Leaderboard

Popular Content

Showing content with the highest reputation on 12/17/21 in all areas

-

Hi Willow, it is chain driven, with 2 brass weights. I bought this clock in a flea market 25 years ago in Amsterdam. I tried to fix it to the wall, it came away, I grabbed it to me, it hit me in the face, brass weight s to the front, and knocked my teeth through my lips. So I really love this clock, we go back a long way3 points

-

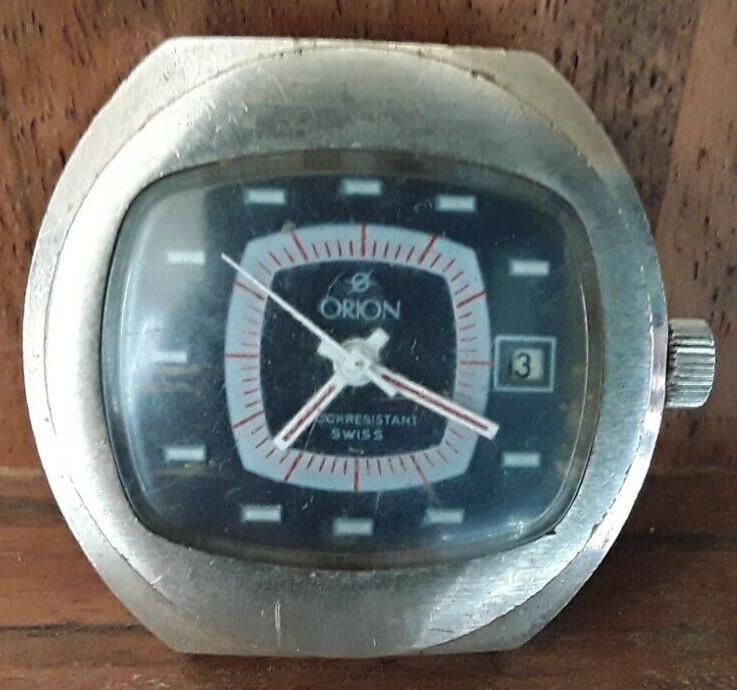

Im really going off sapphire crystals. All my watches that have sapphire crystals I have stopped wearing. I just don't think they add anything to a watch (apart from scratch resistance ) I have been designing and building a number of my own watches recently, and do you know what isn't on my list of must have features? You guessed it....a sapphire crystal. They are just soulless in my opinion. Practical yes, romantic no. And I want a bit of romance in my watches. A bit of tradition. Im very lucky to have a rolex submariner in my collection (don't judge), with the ceramic bezel and the sapphire crystal. I haven't worn it in ages, but I got it out the other day to give it a clean and check everything was in working order. What struck me was that after a quick wipe down it looked like new. I went through a period of wearing this thing every day, all day, no matter what I was doing. I spent a good deal of my working day under cars, or inside engine bays, fabricating stuff, welding, etc etc. Through it all I wore that bloody submariner, and there still isn't a scratch on it! On the other hand I finished building my new favourite watch about a week ago. I specced it with a big old high dome acrylic crystal because I just think they are special (almost as special as domed, flat bottom mineral crystals). Ive never seen a watch that doesn't look better with a high dome acrylic crystal on it. This evening I glanced down at it to check the time and noticed it was covered in scratches. I grabbed the poly watch, gave it a quick buff and it looked as good as new. NO, it actually looked better that new! I don't know what it is about acrylic crystals but the more you polish them the better they look. And you know what? Sitting down buffing that glass I bonded with that watch. I had to put some effort it and look after it, and now I can't stop looking down at the beautiful reflections on the glass when the light hits it in just the right way. I think I never really bonded with the submariner because it was too easy. I never had to put any effort it. It left me cold. I just don't think ease of ownership makes an item special. Out of all the cars I've owned my favourites certainly weren't the most reliable ones. Sometimes I think we appreciate things more when we have to look after them. It feels like something that is perhaps being lost in more recent times. Everything feels a bit more 'throw away' than it was when I was growing up. When I was younger it was common to spend your free time taking care of your valued possessions, because you worked hard for them! Whats wrong with polishing your shoes every morning, and waxing the car on Sunday?! Sapphire crystals are very convenient, very practical. But I think ill take a pass.1 point

-

I always look for the dot on the balance rim. As I only service my own watches, for any without adjustable stud holders, I accept anything less than about 2ms beat error. You can mess about for ages trying to get it right. And each adjustment risks damaging the hairspring. I just make a note to give it a tweak at the next service. The example I show above of the 5 deg angular error - if the impulse jewel were at 2 mm from the pivot (probably less), then a 1m/s beat error equals about 0.17mm lateral position error in the jewel.1 point

-

I'm happy you know that I was being really confused here. Then yes the visual method is interesting in that as you already noticed visual perfect is not timing machine perfect. I remember when I got my witschi timing machine I was all excited and had a Hamilton deck watch which is a really beautiful timepiece and visually it was perfect in beat. But the timing machine was disagreeing with my visual assessment by giving me numbers that were very unhappy numbers. I remember it took me at least 45 minutes to please the timing machine and yet visually it still looked the same. This also came up at work once where with a little tiny Omega watch visually it looked fine but once again the timing machine was laughing hysterically at us. But on some watches Older watches in particular you might find a little tiny dot On the balance rim. Is there to tell you where the stud is supposed to be. In the case the Omega we just rotated it so what was where was supposed to be than the timing machine was happy. But visually you can see no difference at all.1 point

-

No it is not. Not even large mechanical parts are wet in oil for storage, just a different wrapping paper was/is used, Cosmoline in the US, different names elsewhere. That wrapping leaves such a stubborn sticky residue that cleaning it is a big job, and would be totally disastrous for the most delicate item, that is an hairspring exactly. Look at how it was done in the the old times, that light paper is probably rice paper. It is acid free and has good absorption of humidity or fluids. If your parts come in that already leave them there, or rewrap with your own rice paper. For further peace of mind store together with silicagel sachets, and that's all.1 point

-

Without pictures and a more detailed explanation of the problem it's impossible to help or even understand what do you mean.1 point

-

When you go in with a razor blade, choose a location which is inconspicuous. If the bezel will not lift, then tap the razor with a very lightweight hammer.1 point

-

Welcome to the forum As JohnR always advocates, sort through the watches and find on that works before you start, that way if you goof it up you know that you did it. Starting with a broken one gives you only dis assembly /reassembly practice and if it doesnt start working when you finish you dont kow if its somthing you did or if it was irrepreably damaged in the first place. So start with one that at least ticks or tries to. Attached are a couple of documents to help you along. cheers 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

Is there a 3-digit case reference number inside the case back? Eg “820”. The case will very likely be 3-piece, but that doesn’t necessarily make it a front-load assembly. There will possibly be no lip for the bezel ring which I think is done for aesthetics. Try to squeeze a razor blade in to start it lifting. Separate issue, but I would want to correct that buffed finish as it has rounded the edges and doesn’t look right. Even removing the finish would help.1 point

-

Hi It could be potentialy a front loader If so remove the bezel (if no notch) use a sharp blade Ie safty razor blade or stanly. Be very careful and wear a protective glove just in case. Work your way round the bezel untill you either gain entry or make enough headway to insert a case knife.1 point

-

1 point

-

While cleaning doesn't fix everything neither does the handiwork of others applying excessive oil. I had a pocket watch the other week that was like that was literally drenched in oil and for that cleaning is the proper repair. The unfortunate problem with learning watch repair is that everybody breaks stuff. All of us remember the stuff we've broken. If you not breaking watches you're not working on them. But with time The things that you break diminishes considerably hopefully.1 point

-

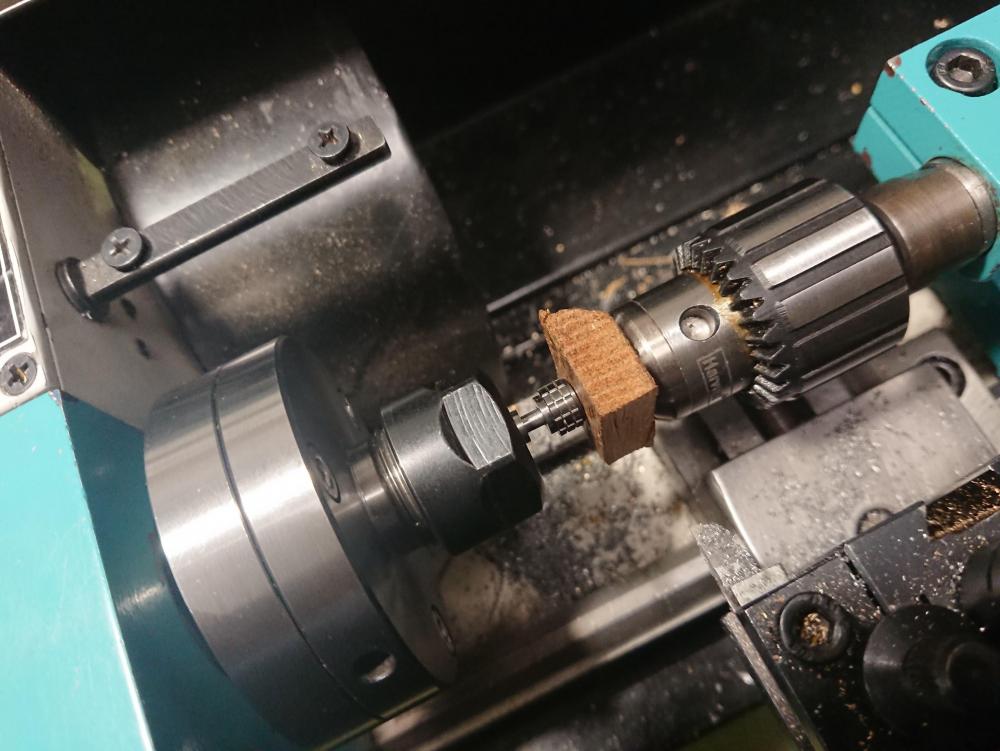

In response to your comments, I posted a new video on my YouTube channel about repivoting a balance. JR, the diameter of the pivot I replace is .10mm. It wouldn't take much to reduce that down to .09mm. JohnR, your comment about the expense of the tooling is noted. So for the bulk of the video I use one of the simplest pivot tools one can obtain. Still there is the collect holding lathe which is a more substantial purchase, but one I would recommend to anyone serious about vintage watch repair. About YouTubers making things look simple, that's the result of years experience and some selective video editing. If you watch the video on YouTube, what I omit in the video is included in the description below the video. 3 things I forgot to include. Comments and critiques welcomed.1 point

-

Ah yes, that's right. The spindles are 8mm diameter, same as Favorite, Chatons SA, and Horia. Horia is still going and sells the spindles individually; they have both keyed and non-keyed (they call it "furrow"), the Seitz takes a keyed spindle but will work with non-keyed, just back out the locating screw. Horia has the spring too. You have to specify 3mm or 4mm hole, and they have 3 lengths; Seitz is 76mm total length, their longest is 74mm, which should work fine. https://www.horia.ch/Scripts/Modules/CustomView/List.aspx?idn=9747&name=ShopCategory&pg=21 point

-

It is. But your data will always fill the space allotted!! Nature abhors a vacuum.1 point

-

1 point

-

1 point

-

Someone had tried on a large Sector watch at the jeweler shop. Only later the owner found that the person managed (how?!?) to snap the stem in the little time he handled it, but didn't say anything. The crown is signed and of a peculiar look, of course Sector service center said that it's not available anymore. Then, somehow I botched on the correct way of removing a stem broken flush on the crown, that is to cut around the top of the female threaded section about 1mm to grab it. The sliding portion left for good and the fixed one was ruined. Time to think something different, all in all it took about two years until yesterday. All work was done an a non-watchmakers baby lathe with standard tools. An extremely useful one is the carburetor jets gauges below. These are now discontinued or sell for a stupid price but I had secured the pair from a German metrology seller. As the usual I apologize for the rough pictures. I started by drilling a blind hole in the original crown "core" to be the largest possible without touching the threads. Then cut off the button from a spare screwdown crown. That revealed the mistery of how the pipe, which holds the sliding portion and its spring, is attached to a screwdown crown. It's screwed in as well! But, once turned to press fit size into the hole of the original crown (3mm) there was not enough material to hold a firm friction fit. That I remedied turning and pressing in a brass sleeve. I left the contact surface a little rough to improve friction on the 0.05mm interference. I don't know why but most of my mechanical repairs involve sleeving and shimming. Then I turned a tube to push the above into the crown. It's sized so to be also used as a stump on the staking set. It went in without issue. Compressing air in there is not ideal, but once I realized it was too late to pull it out back and cut an escape groove. The finished item works fine on the case, all is left to do is to cut a new stem to size and return it to the happy jeweler.1 point

-

Always an adventure, but the correct tools make the job much easier @WatchMaker. I hope to grow out my arsenal of good hand tools, etc. and come up with smart ways to do the rest (cleaning, paint or lume work.) That's true, I was wondering what could be bad if it runs for several hours and then stops or if it's just in need of a service. You make a point on bent vs. sheared balance staff. The timegrapher reading is all over the place but mostly negative, looks like a proper snow storm. I thought if the balance staff broke you were pretty much dead in the water, but it could just be ever so slightly bent from a hard knock. The EB8800 movements are relatively cheap and plentiful. It looks like I might actually be better off buying a running example than just the movement alone. Wondering if it would be better to replace it with one that has more jewels (as opposed to just the one on my balance.) I'm sure it's a common theme where I feel bad taking a watch apart that is running to fix one that isn't running, but that happens a lot with cars too. I'm fairly comfortable replacing a balance after working with those vintage 17J movements, so long as I do not stress the hairspring as I'm not good enough to manipulate it back into shape. I'll admit. Donor movement for the Mustang II watch project comes in this week too! I believe it should be here by tomorrow. Once I have some more time, I can finally add photos to this post. Need a day set aside for my projects to break the tools out again and get to work.1 point

-

I'll take the opposing view then... I've had plastic, glass, and sapphire. My favorite is the sapphire. I do a lot of... high impact/abrasive things. I live in the mountains, and am always fighting boulders, logs, bears, etc. I like to work on cars and other machines. I work-work with caustic chemicals. I weld, solder, and just do a lot of mean stuff to watches. Scratchy things scratch, hot things melt, and chemically things do all manner of fun things. A sapphire crystal can handle those things, glass takes the sort of damage you typically see with plastic, and plastic is just a liability. The cases and bracelets get plenty of love scratches on their own, I don't need a bum crystal making it hard to read as well. Additionally, I try to avoid plastic pretty universally as best I can. Part of the reason I'm into mechanical watches in the first place is because they're made of quality materials. Plastic is not in that category in my book. Metals, precious and otherwise, and rubies, even if they are synthetic. I would never buy a 7750 because there's too much plastic in the movement. Also, for the kind of money some of those go for, I want a column wheel. I have a Seiko NH35 (plastic parts in the date mechanism) in a parts watch with a domed sapphire crystal, but it's my "shop watch" for especially abusive activities.1 point

-

1 point

.thumb.jpg.3cad98a9ff77201b699301ef3212357c.jpg)