Leaderboard

Popular Content

Showing content with the highest reputation on 08/14/22 in Posts

-

2 points

-

Sadly the "Regency" has no shock protection, and a broken balance staff. The other three however now work. The Seconda obviously needed a battery and a new strap. The Timex need a clean and lube. The "Montine" was a little troublesome, as it had been dropped. Nothing needed replaced other than the cracked crystal. The second hand was bent and fouling on the other hands, and the balance was way out of adjustment. It got a clean and service, and the majority of the damage was taken care of. Two issues remain. The hour hand needs repainted and re-lumed, and the crystal is actually a size too small, as I didn't have the correct one in my stash, so the one I used is glued. I do intend to replace this if the watch looks to now be reliable.2 points

-

I would like to share a check list made up by a master watchmaker. I take no credit for it, only think it would be helpful for us hobbyists. Here it is! CHECK LIST I decided to write up what is called a 16 point check that is meant to be a guide to steps required to service a watch this is slightly bias towards a wrist watch but very relevant to pocket watches also: This is a guide and not the definitive answer after going through it a few times add you own additional tests and observations. This is of course for a basic time only non-automatic or any with additional features, I also leave out things like demagnetizing, actual cleaning procedures, a good chunk of common sense needs to be applied also as I say its meant as a good starting point to a correct disciplined procedure, This is version 1 may add or edit/delete later. Check number 1 a Check the winding to see if the mainspring is broken. b Check to see if the setting bridge or sleeve is broken by pulling the stem out and testing the proper snap of stem. A broken setting bridge/sleeve is easily detected c. The balance wheel should be oscillated to see that it is true and the balance pivots should be checked by looking through the upper jewel to see that there is not a flash on the pivot. d. The hairspring should be checked to see that it is not damaged. e Check setting of hands f. The watch should be looked over in every respect, paying particular attention to any rust spots that may appear on any part of the movement. When rust is evident around the stem or setting mechanism, it is most important to remove the dial and hands in order to check this mechanism to see if the rust is very extensive. Check Number 2 a. Examine each part as it is being removed from the movement. b. Check for rust on every part. c. Check every pivot to see that it is not damaged or bent. d. Check the jewels in the watch, to see that there are no cracked jewels. e. Check pallet stones to see that they are not chipped or damaged. f. When removing barrel cap, make sure that it snaps off only after sufficient pressure has been applied to it. g. In the examination of each part, a close check is not made at this time as many of the parts will not be clean enough for that purpose. a much closer check will be made on the parts as each part is handled in the assembly of the watch Check Number 3 a. Upon completion of cleaning and parts removed from the basket into the assembly tray, each part should be checked over with the use of a watchmaker’s loupe special attention should be paid to the jewels, because if there is gum oil still remaining on the jewels, the cleaning job was not done satisfactory . It is also worthwhile at this time to examine the pivots. If the jewels are clean, and the pinion leaves are clean, it is almost certain that the cleaning operation was performed effectively. Check Number 4 a. Examine the condition of the mainspring. b. Check the width, strength and length of the mainspring. c.. If correct, replace mainspring using correct mainspring winding tool, not by hand d. Check the lubrication of the mainspring if required e. Check the fit of the mainspring around barrel arbor. f. check the mainspring end for proper shape to catch in barrel. g. Check the snap of the cap on barrel and replace in correct position h. Check the end shake and side shake of barrel arbor is it also sometime recommended to do this without mainspring fitted to test for free run and end shake i. Check the cleanliness of the barrel and barrel teeth. j. Check the oiling of the barrel arbor after the cap is on. k. Check the condition of the barrel teeth to see if they are bent or worn. Check Number 5 a. Jewel holes must be cleaned with peg wood if necessary. b. Jewels must be checked for chips or cracks. c. Check the train wheel pivots for rust, polish, cuts and straightness. d. Check the pinions for rust’, pits and polish. e. Check the pivots for pitting check that clean pith wood is being used. f. Check plates for tarnish, fingerprints, and polish jewel settings. g. Assemble time train and check end shake and side shake. h. Check wheels for trueness arid upright. i. Lift each wheel with tweezers to check for end shake and to see if each wheel is free enough to fall back to its original position. j. Spin train to see that is spins freely, in dial up, dial down and a vertical position. Check Number 6 a. Replace barrel and barrel bridge and check the oiling of the barrel arbor upper and lower bearing. b. Check oiling of crown wheel. c. Replace ratchet wheel. d. Note: do not oil remainder of movement until after kick-back is checked or cap jewels are present oil those now e. Wind watch slightly to check kick-back and recoil. This check should be made in dial up and dial down positions. If the watch does not have kick¬back, this indicates that the train is not as free as it should be. First, however, before checking into the train itself to determine if there is some frictional error, it would be worthwhile to examine the mainspring around the barrel arbor. Many times the loose fit of the mainspring around the arbor will prevent kick-back from occurring within the train. In such instances, the arbor is simply slipped in the mainspring instead of the train receiving the reversal torque, that normally occurs. If the barrel is found to be satisfactory, then the train. should be checked to see if the trouble can be located. first, the train should be examined carefully to see if each wheel is free, and if no trouble can be found, then it is advisable to remove the train wheels from the watch and replace each wheel in the watch individually and to check the spin of each wheel. If each wheel spins freely, this indicates that the pivots and the jewels are in good condition and that one need not look further for defects or faults in those areas. Next, place two wheels at a time in the watch and check the spin of the wheels. Thus, any error of improper depthing or a badly formed tooth on a wheel or pinion will be detected. It is simply a process of elimination in order to locate the particular trouble, and of course, proper corrective measures must be taken to correct an error when one is found. Check Number 7 a. Oil all the train jewels in the watch, and at this point it is advisable to oil also the balance jewels. b. Check to see that there is a ring of oil around each train pivot and that the jewels are not over-oiled or under-oiled. c. Check the jewels that have caps to see that the globule of oil has been formed properly between the flat cap and curved hole jewel and no keyhole shape if so remove re clean jewels and check seating the re oil and repeat check for perfect ring. Check Number 8 a. Oil stem properly. b. Oil friction parts of setting. c. Oil wolf teeth of clutch wheel and winding pinion. d. Oil clutch wheel groove. e. Oil points on setting lever that contact the setting bridge or the clutch lever. f. Never oil dial train. Note: ‘dial train means all wheels following center wheel staff. g. Seek expert advice on some types of intermediate wheels connecting clutch at setting positions that require oil. Check Number 9 a. Check condition of pallet arbor pivots. b. Check for chipped or loose stones, shellac or gummed oil on pallet stones. c. Check guard pin for straightness and proper shape. d. Check polish of pallet arbor, pivots and fork slot. e. Check end shake of pallet fork. f. Check height of pallet stones in conjunction with escape wheel teeth. g. Check matching stones. h Check drop lock i. Inside and outside drop. j. Draw. k. Hang-up of stones on escape wheel teeth. Check Number 10 a. Check tightness of roller jewel in roller table - uprightness of roller jewel. b. Check the height of the balance wheel in conjunction with the fork bridge and the center wheel. c. Check the clearances. d. Check the height of the guard pin in relation to safety roller. e. Check the proper length of roller jewel and fit of roller jewel to fork slot. f. Check the guard clearance. g. Check the corner clearance. h. Check the jewel pin shake. i. Check the guard test, j. Check the corner test. Check Number 11. a. Check the hairspring in-the-flat. b. Check the hairspring in-the-round. c. Check the quadrant of the hairspring to see that it is formed properly between the regulator pins and stud d. Check for beat of the watch by equalizing the force to receiving and discharge pallets. e. Check for the collet wobble. f. Check for trueness of the balance wheel, and for the flash of the balance pivots g. Check for trueness of roller table. Check Number 12 a. Place the watch on the timing machine and take a rate in the dial down position, then turn the movement over to dial up position and take a rate. There are three things that should be observed from the rate that was taken: 1. Dial up should indicate the same time as dial down. 2. Observe the closeness of the lines to determine if the watch is in perfect beat. 3. Observe how the watch is running in reference to the time error over a 24-hour period. b. Adjust the mean time rate of the watch so that the dial up and dial down positions will record on time. Do not move the regulator more than one degree in adjusting the mean time rate. Any other alteration must be made by adjusting mean time screws or by adding or removing weight from the balance wheel in such a manner as not to affect poise, static or dynamic,. c. If the rates in dial up arid dial down are found to be different from one another, then this indicates a mechanical error in the watch which must be traced out before proceeding. d. If the watch is found to be out-of-beat, then of course, it should be put r in proper beat at this time. We might emphasize that if the watch was put in proper beat in accordance with the proper procedure at the bench, then an out-of-beat condition or minimal amount would not be indicated on the timing machine. e. When the above conditions have been satisfied, the next step would be to take a rate in positions and errors corrected. If everything has proved to be satisfactory, the watch should be tested for isochronal test be made on the timing machine, which consists of re-testing at different winding levels and rate in the dial up position. Check Number 13 a. Check for proper lubrication of cannon pinion on center post. b. When replacing the cannon pinion, be sure that the leaves of the cannon pinion do not come down on top of the minute wheel teeth so as to bend the teeth of the minute wheel. c. Check tightness of. cannon pinion d. Check to see that cannon pinion does not ride up when watch is being set. and smooth consistent operation. Check Number 14 a Make sure that the hands are fitted securely to the parts to which they are attached b. Make sure that the hands are adjusted so that there is equal space between the hands and the hands are set as close to the dial as possible. c. Check to be sure that the hands are shaped to the contour of the dial. d. Check to see that\ the hands are positioned so that they are synchronized with one another. Check Number 15 a. If there is no case for the movement, simply disregard this check and proceed with the next check, number 16. b. Check for proper snap/screw back of the case. c. Check for the clearance of the hands under the crystal. d. Check the crystal to see that it is securely fitted into the case. e. Check to see that the crown is next to the stem and reasonably close to the case. f. Check for tightness of movement in case. g. Check the spring bars to see that proper spring bars are used for the particular type of case so that the band is held securely to the case. h. Check the lug holes to see that they have not been worn badly by the spring bars to a point where the hole may break through and allow the spring bar to come out of place. Check Number 16 a. Set the watch on time with a master clock. b. Let the watch run for a period of 24 hours and check the error in the time repeat in several positions. c. Allow the watch to run until it completely runs down and check the length of run. The watch should run a minimum of 30 hours, preferably 40 hours, if it is in “A. I have no answers to any of the steps since I didn't make this up. Maybe Mark might.1 point

-

1 point

-

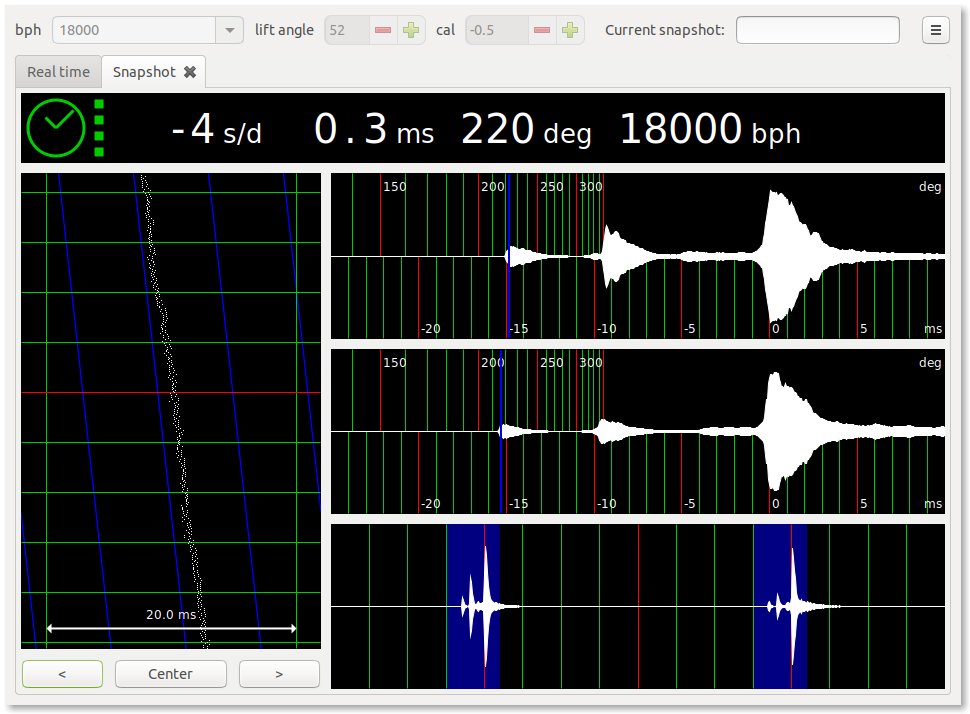

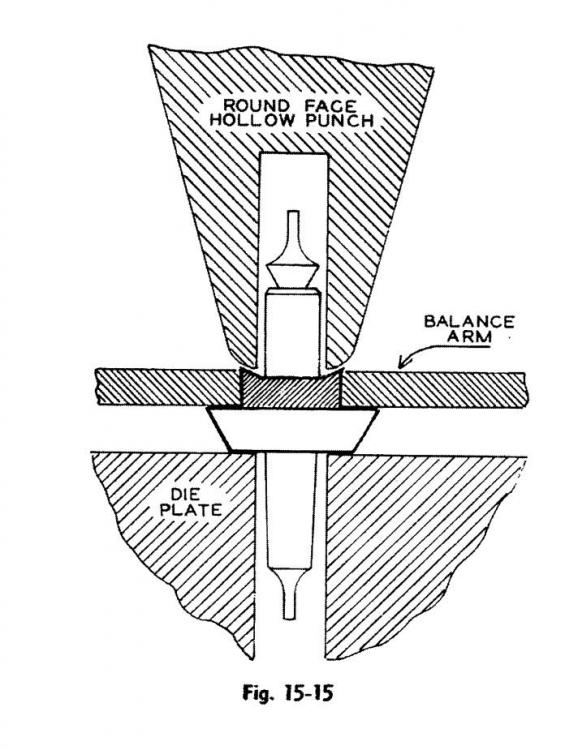

This was my first attempt at replacing a balance staff. I followed instructions from Mark's course and Kalle's videos . I used A and B stakes from my C&E set. The hub disintegrated, did I tap too hard or did I choose the wrong size stakes, did the hub have a manufacturing defect, it was NOS for Omega 330 series. Any suggestions would be welcome Thanks in advance and cheers1 point

-

one of the problems are dealing with a mechanical watch is the gear train. You're always going to have a power fluctuation with the gear train.. Typically will average out typically won't see an issue.. but anything that can cause a wheel to be out of round. in other words as is revolving around it will have a little bit of a binding issue causing a power loss that will show up as numbers changing. So basically bent pivots wheels that were not perfectly round or non-jeweled holes that are no longer exactly where there supposed to be in other words there out of round. Then you start to see a pattern of power fluctuations. Typically on a timing machine you'll see that the numbers will change. If you look at the amplitude you may see it going up and down not settling down to something. At work because we have really expensive timing machine made by witschi I go to the time plot feature. Then it plots the amplitude versus time in a different fashion and I can look for patterns. So I'll see a pattern if there's a wheel out of round for instance in the case of vintage watches it just tells me why I'm having a problem but I don't worry about it. Because typically even if you find a pattern the watch will average out the problem hopefully.1 point

-

I don't know what size those stakes are, but I can see from the last photo that the rivet is still untouched. So yes, you hit too hard, and also had the wrong size punches (stakes are what go underneath). You want a convex punch that just fits over the hairspring diameter, thus against the rivet, then a flat faced punch with the same hole size. Tap tap tap tap tap tap tap round face, turn the balance a few degrees and punch as well in the opposite direction every few taps to even out any irregularities, check that it has spread a bit, then tap tap tap tap tap tap tap flat face to flatten it (turning as before). The roller table diameter should be in a hole in the staking tool die plate that lets it fit just freely, not tight but not flopping around, so the hub is supported on its flat surface. Obviously align the die plate well with the centering punch once you've chosen the hole. If the balance is a light friction fit on the staff (ideal), then you would want a punch like you used to seat it, with finger pressure, no tapping. Here's an image from lesson 15 of the Chicago School of Watchmaking course. It's easily found online in PDF format (I just grabbed this from here and it seems clean). Shows the fit of the concave punch, flat will be the same, also the fit in the die plate of the tool. Remember this is a really small piece of heat treated steel, not a roofing nail . Also, just as reading about a subject always benefits from visual demonstration, visual demonstration will always benefit from some well written and illustrated reading.1 point

-

1 point

-

I remember one online tutorial that opened with a picture of a watchmaker "smoking expensive Swiss cigarettes and crawling on the floor looking for a part" At least you only lost one part. My last disaster was a parts tray explosion, and it took a looong time to find everything that went walkies. Eventually I found everything except a crown wheel screw, plus I found three mystery parts! Have no idea where two of the three extra parts came from. Sigh.1 point

-

Your observations are totally valid and I'm sure they are shared by the majority of us here. I'm not saying that all organic oils dry at the same rate and I'm sure they chose the oil that gave the best results at the time. Refining and blending the base oil stock alos improved those oil's ability to resist oxidation. I also suggests that the process would be hampered while inside of a sealed or semi sealed watch case. I was just speaking to the assertion that "oil doesn't dry". There had to be some reason to send me into the sea to hunt whales or die trying. Shane1 point

-

You only have two variables, parts or procedure. One will not fix the other but faulty procedure can produce bad parts. Dose the escape wheel turn freely by itself? Good luck. Shane1 point

-

1 point

-

Hi there Dmitry ,minutes must be more precisely indicated to give an accurate time reading; simply pointing somewhere between numbers won't work. Therefore, the minute hand extends farther than its counterpart usually to the markers on the edge of the dial so as to provide an exact accounting of the time .With the minute hand being longer, you smoothly travel over the hour hand without it getting in the way.The fact that the minute hand is always longer, and often thinner, than the hour hand, serves a very specific purpose, though. The hour hand doesn't have to point specifically at the hour number it relates to for a person to know what time it is. For example, if the hour hand is pointing anywhere between two and three, anyone capable of telling time will take this to mean it's two o'clock. Probably carried over from early cock days when you pushed the minute hand to set the time so that you would get past the hour hand without touching it . Cheers ,Graziano1 point

-

The mark "SHR" (Societe Horlogere Reconvilier) is for Reconvilier however Ranfft doesn't show a "25" - they start at "26". In 2018 Ranfft posted re: a 15 jewels/size 18 not yet added to his database on Watchuseek (where there are 4 pages of posts with the word Reconvilier) A subsequent post refers to a Reconvilier 12.1 point

-

A small drill is great. If memory serves the Bergeon tool was (is?) basically a small carbide spade drill in a screwdriver handle. Glucydur balances are quite hard and HSS drills don't always want to bite, so go carbide if possible.1 point

-

1 point

-

30's 40's Tissot good buy mate at under a fiver. Hopefully its a simple setting lever fix for you.1 point

-

Works for me. HKD40.40 sounds like a good local currency figure, in which case I would say it is well within the local rules.1 point

-

1 point

-

I pay about €8 for 250ml in my local pharmacy. Thats about the same as a good lighter fluid.1 point

-

Nice one matey, that is also a nice looking watch. I'm nowhere near the stage of taking apart and reassembling yet, not too confident at all. I'm still at the stage of almost shaking as I take a back off to have a quick look. I have nowhere near enough equipment to pretend i'm James May, not yet anyway. I'm still in the caveman part of horological evolution in that if it doesn't work when IO poke it with a stick, I call on an adult to help. Frankie Surely you mean Pubelicly??1 point

-

Hello everyone , my name is Ian and i love watches. I have always liked watches since my father gave me my first Timex military style watch as a lad in the mid 70's. I am sure i still have it , and it will turn up one of these days ... I bought a Hamilton khaki a few years ago that reminded me of it a lot. I dont have any real vintage watches yet , I only really have old watches at the moment ... including one or two that need a bit of love to hopefully get them running again... and a couple of slightly newer ones, Breitling Aerospace and Omega Speedmaster Moonwatch that have tempted me over the years ... dont you just love interest free credit I wish that i had paid more attention to my fathers tinkering and repairing watches for his friends and friends of friends when i was younger, I guess now i'll have to try and learn the hard way I dont have any aspirations to being a watchmaker , i'm just an aircraft engineer in my late 50's who would like to be able to take apart and rebuild some simple watches to running order for my own pleasure and to give the old grey matter something else to think about ... and if i could maybe create a watch from an old case with a homemade / designed dial and hands i would like that a lot. I like leather straps as opposed to bracelets , I dont like gold watches , and i dont like outrageous flashy anything ... I am a simple creature. Not much else to tell you at the moment , I shall surely be posting a few cries for help soon as i stumble along trying to diy it, or more likely "biy" it ... until i can justify / afford to do Marks watch repair course ... I already have my basic toolkit that i bought a good few years ago ,and its had far too easy a life so far and is almost as new so now its time has come ... lets see how many of the tools are worth using and what needs replacing first .... Thank you all for listening to my ramblings Ian1 point

-

Hello and welcome to the forum, Iam from Tadcaster 40 trs there now in Aberdeenshire. Attachec a little reading for you to get started. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

Recently while scrolling through eBay, this watch caught my eye. It's a dead ringer for the one my father wore for most of my childhood (band not withstanding). I'm not sure what ever happened to his but this "as-is" "does not run" watch that shipped from only miles away from my home town, ment something to someone. For all I know, it could actually be his. It's a all stainless steel, Kaltron, 17 jewel, selfwinding watch with a Felsa 4007N movement. Not overly expensive in its day but very smart looking and dependable. It's failure to run resulted from the second hand arbor being seized within it's bore. A few nerveracking hours of chasing three small springs around my bench last weekend and it's up and ticking again. Thanks for all of your support. Yes, I know the date is wrong. Shane1 point

-

I have recently used a jacot tool to successfully re-polish a badly worn pivot in a pocket watch the first time in my life. I have watched Richard's videos about it and I also went to a book printed in the same year I was born in 1976. This book is written in Hungarian and was one of the book used by the state sponsored and only one watchmaker school as far as I understand. (To my knowledge you cannot learn watchmaking any longer in Hungary as of now.) I scanned the corresponding pages as how to re-finish a pivot including the usage of a jacot tool. It was a great help to me so I thought I share these pages with you. After scanning the pages i sent the pdf through a pdf to txt engine then sentence by sentence I translated the Hungarian text to English. I learnt watchmaking in English and it might sound strange but the Hungarian name of the parts and methods were unknown to me. This added some more difficulty on top of the fact that my English is far from perfect. I am writing this because I am not sure how good the end result is. If anyone feels that could correct the text so it would be more readable or would make better sense please do so. Enjoy if you can. jacot_tool.pdf jacot_tool_Kopasok_javitasa_magyar.txt jacot_tool_repairing_wear.txt1 point

-

Anyone new to watch repair really should practice on non-important watches first. So find some scrap balance wheels and practice poising with those.1 point

-

I've said it before, and I'll say it again for anyone new to replacing balance staffs: you don't necessarily have to re-poise the balance. In my experience, more damage is done than good when it comes to balance poising by the watchmaking community. Often balances will remain in excellent poise after re-staffing, so don't assume that it is necessary.1 point

-

Why is dynamic poising more important than static poising?1 point