Leaderboard

Popular Content

Showing content with the highest reputation on 12/29/20 in all areas

-

Almost there- height (most used term, width is probably ok but might get confused with thickness) x thickness x length. The final number isn't always given but it refers to the inside diameter of the barrel.2 points

-

Hello everyone. I signed up for these forums after finding this very interesting thread. You don't need any kind of whiz-bang PC to run this software. Any old PC, even one several generations out of date, will do nicely. Where I live (New Jersey) electronic junk must be recycled by law, it can't go in the trash. I've picked dozens of old PCs out of the recycling bin at the DPW. Most are still working, or I've put together PCs using parts from several scrapped machines. Working keyboards, mice and other stuff all free for the taking. Most of the flat panel monitors don't work, but most can be put back into service for the cost of a hand full of electrolytic caps. As a result, I've got several machines dedicated to running hobby software. One machine in the garage to run auto repair software, another in the basement to run some other hobby software. All it was free, or nearly free. This is also a very productive time of year for dumpster diving. People got new toys and are throwing the old stuff out, almost always in working condition. I'm typing this on a machine I put together entirely out of scrapped parts. For my next project, I'm going to see if I can't get this software/DIY hardware to work for me.2 points

-

As you noticed on that tired mainspring, it should have an "S" shape. This one at Cousins will do the job, it's a little shorter than what's listed on Ranfft but that won't make much of a difference 1.45 x 0.10 x 300 x 9 Non-Automatic GR3953 If you get another FHF175 donor movement it might have a similar old mainspring, and you'd need a mainspring winder to put in into your barrel unless you just swapped the whole barrel over, unserviced. As you've probably seen, the new ones come in a package so you don't need a winder. New spring is much cheaper than a winder, until you're replacing lots of mainsprings. You can fiddle with some of the other dimensions when finding replacement springs, if you can't find new or NOS fits, but the next shortest spring of a given size is usually the best bet.2 points

-

Probably not, unless it was for a simple posing job. If it were me, I’d try to make one for that: easiest option might be to dress a carbide Stanley blade with a coarse diamond lap.1 point

-

Hello and welcome to the forum Gareth, The watches dont need to top end kit we apply the same to all watches. I have attached a little light reading for you to fire the desire. Watch Glossary.html 1612608791_ToolsfortheHobbyist (1).pdf TZIllustratedGlossary.pdf1 point

-

For pivots under 0.15mm-ish, especially balance pivots, you really don't want to use a micrometer. Even with a very soft touch you are almost sure to make a microscopic (or not so microscopic) pair of flat spots. For these it really is really important to use a jewel gage, which is a plate with jewel holes in increments from 0.07mm up to 0.25 or so, by 0.01 or 0.005 or 0.0025mm increments depending on the tool. Some will go down to 0.06mm (you really really don't want a mic on those little guys).1 point

-

I don't think Vallorbe makes the thinnest ones anymore. I also have many acquired secondhand over the years. Last I actually measured I have a couple that are about 0.12mm at the edge, which is probably ok for balance screws except for the really small ones. 0.35 would be way too big. 0.20 might be ok for some pocket watches.1 point

-

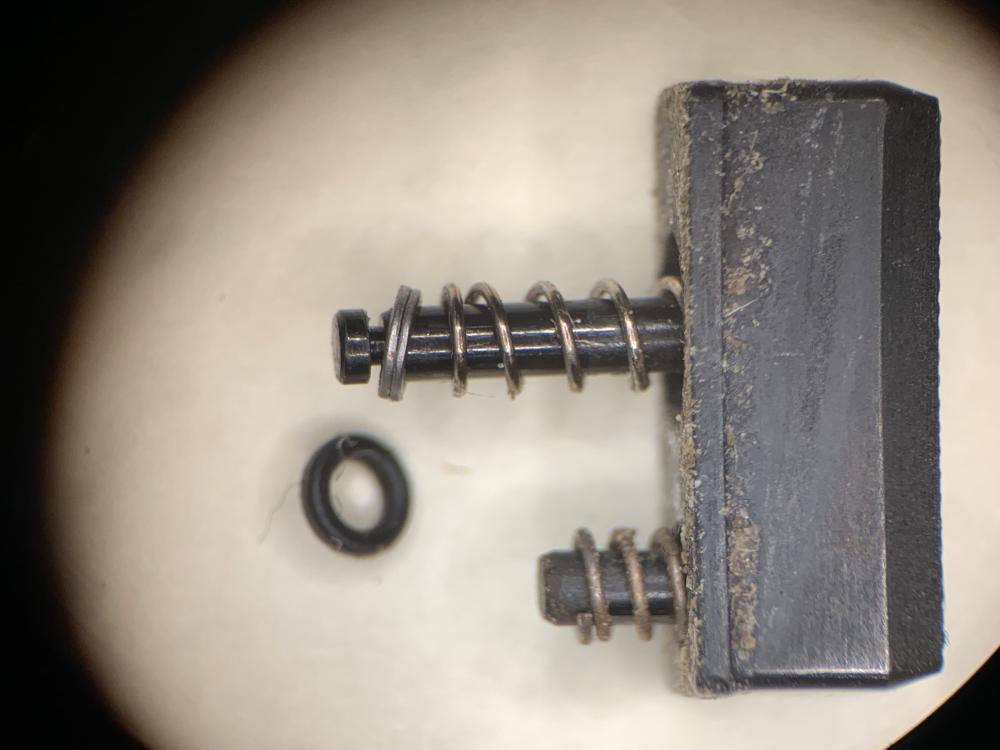

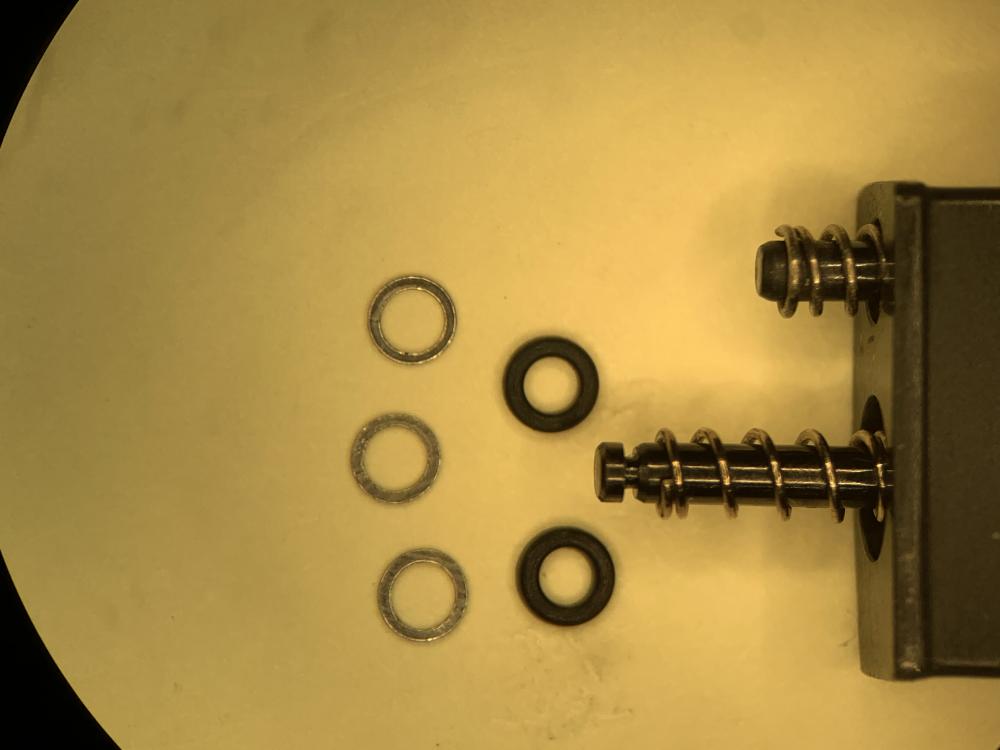

Yes, these are definitely serviceable parts. You will often find lots of dirt and in some cases corrosion (springs) inside. I've seen some pushers that were hard to push in and they would not retract due to dirt accumulated inside. Servicing these ushers is easy. It appears that you have C-clip type pushers, not Screw-in. Thus, you will only need a flat screwdriver to push down the C-clip once the pusher is.. Pushed In :-). And you will need some patience also. Do not soak the o-rings (you will find 1 or 2 inside pusher tube) in any cleaning solutions - just use water and paper-towel. Before installing them - apply silicone grease. Same goes for the C-clips - apply silicone grease on them before installing. This will keep them in place and they will not fall down. Use flat screwdriver to push / slide them Vertical down into Pusher's Groove.1 point

-

Hi there, This is how almost every old carbon steel mainspring looks like. These are pre-1960-ish production mainsprings and they never looked as S-shaped, not even 60 years ago, not 150 years ago or ever. The newer alloy springs do look like "S". I would not recommend getting NOS carbon steel mainspring. It may be waste of money and it can break at any time.1 point

-

Hi Gary Middle to tip that should be parallel, It rather depends on whether the shoulders of the staff/pinion you are measuring conical or square shouldered. the bit you are measuring is the working surface of the pinon.1 point

-

1 point

-

1 point

-

It could be a dozen different things. This would be like replacing the fuel injection system on a vintage Volvo 164 then asking why it only runs at idle... could you supply any more information? How did you do the service, what have you checked so far, how well is it actually running in that one position, close up pics if possible with balance removed and in place, etc.1 point

-

It does sound like a broken mainspring. When you set the time you are slipping a friction clutch that is directly mounted to the center wheel of the watch- which is also what directly receives the power from the mainspring barrel. So when you set the hands forward you are supplying forward power/ motion to the gear train, and this is running the watch. Totally normal.1 point

-

It can definitely be repivoted*, the question is is it worth it? I don't know about the availability of components for this caliber but in general Unitas stuff is not too hard to find. I checked Jules Borel parts database and they don't have it, but that's just one source. * I repivot a lot of stuff that is probably available cheaply just because I'm set up for it and it's a quick job in my shop. Something like this would be about 50 bucks to another professional, and they do or don't mark that up as they see fit (it's often a "rescue" job where they've broken the pivot, haha). For a tiny LeCoultre escape wheel with a 0.08mm pivot the price is quite different. That's why I say is it worth it- I would bet that part can be found for less than 50 bucks.1 point

-

1 point

-

1 point

-

A piece such as this should come with a Provenance. You need to ask them how and when they got where from and where is the paper work. Something tells me this is not right its just a feeling I have. The scroll work on the balance cock looks as if it has been made by two different workers it is not consistent all the way around. The dial that is damaged is just enough to make it look as if its old but doesn't show any other wear. Those brass pins are modern, I know pins get lost or fall out and get replaced these are recent.1 point

-

1 point

-

Of course right you were! I wasn't looking at ALL the parts I am now almost ready to post the entire story about the clock.1 point

-

8 days alarm, the wheel is external to the plate. The alam winding is the same, just a bit smaller. I suppose that square hole bent washers (now missing) friction fit the arbors and keep the wheels from coming out. My question is, for the best execution should I also fit a flat washer between the bent one and the ratchet wheel?0 points