6 - that would be a car clock. It was meant to be mounted into a corresponding hole in an automobile dash, low enough that the crown projected just below where the watch could be set and wound. They usually had a large enough mainspring to run for eight days. As to model or movement, that would require pictures of the works and likely a serial number lookup at the pocket watch database.5 points

-

I have never considered Moly to be a braking grease, nor can I remember ever having seen it being recommended for this application on any sheet including Rolex - or at least I have most of the Rolex service sheets and can't remember seeing it. Kluber 125 is my go-to now but sparingly applied, I've seen it really being piled on in certain Instagram posts in the past . To the OP - my two cents: I recommend grabbing some Kluber or 8217 if you're going to be working on any number of automatic movements - it will definitely improve performance and give you peace of mind that you have done a good job.3 points

-

An easy way to test the continuity of the coil is to hook up a multimeter to the positive and negative terminals and give the balance a swing. That tests the contact spring as well asvthe coil. If there is no reading, then you may have ti disassemble the balance and test the coil itself.3 points

-

There is an old thread here that shows a YouTube vid of how to remove the EtaChron stud from the stud support, which I think is a bad idea, as there is too much downwards pressure on the stud support when using tweezers. It can be done that way, but isn't ideal, especially when working on a clone movement where the stud support isn't as strong as an ETA movement. I put a lesson together for my class at https://efhc.org.uk/wordpress/index.php/centre-facilities/ to show how to do it without risking damage to the stud support and how to save over £60 making your own tools to perform this task (That's another lesson on hardening & tempering, if anyone is interested) Here's the PowerPoint presentation. The video's within the presentation are marked in the top left hand corner of the slide 'Video' Enjoy... Lesson 7. EtaChron adjustment & regulation.pptx2 points

-

8217 is probably the cheapest option for braking grease. All the other lubricants you have does exactly the opposite.2 points

-

Are you sure? Kluber is graphite filled and a dedicated breaking grease. DX is PTFE filled and not adverticed as breaking grease.2 points

-

it would be nice if someone had a list of all the local watch repair clubs I unfortunately suspect the list would be really really short. That is if you restrict it to watch repair only while it's a collecting Association does have involvement with just about everything associated with horology. This means you never know what you're going to find at your local meetings. But you also have the regional meetings where one or more chapters will combine together and have a really big usually yearly meeting. Up until the existence of eBay the regional meeting was where I usually spent my money to pick up tools watches and other things. Then if you can manage to go to one of their national meetings that's the entire US really opens up the possibilities for things. There's also another Association which is the American watch and clockmakers Association https://www.awci.com/ out of curiosity how far do you want to drive to your local club? I notice they're having their annual meeting it's going to be in Harrison, Ohio. the annual meetings can be very interesting they even had one south of Seattle once it was quite nice at least as far as lectures went. the vendor display totally sucked as they were protesting a policy decision that they had made regarding Rolex parts so basically had local vendors only no one else which was very sad. But still the lectures were outstanding I see they do have a list of the affiliate chapters not sure if there's any going to be near you. https://www.awci.com/member-center/affiliate-chapters/ one of things interesting with chapters in this Association is at one time there were considerably more of them. For instance there was one in Seattle it still exists I still go to meetings which are really quite fun I learn a lot. ut as you see it's no longer on the list I don't think there's any chapters west of the Mississippi anymore. we dropped her affiliation with the national Association and never looked back on that decision and were still in business. More than likely there may be otherformer chapters out there somewhere perhaps1 point

-

Hi, I'm looking forward to gaining knowledge and experience of, what I'd consider a complicated, technical and often beautiful area of craftsmanship.1 point

-

You can read all the books and watch all the videos in the world. But nothing beats first hands experience. I still trash hairsprings due to clumsiness/complacency on occasion. Experience is the best teacher so don’t beat yourself up too much about it1 point

-

Your quest is difficult to say the least. A donor movement of eBay could be your best bet. Getting the correct strength and size of hairspring is really difficult because you need to know what strength and size of spring you need and measurements are difficult to achieve accurately.1 point

-

1 point

-

I am also confused here. the Kluber is a black really sticky substance that if you use too much it has too much breaking and is very bad.The DX is actually rated as a lubricant for very high pressure applications and I wouldn't consider it a breaking grease at all. So I'm a bit confused for the same reason. I really wish it was this simple we would all be happy to have one bottle of oil for everything it would make things so much nicer unfortunately it doesn't work that way I have a interesting video for you the problem with the video is it conflicts with the theme of this discussion, The wrong lubricant will lead to the barrel destruction. The wrong lubricant if the mainspring doesn't slip leads to timing issues which probably be acceptable on a cost basis in other words does the watch have to really keep time versus how many kidneys you have to donate. You know in some countries you wouldn't have to use your kidney just steal one from somebody else I've heard that's a thing. the bad of the video is it explains consequences of the wrong lubricant. If your mainspring doesn't slip as you can see in the video you will have timing issues. If you go the other direction something that's too slippery the mainspring may not have enough power at all to run the watch. probably if you keep it on your wrist you'll be okay just depends on how easily it slips Then at about three minutes we get the interesting aspect. not only do you have to have the right lubricant but how it's applied is important. For instance in the video if this was Kluber and you apply as much as he's doing I don't think the mainspring would slip at all well it was slept but it be really really hard. the Rolex lubricant is called TEPA the reference I'm looking at indicates it's not of the same color as the DX which makes me suspect it's not the same thing. but breaking grease does have to have a grease characteristic to keep the barrel wall from disintegrating. Which makes me suspect that probably uses Teflon so it is a breaking grease with a Teflon lubricant. https://youtu.be/7KNTrHVD088 learning watch repair can be interesting thing that requires a lot of practice. But maybe it also requires some experimentation and this is a multiple-choice question so I'm will vote for the DX as the others are totally unsuitable as they would have zero breaking effect at all. So let's try the DX and see what happens.1 point

-

1 point

-

That's not what I said. I've just been sent down some...strange and very fictional rabbit holes from some people on reddit and watchuseek, not so much here. Also my bird-son and I could take your missus. Tell her to bring her A game. Yes that's right haha. I already knew this and just completely forgot. Sadly that's a lot of tools I don't got. Cheap consumer metal 3d printing can't get here fast enough. Jon is fantastically helpful!1 point

-

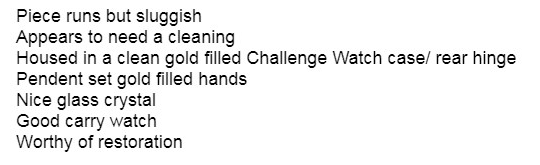

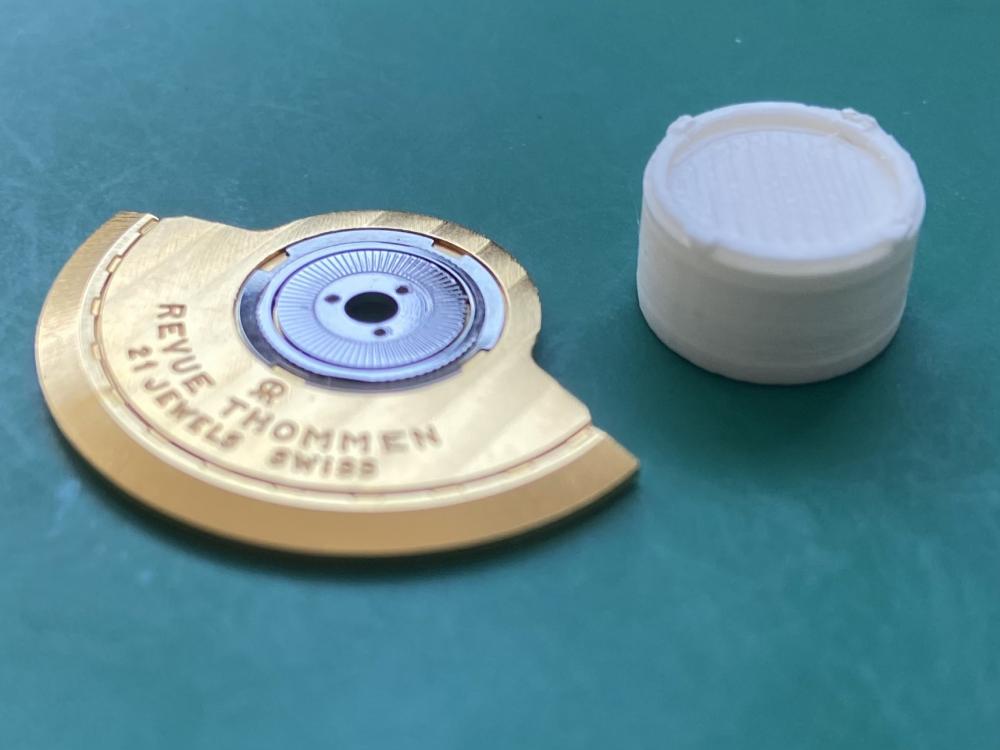

Hello Everyone. Just won this one. Elgin Antique American Gentleman's Pocket Watch Grade 303 Circa 1927 (#29296413). The practice movement I bought is from the same Grade and a reasonably close serial number (#23687805) so I hope to be able to make a working piece out of the two. Practice Movement: https://pocketwatchdatabase.com/search/result/elgin/23687805 Semi-Working Pocket Watch: https://pocketwatchdatabase.com/search/result/elgin/29296413 Here's the description: Wish me luck in this restoration! Does anyone have any tips for me? g. ----1 point

-

And for those who want to make the Etachron-Tools themself, there is the Info already on WRT, thanks to Jon see here regards, Ernst1 point

-

Unfortunatly the OP has financial constraints and is/was looking to make use of what he has not shelling out for another expensive product. Kulber P125 was discussed on the nawcc site, and Henry B Freid used graphite / oil paste , so there are vairied alteratives on the market.1 point

-

Hi the weights are cuckoo clock ones, I repaired one two years ago and re weights were lead encased in a brass sleave as per the picture below. I have had tow of these wooden framed clocks the second one had copper chains not brass. Also when dismantling take many pictures, the bearings are brass inserts into the wood and the hour wheel used a type of soft rubber compound as the friction from the mains haft to drive the hands.1 point

-

There are many years of thread posts in this "General" sub-forum. In an attempt to better organize and categorize these threads I have created a number of sub-forums within the main category of "Tools & Equipment" over time (a long time as it's a painful job), many of the posts within this General sub-forum will be moved to a more appropriate sub-forum depending on the subject. Please help by taking a quick look at the sub-forum titles and post in the appropriate section and as a last resort, if you do not find an appropriate sub-forum for your subject then you may post here. Thank you for your co-operation1 point

-

1 point

-

I have branched off the Tools & Equipment sub-forum and made it a separate section on the front page with sub-forums on specific topics. I have done this because, as a sub-forum, the Tools & Equipment area was getting way too congested and it was difficult to find if a topic was already discussed. I've moved a heck of a lot of posts from the old sub-forum into relevant sub-sections but there is still about 60 more pages to go through, I will chip away at moving posts into the new categories whenever I have a spare moment, and hopefully some of the mods here can do the same, but in the meantime, please try to help by checking the new sub-forums in the "Tools & Equipment" section and post any new threads in the correct place The old, Tools & Equipment sub-forum has been retained as a "General" sub-forum to the new front page section and no posts have been lost. If you previously posted there and cannot find your post then you can either find it via your profile page or by going through the sub-forums, I have tried to be as accurate as possible so far in matching topics to the sub-forum. New section: https://www.watchrepairtalk.com/forum/55-tools-and-equipment/ Old sub-forum, now part of above new section: https://www.watchrepairtalk.com/forum/21-general-tools-equipment-discussion/ Thanks for your co-operation1 point

-

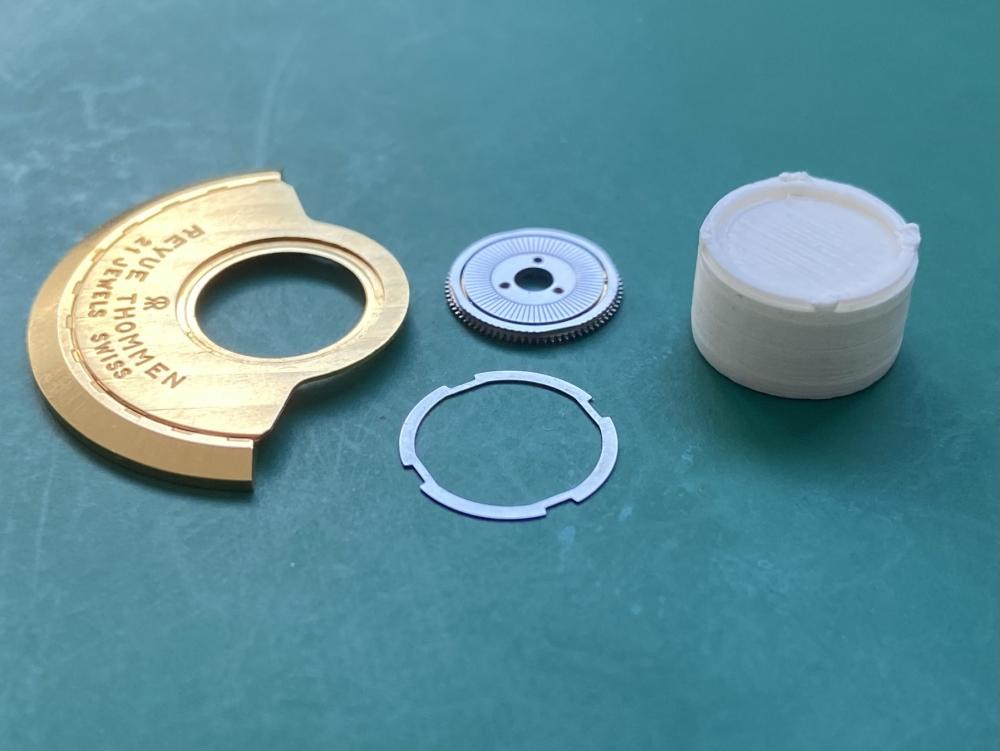

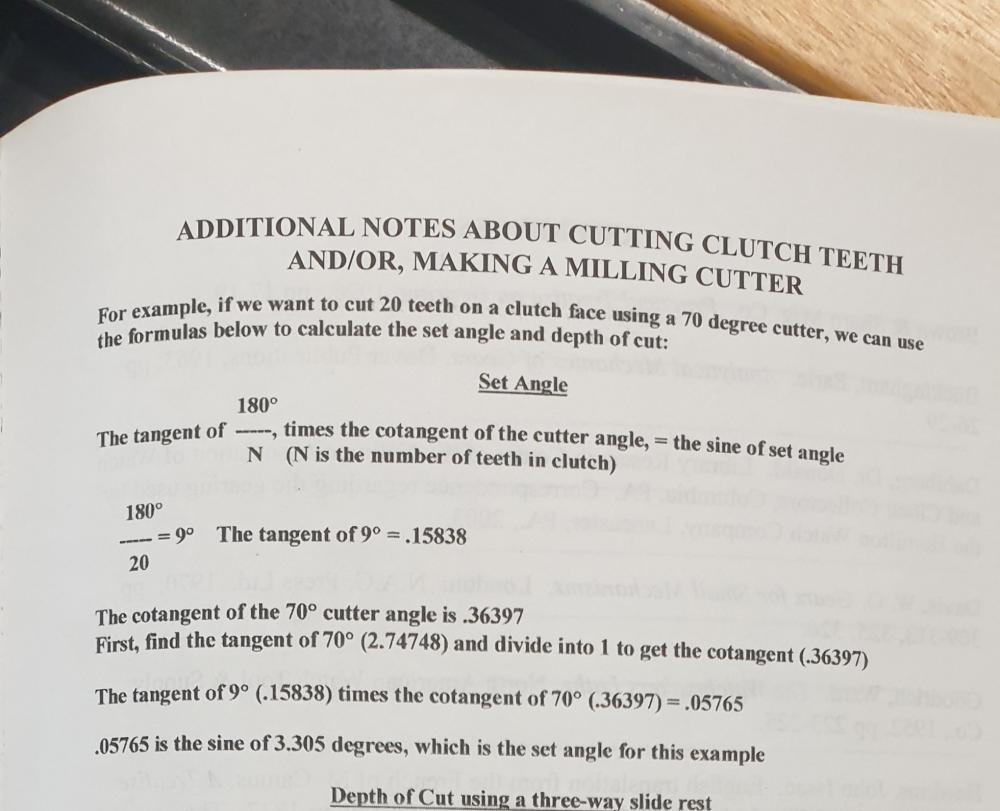

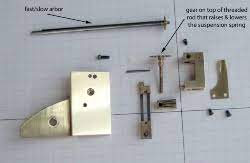

Wait are you T+T+T? Good vid (as are most of theirs), but they missed something it seems almost everyone does when making a winding pinions- the feed of the angled cutter isn't in a line perpendicular to the axis of the pinion, it's a specific angle depending on the angle of the cutter and the number of teeth. This ensures full engagement of the teeth from periphery to center. You can see it in this excellent illustration from Levins' Practical Benchwork for Horologists. They include a chart with the set angle for various numbers of teeth and cutter angles. Sometimes the cutter angle isn't a nice round number 60/70/80 degrees etc., like this tiny Piaget 430P winding pinion. It's 67 degrees, which I've seen and done before and probably explains why I happened to have a 67 degree cutter in my collection. Plugging that and 8 teeth into the math (from Robert Porter's The Clock and Watch Makers Guide to Gear Making) gives a set angle of 10.14 degrees, or 79.86 depending how you view it, which falls neatly between the numbers in the Levin book. You can see how tilted the axis of the dividing spindle is in the milling setup- quite pronounced. Worked great, and a big thumbed-nose to Piaget for making the part so weak to begin with AND not selling parts!1 point

.jpg.380449ea5620a0d3f92076d813f2df66.jpg)