Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/16 in all areas

-

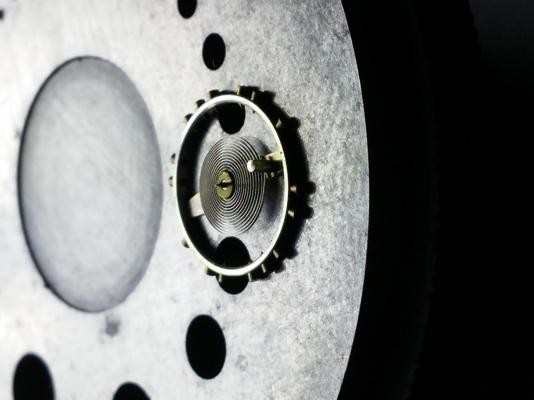

I have over the years refinished a few Speedmaster MkII cases for friends. They are fun to work on as they are,usually quite beat up och the surfaces have been polished a few times to many. Last week a friend of mine told me that there was a 1970 MkII for sale on a Swedish auction site. I was born 1970 so this watch I just had to have! On Sunday when the auction was about to close the website where the auction was held started to act up and I could not log on......... About thirty seconds before it closed the webpage loaded and I was able to submit my offer....then it was down again......did I win or not!!??, I waited for the usual confirmation mail when you have won an object and five minutes later I had mail, -Yesssssss..... The watch arrived On Tuesday and looked like this: Not to bad, but the sunburst was gone and the top surface had......"straight graining" .....I guess the previous owner used a abrasive rotating mop or something! The case was practically free of deeper scratches and dings so a good prospect for a lapping session! The case was stripped and I started with the sides: I do this part in my small Boley lathe with 90mm discs that I have made and a small tiltable table to set the angle. Depending on the geometry of the case you can either slide the case directly on the table or use a adaptor to get the right angle - in this case no adaptor was used. First run on one side done: First disc is 400P so you have to be careful, especially with the start/edge where the case can grip the disc - and you do NOT want this as you will have a case with scratches in places they where not intended to be! After 400P I move up to 1000P and finally a last run with 2000P. This usually gets the surface almost up to mirror finish but,a quick final touch with a mop gives it,that final shine. When the surfaces are flat and when needed polished, it is time to grain the sides and lapp the sunburstpattern on the top. This is done in a small mill I have with a tiltable spindle using a 305mm rotating disc and another home made tiltable table. For this case I use a 120P paper so you really have to take it slow and be sure all the angles are set up correct or the disc will chew material in places you do nor want it to! The result I was not 100% pleased! There where some spots there the graining did not go al the way up to the grained edge around the glass. This was obvious in the pictures and reflections in some angles on the wrist - I relapped to top surface.... Some grease from my fingers on the chamfer in the pictures but the graining is better now! I am waiting for a NOS dial and crown - when they get here I will strip and clean the movement as well.2 points

-

I picked this up from ebay for a restoration project and I wanted one anyway, so the resto so far is going well. All the holes in the box have a punch of some type, will upload images when it's finished. It cost £33.00 or $43.00. last 3 images are: rusted in box, after soaking in white vinegar, and soaking in 3 in 1 oil.2 points

-

2 points

-

Well I understand what you mean & am looking to branch out I just didn't know what others were available.& parts for them. Perhaps you can steer me. In the right direction. I thought staying American would make things easier. What are your thoughts on "Trench" watches? Also that Hamilton isn't my only watch. I have . I have six other pocket watches of different brands & styles and two wristwatches all restored. I also have two I'm working on now in differing stages of completion. I will post them a bit at a time. With a handshake , Thanks2 points

-

All, I've posted two new pdf versions of the complete eBook for K&D's 1910 "Staking Tools and How To Use Them" in my dropbox (download links below). The first is an improved version of the one previously available with high resolution (1200dpi) images only. I found a mistake in the front cover image and corrected it. Otherwise, the book is the same as before. I've also created a new lower resolution version with full text search. The images are 600dpi and still look good, but the file is now half the size of the high rez version and includes the ability to search the text. I tested the text search in many different ways and the quality of the OCR by Adobe Acrobat it surprisingly good. I couldn't find a single mistranslation. Neither of the files are small, but it's 163 pages so that part isn't surprising. Enjoy! Tom1 point

-

Hi all Well, after a very long time lurking, I thought it was about time I joined this forum! My name is Olivier and I live in the UK, in the South Coast area. I have been a watch collector for a many years. My interest (obsession?) for working on watches started a few years ago, with a cheap tool set from ebay, and the plan to customise a Seiko SKX. It turned out great, and by then I was well on that slippery slope! A few years down the line, I have a little workshop area setup in my house to practice and enjoy the hobby. I mainly work on Vintage Mechanical Seikos. I have learnt so much through reading threads on this forum, I hope I will be able to contribute as well. I will conclude my first post by thanking Mark for sharing his knowledge on his youtube channel - It has been inspirational for me, to the point that I have now decided to take the hobby to the next step, I will soon be starting formal training with the BHI. All the best Oli1 point

-

This Hamilton 912 is project I recently completed in May. The movement just needed a good cleaning. The dial was a mess & the case had a lot of dents to remove on the back.I broke out the Dremel to remove the many small scratches . The crystal was badly scratched and plastic, installed a new glass nos crystal.1 point

-

1 point

-

Vintage Cherry bench from the Joseph Bulova School of Watchmaking in Woodside, New York My Bulova Watchmaster ultrasonic and an older L&R cleaner Work in progress: Parts and supplies: Larger tools and more supplies: Various Horotec presses - Crystal, case, hands, crown/pusher tube press. Some other crystal presses including a BB. Timing machine is on the right. Ultrasonic and steamer Lathe - in parts awaiting cleaning.... Waiting their turn:1 point

-

1 point

-

Adjusting pivot lenght (endshake) is done by trial and error, file down a bit and then try it.... until it has no endshake but spinning freely. Pivots are shortened (and polished thereafter) on a Jackot tool or on a dedicated pivot polishing tool:1 point

-

1 point

-

Some self-made "tool makers" here are excellent, posting greats threads and pictures rather than grumpy condescending statements.1 point

-

My "new to me" 7t42-6a50 Too much gold on bracelet and a link too short fort true comfort so just ordered a brown stingray leather strap.1 point

-

Hello Christopher, Welcome to this friendly forum. Plenty of info for you on here. For starters if you are seriously going to make a living at this then you need very good tools, there not cheap, but will last a life time.1 point

-

These are before and after pictures of my just completed restoration Waltham size 18 15jewel 81 grade model 1883 sterling silver hunter case pocket watch. The only thing I didn't do myself was fitting the new balance crystal, because I don't have a set of staking tools. I'm very pleased with how it turned out.1 point

-

Well, instead of buying a set, you might try and find some individual pieces that are not that expensive to start. First, an anvil which can be as simple as a metal block with some holes in it. Better is an anvil that supports the punch and keeps it square to the work, I've seen serviceable ones sell on the bay for not much money. Unfortunately, the punches are very specialized, and I can't think of an alternative off the top of my head. They are, however, also available individually or in groups both new and used, and can be inexpensive if you are willing to clean them up yourself. I was patient, and finally found a serviceable set used that I purchased for a bit more than $50, you can probably do better than that if you take your time. My suggestion would be to download and study material that @tomcolson has so kindly made available here - http://kanddinverto.weebly.com/ and then hone in on the items you need to do the jobs that you have at hand.1 point

-

I've been using Kleenstrip VM&P (Varnish Makers & Painters) naptha, it seems to work OK. The following is from the MSDS which is on their site. The CAS# is a standard chemical ID. CAS # 64742-49-0 Hazardous Components (Chemical Name) - Hydrotreated light naphtha Concentration - 95.0 -100.0 %1 point

-

if you check the side of the lighter fluid cans of various makes then you will probably get as near to it as possible for what you want ie Petroleum Spirit - Light Aliph (Naptha). I found a tremendous variation in the fluids but look for "Extra Refined" on the can and the only substance to be stated as being Naptha as in some cases the light Aliph is diluted by kerosene / parrafin. All companies are obliged to publish a sheet to state what is within their product and for instance Zippo is a mix of Naptha and Kerosene where in the past it used to be pure Naptha and was probably degraded for financial reasons. Note that it is not always the expensive ones that are the purest. In any case as someone who just works on one watch at a time I use the lighter fluid for the first clean and Isopropanol for the wash. You may wish to keep the Pallets out of this for fear of melting the glue / shellac. A handy test for any liquid given by George in this forum is a few drops of fluid on a clean mirror allowed to evaporate then wipe the mirror with a black cloth if you get a white residue don't use it. Cheers, Vic1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)