Leaderboard

Popular Content

Showing content with the highest reputation on 12/02/21 in all areas

-

2 points

-

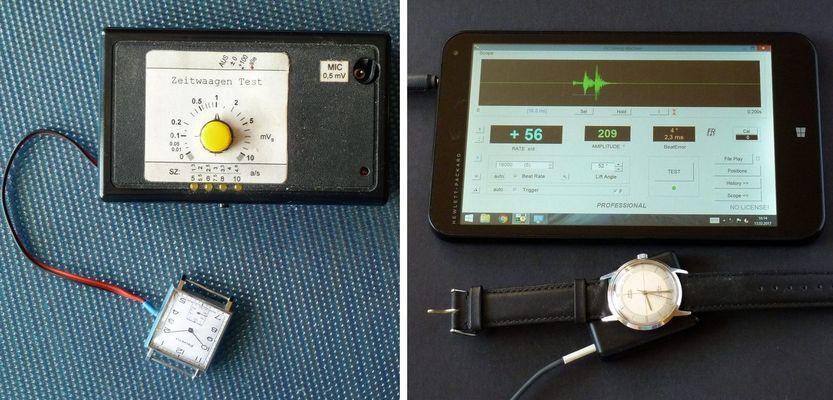

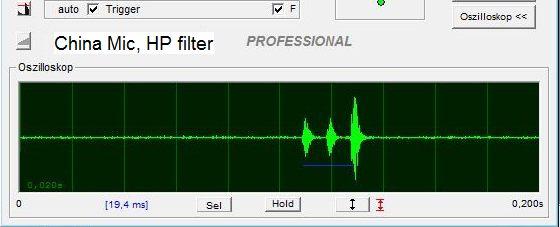

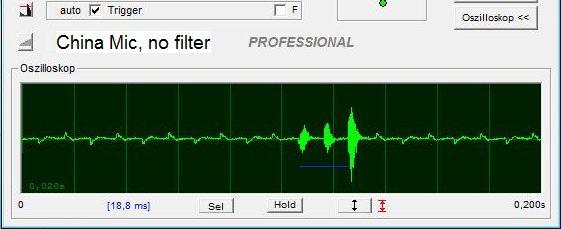

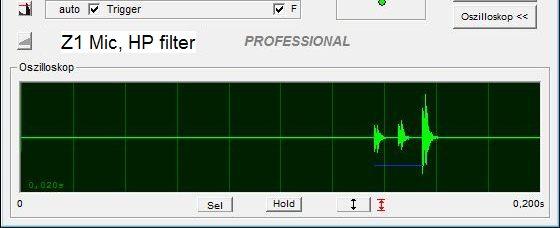

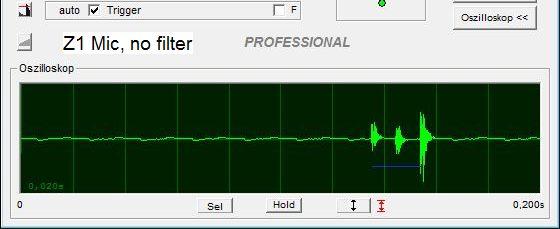

Thanks for your interesting review, xyzzy Stimulated by the hint to that mic, I ordered one, too. I wondered if the Chinese had some tricks that I dont't know yet (they do not!). It is the type without movable stand (don't need that), and has a LiPo battery already. 2/3rd of the circuitry is needed to charge the battery. It came without any connecting cable and - of course - without any manual. The seller was not at all interested in my complaint about the missing cable. I suppose, anyone without electronic skills will not be able to get this set working. The amplifier is made from a LM386, an older headphone amp IC. Circuit is exactly like its data sheet application. No filter, just the piezo properties add a bit HP filtering. I made some measurements, using my software TM and my tic-noise generator and compared the chinese mic to a simple Z1 mic (piezo disc, 1-transistor amp, no battery needed) Both mics produce about the same output voltage from a given ticking strengh. But the chinese mic needs a much louder watch because of its worse signal/noise ratio. For testing mics, the watch is substituted by a piezo disc driven by a tic noise voltage. Test results Needed for full recording level (volume = max, +0 dB): CN mic: 0.75 Vp / Z1 mic: 0.3 Vp @ stimulating piezo disc Sensitivity for "amplitude measurement possible": CN mic: 45 mVp / Z1 mic: 9 mVp @ stimulating piezo disc The chinese mic seems to react a bit sluggish to the stimulating tics. Some scope views (stimulated by 0.15 Vs @ piezo, equals a medium loud wristwatch): Frank2 points

-

If you are determined to do this yourself, and I would advise against it If you are not confident in your ability, then as you say, proceed with care. If you lose or damage anything, spares are expensive and hard to find. Also: At every stage, make sure you know what you are doing and how to do it. Ask here If you are unsure. Get the right tools for the job before proceeding. Take lots of photos to remind yourself what goes where. Keep the parts in functional groups before, during and after cleaning. Don't rush. Good luck!2 points

-

I posted about this here. Well...I have made a lot of progress. I had to disassemble the watch while still in the case because the rust around the stem locked it in solid. After trying various techniques...WD40 etc. I was able to remove the stem but the keyless works were still stuck in the movement. I have some super duper penetrating oil that has been in my chemical bank for probably 40 years or more...soaked the main plate with keyless works for 24 hours...voila!! After removing all of the parts, I ran everything through the cleaner--first the ultrasonic and then using the L&R (no, I did not run balance and pallet fork through the ultrasonic). After everything was clean and dry, I did the reassemble. Obviously I could not wind it with the stem, but could wind with the rachet screw. I did not install the crown wheel because I did not need it for now and I was also missing the crown wheel spacer (I think). Well, here it is and it is running. I took a short video of me installing the balance when with power so that exact moment when the watch was recalled to live could be captured. After checking with family, I am confident that this watch was retrieved during the Battle of the Bulge in 1944/45. Where to from here? I am going to need a new stem, clutch, winding pinion, setting lever screw, and perhaps some other things as well. I also need to do a proper clean/oil on the balance jewels. For now...I am happy with my progress.2 points

-

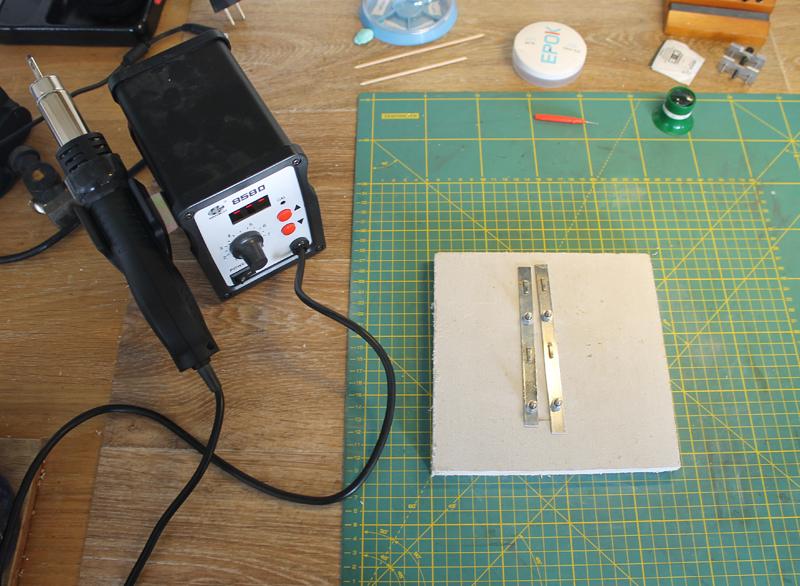

Thought it may be worth to share; I received a pretty beaten up, none-running 1890-1900 cylinder-escapement pocket-watch. It had all sorts of problems, a list too long to go into details. Among those problems was a bend/broken minute hand. It inevitably broke off when trying to straighten it. The center-hole diameter of the minute-hand was 0.5mm and the length was 15mm. The hour-hand had a hole diameter of 2.0mm and the length was 10mm. Searching the internet to find an identical set proofed futile. The watch is a heirloom so originality was a priority. The hands turned out the be made of bronze, a copper-tin alloy. Therefor it made sense to attempt soldering but the part that had to be soldered had a thickness of only 0.3mm. Both parts had to be fixed in place with a sort of clamp capable to fixing both parts, being heat resistant and "none-sticking". A soldering iron, even with the smallest tip, would be far too big for the job and to avoid touching the parts, I choose to use a hot-air gun used in electronics for soldering SMD-components to a circuit-board. A few test were made which tin to use and at which temperatures. 300 degrees C with tin used in electronics seemed to work fast and made the tin to flow nicely. I used a soldering flux-paste. The clamp consisted of two metal rails, slightly diverting from each other to give many clamping options, bolted on a plate of gypsum. Pulling over a #1000 grid sand paper, I made two 45 degrees chamfered edges on either end of both parts; The two parts were clamped in; Applied some soldering flux, heated it all up to 300 deg.C and applied a tiny bit of tin. Once cooled down, I removed some excess tin with a small diamond file. Here a picture of the back side of the minute-hand; And here the front; the tin didn't flow further away from the soldered joint or around the edges Most likely not the strongest repair in the world, but when not touched it should be strong enough to do the job. On the picture the hand color looks black, but that's due to the lighting. In reality the hand hasn't lost any of its shiny patina at the front ...... Anyway, I thought to share this repair as one of the many different possibilities1 point

-

1 point

-

very true. If nothing comes of this I can at least be happy I was able to get all the bits back into place.1 point

-

Hi and thanks for all the replies. I understand all your concerns and appreciate the thought but I did not do these courses just to play about. I have already played/practised with many different movements and the time I feel is right. Yes I will be meticulous, yes numerous photos will be taken(always do), yes I will ask if a problem arises and yes I understand the risk of breakages/spares etc. The auto wind mechanism has always been missing(if anyone knows of one or a contact I would appreciate it) so in fact it is already an incomplete movement and theoretically of little value. I would expect the case and dial are worth more. My set up is pretty good and the 5spoke puller was already on order from Cousens- appreciate the link though. Just taken this photo and ironically the movement it has decided to spin again quite merrily. Had depowered it and wound it up again so as of now its under observation until further notice! Watch this space Cheers Simon1 point

-

1 point

-

Try mwrforum or http://www.obsoletewatchandclockparts.com/ . Well done.1 point

-

well I figured it out and oh course what did I find? Right! Someone was already in here and "borrowed" a few parts.. dang. I have another by Stellaris that does not run so will see if from two I can make one. Between them both I spent maybe $15.00 so if nothing else I learned something. Yeah, there is a reason these go for so little on eBay!1 point

-

Haven't used it enough to know. Having the articulating stand is vastly more convenient than the loose microphone, that's for sure. I don't see a metal one for only $15 more. I got this for $47.76 with shipping, the cheapest I see the 1000/1900 microphone alone for is $87.45 with shipping. But I don't have one to know if it's worth the $40 extra. I think it needs a preamp too? Certainly one will need to modify the cable to connect to a computer. There doesn't seem to be a way to post audio here. I could do youtube maybe. I have on my computer's microphone input with the mic boost at +20dB and input gain at 0 dB, which produces about -15dBFS SPPM with the Seiko 7S26. Dragging my finger on the stand base is about -12 dBFS. Typing this on my keyboard, about 1' away on the same desk, and it's extremely noisy keyboard the likes of which has not been produced in over twenty years, gets to about -18 dBFS. Normal volume talking is about -20 dBFS. The noise floor is about -39. The Seiko is pretty quiet, so I tried an Elgin grade 173 0s pocketwatch. For that I need to lower the mic gain to +0 dB to get it to around -17 dBFS.1 point

-

I think you need to clarify what it is you like? Reason for the clarification is quartz typically comes in digital is typically all electronic zero or nearly zero mechanical components. Then there is analog quartz watches there is gears and setting parts like mechanical watches and interesting challenges that don't come up with mechanical watches.1 point