Leaderboard

Popular Content

Showing content with the highest reputation on 09/19/20 in Posts

-

In my opinion I would do this on the keyless work of a watch. As there are no oil sinks tells you that where ever you oil the oil will go wherever it wants too. So I would use good watch grease wherever two or more pieces come into contact even on the stem. Never put great globs of the stuff on. With clocks. Clicks and ratchet wheels that are hidden from the eye again use grease and you do not need to be over fussy if it shows. Same goes if metal parts are used as a function and touch, a tiny bit of grease where they touch, clock leaver posts should have grease or oil, if you use oil make sure its just a tiny amount as it can run past the posts and go onto the plates. I used clock grease. When it comes to visible movements like carriage clocks, be extremely careful as the customer doesn’t want to see clock grease all smeared over the click and ratchet so grease is applied so the customer can’t see it, tiny bit of grease is applied to the shoulder of the screw that holds the click to the back plate, tiny bit of grease on the tip of the ratchet that engages the ratchet wheel and a tiny bit between the ratchet spring and the ratchet. Platform escapements should be oiled in the same way as watch escapements but with pocket watch oil. I will now wait for the you know what to hit the fan. I bet I have left something out.2 points

-

I gather that ratchet wheel( the big wheel) turns clockwise to wind, in which case picture 3 shows the click spring's correct setting. Winding wheel( smaller of the two large wheels) should turn anticlock as you go to wind through the crown, therefor ratchet wheel turns clockwise to wind. Show the click's bottom-side upclose, click pin might be broke.2 points

-

On causins search for movement spacer ring . On esslinger , case ring.1 point

-

not really helpful but I do have a link that has some additional information https://17jewels.info/movements/r/raketa/raketa-2628-h/1 point

-

I've found the chart on pp. 6-7 in the Jules Borel Horological Catalog to have essentially all of the movement marks I've come across so far. It's a pdf download on their website. Very handy reference.1 point

-

1 point

-

This is a very difficult question, but the “national watch” back in the days would have been a watch branded “Leijona”. The watch was originally an ebauche from Switzerland, now days it’s not. But that watch on the picture seems to be with the authentic look on wristband and everything but looks very German, like a Stowa Ancre or something like that just looking on the hands and dial.1 point

-

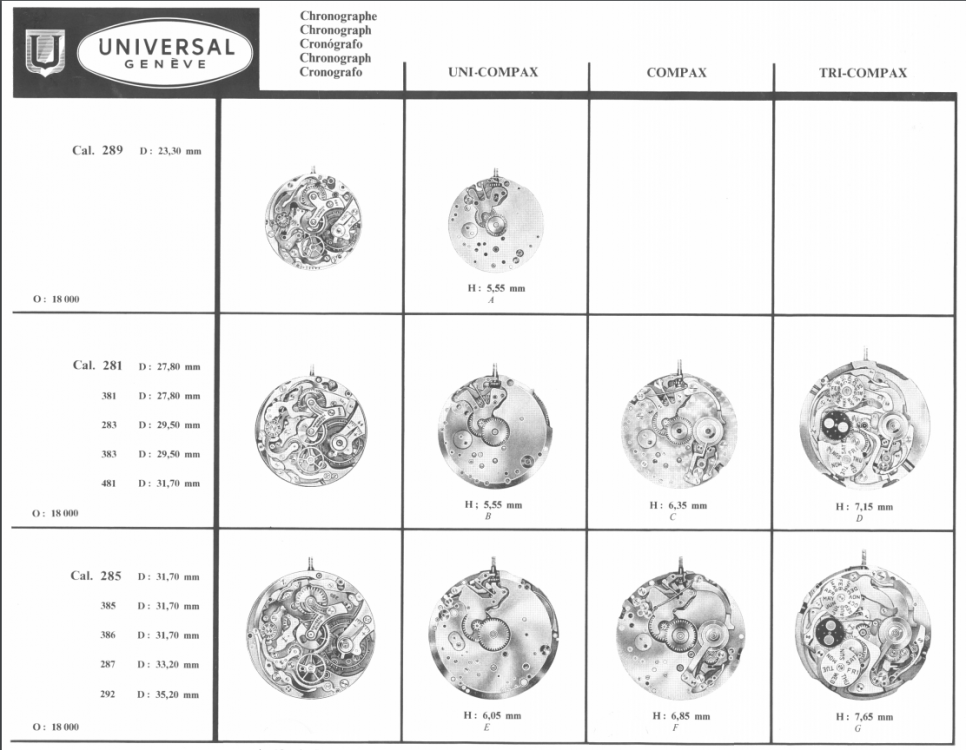

Yes all these 28X has a close likness since they are based on the same movement. Your movement is 16"' (Ligne) in size. To convert this to millimeters one has to divide the ligne meassurement with the magic number 0.44326241134752. So, 16 / 0.44326241134752 = 36.096 mm. So it should actually be a bit over 36mm when you meassure it. Then we have the UNI-COMPAX, COMPAX and TRI-COMPAX, here it is probably easier to see a picture of the differences on the dial side. Hope this helps.1 point

-

1 point

-

Well I have to admit, this little watch wasn't quite what I expected. It works fine, and after a clean and lubrication it even puts in a fairly reasonable performance. However I was expecting it to be a USSR movement, but unless I miss my mark, it appears to be a variant of the Chinese Standard 17 jewel instead. Whatever it is, the finish of the movement is not too shabby, clean and functional with at least a hint of a care having been take with it. The case too is in almost new condition. The dial however has a very odd and barely discernable rash and there are a couple of tiny scratches on the crystal. The sellers pictures looked as if the thing had a gold finish, but it actually has what appears to be a high shine stainless case, or at least one with perfect plating of some sort so I guess the gold look was a trick of the light. Determinately a little bit of an odd ball Sekonda, and well worth the 0.99p I paid for it. Mind you at that kind of money, I guess the bar is pretty low, so getting something that actually works is always a bonus. For the time being at least, it has deposed the re-discovered Casio QA-321 as my daily beater watch.1 point

-

I can tell from the distinctive auto-mind mechanism that this is an A.Schild (AS) movement. Probably something from this family: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_1983 Look under the balance wheel more closely and you should see an AS symbol. Can you also see a number?1 point

-

Yeah, really tiny o-rings are non-standard. If you search the Parker O-ring catalogue, you'll find all the "dash numbers" that correspond to ID and cross section. But the smallest standards are: 5-051 which is .070 ID X .040 cross section (thickness of the ring itself) so this is .150 OD (INCHES) 2-001 .029 X .040 (.040 cross section is 1.02mm, so rather "fat"- most are 0.5mm cross section) 2-002 .042 X .050 2-003 .056 X .060 Then the "real" standards start 2-004 .070 X .210 (1.78mm cross section) and up from there... If those first sizes will work, you can get bags of 10 or more for less than what one "watch" seal will cost. There are also a few other non standards that are smaller but those are harder to find. Check McMaster-Carr...1 point

-

Thanks OH. I've learnt a lot from you. I discovered that a dental microbrush applies oil to the pallets in a very controlled manner. The microbrush is also useful for "pegging" out pivot holes. I just received my 3rd Smiths clock. This one appears older than the 1st two. It uses a strip metal pallet instead an anchor. This one seems to have a problem with the escapement. It will tick for awhile then suddenly lock up. I'll probably start on it next week.1 point

-

I forgot to say when it comes to the click always use clock grease not oil, oil will just drip away, grease will stay put and do the lubricating better.1 point

-

The setting lever was definitely disengaged from the setting lever jumper. Once I could see the relationships of the parts I think I just said "what a flippin' mess" and started fixing it. I really wish I had stuck it under the microscope and taken a picture first. That said, your description of the sliding clutch being disengaged from the yoke and the yoke being trapped between the winding pinion and the clutch definitely sounds like how the watch felt when trying to manipulate the stem and/or turn the crown during the malfunction.1 point

-

1 point

-

I wrote about such a tool somewhere else in the forum which I called a "regulator arm tool". It can be easily made from an old screwdriver. It straddles the regulator arm from the top, so that reduces the chance of slipping and damaging the hairspring. It also gives much better torque control allowing very small adjustments of the arm.1 point