Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/16 in all areas

-

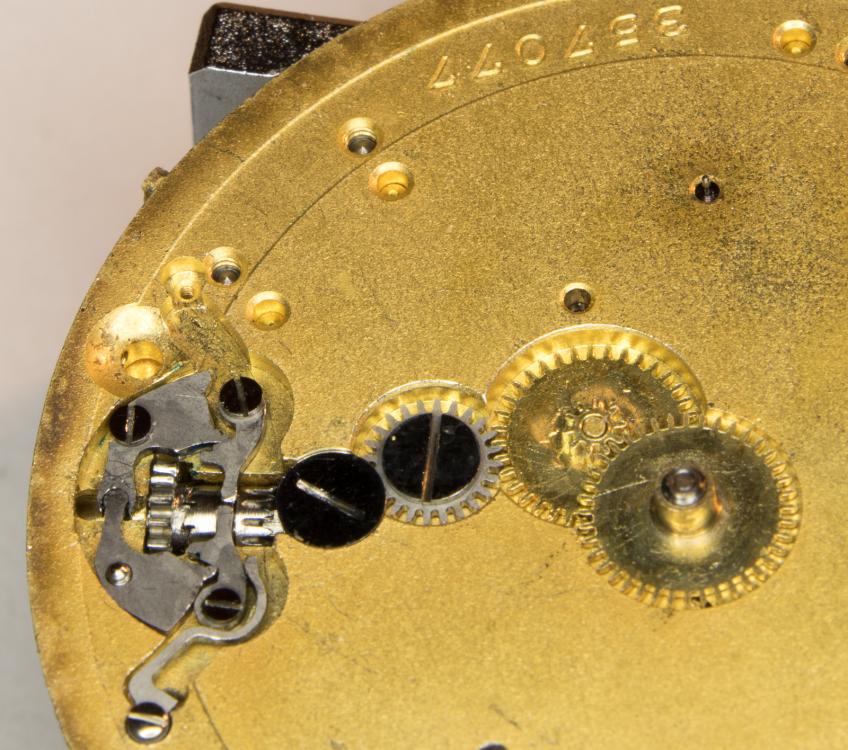

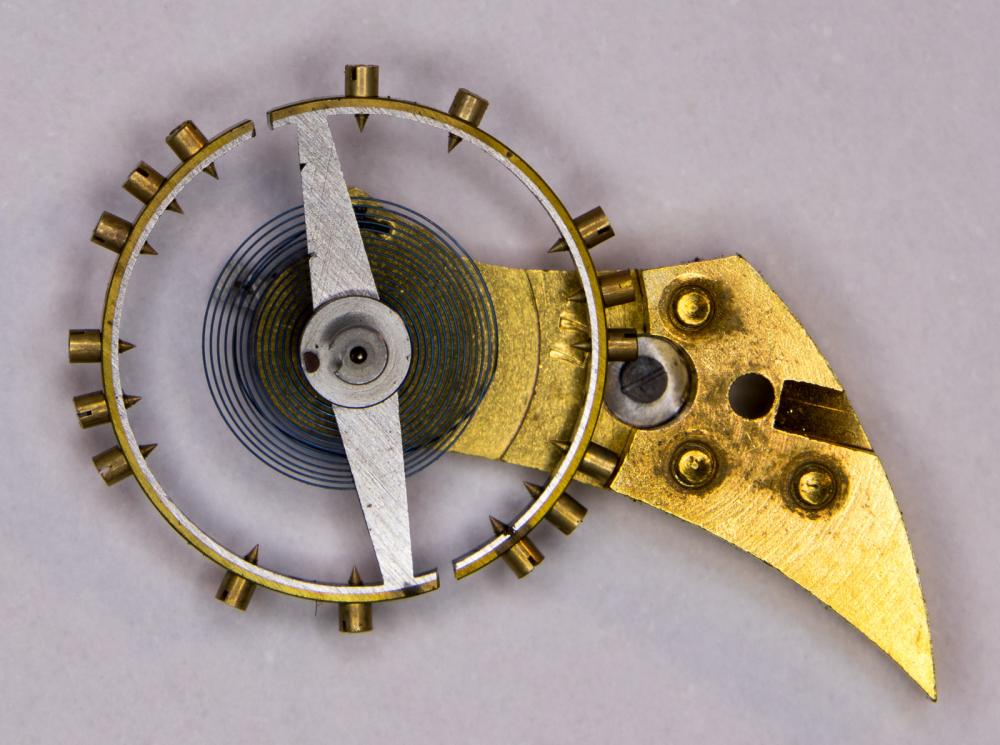

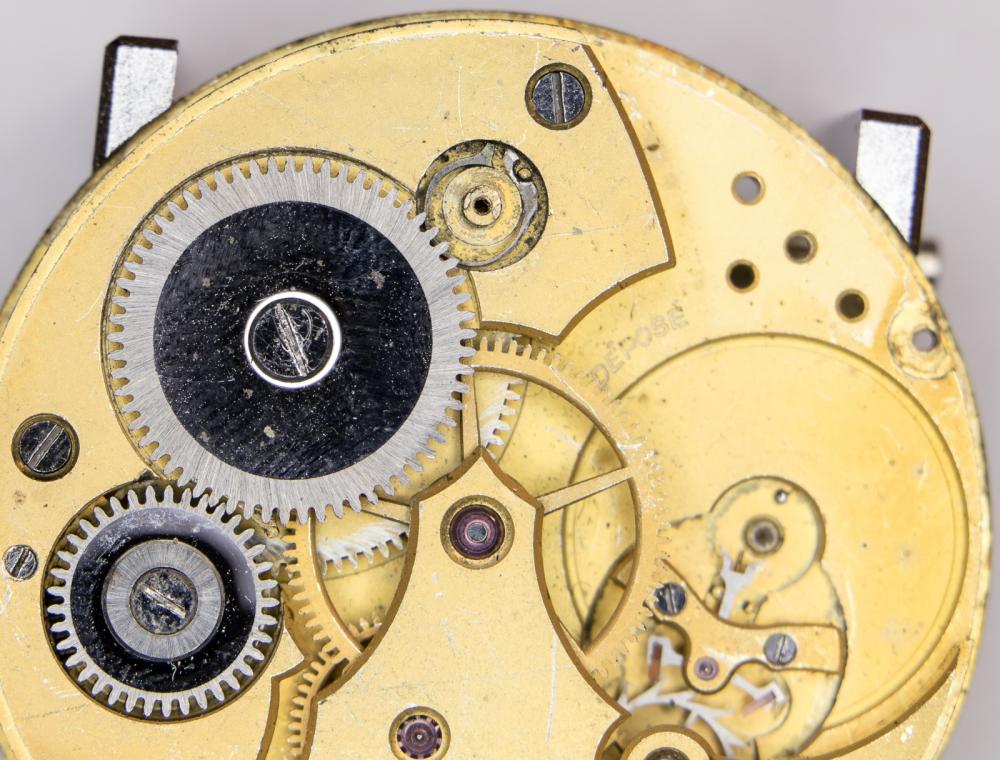

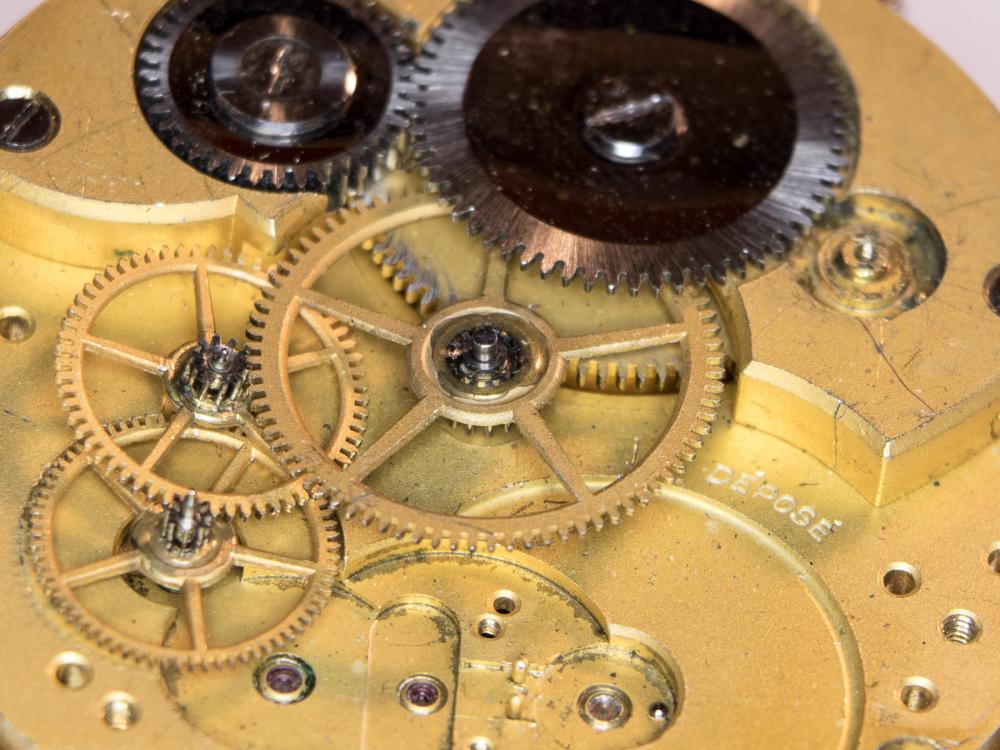

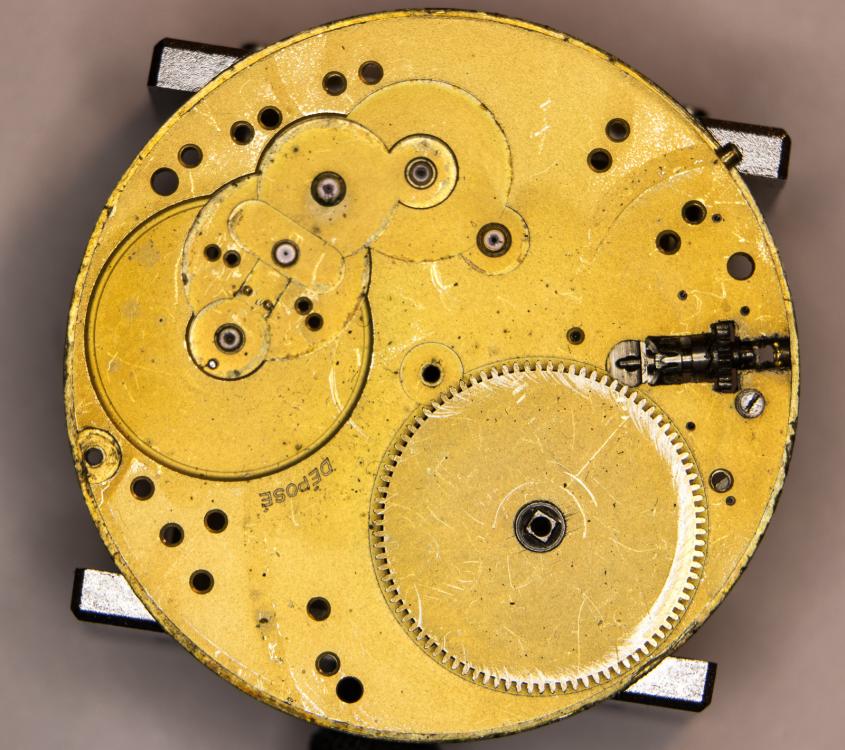

Thank you @szbalogh! That makes absolutely sense to me. I totally overlooked this important sign. This is why it makes sense to publish this on this forum. It would not have occurred to me. I'll keep that in mind. I am now finished with it. Here is what the timegrapher told me BEFORE (Dial down) Beat error 0.7ms Angle 135° +320s/d AFTER (Dial down) Beat error 0.5ms Angle 270° +100s/d Here are a few more pictures. Some of them are merely for the sake of taking the pictures. I love crawling inside the movement with my huge DSLR2 points

-

Those marks on the edge of the barrel are telling me that the arbor is not or was not upright. It can happen by worn out bushings or if the barrel bridge is not placed back correctly. The edge of the barrel was sticking to the bridge cousing winding hard. This also explaining the marks on the crown wheel teeth and the broken stem. Excellent pictures and presentation2 points

-

Lots are available https://www.abebooks.com/book-search/title/know-escapement/ from $30.1 point

-

I will make an adjustment next week. If the issue isn't resolved. Will video but it's a bit like sitting there waiting for paint to dry. If I spend anymore time upstairs now I think my Mrs will shoot me. I know there's power through the train. All the wheels and teeth are good, including all pinion gears. Sent from my SM-G920F using Tapatalk1 point

-

It's not the balance you need, it's the regulator. Only £6 unless you have an adjustable stud carrier in which case £101 point

-

1 point

-

To understand this theory please first imagine a straight line drawn through the escape wheel pivots, lever staff pivots and balance staff pivots. when this line is created the lever must also follow, the spring must be quiescent or in it's unstressed condition with the roller impulse jewel resting in the centre of the lever forks slot, this position is the most favourable for impulse, because a small impulse is sufficient to unlock the escape wheel and energize the balance under the least resistance of the spring. This is essential if the escapement is to be self starting from the run down condition. The quiescent position of the spring is then the centre line of the escapement. *Please note that the diagram you provided is how the escapement works, and all though figure (C) shows the correct positional locations for the pallet and escape wheel tooth for the escapement to be self starting, the angle of the lever is not ideal, it is not straight and will create an oscillation that is not isochronous. When the line is created an escape wheel tooth must be over either the entry pallets impulse surface or the exit pallets impulse surface, either is sufficient to create a self starting escapement. The creation of this centre line is also a must for the escapement to be in beat. The position of the banking pins is crucial if the unlocking, impulse, lock and run to the banking is to be set correctly, this will require most careful and precise craftsmanship if the escapement is to work well. Most tedious examination will be required to set these correctly. Keeping close attention to the locking depth and drop of the escape wheel teeth to both the entry and exit pallets. I hope this explanation helps.1 point

-

Thanks for pointing this out I completely missed that when I first looked at the photos, but once pointed out its very obvious. Its tips like this on things to look out for that are very helpful for someone like me just starting out.1 point

-

If you can find a copy of 'Know the Escapement' by Sarah & Homer A Barkus it goes into great detail about how much clearance there should be, but they only printed 5000 copies in the 1940s, so its hard to come by, but they do turn up on ebay.1 point

-

1 point

-

1 point

-

1 point

-

Cleaning the mainspring in situ is a really bad idea. Where does the old grease & crud etc go if the spring is still in the mainspring.1 point

-

these new semi sealed main spring barrels sound like a good idea. if it works, "leave it alone". that applys to the older ones also. unless it;s rusty or broken; leave it. it can be tested - early in the dissembly by removing the balance and fork. (don't forget to let down the main spring tention FIRST). most new guys don't read the old posts. vinn1 point

-

All mainsprings doesn't matter if its a watch or clock spring should be cleaned. Cleaning will remove dirt, old oil and old grease. If undertaken properly the movement will work much better. You don't need a mainspring winder it can be done by hand, although if its a clock spring I recommend a clock mainspring winder this will prevent distortion of the spring and help the clock to keep good time.1 point

-

You do not necessarily need to winder to place back a mainspring into the barrel. If in doubt, leave it alone, it's not something that crucial especially for a beginner.1 point

-

1 point