Leaderboard

Popular Content

Showing content with the highest reputation on 03/18/22 in all areas

-

Hi all. Hope this is ok, I did search first but found no similar threads. Given that many of us are not blessed with high salaries or pensions and cannot afford to buy high value tools from the Swiss makers, we only have what China offers for our hobby and as many have found a lot of what is sold on the likes of eBay turn out to be just rubbish and not even worth the low prices asked. After buying a few useless tools I started to look at some of their better quality offering, which although quite a bit more expensive, were still miles cheaper than the Swiss tools, sofar the few I have tried turned out to be of excellent quality. So to help others less well of could we have this thread for people to post about their quality Chinese Tools, for others new to hobby but put off buy high prices might find a better tool at a more appropriate price. If this is OK I will start it off with some of my recent acquisitions. Thanks. Paul3 points

-

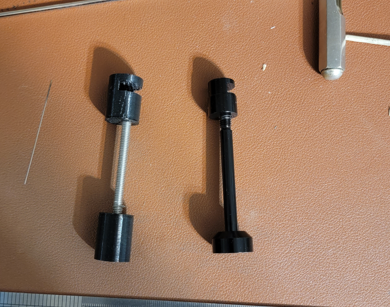

I bought a set of stands for holding movements while working on them. Got them yesterday and quickly realized that there was a trivial 3D printed solution, so I designed a set of stands using printed top and bottom and an M4 bolt. 3D printed one is on the left. I made mine a little taller, but the height is just the screw choice.3 points

-

Hi, if it’s a close fit then I will use a minuscule amount of Loctite applied with a fine oiler. I think this is acceptable as it’s entirely reversible. If it’s very loose to the point where the roller will possibly not sit in correct alignment with the staff then you can very carefully close it with a punch and a staking set. I can’t stress enough how delicate these things are - it’s easy to deform them and break the impulse jewel off.3 points

-

There is always the method favoured by Nucejoe and it works and that is coke a cola and soak cleaning off with warm soapy water.1 point

-

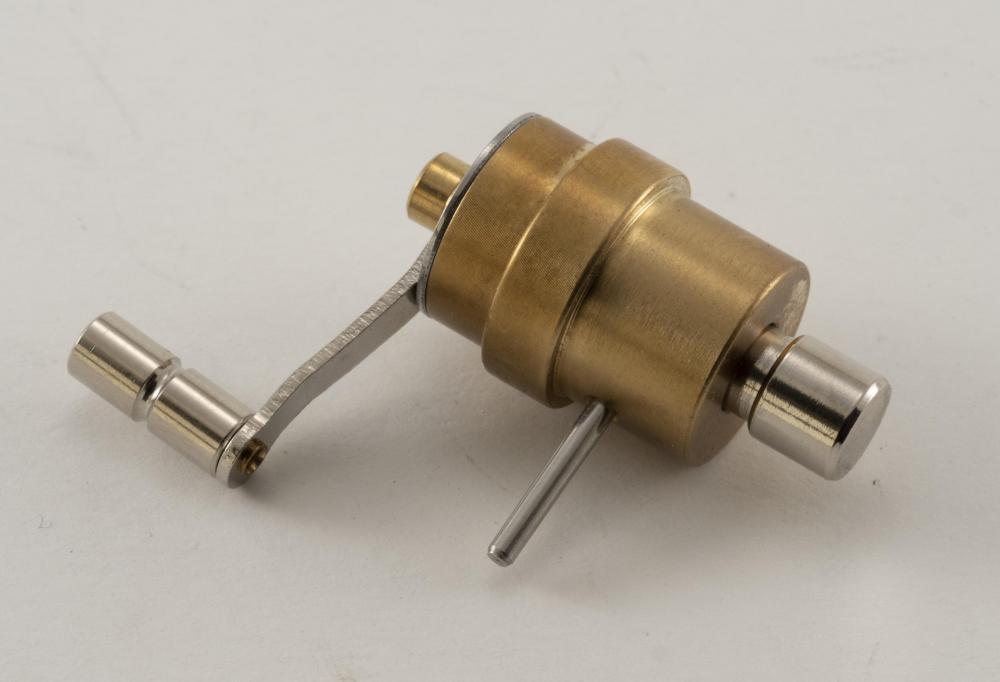

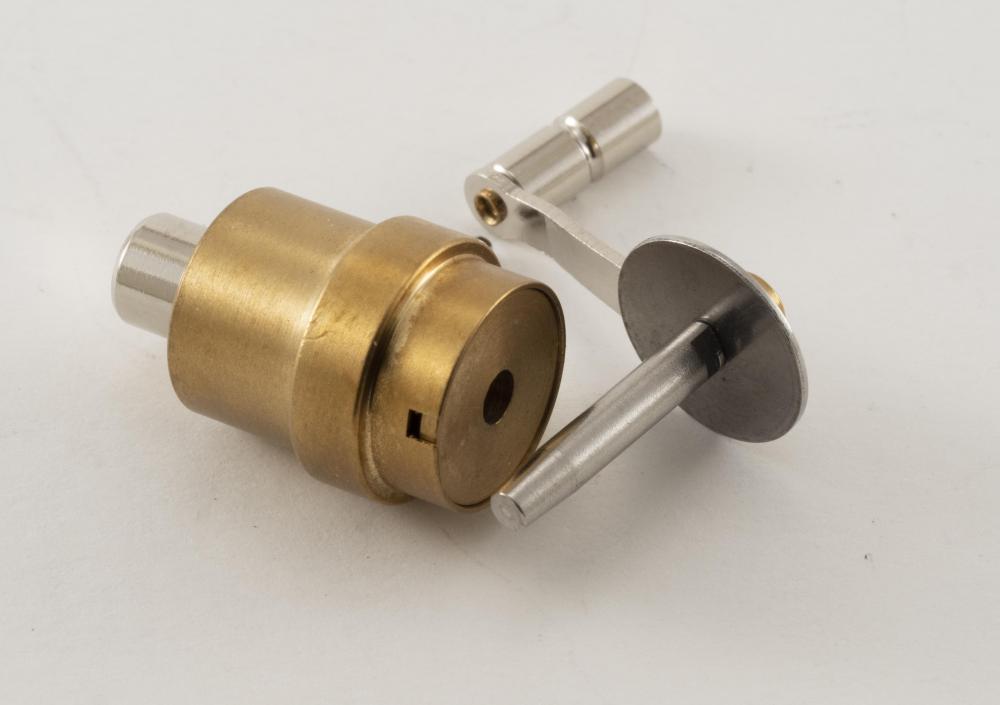

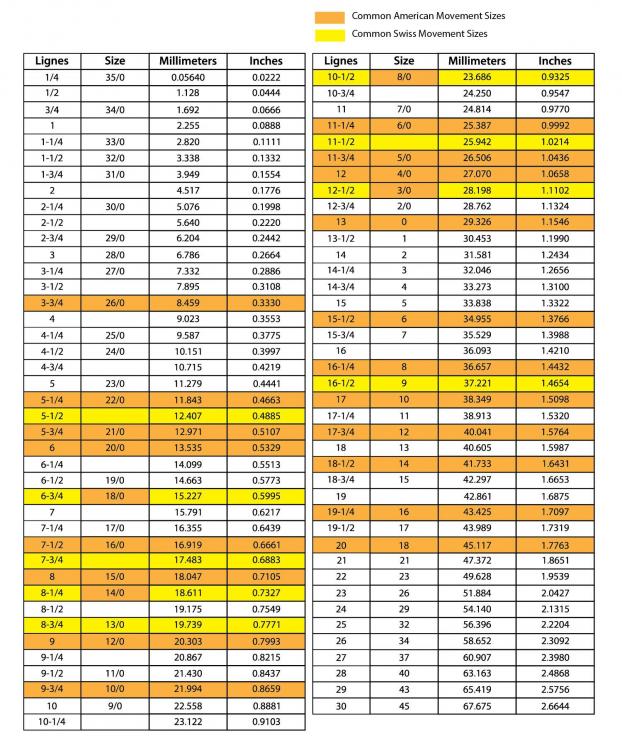

So here we go with the first tool in this series The obquous mainspring winder ser. This set came from Aliexpress and the price seems to fluctuate around £150 https://www.aliexpress.com/item/1005002838742309.html?spm=a2g0o.order_list.0.0.21ef1802uk2ABx A set of 20 winders with lrft and right hand sizes plus one handle. With this set the important Arburs are all steel and they are sold steel throught the range even some of the bergeon ones use a brass core with steel sleeve on the larger sizes, these are all steel. Construction and machining is all to a high standard Now to the handle which is often a point of critisism in these Chinese sets as there is often only a right handed handle included which can make using the left handed winders a trifle fiddly which is why Bergeon supply two handle in their kits. The handle in this kit is actually cut for both left and right hand use so only one is needed. So on the whole a high quality tool that works well and well worth the average asking price of around £150. Photos below, more tools to follow.1 point

-

1 point

-

1 point

-

Yes I have seen them where it looks like Fred Flintstone has chiseled the marks.1 point

-

Most of the time the clocks I see the barrels, lids, and train wheels are already marked by a previous repairman... usually with HUGE deep scratch marks . If I need to mark them I do it as you say, in a non permanent way, or just keeping them separate during cleaning.1 point

-

With a strike or chime always have the correct number of tubs to put the parts in, that way you won't muddle things up. The chime spring is always stronger and you will find the barrel bigger and so will the arbor, on the strike and going sides quite often the complete barrels are the same size. Always best to mark them with something that doesn't leave a permanent mark.1 point

-

It would be hard to give general recommendations as the quality varies from seller to seller and even from batch to batch. For example, it has been mentioned several times in the forum that mainspring winders from China vary in quality, from to good to rubbish. And price cannot used as an indicator of quality as there are vendors who sell junk at premium prices. I bought a pretty good Presto style hand remover several years ago. But when I bought 2 this year, they were rubbish. But there are good quality Chinese made tools and equipment. I've seen them. They are not sold on AliExpress. One of our new members from China mentioned this before too. We haven'theard from him lately, I hope he's ok. The only recommendation I can safely give right now is a timegrapher. Most of us have a timegrapher from China and I haven't heard much complaints. As for hand tools, most of them are rough. But if you are willing to put some man hours into improving the finish, they are usable. Good luck in your foray into the Chinese market.1 point

-

Possibly excessive depth of lock if the banking pin was allowing the pallet stone to enter more deeply than necessary. It’s worth investigating / observing the depth of lock as it can steal energy from the balance. If you still have issues with the escapement locking up then perform tests to check the “safety action”.1 point

-

Looking at the regular fluctuations in the trace, I think that there is an issue with the escape wheel. Maybe the pivot of the escape wheel is bent and when the tooth farthest from the axis reaches the pallet jewel, it doesn't unlock. Moving the banking pin might free it.1 point

-

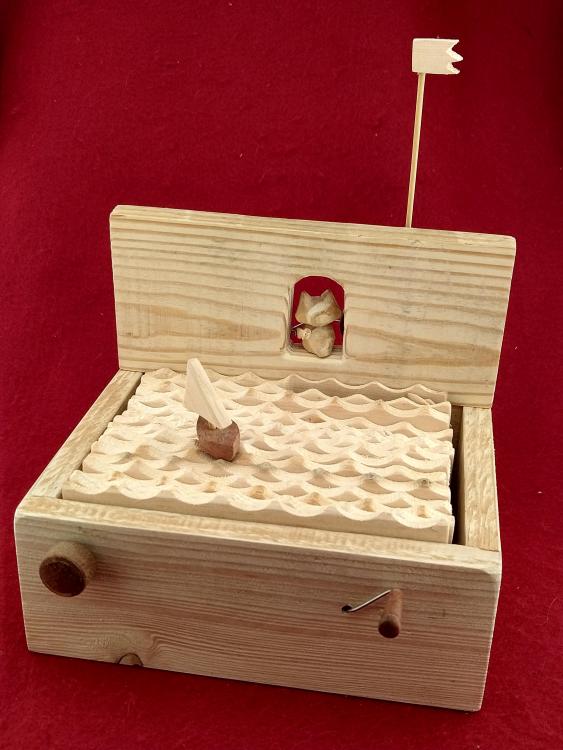

It does Andy. The sea theme was not my idea it was the project the students do at the end of the course. The original one came with a bird, but I wanted a cat and a fish. We have two cats and my daughter loves cats. I place the link to the course here not sure if it works or not: https://www.domestika.org/en/courses/3203-wooden-automata-bring-sculptures-to-life-with-movement/course As I do woodworking anyway and as I have played with the idea to make automatas in my head for a while before I found the course it did not help an awful lot with my woodworking skills but I loved it regardless. It is good for inspiration and also I wanted to reward the effort to put the course together. It also collects some info about the automata in general. It is well made and probably made for ppl with the basic tool set and knowledge. I saw an example which was made out of cartoon paper not wood.1 point

-

1 point

-

Hokay, last post from me on this one, 'cuz I'm giving up on this movement and buying another replacement. While doing the diagnostic watchweasol suggested, it seems I clumsily bent the third wheel, and now it periodically skips when it disengages with the fourth wheel. Unfortunately, the third wheel's also the one part I don't have a spare of (it was the original broken part in the movement I was replacing), though admittedly I've also broken a couple extra parts in the process of all this. >.> It also seems like something funky's going on with the balance wheel–pallet fork–escape wheel combo, 'cuz the pallets keep getting stuck on the escape wheel's teeth. If I had to guess, the hairspring seems like it's no longer transmitting enough force to get everything to move properly, and/or this particular chassis placed the pallet fork and the escape wheel too closely together, because mass manufacture movement w/ bad QA. To at least test the mystery of the cannon pinion, I gave the pinion a few pinches along the center & top to see if that'd sufficiently reduce friction; it helped some, to be sure, but it didn't completely fix the issue, so I suspect I'd have to broach it to properly fix it (and I am currently feeling too cheap to get broaches this early into the hobby, especially when I'm not 100% sure what size(s) I'd need). That all said, thank you for the attempts at helping, and extra thanks for the reference materials! watchweasol, I appreciate having such a thorough reference for part names handy; I'd been getting by with Googling "watch movement parts," but this is much more convenient. Klassiker, the article you linked was very handy in understanding how the cannon pinion interfaces with the center wheel & what I should be looking for w/ the notch the others mentioned; much easier to spot now that I've seen the cutaway of it all fitting together. Hopefully I'll be able to manage my watch repairs well enough going forward, but I suspect I'll be seeing y'all around.1 point

-

Another lesson learned, dont rush any job.1 point

-

https://www.electric-clocks.co.uk/Frequency Converter/frequencyconvert.html1 point

-

I would 1. remove all trace of old paint 2. Spray a dark coat of paint 3. Remove paint from the hour markers and polish them or sand them. Its probably brass and will shine up well. You will need to follow up with some lacquer otherwise it will discolour. One slight issue will be the hands seem chrome so that will be a mismatch. Painting the markers is doable but you'd need a steady hand. Good thing about these dials is if you screw it up you can remove all the paint and start over. Good luck. Anilv1 point

-

As far as I can see there are three options 1 leave as is. 2 restore 3 replace with a donor Ebay1 point

-

So I have pulled the trigger and bought this kit from DWC https://shop.diywatch.club/collections/watchmakingkit-diver/products/diy-watchmaking-kit-expedition-watch-with-sapphire-dial-dwc-d021 point

-

1 point

-

Yes. Never put the coils, pcb and the magnetic rotor into the cleaning solutions. And needles to say, the dial and the hands too. I have never seen any courses on quartz watch repair and there are very few books covering the subject. I guess most of us who repair quartz watches have some background in electronics and it is just natural for us to progress from mechanical watches to quartz and electrical watches. Not all quartz movements can be disassembled and cleaned. Cheap movements are normally riveted or utrasonically welded together and not designed to be repaired. These are normally cheap enough to be replaced. Some mid-priced movements are in-cooperating plastic parts into the gear train. These can be cleaned and re-assembled with great care and dexterity. I wouldn't recommend these to beginners. All-metal gear train movements tend to be expensive and best avoided by beginners. My advice will be to stick to mechanical watches first then progress to doing some ladies watch movements. The small sized parts of ladies watches will familiarize you with working with quartz parts. And until you can re-assemble a mechanical gear train in under 2 minutes, I wouldn't recommend disassembling any high-end quartz movements. Good luck and practice lots.1 point