Leaderboard

Popular Content

Showing content with the highest reputation on 06/07/17 in all areas

-

All links and content removed. We take a dim view here of members who sign up with a sole agenda for promoting their wares, much much better to become an established and respected member of the community by contributing in a meaningful way like everybody else does3 points

-

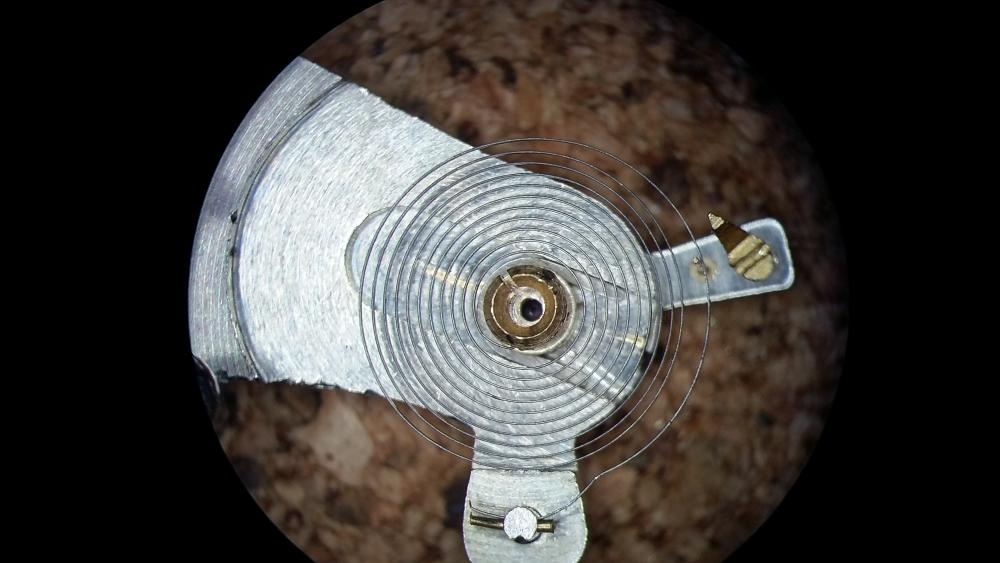

So it's been a few months since I posted here...but I've been regularly checking in. Hi Mark and Geo! So as a few of you know, I have a hobby of building watches. The one thing I hated was relying on some of the very few companies that actually print dials. Here is the USA there are only a handful that do this type of work! I was lucky enough to find an antique dial printing machine on eBay. It was just a vessel to move the dial from printing plate to paint application. I found a willing company to "Fill in the Blanks!" I won't name them here because I don't want to seem like I'm Selling this company! Anyway, they were a very big help when it came to me having questions. The sales, engineering and billing staff were first rate! They helped me pick the proper printing pads, helping me design and then produce my printing plates and then help me choose the proper ink and also recommended how to prepare the inks, pads and thinners to get the best results! So, here I am....First try at printing a dial.... I designed the dial myself using a free online software. The dial is printed in 3 stages. The first step was printing the hour chapter. Then, the second step was to print the sub seconds chapter. Lastly, I printed the name of the manufacturer that I will be using for this build. This was more of a proof of concept to me...Now, I can't wait to try new designs and styles! And, Now I have more control of what I build! That's very important to me...Cheers!2 points

-

Old post, but if you have some basic tools you can make a simple presstool like this. I use it on pendant tubes as well as pushers.2 points

-

ah the Timex Electric is a fantastic series of models. The first tip I can advise is to get a can of CRC QD Elecrtic Cleaner. This is used to clean the contact point which makes and breaks to the balance staff. You than follow with applying lube to pivot points and the train area near the battery compartment. Noting you location as York Pa reminds me of the once in a life time opportunity I had to acquire a mega load of vintage Timex watches. These had belonged to a gentleman named Fred Symthe who had worked at Timex and specialized in the "Electric" watches. More of that to come in future posts. Also as an introduction of myself, - I was a member of the "second" Timex forum on Network54. That is where I learned and shared many years of vintage Timex repair. Here are a few recent restores that I applied the above technique to.2 points

-

I love mechanical things, not least the watches, clocks and other mechanical hardware. To be able to repair watches have been a wish in a really long time. Unfortunately I have not had a real place to practice and must recognize that doing it in the kitchen just cannot be reconciled with the family. That is why I am now going to remodel our 70 's garage into a workshop and hobby room for joy for me and the rest of the family. It is anyway too small for a modern car. The garage is at about 6.8 x 3 m. and there for approx. 20 square meters. The redevelopment will be extensive as i have to make heating and floor heating window and a small kitchenette. I am now almost finished clearing out the garage so that the work can begin. I will put up some pictures every now and then as the project progresses!1 point

-

If you folks get tired of me posting my watches, just let me know! I wasn't sure how a white dial would look as a pilot style watch. I got really lucky with the Printing of this dial. It turned out very clean with nice, sharp edges.. BTW, I test all my watches with the same strap...no, I didn't buy hundreds of them!1 point

-

The Seitz manual can be found here http://ihc185.infopop.cc/helphand/pdf/seitz.pdf See page 221 point

-

1 point

-

I googled a bit more and found someone who had wiped/cleaned a dial using a light oil. So I put a couple of drops of 9020 oil on a cotton pin and gently wetted and dried off the dial. And indeed a lot of green stuff (oxide?) stuck on the pin leaving the dial in the shape below. Not too bad considering.... Any comments or feedback on this is appreciated. Sent from my iPhone using Tapatalk1 point

-

Have a look here. It shows you how to use it some way down the page. http://www.geocities.ws/dushang2000/Jewelling.html1 point

-

1 point

-

I have been reading about this with great interest. The problems one can come across when you have too much wear at the ends of the barrel arbour. Not only can it foul the centre wheel as Mark has pointed out. It can cause any amount of wear, from the ratchet wheel teeth wearing down which can cause slipping when trying to wind, crown wheel wear which can affect all the winding wheels, the barrel bridge can suffer by being rubbed by the ratchet wheel and the barrel teeth can wear to be uneven. Jewels are the best to use that is if you can find the right one like any bush you use it is down to the right one. Bronze as you know is much harder than brass that would be my next chose. If you have the means and experience, you should be able to turn some bronze rod in your lathe to the right measurements. You might find the thickness of the plate is poor, there for the best thing to do is buy a new barrel bridge or bottom plate depending where the wear is, if not available try to find a suitable donor movement.1 point

-

Today's watch! Not my creation but I've always wanted one..I just picked this one up off eBay for $80. Its from 1995 and its a Seiko Diver model 7002-700a. It has di directional automatic winding, but without manual wind or hack. Popular with "modders" today, you can buy all different kinds of dials, hands and bezels to totally change the look of the watch. I think that's awesome! Whatever brings more people into watch collecting I'm pretty much for... speaking of which, though this looks pretty much stock, it has a new dial, chapter ring and bezels insert. It was "serviced" as well...so the listing said. But when I received it, it was running about 3 minutes fast a day.... Oh well, I regulated it and now it's running very accurate now... This is kind of my "beater" watch. I'll wear this if I'm doing work and the house or in the car. Great watch!1 point

-

if my memory serves me well I think that was the issue with the watch i repaired.1 point

-

I really love Breitling watches but with our weak currency buying a new one is simply out of the question. So after saving I finally managed to buy my first used superocean. After the first day the watch would just stop erratically. So I tried some local watchmakers who refused to touch it. I needed to see if the movement was real (allot of good fakes here) and being worried about the fault, I decided to go online for help. After watching Mikes tutorials I plucked up the courage to buy a case back remover and opened it to see. I saw that the ratchet wheel screw was laying loose in the case. I called Breitling SA to ask what a service would cost. They informed me that they would not work on the watch as it had been opened by me. I replaced the screw but then the stem got stuck! Thinking I was buggered I turned to Mark's tutorials for help (as no one else would help). After half a day of struggling with really cheap tools I am proud to announce the she is purring along beautifully and 100% functional! I am sure it is not advisable to attempt your very first watch repair on a Breitling but not having a choice I had to. Mark I cannot thank you enough! Your videos turned this poor soldiers nightmare into a dream come true.1 point