Leaderboard

Popular Content

Showing content with the highest reputation on 04/25/22 in Posts

-

When I have needed to move a post I always message the member explaining the reason and wait for an OK. That is I think the polite way to go.4 points

-

Hello and good morning, Just to say I find the new background a lot easier and not so hard on the eyes. brilliant. And as regards the moving question which Mark quite rightly nipped in the bud, I think Old Hippys suggestion is probaby the right one. One cannot please every one but as said a compromise has to be found and informing the member his post was moved and why is a good compromise. I am sure that we all have faith in our Administrator and moderaters to find the solution and continue to provide a brilliant forum which is open minded and informative. Thank you Gentlemen your work is appreciated.3 points

-

Just as an example, here’s my little lathe set up. I was lucky and got a nice stereo microscope at a yard sale for $75. The scope boom was $200 though. The lathe is a Sureline 1000 that I inherited from one of my dads friends. ( more luck). The guy used to make model airplane engine parts on that lathe, talk about a master! I’ve not made many watch parts on it, but I have made many many other things with this little lathe. I just wish it had dial or digital readouts, using the just markings is very hard. I have added a magnetic dial indicator on the cross feed when I really needed to make a precise turn, but it’s a pain to set up each time. Like nicklesliver stated, take your time and master each step. Start simple and really learn how to use your measuring tools. A bad measurement equals a bad part. On top of that, Have fun!3 points

-

Sometimes blunt gets the job done my friend. I like people to know where they stand with me and me with them. I'm honest and genuine. I don't BS and say things as I see them. When I think I've make a mistake I will hold my hands up and apologise. Life's too short to have it surrounded by drama , been there done that didn't like. Tiny mate here you go a simple visual. Photo 1 this was me when I started. Photo 2 this is me now. High tech or what.2 points

-

Cleaned up the thread a bit as it was going seriously off-topic - out of respect for the OP and other people who follow this thread - remember, emails are sent to all subscribed to this thread after you post and they might not be interested in personal conversations - those can be executed via PM2 points

-

Finally got it done after lots of agony. If mods aren’t happy with me posting video they welcome to delete it2 points

-

After having watched „thousands“ of watch repair videos I stumbled into the chanel of clock maker James Martin by accident. Meanwhile I frequently enjoy the fine quality of these videos as well as the insight into the more „macroscopic“ world of clock making. https://youtube.com/channel/UCHQBjQNQD2ZMQ9nZYtkGF9Q1 point

-

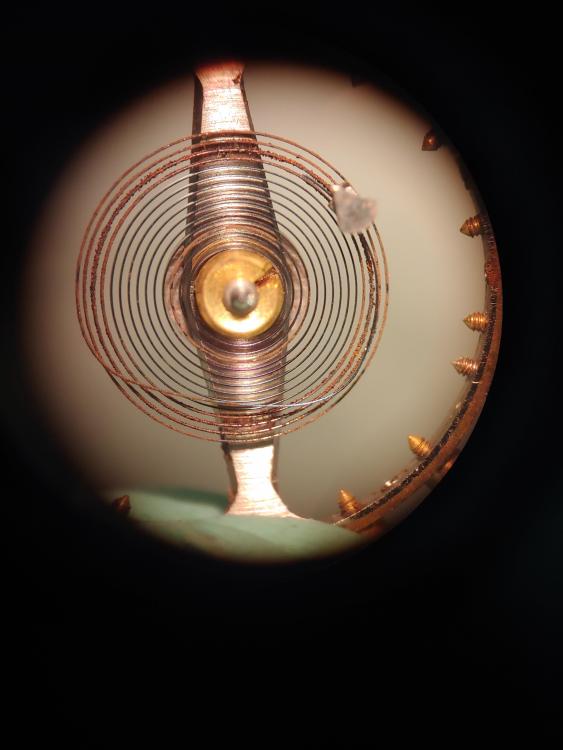

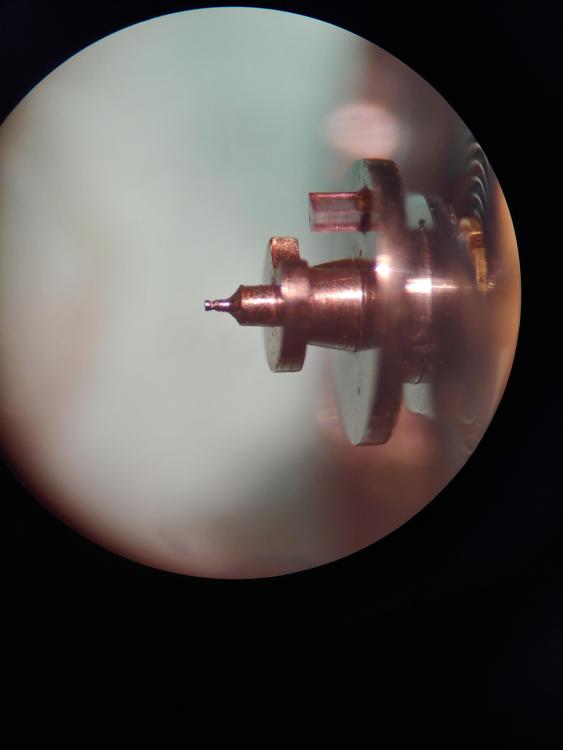

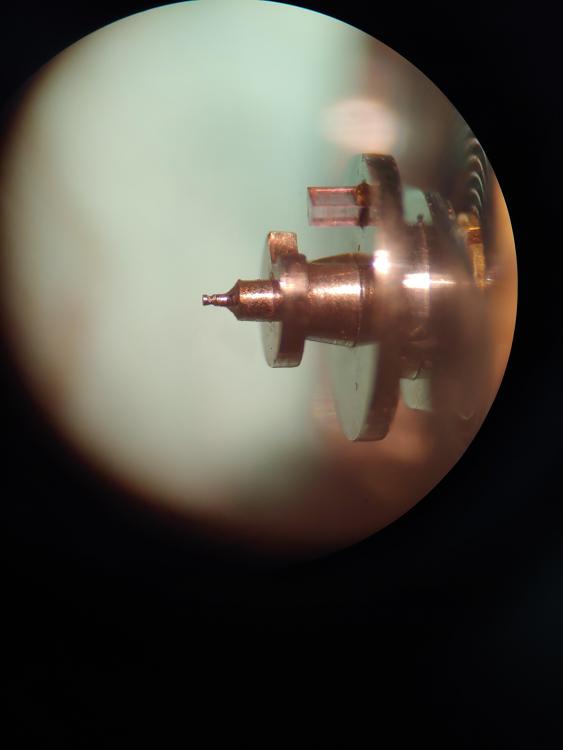

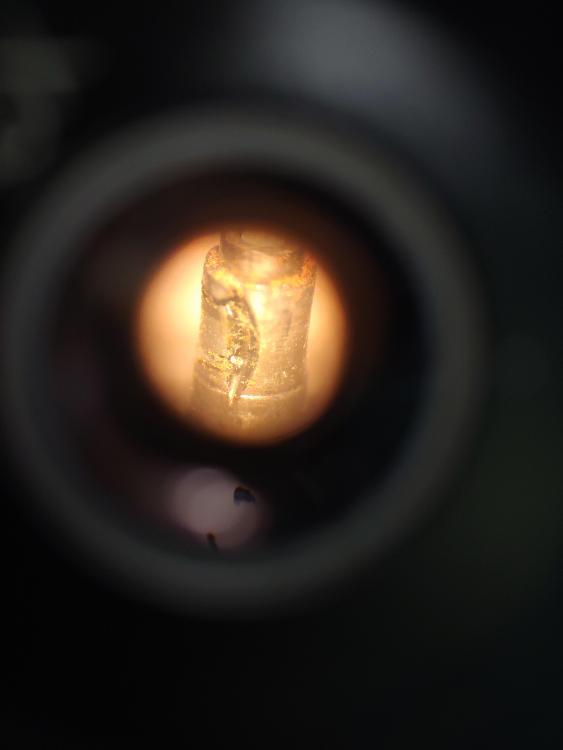

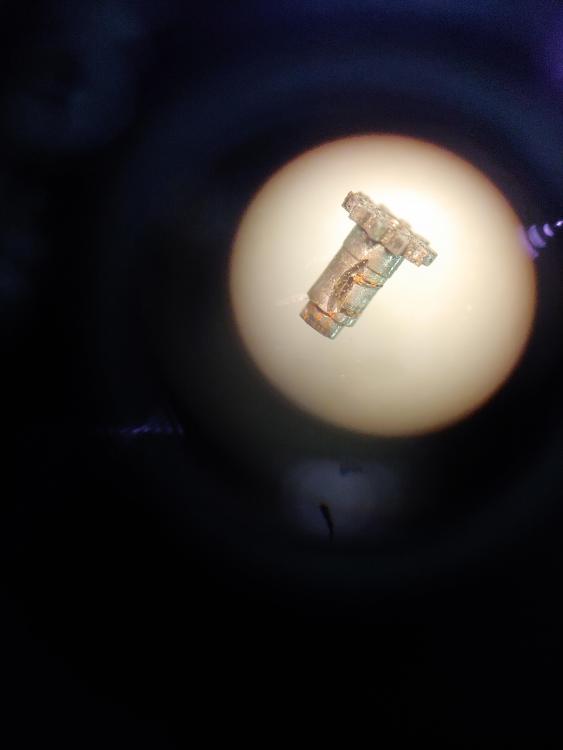

Hello everyone, I am currently working on an Elgin pocket watch, grade 417, size 3/0s, hunter case, year 1918. When I took it apart and inspected each part under the microscope I realized about the following problems. (I am attaching pictures as well) 1. Hairspring is rusted. (Some screws as well) 2. One balance pivot is badly damaged. 3. One balance jewel (the one on the main plate) is broken. 4. The cannon pinion is badly damaged. 5. Mainspring completely destroyed. Questions: 1. Is there a way I can get rid of the rust in the hairspring? I tried lighter fluid, but it did not work. Should I try to find a new hairspring? 2. Is there a way I could restore the damaged balance pivot? Or, should I look for a new balance staff, or should I replace the entire palance (balance wheel, staff, hairspring, etc.) 3. Where could I find the correct balance jewel (the one that goes on the mainplate)? What is the best approach to chang it? 4. Is there any solution for this cannon pinion at all? Or is it better not to waste time on it and find a new one? Guys, so sorry for the many questions, I am learning from you a lot. Tons of thanks in advance!!1 point

-

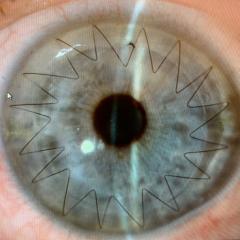

I am new to horology although I have spent a fair amount of time studying horology over the past 6 months including completing Mark's course. I am a recently semi retired eye specialist having performed complex eye surgery for over three decades so looking forward to this new and very interesting challenge. I have purchased a lot of nice equipment but am waiting for completion of a new home before I am able to set up my workshop. My interest includes both vintage wrist and pocket watches and my plan also includes micro machining - turning, milling of watch parts. I also intend to use my equipment to service and repair microsurgery eye instruments. On an aside given my background I will be using a stereo microscope. I look forward to participating on the forum. Below is an example of the work I did in my previous life - corneal transplant.1 point

-

Hello all. Actually thought I registered for this site back when I took the watch repair course but guess I was wrong. My name is Chris. I am retired military and have been working on clocks for around 8 years. My dad owns a clock shop and taught me everything I know on clocks. I recently just graduated watchmaking at Gem City College in Quincy, IL. Will be moving to Arkansas in a couple months and going to help dad at his store. Guess that's all I have for now. Looking forward to helping and gaining knowledge from fellow horologists.1 point

-

Hi I'm a student of Russian politics in London who has rapidly gotten in over his head with Soviet watches. The variety and cheapness is amazing- however I am yet to really find a watch maker for certain movements. Looking for advice here.1 point

-

Well, you certainly can never have enough watches. That is one thing i have learned(; I have probably worked on at least 200-250 watches by now. Everything from Doxa, Timex, Lagonda to some nicer brands like Omega, Longines, Zenith and now recently some chronos. I would say that I am really good at standard mechanichal watches with simple complications such as date, day, automatic works and so on. I understand the basics. I am however a beginner on chronos. Ever since I bought my dream watch, a speedmaster, I have wanted to start servicing chronos. After About 3 chronos, all with landeron movements, I am starting to sort of get the hang of it! I started a small business out of this and recently launched a website. I wont advertise myself but since I have managed to sell many watches I have worked on I have managed to buy a nice arsenal of tools. Some really nice bergeon screwdrivers, Dumont tweezers of some different sizes, a nice vintage crystal press, a reaaaally nice Olympus microscope, a vintage Elma Super Elite if I remember the name correctly and all other basics. My personal watches are however few. I am very picky with what I wear. My favorite is my 2020 Speedmaster Sapphire sandwich which has been my dream watch since I was 13 so I saved up by selling watches and some other work and managed to buy one at 15. my second favorite is my modded Seiko skx031 from 2008 with some thin mercedes hands and a wonderful chromed-matted aluminum pepsi bezel. Of course I also wear my newly aquired vintage Ledian chrono from ~1950 with a newly serviced Landeron 48. lastly I have a Certina Blue Ribbon Volvo 50th anniversary from the seventies in absolutely incredible condition!1 point

-

I'm not sure if it has a technical term but basically it's a cascading failure. According to Elgin the reason why this occurs is because somebody touched the mainspring with their hands. The bad chemicals in your hand react with the steel and cause rust and that causes fractures and then the spring breaks. The other problem is the metallurgy may not a been the very best at the time the spring was made except? I've seen the exact same thing happen to a Rolex watch with a modern spring that was covered with rust. Athletic basically when I wound up nice and tight one coil just one place breaks and the break ripples right across the whole spring. There are liquid rust removers some specifically designed for horology that will remove the rust. Typically there time-limited if you leave it into long it might turn all the steel parts blacked that's very undesirable. I think some people on this group recommend Coca-Cola because the acid in that is equivalent to the rust removing chemical and I think I've heard other people use strong tea As supposedly that will take rust off but I've never tried either. I have tried the liquid rust remover that I bought a long time ago and it did take the rust off. They hairspring doesn't look as bad as some I've seen if you do take the rust off the hairsprings been compromised so it won't be perfect but considering the rest of the watch study pretty good can you get a new hairspring may be? Elgin hairsprings were premade but matchstick each balance wheel we can probably figure out which one it is and then you'll still have to match it. In other words even if we had the exact replacement you'll have to play with timing screws to get the balance to match the hairspring For the balance wheel how much lathe work do you do? You could replace just the pivots if you're really skilled. Otherwise it replace the entire balance staff. Or if you a time machine you can go back in time I get a balance completes because we get a balance complete now you have to cannibalize something else to get it probably or if somebody sells you one off of eBay they've already cannibalize the watch for you. But on pocket watches swapping parts isn't necessarily what you want to do is a do not necessarily interchange. For instance when you change the balance staff like for instance http://www.elginwatchparts.com/ If you go to the link above and enter in your number 417 we get a parts list with problems? Microphone off Balance staff as you can see we get a part number and a warning note? Staff number 869 and something they don't have they refer you to something else? This is because there's almost always variations especially with Elgin staffs variations will be by pivots size always for almost every single staff and then the be other variations. Good news is the only have three different balance staffs just different pivots sizes. Apparently this watch came as either a single roller or a double roller in the staffs the same. Then the balance jewel is sort of easy it's held in with two screws. Take the two screws out push it from the inside pushing out there is a end stone now come off separate and then the hole jewel. At the website above you can get a part number and of course with the part number you also need the size corresponding to the pivots size of your staff. If you had access to modern jeweling tools you to just smash out the hole jewel agreement out from modern jewel and put that in. Then I really can't tell From the pictures how badly rusted the Canon pinion is it may just clean up in the same solution you can use with the hairspring. Then you can try this place for your watch parts https://www.daveswatchparts.com/index.html For mainsprings I usually get them for my local material house but everyone else said recommend eBay. You can usually always find American pocket watch mainsprings on eBay. Balance staff be purchased at the link above you may have to ask otherwise eBay would be a good source again. It's amazing how much American material can be found on eBay in the US especially Elgin.1 point

-

If as you suspect its been glued/loctited a little heat will release the glue but not too much heat. as you warm it up keep tyring to move it.1 point

-

1 point

-

Gary I'm using chrome but sorry it's themes at the bottom lol I'm glad your all sorted1 point

-

Hi LWS this is ascan from the page in the book. the images are the correct size and are used to assemble the suspension wires hope this is some use. I SCAN FROM HOLOVAR BOOK.pdf1 point

-

if you go to main page right at the bottom you will see light or dark theme Hope this helps just under the youtube logo1 point

-

Thank you WW and NEW I did write a long long reply but deleted it so I didn't look BLUNT just to keep the friends I've made on this wonderful forum1 point

-

Hi T as far as I know the post is about the same as for any where in europe/Asia It get here if and when. The problem with the Indian watches is they aere usually cobbled together (Mumbai Specials) from several watches to make one, from previous posts they seem to vary in quality. If you are buying one to play with or spares probably ok.1 point

-

Hi T the bestway to store a balance is to lie it on its back with the balance upside down on the cock and cover with a glass. There are all manner of balance holders , some good some bad. If you are adjusting the collet , the tool shown and suitably modified aka Hector's post so the balance is held on the device and the post adjusted to support the balance and get the spring to lie in its horizontal plane at rest. I dont think the balance springs of today are as soft as those in the past. The damage is done when the balance is left hanging with no support for an extended period. The safest and cheapest way is to put it on its back.1 point

-

Thats Beguelin watch company, they owned the Damas brand and I have seen their movements in Galo watches plus a dozen other companies, also supplied parts or movements to Rolex. Have you check julesborel.com? Regds1 point

-

I was really hoping you were going to say it was tangled up a little bit. Getting replacements going to be challenging as Nucejoe Indicated you can find identical looking hairsprings but they won't be exactly identical.. But sounds like you have no other choice. Then if they hairspring is this badly disintegrated how bad is the rest of the watch?.1 point

-

If the bellows is leaking its a specialist job. I know something that services these clocks every now and then and if the bellows is leaking he sends it off to a specialist in the USA for fixing. The pivots must be perfect on these clocks for them to run.1 point

-

1 point

-

Well I think its safe to say a resounding sucess regarding the colour scheme. A cracking idea to change it.1 point

-

1 point

-

1 point

-

That's a very old example. Newer ones would have the second hole you mention, meant to control where the pulley sits on the simple runner. With these old ones, a pulley was fixed directly to the work, and the bow would run that. In the pic you can see some drive dogs on the left, for larger work turning between centers, the little box with the "fish" that clamp onto pieces also for turning between centers, or to be driven by the finger on the pulley of most Jacot tools, and above that a couple of little pulleys (they get even smaller) for clamping directly on the work. I think you would be best to set this tool aside as a decoration, and find a more modern tool for actual work. If you hunt a bit you can find a modern Steiner for a good price (also called Hahn due to the trademark) like the pic, they are honestly the best. The pic is of two sets stacked on top of each other, one the basic set, the lower one with extra runners. You'll still need to track down a set of the split drivers like in the little box. Still available from Bergeon and Horia at new prices, but can be found used.1 point

-

Thanks for the response. Trying to get a little familiar with navigating the site and will be happy to follow your advice. Regards, Jeffrey.1 point

-

Nice. Impressive boom. I have been playing around with different configurations for magnification and for now am using a Bulova Accutron microscope (30x). For awhile, I had a setup similar to yours (different style boom) but I never got the viewing angle and body position right. Probably should revisit that someday. Using stereo magnification just cannot be beat.1 point

-

I can't see if the original hairspring is broken, in case it isn't, lets see what its coil looks like, your prefered option can very well be to sort out the original. If broken and is short by only a few mm, you can adjust it by adding weight to the balance screws. Unfortunately a hairspring's strength is not easily decernable by looks or dimentions. Regds1 point

-

1 point

-

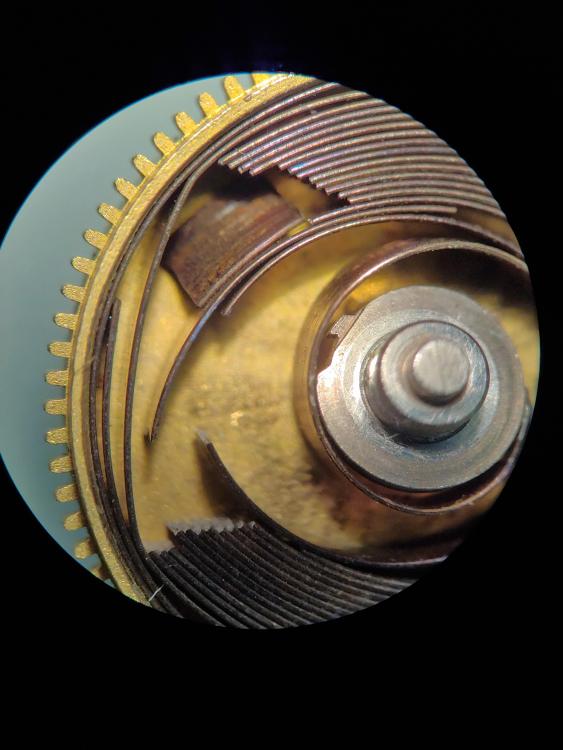

Took me a bit of poking around, but I would bet good money that it was made by Henry Sandoz of Le Locle. With two hammers, it would be a quarter-, five-, or minute-repeater. It is also a flyback chronometer (those fine-toothed wheels atop the barrel bridge and third wheel bar). I have to agree whole-heartedly with you: that is not a beginner's watch. There are experts who turn pale if a customer should bring one in. Parts will not be easy to come by. But take heart: later on, with more experience, you can take your time. You won't have a deadline like some repair technicians. And you can take plenty of pictures as you go. Disclaimer: as to the maker, I am NOT an expert nor an appraiser. I'm only making an educated guess. But I do happen to be a fan of Sandoz and his method of constructing repeaters, and I have worked on one of his. In my own personal opinion, that watch has his style all over it. But I could still be wrong. I believe his layout was also copied by others. If I had to guess a year of manufacture on it, I'd speculate mid- to late-1900s, but maybe not 'teens. EDIT: smashing watch, BTW. The more I look at it, the more I think it could actually be from the 'teens. Out of curiosity, does it run at all? Does the balance swing evenly and with no wobble to speak of?1 point

-

Good job @Kalanag! I want to get to a place where I'm comfortable enough to service my Zenith. It's going to be a while...1 point

-

I don't suppose it be possible when you're moving discussions that the pointer to the new discussion can at least take you to the actual question and not the first page of the discussion?1 point

-

Came up recently in the above thread that JDM was responsible for the junk drawer thread practices despite not being listed as a moderator. He responded that he'd prefer to be mentioned by name on the subject, so I'm respecting his wishes accordingly. Additionally, I've exchanged friendly PMs with JDM on that exact subject in the recent past related to a completely different collection of wholly unrelated threads; AndyHull's intro thread, and the 404 Club thread. The 404 Club idea absolutely originated with Andy, and he gets full credit for that, but his personal adventures, while frequently 404 flavored, are not exclusively 404. Additionally, in true junk drawer fashion, the 404 Club game would be completely lost when it was spilled out on the 20th page of Andy's thread about his own watchmaking exploits. Similarly, Andy's exploits would be completely lost in the 404 noise. Fortunately, jdm was dissuaded from junk drawering the two threads, but he was not convinced to abandon the practice at the time. I sincerely hope, in light of this and other similar events, a compelling enough case can be made for jdm and any other mods who wish to be directly addressed on the subject to abandon the practice, allow/enable/enact a suitable replacement within the normative bounds of the greater internet and make WRT a better, more informative, and more inclusive place where anyone can come to learn all of the ins and outs of watch/clockmaking in an encouraging and welcoming environment.1 point

-

For some perspective for you guys about to pick up gravers: In my workshop (which is a shared workshop between me and a small 4 person company), when they want to hire a new person, they do a week long test, and one of the tasks is to make a balance staff. The first guy to take it had made a tourbillon he fit up into a movement with the gears and such of another watch before coming to us. After 2 days we moved him on to other tasks, not completed. Next guy, had worked for various ultra high end makers, graduated from the top level class at the best French school, 2 days, not completed. Last guy, graduate of WOSTEP full training course, spent almost 2 years looking for a job, hadn't touched a lathe in that time, knocked it out in 6 hours* and was super apologetic for how long it took, haha. All in their early-mid 20s, all had spent weeks and weeks(used to be months and months) in school turning and turning and turning, lots between centers, and still. So when your're starting out, heed the practical experience of LWS above and my advice above, start simple, master each step, and progress. I see lots and lots of watches doing restoration and repair, and see a lot of staffs and stems that are clearly not original. Sometimes they do work just fine, but are ugly. The goal is to make something no one would suspect is not original. I also see the few vids on YT addressing staff or stem making and, uff, I've yet to see one that is really any good. Maybe one of these days I'll do one!- (some other guy will say it's not any good, haha). But start small, work your way up, get good at each step. Keep practicing, and don't get discouraged- remember the hoity toity watch school grads who knackered the staff part of their bench test. *A major company I did vintage work for until recently would send stuff with a time estimate; if there was a staff to do, they counted 8 hours for that. 4 for a stem. The fella who did his test (on unfamiliar equipment under stress) in 6 hours already beat that. A friend who works there told me the people there usually took 2 days. If one of those landed on my bench, ha, I took that work to the bank! But I do lathe work every day, keep my gravers in top shape, always try to find ways to improve, and most importantly, keep my basics in order. Square shoulders, straight clean cylinders, it's not a race- when you try to go fast or skip steps you will cost yourself more time.1 point

-

1 point

-

The markers are out! Heat, heat and more heat was the answer in the end. After sustained contact with my biggest soldering iron (100W) one of the markers began to creep out of its hole. The other needed a bit of persuasion from the 3-jaw chuck on a power drill, but also came out without a fight in the end. You can see the discolouration on the parts. It's hardly anything, just a tiny bit of dried up grease or surface rust, but because of the close tolerances, enough to jam up everything. Now to get to work cleaning and polishing!1 point

-

The logic is completely understood and appreciated. It's the methodology that is problematic. While not taking the time to search, etc. is implicitly causing the more senior users to answer the same questions repeatedly, the means by which you address this issue causes those offending users to [i]rightly[/i], if not correctly, assume that the question has not been asked or answered. Ultimately, it is you, @jdm, are the one causing people to have to invest far more time than is necessary by treating this duplicative content in the manner you are. This is a self-inflicted wound, and it's one that is so very easily cured.1 point

-

Consider this in the spirit it is intended: @jdm, this is a very poor way to handle this. It causes problems, frustration, confusion, and going forward, causes me to call you out on it every time. There are so many better ways to handle this. Pick one. If you need help, ask. I've offered proactively, and I'm sure others would rise to the call just the same. I'm not the only one who feels this way, I just know it's such a poorly considered... it's not even a policy (calling it what it is might come off a bit harsh)... that I'm willing to call you out on it. Consider it constructive criticism and an offer to assist in a limited capacity.1 point

-

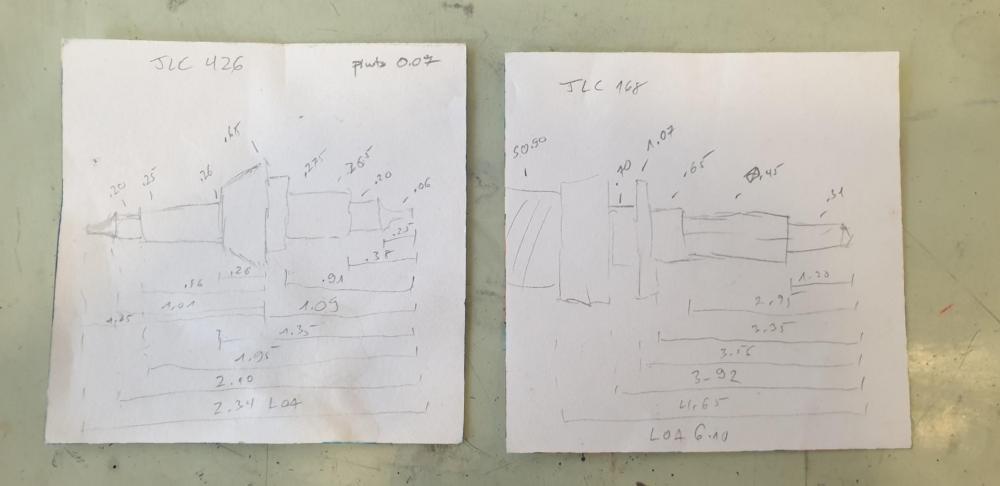

That will work. Another thing that's really important is to avoid stacking up errors. When I make a drawing, all lengths are referenced to one datum, which is logically the very end of the piece, whether a staff or stem (or whatever). All lengths come from that point; if I make a measuring error when cutting of 0.05mm on the first length, there's no reason that will translate to the next or further ones. I see a lot of drawings where each individual length is called out, and I imagine the person fighting to measure those, and stacking things up to an overall error that's huge. If you look at the pic (typical staff and stem sketches I make), all lengths are off the tip. For a staff, I then fill in the lengths off the lower part of the hub as datum, as I cut those with another tool in the slide rest- but they are derived from the original lengths, so any error introduced is in my visual centering of the second tool, which is a one time error. It's rare for me to be off more than 0.02mm overall on a staff length. You can also use the tail (rod) of a digital caliper the same as the Levin tool, but depending on your caliper you might not have a enough material in the body of the tool next to the rod to provide a stop for the end of the workpiece.1 point

-

1 point

-

Hi This link explaiins what the beat error is, Basicaly the clockwise swing of the balance and the anti clockwise swing should be equal in a perfect world but shoule the swings become unequel by say 0.02ms we say theoreticaly its out of beat. There is a tolerance level and they should be as close to 0.00 as possible, because of mechanical diferences not always aceivable https://r.search.yahoo.com/_ylt=AwrJO2Ucw2NiK3cAcxJ3Bwx.;_ylu=Y29sbwMEcG9zAzIEdnRpZAMEc2VjA3Nj/RV=2/RE=1650733981/RO=10/RU=https%3a%2f%2fwahawatches.com%2fwatch-talk-whats-the-beat-error-of-a-watch%2f/RK=2/RS=msWff1UEcXpApDmY2DCeM1vEINQ-1 point

-

I think the price of a normal service in the UK would be at least twice the cost of a Soviet watch. You might have to learn how to service them yourself. Soviet watches are pretty tough but prone to rust. So make sure you screw down the crowns of your Amphibias and Komandirskies properly. I have 5 Soviet watches so far. 2 Vostoks, 2 Poljots and 1 Sekonda. I'm looking for a Luch vintage quartz but their prices are crazy.1 point

-

Sticking or the coil fouling itself and though rare but having wrong hairspring on the balance wheel, or wrong wheel fitted on the staff.1 point

-

I've typed up a half dozen responses to this since it was first posted, and I'm going to commit this time! This is not a criticism in any way of the method/tool there. Just genuine discourse, engineer to engineer. Please consider it in the spirit it is intended. I place cap jewels flat down on a piece of watch paper (so far so good), then fold a corner over, and just rub it around with my finger tip wearing the requisite finger cot. Not sure where I picked this up, but it's such a simple solution to a task that can go so horribly wrong that I'm sure I got it from somewhere else. Mark or some other youtube person, most likely given the fundamental nature of it. What is wrong with that approach? The only thing I can think of based on the above discussion is that it might go flying if I were to crinkle the paper or something. I've had that happen to where the jewel jumps, but never very far. I know better than to discount my own clumsiness and relative naiveté though... What about that is this addressing, and what other issues might be being introduced? The paper being taped down solves the fly away crinkle problem, but the stick seems like an abstraction from the manual manipulation that could (and in the not discounting clumsiness paradigm, will) result in equally annoying unplanned flight. Additionally, the tendency to apply additional force through the tool without its own escape prevention feature seems to magnify this, compared to the finger method having all that squishy finger enshrouding the jewel on all sides, prohibiting any possibility of escape during manipulation. A simpler solution, if we allow/agree/accept/whatever that the paper being taped down is a mandatory practice to avoid Alcatraz-esque exploits in escapery, would be to replicate the cotted finger and a second sheet of watch paper over a second, taped piece of watch paper. You have the required manual control over pressure and position, the escape prevention of the finger flab, and backup escape prevention in the form of the captive second sheet of paper, combined with the sproing mitigation of the taped piece of paper. Again, consider this in the spirit it's written AND consider the source. I'm not quite two year into learning this stuff, and that's on a as-can-find-time basis with work and a baby/toddler in a pandemic.1 point

-

In order to maintain a healthy and friendly community there are some restrictions for new members as well as benefits for those who contribute the most to this forum. It has occurred to me - or rather, been pointed out to me that I have never really made the details clear. And for that I apologise and I hope this post will be helpful. All members will find their current forum status in the left pane of any content they post on the forum (non-mobile) or by clicking on their display name to view their profile. MEMBER LEVELS NEW MEMBERS (Zero to 9 Posts) New members can post immediately and have access to most areas on the website. New members cannot customise their signatures New members cannot create polls but can participate and vote New members can edit their own posts within 10 minutes of posting that content New members can report posts to moderators New members can start up to 2 private messages per day and to a maximum of 1 recipient per message - with a 50 message storage quota New members are automatically promoted to full Members when they have posted more than 9 times and have gained reputation (*). MEMBERS (10 to 99 Posts with positive reputation *) Members can customise their signatures (**) Members can create polls as well as participate and vote in other member polls Members can edit their own posts within 3 Hours of posting that content Members can start as many private messages per day as needed and to a maximum of 5 recipients per message - with a 150 message storage quota Members are automatically promoted to Advanced Members when they have posted more than 99 times and gained 50 or more reputation points (*). NEW: ADVANCED MEMBERS (100+ Posts With 50+ Reputation *) Advanced Members can customise their signatures (***) Advanced Members can edit their own posts within 3 Days of posting that content Advanced Members can start as many private messages per day as needed and to a maximum of 5 recipients per message - with a 200 message storage quota Patrons and Supporters gain the same privileges as Advanced Members * Reputation is gained when you post content and other members react to that content - you can see your current reputation score within your info-pane, under your avatar. ** Members are allowed up to 1 link in their signature which MUST follow the forum rules and up to two lines of text. To keep the board clean we do not allow images in signatures. *** Advanced Members are allowed up to 2 links in their signature which MUST follow the forum rules and up to four lines of text. To keep the board clean we do not allow images in signatures. RANK TITLES Ranks are just a bit of fun to acknowledge your level of participation on this forum. It is mostly based on your post count. Your forum rank is displayed in the Info Pane of any post you submit on the forum and your rank is displayed under your Display Name. WATCH ENTHUSIAST - 50 Posted Content Items WRT ADDICT - 100 Posted Content Items SUPER WRT ADDICT - 500 Posted Content Items After you have posted 500 content items you will be able to customise your own Rank Title to display under your Display Name DISTINGUISHED MEMBER - 1000 Posted Content Items If you have any questions regarding the above then please post your thoughts below and I will try my best to answer.1 point

.thumb.jpg.a20e2ce45b188a58f5b185fbef3fcfc3.jpg)