Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/22 in Posts

-

I just use the Presto version of the Bergeon 30637-2. I haven't seen a cannon pinion it couldn't pull. And I work on both antique pocket watches and wrist watches. No issues so far. (I should probably go knock on wood now.)5 points

-

Thanks for the tips everyone. I went with the feeler gauge option as it was to hand. Rather than risking the temper I used a mini angle grinder (plus constant cooling) to cut a rough blank, then carbide drills and diamond files to drill and shape the part. I tried scribing the shape on to the part but eventually having scribed a copy as a template I glued it to the blank and worked on that: I changed the design of the detent spring slightly as the original obviously had a stress riser at its root. I couldn't match the exact shape of the detents but their positions are identical to the original. Time to check for functionality and fit: I bent the spring slightly (about 0.3mm at the tip) down towards the setting lever. It functions perfectly and feels smooth with a distinct click from one detent to the other, so I'll polish it ready to fit to the watch when it is cleaned: Thinking of stress riders I polished the cut edges of the spring with metal polish on the tip of a toothpick . It will be interesting to see if it lasts.4 points

-

The only concern I would have with this method is if you don't pull Absolutely straight up you could Bend the center shaft.2 points

-

Yes a rather interesting substance. The most interesting thing for me was when visiting bergeon In Switzerland they commented that they purchase it from Canada they purchased the entire supply of it. Conveniently they didn't tell us what it was originally made for? Then just reminder of something I was reading a review In a BHI magazine on a witschi timing machine. The person was all excited with the ability to measure amplitude and discovered when cleaning balance pivots they had a loss of amplitude. So I'm always careful to keep it away from pivots. Actually find that there's a lot of shops it totally banned the substance altogether because it does leave a film behind or at least it can. On the other hand it's very useful for all kinds of things if you just mindful of it's not perfect.2 points

-

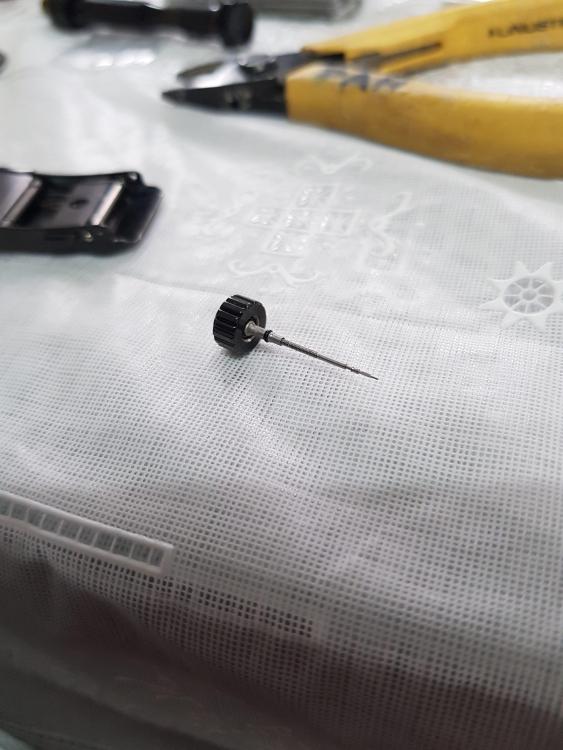

I recently purchased a watch off eBay with broken stem I have cleaned and then dissolved stem in alum powder and replaced with new stem movement is e168 so stem not to hard to find hope you enjoy the pics Watch back with broken stem dissolving stem in alum powder mixed with water put this jam jar in pan of boiling water on cooker ring and 10 hours later over 2 days you get a crown minus stem if crown is stainless steel. Old stem and new stem next to nice clean crown and clean crown crown with new stem cut to length and tested the loctite thread seal used and seals put back . case back cleaned and seal lubed. The watch was cleaned in ultrasonic bath before reassembly. watch all back together happy happy hope you enjoyed1 point

-

Something a little different today. An early quartz alarm ESA 926311 based "Claude Helier Paris" with a white enamel dial. I can't quite make my mind up about the case. It may be gold, as it has a stamp next to the crown, and the metal where scratched doesn't appear to be plated. I'm in two minds about this one, and I'm going to presume for the time being that it probably isn't gold, unless of course someone can prove otherwise. I didn't take the mechanism out of the case as it is fairly pristine, other than the scratches on the case from previous battery changes (not made by me I hasten to add). It came with a suede leather case, embossed with "Claude Hellier" and an apparently little worn, or unworn "genuine crocodile" strap.1 point

-

1 point

-

Hello Nucejoe, I promised to inform you after further investigation. The cannon pinion of the Parrenin consists of two parts (extra gear for friction). The cannon pinion was functioned oké. After lubrication of the jumper mechanism and the date ring groove, the watch runs very nice. So thank you again for your advice.1 point

-

Hi @Neverenoughwatches I must admit to having a soft spot for Marvins and have several in my personal collection. Their movements have always appeared to be good quality ... and even a little quirky / original thinking like the 580 if you ever get a chance to work on one. Okay their absorption into Manufactures d'Horlogerie Suisses Réunies (MSR) meant they moved away from their own in-house movements but they have still always seemed good quality and using movements from the likes of ETA. Although clearly an older watch the stand-out here was that rather unusual setting lever spring (did I say "quirky"? ) .1 point

-

Hello all hope everyone is well. I have been away from this site for a long while and usually reside reside at WUS in the Russian section. I am to a point now that I am going to start servicing the 24XX series movements and am thinking of purchasing the Supreme watch cleaner. I have been reading through the posts and have read good and bad. It is a little scary as the place I am ordering from says NO RETURNS A few questions on the unit. Have they improved the speed control to run the motor at a slower RPM? Is a 1 amp fuse correct to install on the "Hot Leg" for the 110Volt unit? Would there be an advantage to install a dimmer and a inline fuse on the heater circuit? Has anyone re oiled the motor bearings yet? are the bearings ball or oi-lite? Thanks so much your responses will be greatly appreciated, James. P.S. I would also like to give a shout out to my buddy..... EndeavourDK Hello Roland my friend I hope you do well, best regards sir.1 point

-

Came up in my feed this morning, published yesterday. Pretty shallow, but excusably so since I imagine the audience are not watchmakers. Still, reminded me of this thread. https://www.watchtime.com/featured/did-you-know-that-the-difference-between-a-modular-and-integrated-movement/1 point

-

Almost - I hold it in my right hand, lower it on to the cannon pinion, then hold the collar with my left hand, and twist the barrel until it's tight. Then pull straight up, but I do that by resting my hand on the table and just using my fingers to pull up. On pocket watches I usually use heavy brass tweezers, and just hold the movement and try to lift straight up. I fit my thumb under the tweezers and and try to lift that way, rather than levering, which could bend things. Hard to describe, and probably not the best technique, but so far so good. I'm sure I'll end up with a Presto #2, but my tool budget is stretched a bit at the moment buying collets for my lathe. Darned expensive, even for used ones.1 point

-

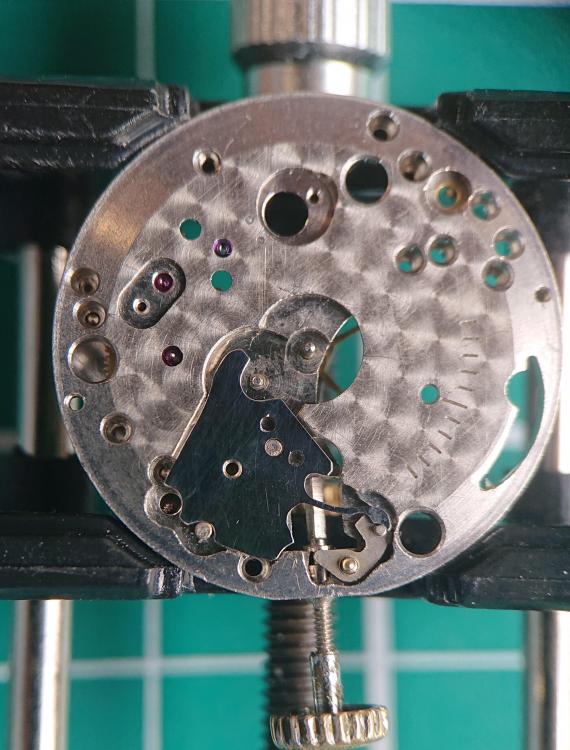

In the last picture it gives the impression that the setting , cap jewel and spring are miss in altogether. have you looked at Dr Ranfft's site for the lip "ranfft lip r25" should bring up the page.1 point

-

1 point

-

These clocks work best on very little oil and it has to be in the right places and a good oil. The main thing with these clocks is getting the clock in beat, slight movement fitting the new suspension spring and you will have trouble. As Bod has suggested photos are needed. This book which is the bible to repairing these clocks is a must, Horolovar 400 Day Anniversary clock repair guide book 10Th Edition by Charles Terwilliger, look around for best price. I forgot to mention you are going to need a clock mainspring winder if you intend to repair the clock properly.1 point

-

Have you serviced the movement. 400 day clocks have to be absolutely perfect for them to run. Pivots polished etc. They are a challenge but I love em1 point

-

When I first started, I used a cheap Chinese hand remover for removing cannon pinions too. It works quite well. Then I bought a vintage K&D cannon pinion remover on eBay. But it couldn't even close down on collets that were 1mm, making it practically useless. I modified the collet and removed the centre ejector pin. Now it can close on collets smaller than 0.7mm.1 point

-

I have experience with one Skagen model. I had to remove the stem, replace the back, and using a syringe on the case tube, blow out the crystal. Scary as s**t, but the only way.1 point

-

1 point

-

Coincidence i already have that tool. I made it to get a shock spring into its seating that had three cuts outs to go in at the same time. I now have another use for it, thanks watchie1 point

-

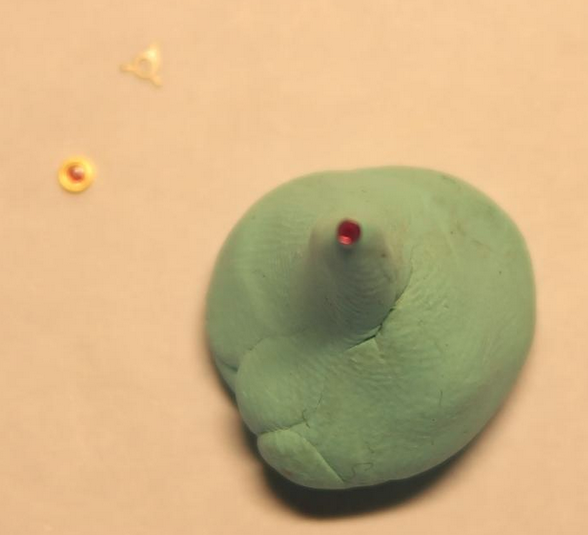

I love this high-tech jewel cleaning tool. Up till now I used to drag the cap jewels over tissue paper holding it between the tweezers tips for the side wards motion and holding it down with the tip of a peg wood. It works but this sophisticated tool seems to do the job a whole lot better and saver! BTW; to further handle the cap jewel safely, I taper a small piece (much smaller than the one shown on an old picture of mine below) of Rodico and pick the jewel up on the domed side. You can now safely handle the jewel; pick it up, inspect it under the light, oil it and place it in the Chaton. After placing the jewel in the Chaton, you hold the jewel down with the tip of your tweezers and remove the Rodico. Combine this with your cleaning tool it seems to me that the risk of pinging a cap jewel is a thing of the past .... well, lets hope so Thanks for the cleaning tool tip !!1 point

-

Hello everyone, I'm looking to purchase a polishing tool and wanted to ask for your opinion. I am torn between a handheld Dremel or a Deluxe bench top. I assume that with time, I will probably buy both, but due to current apartments constraints and pending negotiations with my wife, I am more leaning towards the Dremel as it is just easier to store away. One reason why I'm also leaning towards the Dremel is that I will soon be restoring a lathe and being able to polish some parts by hand should give me more flexibility to work on non flat surfaces that may be a bit harder to reach (also I cannot stick the whole lathe under the desk top tool ) I guess now that I wrote it down, I pretty much have my answer, but maybe there are things that I am failing to consider? Thank you1 point

-

I picked up this 1959 Bulova 11ACC on eBay last week for $30. The movement was thoroughly rusted into the caseback--first time I've every used WD40 on a watch. Finally got the movement out of the case--got as much surface rust off the parts as possible (and chipped the intermediate wheel in the process ), cleaned it, straightened the sweep second hand pinion a bit (didn't want to tweek it too much), and reassembled. Keeps +/- single digit time in all positions with pretty good amplitude (270-220). Since I re-used the mainspring, I'm going to call it a win and move on to getting the case/dial and hands in order.1 point

-

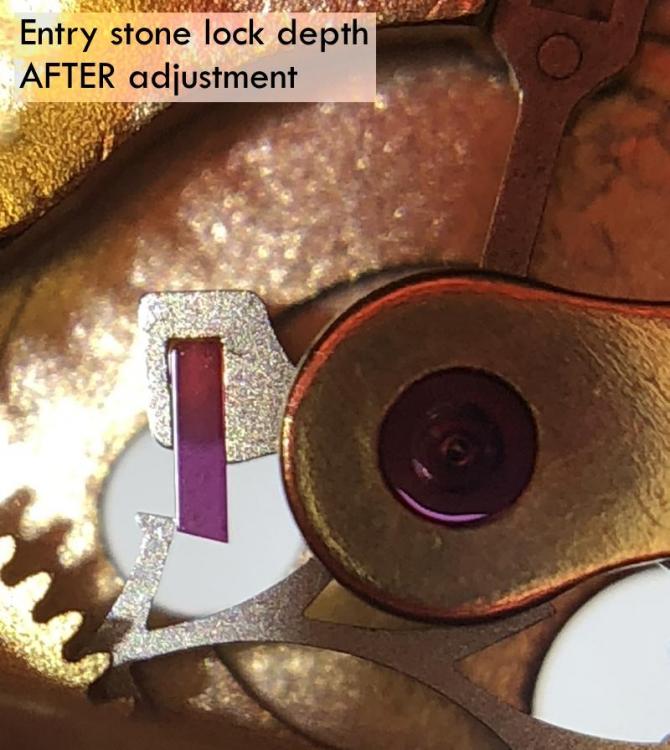

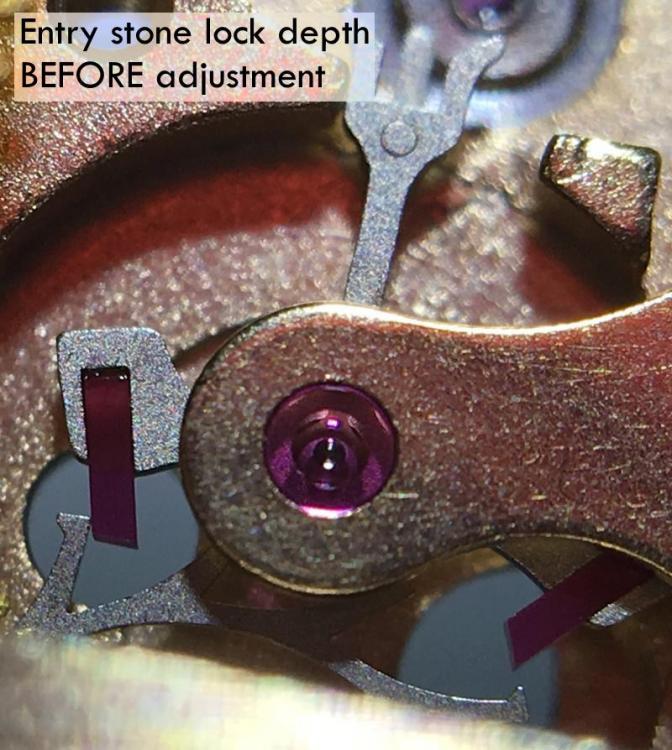

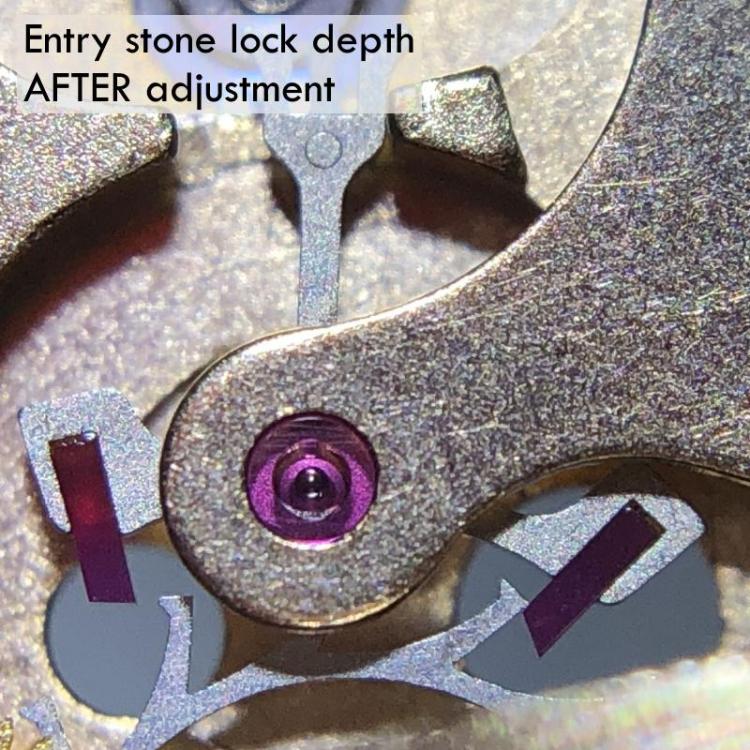

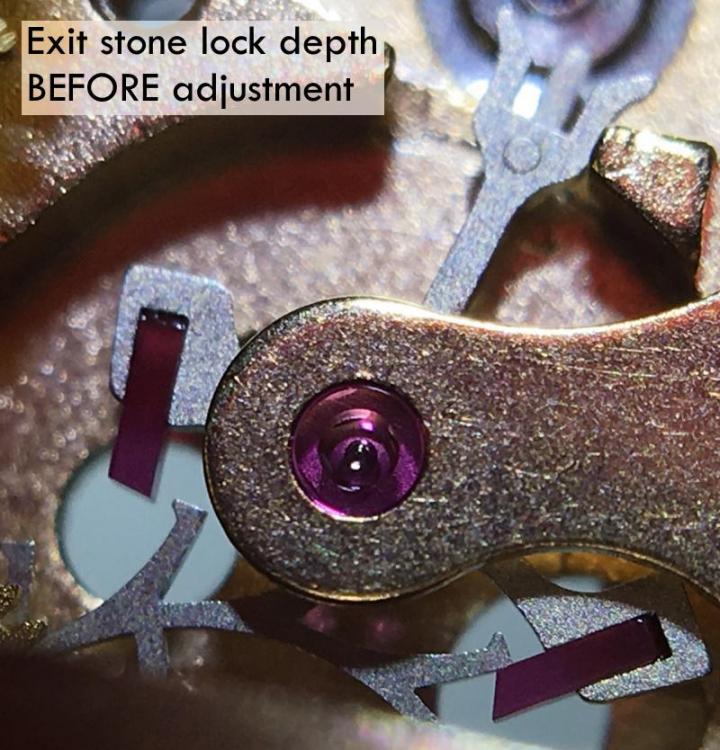

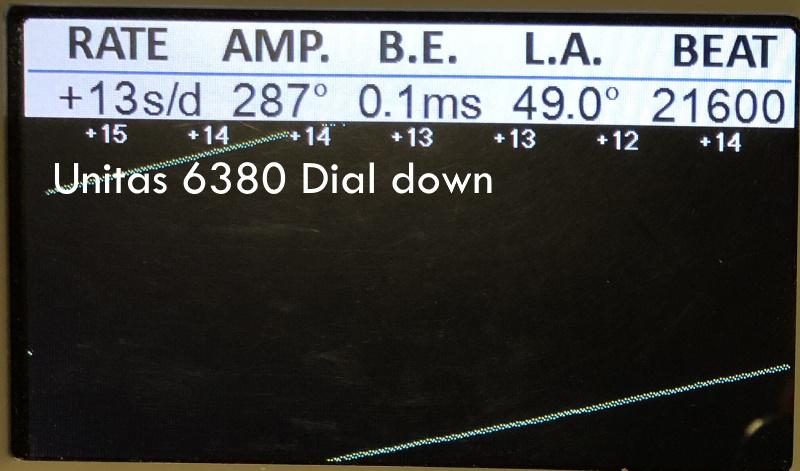

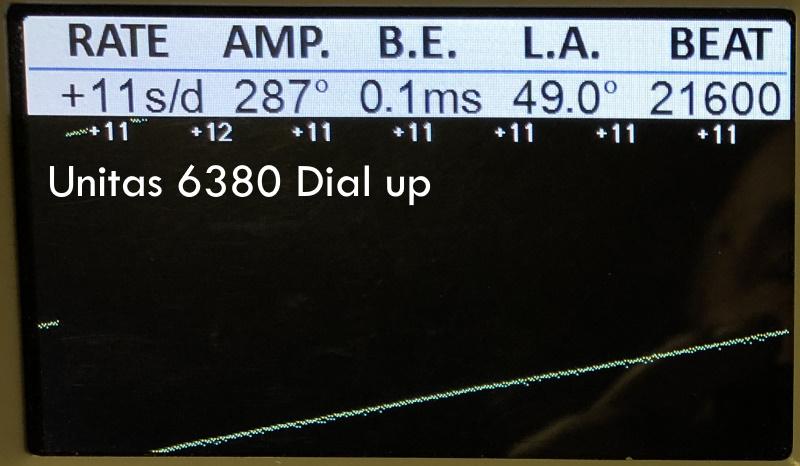

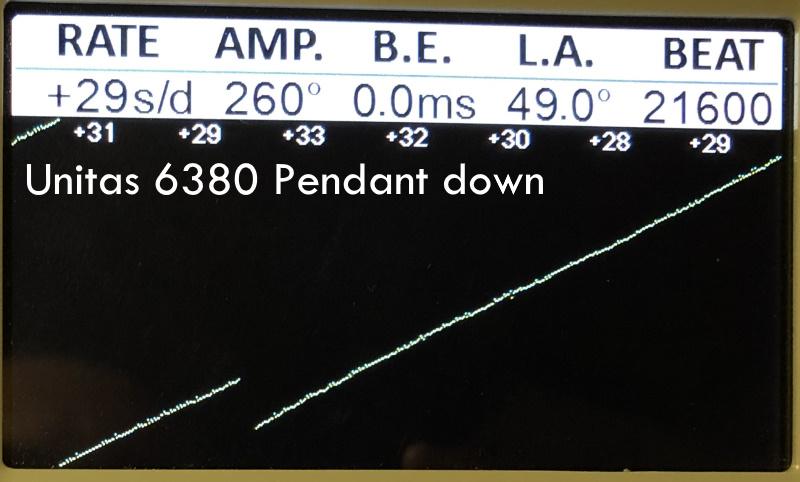

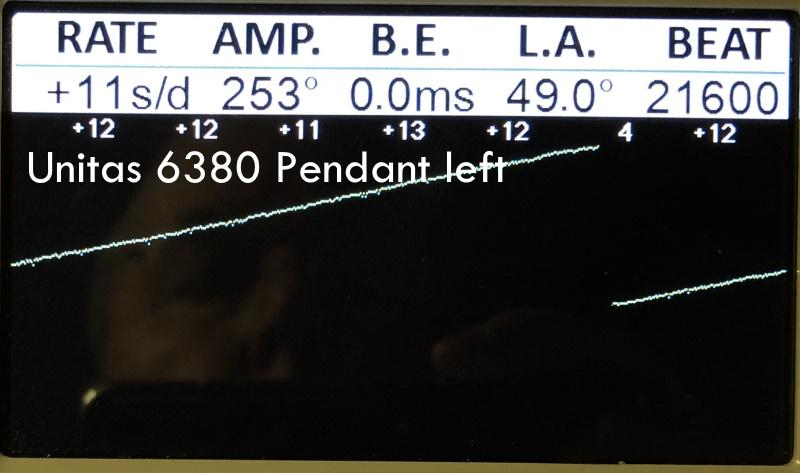

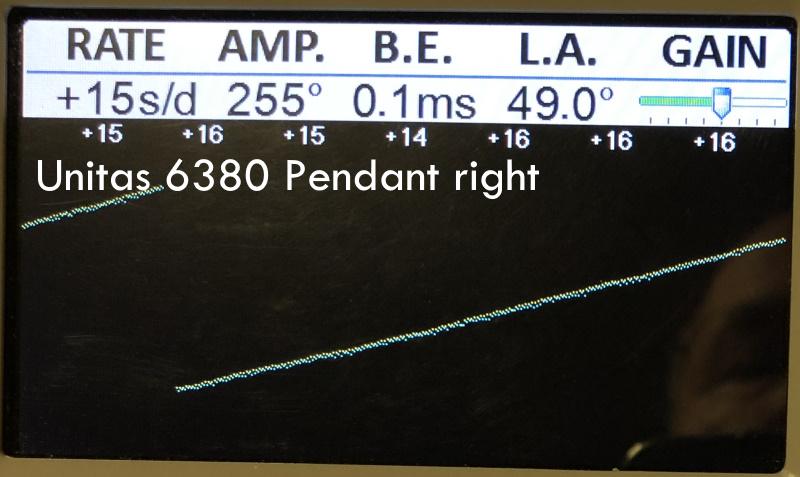

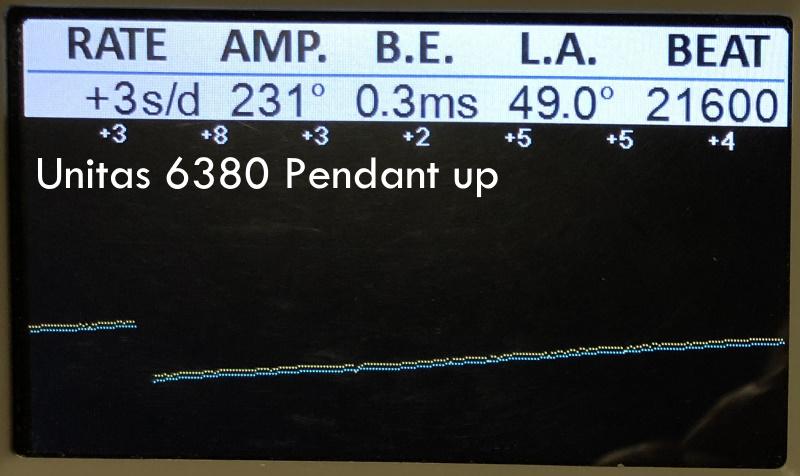

So, I finally got the time to return to my low amplitude Unitas 6380. You were right about that John. There was plenty of room to push both pallet stones back. I didn't just warm them but re-shellac:ed them. The reason for doing that was twofold. Firstly, I wanted to try my newly bought shellac flakes (from CousinsUK). Secondly, it was easier, or at least appeared to be easier, to adjust the lock depth before applying the shellac. The shellac flakes is the best shellac I've tried so far. It's very hard, but not as brittle as the shellac from my clear stick of shellac. To the question of how far I should push the pallet stones back, I tried to follow Henry B. Fried's advice in the book "The Watch Repairer's Manual" where he writes: "In a well-adjusted escapement, the lock should approximate 1/3 the thickness of the pallet jewel." This is a 15 teeth escape wheel 21600 BPH calibre and Fried's example was a 18000 BPH calibre. I believe I read somewhere that the lock depth should be shallower for a high-beat, 20 teeth escape wheel 28800 BPH movement, so I was somewhat ambivalent, but I believe/hope I made the correct decision? I thought about that a lot, and decided, as I was already at it, to re-clean and oil the cap jewels. I also re-cleaned the entire balance and polished the staff pivots with a bit of Dialux green rouge applied to an oil-drenched piece of peg wood. I should really have done this cleaning before adjusting the lock depth of the pallets in order to be able to tell what had the most effect, but hopefully there'll be plenty of new opportunities to test this in the future. Anyway, thanks for reminding me of how very critical this is. With parts being so very small it's easy to underestimate how very critical cleanliness is. Cleaning the cap jewels I made me a new peg wood tool which I was pretty happy about and that I demonstrate in the following video: Anyway, here's the end result of these two activities (cleaning the cap jewels/staff pivots and adjusting the pallets): The pendant up position isn't all that impressive, but I've decided not to dig any deeper at this time but instead reassemble the rest of the watch and wear it for a while to see how it fares. After a bit of regulating I wouldn't be surprised if it turns out to be a pretty decent timekeeper, or at least that's what I'm hoping. Anyway, always being curious, any ideas of why the pendant up position loses about 20 degrees or so?1 point