Leaderboard

Popular Content

Showing content with the highest reputation on 03/04/22 in Posts

-

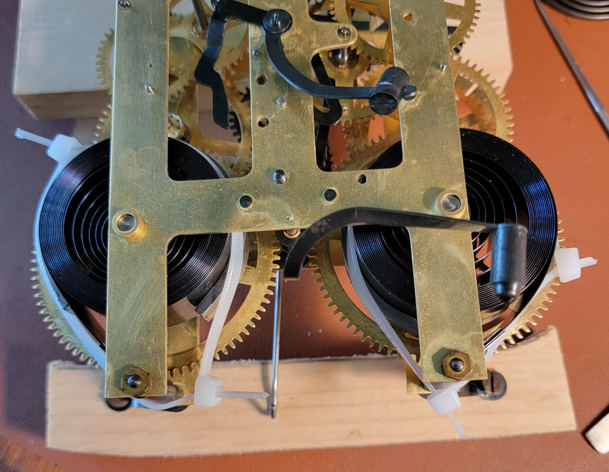

I got it for 60 bucks. Come on!! Who could pass that up. I know the machine--I rebuilt mine!! I need one at my remote location anyway.2 points

-

Looks to be an FHF 120, Generale Ressorts ref. 3473 1.35x 0.08x 240 7. Cousins has it GR3472.2 points

-

2 points

-

That's a safety guard for Jacot tool. It helps especially when burnishing conical pivots with long conical portions; it can be set so that the burnisher makes minimal contact with the conical section. If too much pressure is applied to this area the risk of breakage goes up. It can be useful too for straight pivots where the difference in size between pivot and and the next diameter is very small (dial side of many center wheels comes to mind). It helps avoid accidentally riding up onto the next diameter. Whether it fits a given tool or not is another issue. All of my Jacot tools are Steiner, and they use 8.8mm diameter runners. There were numerous makers though, and certainly different sizes. It doesn't have to be a perfect fit, but does need to stay in place without shifting.2 points

-

I was informed that this type of jewel is friction fit, and not meant to be removed. The "spokes" that look like they'd take a special tool are in reality vents to assist in cleaning and drying. So there you have it. Cheers.2 points

-

1 point

-

Hi all. The story behind this watch is - It was given as a gift for long service to a gentleman. He had a choice of a gents or ladies Rolex and he chose the ladies and gave it to his wife as a present. She wore it everyday and cherished it. She left it to her daughter who kept it in a drawer not working and judging by the internal marks serviced only twice in its lifetime. It came to me as we know the lady who is now in her 70's and she would like now to wear it so I offered to service it and here it is. I think wearing it will bring her closer to her mum -in a nice way. I need to obtain a mainspring for it as the original is distorted. Can anyone help identifying the correct mainspring? On the back of the main plate it has a number stamped 120. Thank you for any help.1 point

-

I opened this exact model of watch today. It’s a snap on back. There did not appear to be a lip, but enough of a gap to get a case knife in. Movement is an ETA 2824.1 point

-

1 point

-

1 point

-

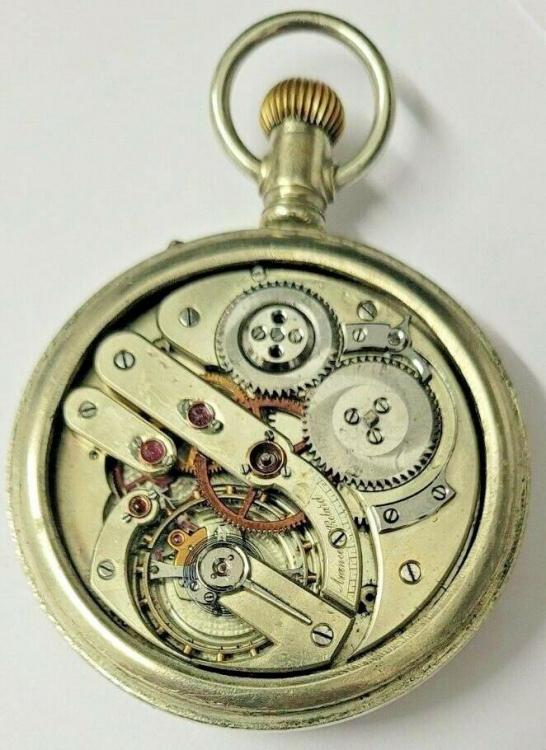

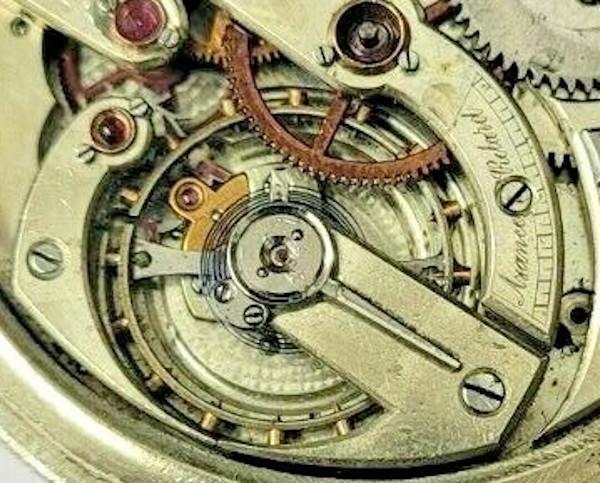

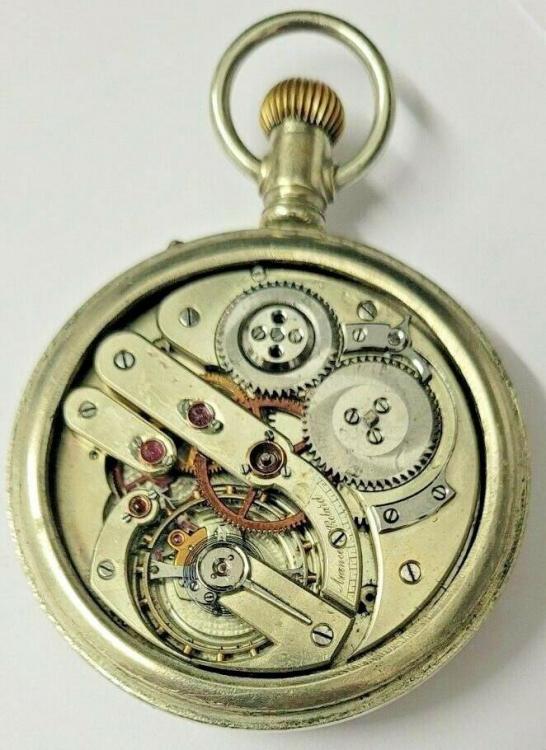

The pocket watch in the above batch also interesting, and I might add, filthy. There are many similar mechanisms out there from many different makers, but this one has somewhat IWC (Schaffhausen) like characteristics. Compare for example with the IWC 66 19'''H5 This of course does not mean it is an IWC. In fact it is not an exact match for any of the examples I can find on line, so possibly some other manufacturer produced something very similar. It also has "Advance -- Retard" scribed on the bridge, rather than the balance, suggesting that the pointer should be pointed towards the bridge rather than down the balance cock, which is obviously not the case currently. All may become much clearer when I can get a better look at this when it arrives. There may be some makers mark on the dial side.1 point

-

A helpful tip for anyone looking at this discussion? I snipped out an image found up above a typical newbie mistake? People usually reassemble the watch in the opposite order they took apart. Usually what I'll notice is they put the pallet fork in right at the very beginning and that's a big mistake. Yes you can put it in but you don't have to. If you don't have the pallet fork in you can verify that the gear train spins. It makes it a lot easier to put the wheels back in if the pallet fork is not there. So typically you put it in just before you put the balance wheel in makes things a lot easier.1 point

-

The square drive toward you're looking for is called the bench key. Typically they'll come in sets like picture of three that I have. That will correspond to most of your American pocket watches and conveniently they work on European watches. Also a picture out of the Elgin school training handout of not sure what was actually called but this is the page on making your own Then from vintage tool catalog example of a Friday at types. They also have the other type for holding onto the square of a key wind when you don't have the specific key. Then it looks like from the description some other keys must've had both one and was Mail and the other end is female which I didn't know existed. The problem with finding these brand-new is that they're not really useful for modern watches. It's hard enough to get modern parts for modern watches let alone get tools for a vintage watches. That unfortunately means you're at the mercy of the eBay sellers who seem to think that their rare and they should be really expensive.1 point

-

Hi LWS I think a little therapy is required1 point

-

1 point

-

Coaxial movements by Omega are very popular aren't they? I doubt they'll appear in other Swatch brands as they will want to keep it 'high end' (maybe Breguet?) Seiko (Grand Seiko) have something similar: https://www.grand-seiko.com/global-en/news/pressrelease/202010131 point

-

Before replating, the base metal must be brought to a perfectly smooth finish. With deep damage, and on a soft metal like brass, that will deform the shape considerably. Then, good luck to the OP in finding someone that will do a good job, and consider that the cost will largely exceed the material value of the watch. If one is interested in case refurbishing, the only material that makes that relatively easy is Stainless Steel.1 point

-

Hi The condition of the case is woe ful, loss of plating and wear. As the dial its self is in good condition I would think a clean and replate of the case would enhance the watch, as it is it detracts from the general apperance, Its your watch but in my opinion it would be better done than left undone.1 point

-

Thank you for the information. Looked at Ranftt for information on ETA 2789 and ETA 279-1. They do appear to be the same. I contacted Speedtimerskolection who could not help. However, I'm sure you members are correct. I've ordered the set of Escape wheel, Pallet fork and bridge. I'm sure I'll cock up at some stage. But as commented. It's a great learning curve. Really enjoying myself. Days are smiles. Regards Ross1 point

-

Hi Ross, You already have acheived a great deal, actually the movement itself is a good teacher, by the time this project of your is finished, you will have acquired plenty of knowledge and no book can teach the dexterity you gain along the way. A couple of more projects and you gain much confidence. All the best.1 point

-

I decided not to read anything below the pictures because we have a problem? As a reminder this is an American pocket watch and there's a problem? When the movement is out of the case there is no stem. Why is that a problem the stem is found in the case the position of the stem is controlled by the sleeve in the case. When an American pocket watch comes out of the case it goes into setting. Like my picture isn't that wheel in the setting position? As everybody should grasp if you run a watch while in setting your driving the entire setting mechanism and simplistically that is bad. American watch companies grasping that their movements might have to run out of the case usually have a procedure to put it into the winding position or running position. I can't see enough of the movement to see what I need to see. Sometimes they'll be a screw that you turn other times they'll be a little lever like thing that's near where the stem would go in that you pull out. To basically look at how the setting components work and there should be something in there to allow it to go back in the winding position. That hopefully will improve things then if you ever seen any of my windings and fussing is about hairsprings now you know why hairsprings are typically vibrated to each balance wheel. But if you have an over a coil of the over coil has to be made very exacting position. So what they do is they match the balance wheel to the hairspring. The factory had all the different timing screws and then they also undercut the balance screws themselves to bring each one into the right timing to match the hairspring. This is why mixing and matching hairsprings will result in dramatic timing issues. So I would put the original hairspring back on the balance wheel and try to deal with the hot otherwise you're going to have to be playing with the screws quite a bit and you may still have to do it if somebody did a mix-and-match of not grasping that one hairspring is not identical to another.1 point

-

This is 99.9% the case for amplitude problems- in my experience it's rarely the mainspring. From the pic, the balance could be very much out of beat- the balance arms are supposed to be perpendicular to the line along the fork and escape wheel when at rest; it could be in beat, and someone installed the roller table without aligning it. That's one possible source of amplitude loss. Some others: -hairspring rubbing -excessive or insufficient endshakes -wear (in general), in particular at the bearing points of the center wheel and barrel -escapement out of adjustment -damaged or worn pivots -wear in the fork slot, fork pivot holes not perfectly clean (must peg them), debris on the roller jewel, roller jewel not vertical, chipped pallet stone(s) and probably a dozen other possible things With the balance and fork out (let down the power first!) put a few clicks of wind on it and see how the train moves. It should spin freely, and when it stops, ideally the escape wheel will reverse direction at least a little bit, or even a couple of turns. Now put the fork in, few clicks of wind, and see if it snaps from banking to banking cleanly with a slight nudge. That's a basic check, if it looks good, you can concentrate in the balance area.1 point