Leaderboard

Popular Content

Showing content with the highest reputation on 06/14/20 in Posts

-

Though dumont makes high quality tweezers, facts are a beginner will destroy a couple of tweezers before one gradually learns proper use of tweezers at which point you are ready to use higher quality tools and that mostly for finer tasks, following which one graduates to using quality tweezers more often, so I search and get a cheap one by the looks and your own instict helps select one that suits you, nevertheless the kid in us likes, chooses and buys one or two he likes, the new toy should come to use when we qualify to use em. same goes for screwdrivers. As we grow more experienced our eyes go for retirement, so I say you can't waste money on optical equipment , only thing, go with the ones that give you the option of trying one at home before you invest your money, what you,d be investing in is actualy you eyes. Companies providing optical equipments to medical doctors work with you and provide councelling to get you what suits you. So far as the tools for basic watch service, a stem holder, screwdriver shapenner and add on as you feel the need. I use acupuncture needles as oilers, contact lenz containers for the oil, used tooth brushes and convert broken screwdrivers to hands pusher, basic punching and case tube remover .... So when you get to machine work be ready to sell the house.2 points

-

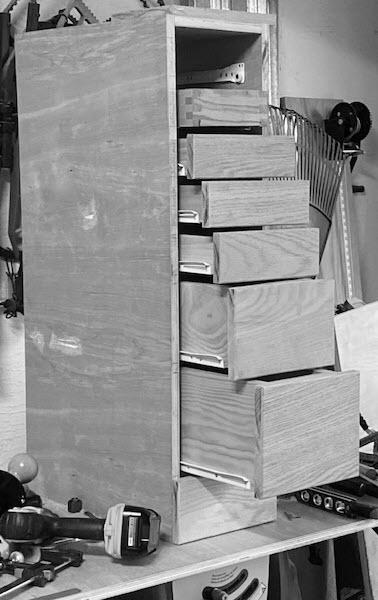

Here is the right side drawer encasement with drawers. Making the bench satisfactorily is consuming a lot of time, but I have no regrets. I enjoy the work. I think after the drawer-fronts are done and pull-handles installed I will make the back, and left/right sides of the bench. Then I can take it inside and have a surface on which to work; while I complete the left-side encasement and drawers. It might take some months; but I know when it's finished I will have known I did my best on everything.2 points

-

Must be a ton of supply houses in USA. Jules borel and Twin city supply. Perrin if you are close to Canada. Startimesupply and Esslinger. Cousisnuk have them otherwise.1 point

-

1 point

-

1 point

-

I'm not sure I agree with the cheaper tweezers suggestion... $25 is a week's coffee (if you're of that bent), and not the end of the world if you mess them up. I have a pair of cheap tweezers and a pair of Dumonts, and the cheap ones are barely usable while the Dumonts get the job done every time. I put off buying pegwood, and now that I have some, the cheap tweezers (previously used as a second point on shock springs) are used pretty much exclusively with the cap on, and a little blob of Rodico on the tip as a small parts pickup stick. My cheap tweezers are more frustration than useful; they're also especially cheap. I went straight for the student model Bergeon screwdrivers. No regrets. Can't say anything about the inexpensive French set. Like the tweezers, you're using them constantly, so if you're going to put money into tools, these are a good place to put it. I got clip on, flip down loupes from Bausch and Lomb (discontinued). I'm not sure that was the best route necessarily, because by the time I get a good high magnification for the finer work (i.e. manipulating hairsprings), I keep bumping tools into my optics... I'm probably doing it wrong. I don't know what the Harbor Freight equivalent is in the UK, but HF has some decent clip on loupes on the order of $6. Things that don't often get brought up are lighting and seating. You need at least one really good light, two is probably better (or a wide light source). If you're working at a normal desk height, you'll want a really low stool. Like 1' max. And room to put your feet. You eyes will try to jump out of your head without the light, and you neck and back will join them without a proper working height. Oils, oilers, hand pullers, movement holder, work mat, Rodico, parts tray, finger cots or gloves, demagnetizer, case opener, pith wood, and if you've got budget left over a timing machine.1 point

-

I made this for anybody getting started, feel free to share. Recommended Lubricants for Getting Started.pdf1 point

-

If you have a lathe you do not need a bulls foot file. Needle of various shapes and cuts as well as slotting files are always handy to have. I always preferred to turn the bush down to the right size and height without using files, bulls foot file will mark the plate you are bushing. I always made my own bushes. Sinkers are good to have as well.1 point

-

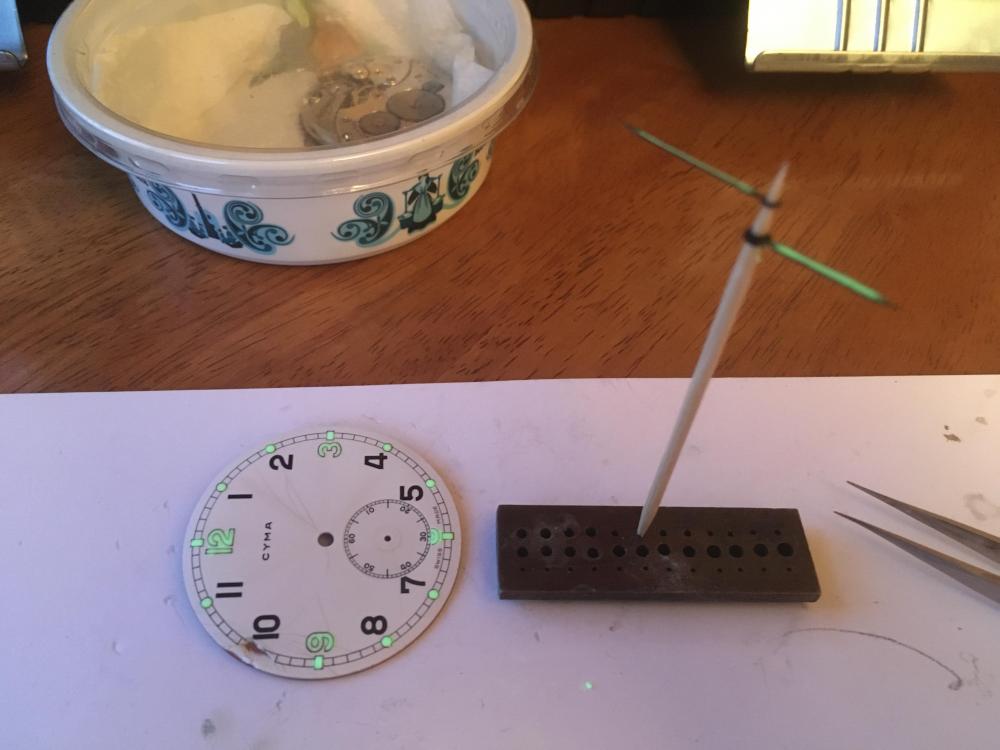

Hi, I thought I’d share with the group this project. When I un-boxed the watch I immediately realised I had a few job to do, the Crystal had yellowed over time and the crown wasn’t winding. On closer inspection I found that the ‘setting leaver spring’ was broken as was the mainspring and the whole movement was not particularly clean. I tackled the cleaning first by hand while getting some useful advice from the forum on where to find a new setting leaver, I ordered new parts while getting on with cleaning and inspecting all parts. Rebuild was a pleasure until I realised I had Installed new mainspring upside down ‘slap head moment’. Purchased some lume powder on eBay a first for me seems to be working fine. Now checking time for a couple of days then it’s getting packed up and posted to my son for his birthday. Hope he likes his 70 year old peace of military history1 point

-

1 point

-

1 point

-

Hello and welcome to the forum Wayne I have attached a couple of PDF's jut to whet your appetite, read and enjoy TZIllustratedGlossary.pdf 1730319243_QAStudentWatchmaker.pdf1 point

-

1 point

-

unlike the book that you mentioned which I do have this thing is way more detailed. Goes in the details about every thay I kinda consider at the must-have book if you want to understand timekeeping..1 point

-

There's a hole in the collet, and the spring was held in by a tapered pin. The pin needs to be pushed out, the old piece of spring as well, and the spring bent and refitted to the collet, either with the old pin or a new one that gets trimmed to length after fitting without damaging the spring (this is how it's done). All that done you're now "that much shorter" and it doesn't look like you have any extra spring at the stud to let out, so if a balance with screws you'll need to add a fair few timing washers or your 18000 bph watch is now like some of the old Lecoultres beating at 20222.1 point

-

Hi Willow as long as you have 5 sided cutting broaches and smoothing broaches you will be ok you will some time need to trim a bush using a bulls foot file (look it up). I have a full selection of needle files used for a variety of jobs, they are always usefull.1 point

-

Hi Best practice is to fit the pinion on a piece of brass wire that fit snug so as not to crush the pinion. http://blog.watchdoctor.biz/2018/02/11/what-is-a-cannon-pinion/ This link will explain how to do it. with pictures to help with the explanation. cheers1 point

-

Hi Peter and welcome to the forum... The indiglo watch uses a thin layer of phosphous as the light source a voltage between 150 an 200v AC is applied and the phosphoursr which then emits photons and therefore light . A 1:100 transformer inside the watch converts the low battery voltage to the 150/200v needed to drive the light, So if the batteries are in good order then the electronics with in the watch have failed in some way.1 point

-

That Schaublin brass ring is smart. You could make something like this without too much difficulty in brass. Back to the original question, I think simply that ring/stepped collets are going to be more accurate. But there are advantages to using an adjustable chuck - you may get deeper jaws and you can customise your own jaws. I made a set of smaller brass jaws for one of my Burnerds last week so that I could increase the maximum capacity. I also prefer brass jaws on some watch cases.1 point

-

Ok, I stripped, cleaned, rebuilt, behaviour was slightly different but still similar, repeatable time gain/loss on the minute. So went through it all again and I finally managed to diagnose the issue, and partially fix it... but then made it worse! It wasn't the 4th wheel itself, but the tube it passes through that is part of the main plate, it was slightly out of true, by pushing it in various directions I could remove the erratic running. It then just ran consistently fast and with higher amplitude... however, I should have left it when it was 'good enough' rather than trying to get it 'perfect'. In pushing it back and forth I loosened it (it is a push fit in the plate) sufficiently that now it barely runs at all I have a spare main plate from another 2390 from the same ebay lot, so will strip everything again and rebuild on to that. It seemed incredibly sensitive to the alignment of this, I guess at some point it got damaged while fitting hands or something? A good learning experience anyway, another thing to bear in mind for future projects to keep an eye on.1 point

-

The original crystal looks close to the profile of a standard Sternkreuz HW. An extra high dome might be what you'd use for a chronograph watch.1 point

-

I've put a 6r15/Ne15 in my SKX. Just because I could. Swapped the stem and crown to have access to the hacking and handwinding capabilities of the movement. There's a few other little parts you need to take off a 7s26 to convert a 6r15/ne15 to run a day wheel. It's a little easier to regulate to a more stable positional variance and has a longer power reserve. But I still don't know how to fully strip down, clean, oil and reassemble. I know my limitations and It's something I'd love to find the time to do but I know I can't commit the hours at present. I think crystaltimes has a display caseback if you want to see the machined rotor striping. Also, most Seiko dials and aftermarket modding dials are the same size, some are for crown at 3 and some are for crown at 4 but snipping the dial feet and using dial dots can mean you can use most dials at 28.5mm. If that helps. Good luck with your new venture and yes, Mark Lovick has a great series of 4 videos (freely available on youtube) where he strips down and rebuilds a 7s26a movement. These movements have very similar architecture, with the 6r15/nh36 etc having been built off the back of the 7s26 and having some swappable parts.1 point