Leaderboard

Popular Content

Showing content with the highest reputation on 01/05/22 in Posts

-

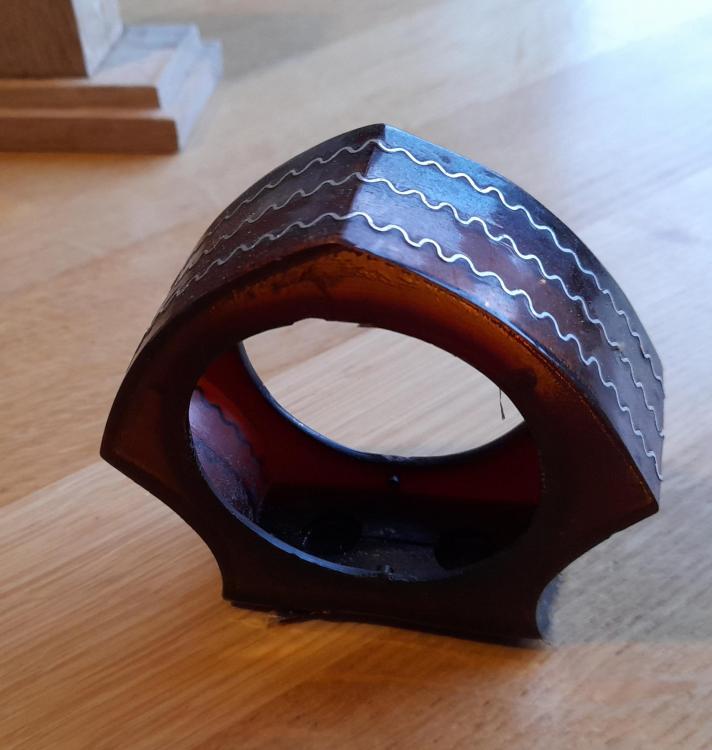

Good evening, I've been busy in my dark/cold garage over Christmas. Flushed with my success of servicing my first clock, with the kind help of the people on this forum. I thought I'd share my first clock come up cycle. Please be gentle with my carpentry, it was all made with hand tools other than a drill with a hole saw. The clock came in a hideous plastic/celluloid housing, as you can see from the picture. With a bit of trawling the web I think it originally sat atop a jewellery box of some kind. Anyway my next door neighbour had a new kitchen fitted and they let me have a few odds and ends to prolong the life of mine. Including an oak draw front which I thought I'd build a mount for my clock. A challenge in itself, but I'm fairly pleased in the way it turned out. you'd never know it was piece of a kitchen. Thanks once again to those who on the forum for their advice.2 points

-

Another thing helpful to do especially if you're going to work on one particular watch is to search online and maybe might find somebody else servicing one. It would be really nice to get the technical bulletin but that might not actually exist? One of the problems with companies like Omega is didn't get a parts list but they tend to assume that you know how to service the watch and you will not typically find individual detailed service bulletins for every single watch they ever made. Then newer stuff that might be available becomes problematic to find because they watermark every single page and anyone who has access to that would never release it in the wild because there must be a reason why Omega so paranoid over where their technical documentation has got to. Which means even if it exists you probably won't really get it. Out of curiosity how did you pick your oil choices? If you look at link number four on the cousins website I searched for a particular word which Gives us a whole list of interesting documents? This is a sampling of Omega working instructions unfortunately that have considerably more but this is all cousins house. You should download number 40 which covers lubrication and number 81 but 40 is more useful. One of the more interesting features for you in this would be 11.1.Procedure in Customer Service for lubrication of reversing wheel. Ill find that some of the links I have below they disassembled the reverser wheel which require special tools but That isn't entirely necessary there's a special lubrication for the wheel LUBETA V105 Which can be purchased in a small bomb it's not that expensive. Otherwise if you don't do it right they can make a horrible grinding sound. Then I didn't really look but there's probably videos on YouTube of people servicing the watch. You do have to be careful with any of the videos any of the links or anything else just because someone has a video has a link shows how to service the watch doesn't mean they actually know what they're doing at all. But still you can see pictures of the watch in pieces etc. https://www.watchrepairtalk.com/topic/1661-omega-562-walkthrough/ https://watchguy.co.uk/service-omega-seamaster-calibre-562-2/ https://clocksavant.com/blogs/news/servicing-a-1960s-omega-seamaster-calibre-562 https://www.cousinsuk.com/document/search?SearchString=Working1 point

-

Normally there is difference in the pivots length between balances complete that are made for regular, or for anti-shock jewels. Because of that they are not directly interchangeable and have slightly different part numbers.1 point

-

Yup, and we will be buying our beer in firkins and purchasing our gruel with florins before you know it.1 point

-

A Thomas Robert Russell pocket watch dated to 1892. Here's some history on this maker: https://www.timewornwatches.co.uk/manufacturers/thomas-russell-son/ Value? Unlikely a lot but worth taking a look at ebay sold items to get a better idea.1 point

-

The Fact is its no harder to repair the omega than any other Automatic just more expensive if you cock up, so with that in mind do as Vwatchie advised and practice. The watches you have are all broken, fine for disassembly etc and attempted repair but I would add get one or two cheapies that at least work that way once cleaned and re built and still working that's an acheivement on its own and will add to your confidence. all the very best.1 point

-

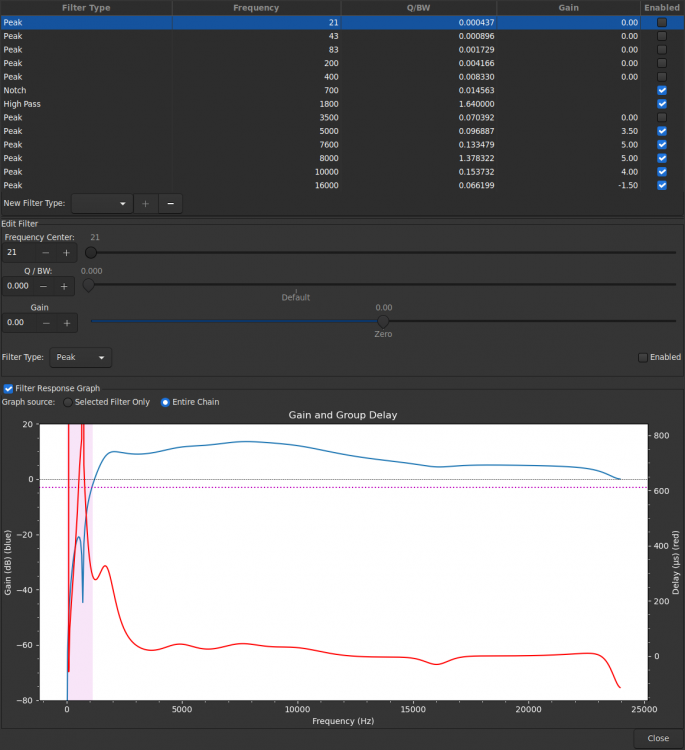

I haven't seen that application before, since I don't use Windows and it's not portable. It looks like it lets one setup a biquadratic filter cascade but it doesn't actually do any audio processing. It makes a config file for another application called Equalizer APO, which does the actual processing. I wanted better filter control in tg, so went overboard and made a fancy system to create biquad filter cascades. I've been working on it for quite some time and it looks what I've done is reimplement both Peace EQ and Equalizer APO put together, except it's portable and not Windows only. The filters can be adjusted and audio reflects the changes immediately as the sliders are dragged. The graph updates in real time too. I also avoided some limitations. It looks like PeaceEQ forces one to have exactly 13 filters in the cascade? I allow any number. And the equalizer limits filters as if the sampling rate is 44.1kHz, while I allow for the correct sampling rate, e.g. 48 kHz is required for most USB audio devices most PC hardware can do 192 kHz (I've found > 48 to be useless). They do have some extra filters I haven't implemented. This is what your chain would look like. I turned off the 0 dB gain peak filters, since they do nothing to the audio, but do add numerical instability to graph, as it is generated from an equivalent single higher order polynomial rather than the cascade of quadratics. The Q values are different because I used a sort of normalized bandwidth instead. The idea is the notch or peak is a certain width in Hz for a given BW value, then you can drag the frequency around and the notch/peak moves with it and *stays the same width*. Using Q like in PeaceEQ results in the width changing as the frequency changes. I found this annoying when interactively adjusting the filters.1 point

-

1 point

-

Good man recycle and utilise, my whole watch bench is made from recycled kitchen equipiment quite comendable well done1 point

-

Yes one of the unfortunate problems in the universe is not everything is findable online even if it does exist online. Then of course there's a lot of stuff that just isn't online the material houses for instance don't list every single part they have in possession of a lot of watch material is out there but you can't find it online.1 point

-

1 point

-

Good question John. I guess my feeling is that if I open a restoration business, as I would like to do eventually, it will add something to my credibility. Maybe I also have an ingrained student mentality where you can call yourself good when you are evaluated as good by an expert (incidentally, I am also a grad student). I am far from being committed to it, but I think it's good to have a vague goal. But you know, it's a journey and I may or may not do that. Happy for your thoughts.1 point

-

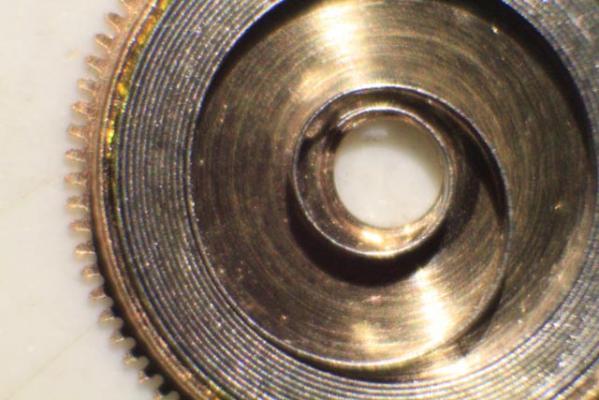

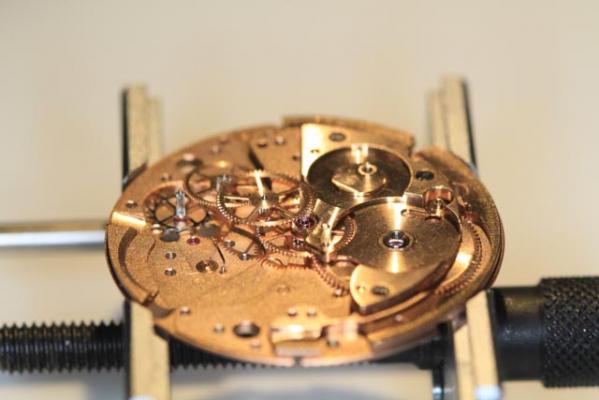

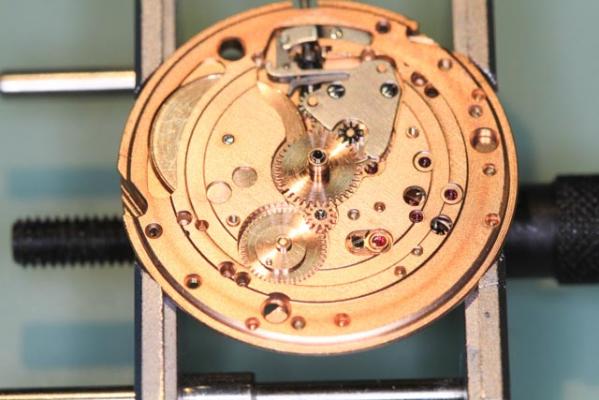

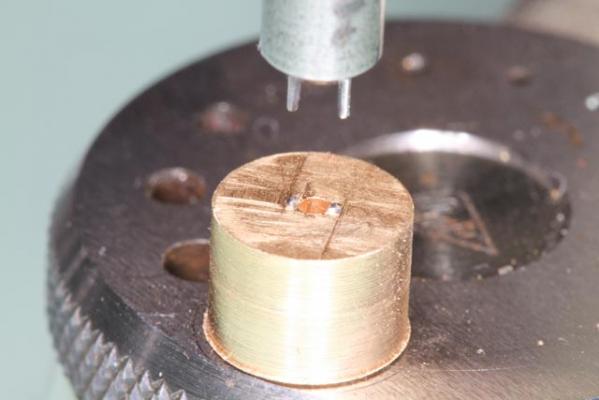

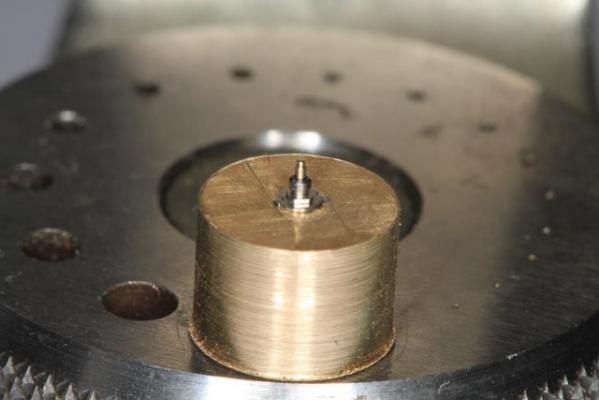

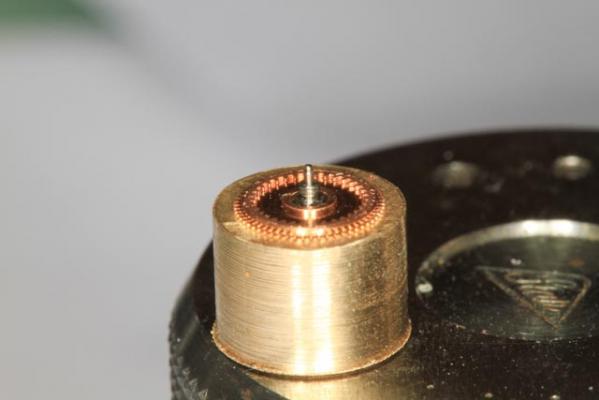

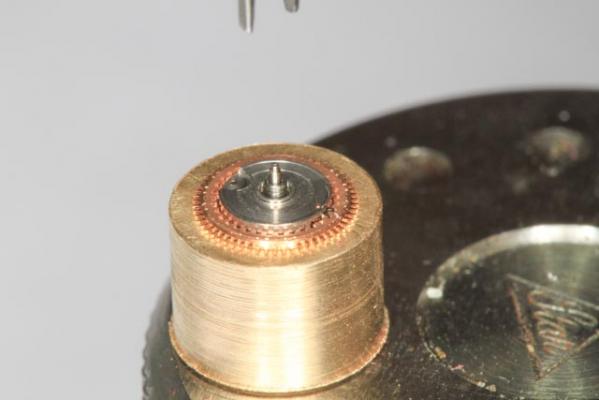

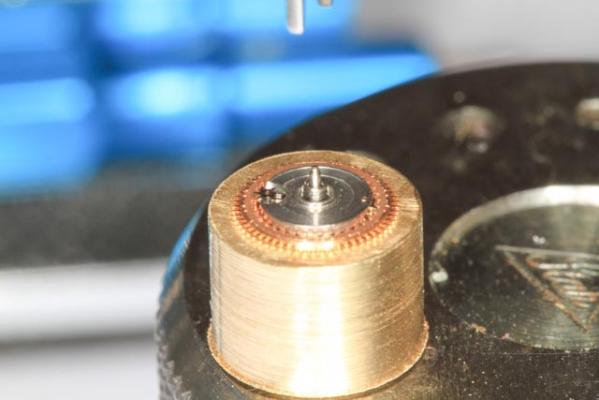

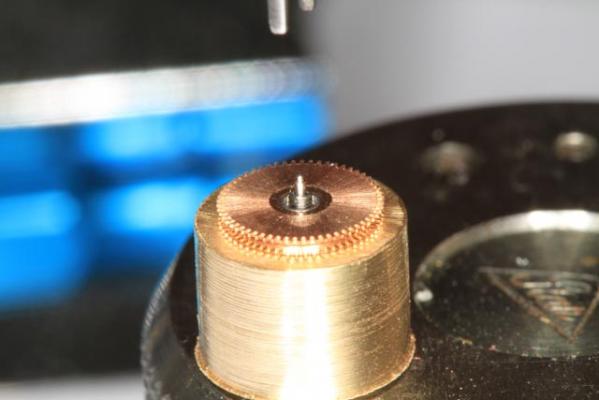

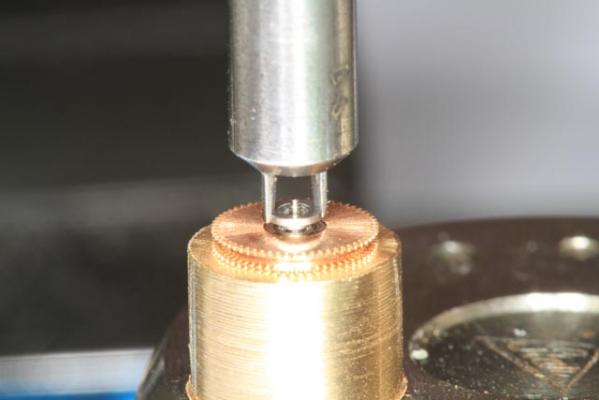

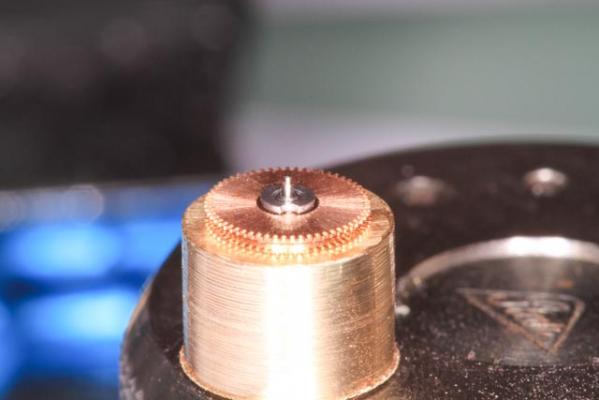

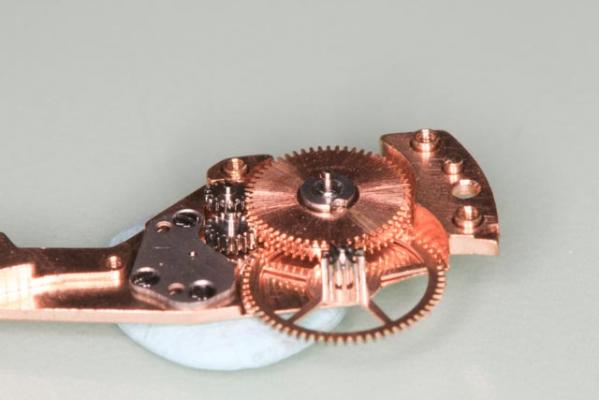

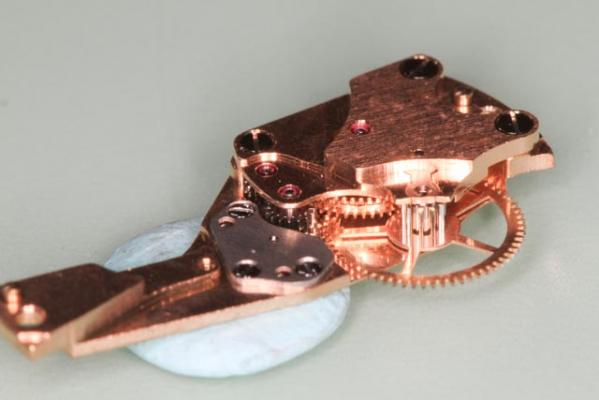

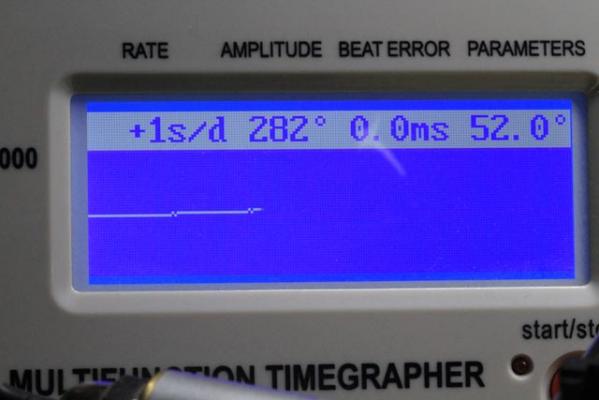

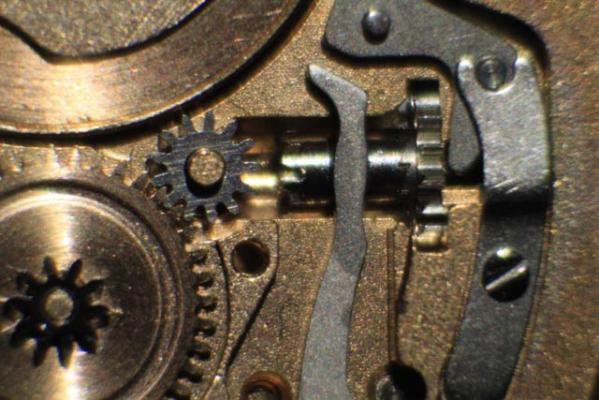

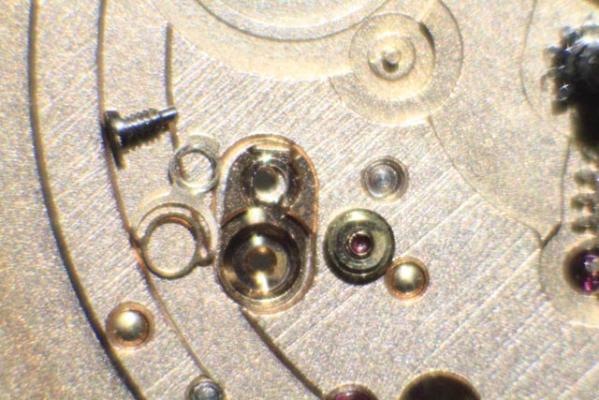

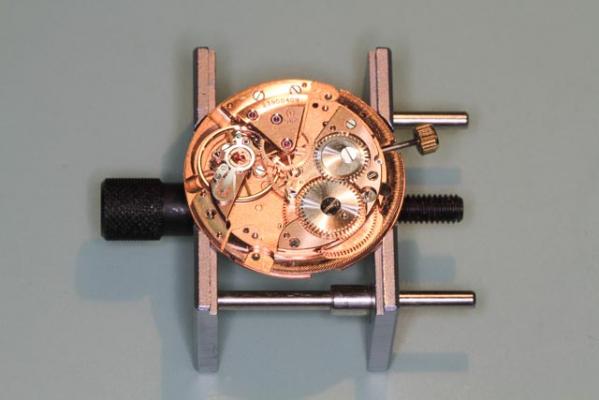

Here's a quick walkthrough of an Omega cal 562 I've just finished. Prior to the photos, I've stripped the movement down and cleaned it, experimentally, in Zippo fluid in an ultrasonic bath, which seems to be extremely effective and quick. I don't have a watch cleaning machine. Comments and criticism most welcome. First, I lubricate the barrel wall with braking grease 8213, and I add a dab of 8200 on the spring itself (not sure if I need to or not) Fit the barrel bridge and centre wheel. Lubricated with HP1300 Adding the train wheels - these are fiddly (i think because the jewels are all olives) Fit the train bridge. Lubricated with 9020 Fit the centre-seconds spring. I lubricated the seconds arbor with a tiny dab of 9020. I left the spring dry (vaguely remember reading that somewhere) Separate the ratchet from the manual winding wheel to lubricate it (HP1300) ...and reassemble Winding gear all back in place. Rodico will clean this up... Pallet fork in place. Strictly no lube! Tiny dots of 9415 on the pallet jewel faces, and worked the escapement round until there was reasonable coverage. Fitting the keyless work. 1300 on the wheel arbors, 9501 grease on the yoke and castle pinion Disassemble the lower incabloc setting. Lubricated with 9100. Train all together And running quite nicely Time to fit the motion work and the date-setting stuff. Completely forgot to take any photos! Now the fun begins. Assembling and disassembling the reversing gear isn't trivial. I made a tool that sits in my staking tool to screw it all back together. Here are the components of the reversing gear ready for reassembly I sit the winding pinion on my homemade tool: Then add the superior winding wheel (tiny dot of 9020 in the hole) Fit the superior satellite pinion to the winding wheel core. A dot of 9020 keeps it in place... ..when you sit it in the winding wheel Then add the inferior satellite pinion (their name for it, not mine) And place the inferior winding wheel over the top Then screw the inferior nut onto the winding pinion using another home-made tool: ...and we're done. Putting it all together on the automatic bridge Lubricated with 9020 And fit the whole lot to the watch. The instructions tell me to dip the rotor gib in a piece of elder pith moistened with oil (9020 again) Finally, fit in to the case. This takes several attempts since every time I attached the case clamps, a new hair or dust spec would magically appear behind the glass. Job done. Hope that was informative.1 point

-

Hi folks. Sorry I have not been on much lately. I have uploaded the Service document to Google Drive. Hopefully this will allow everyone to get to it again. Here is the link: https://drive.google.com/open?id=0Bw4CFczC5vh0XzI0TjVTRDQzaWc Please let me know if you have any issues accessing it.1 point

-

Quick update: I received the adapters and was able to connect the Witschi mic into the preamp just like I have been using it with the other mic with just ok results. The amp is transmitting ok, I can see the big jump in the waveform when I tap on it. But just like @tobmack said, the signal is too weak and when I increase the preamp it boost the noise as well. Quickly compared with the clip on Korg mic and it had a discernible waveform. This was all quick and dirty because of time restraints, I'll post pics asap. Thanks for your input! Sent from my iPhone using Tapatalk1 point