Leaderboard

Popular Content

Showing content with the highest reputation on 08/04/16 in all areas

-

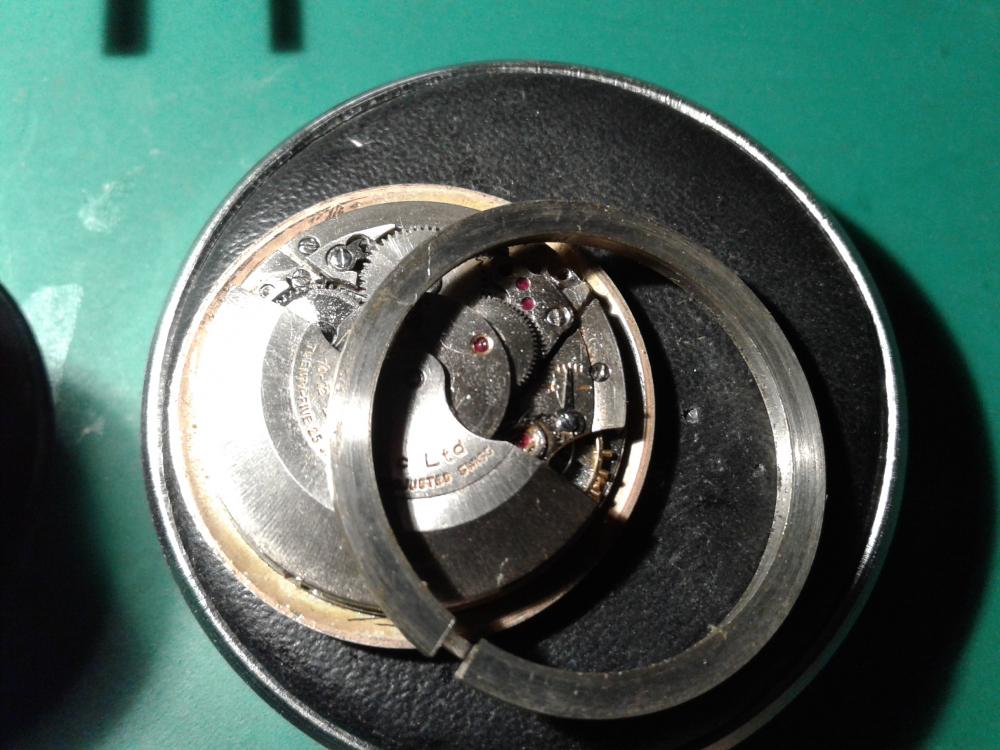

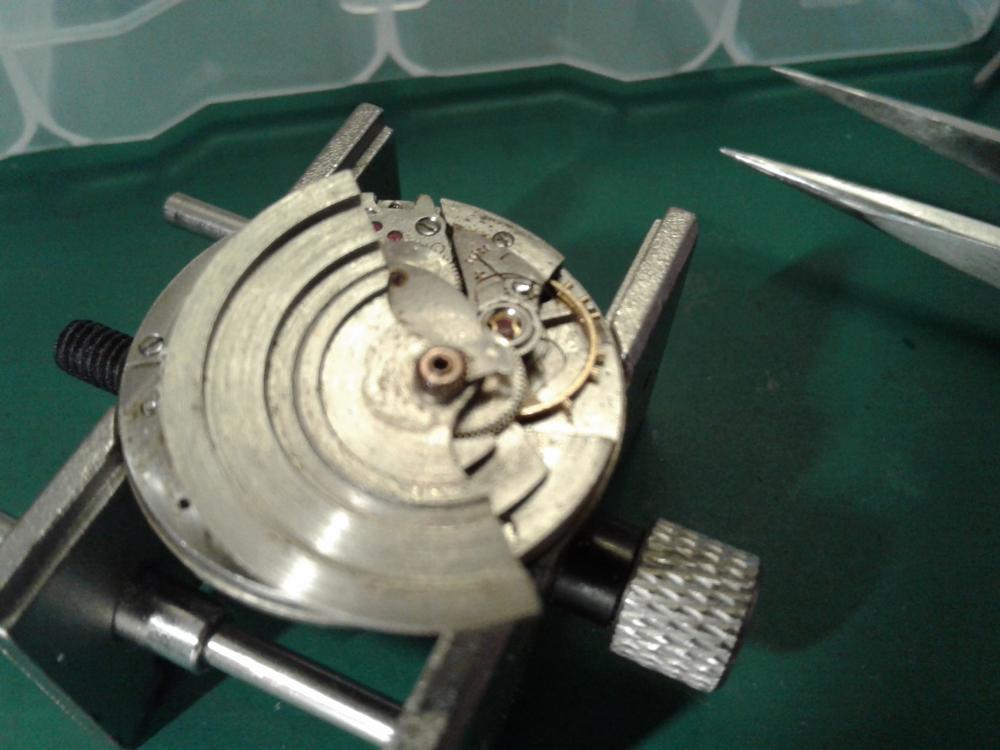

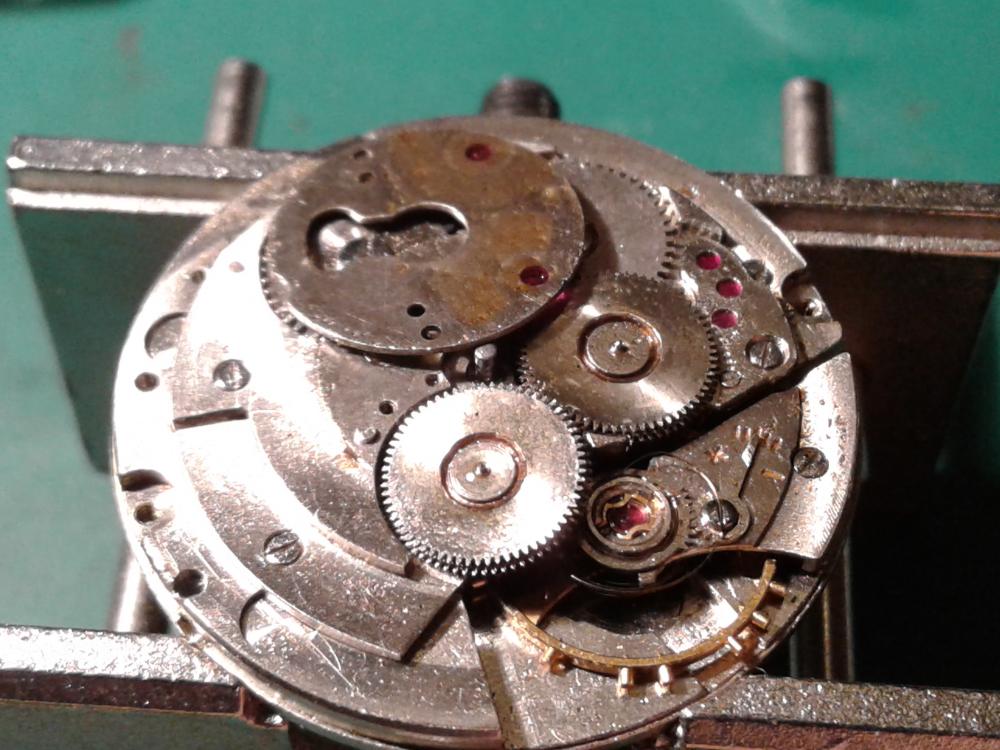

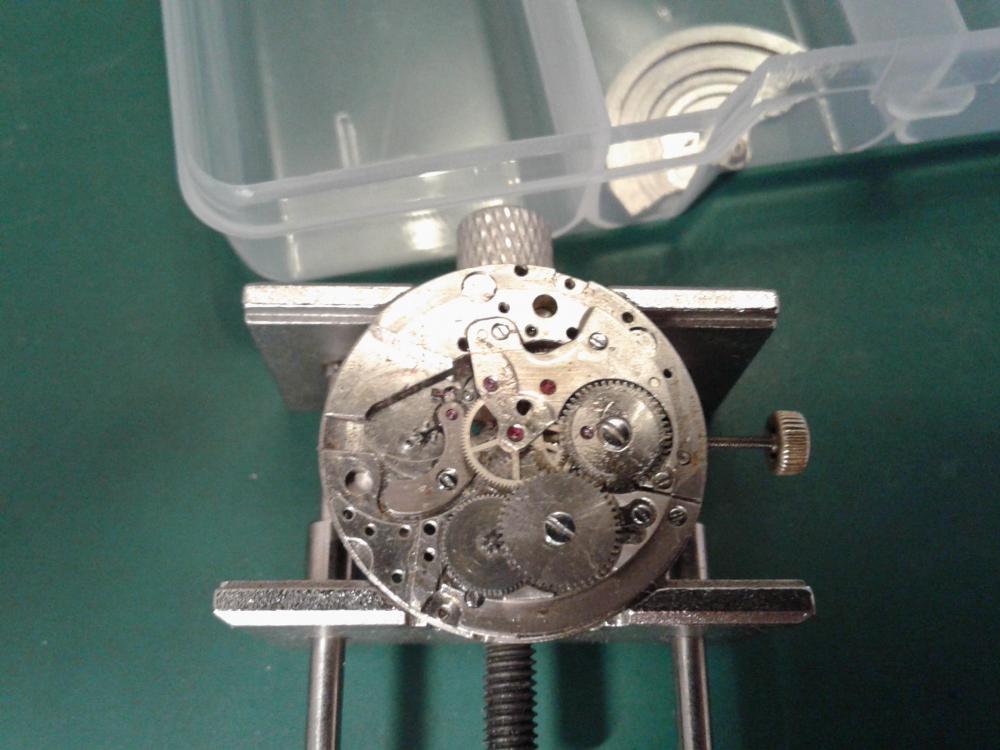

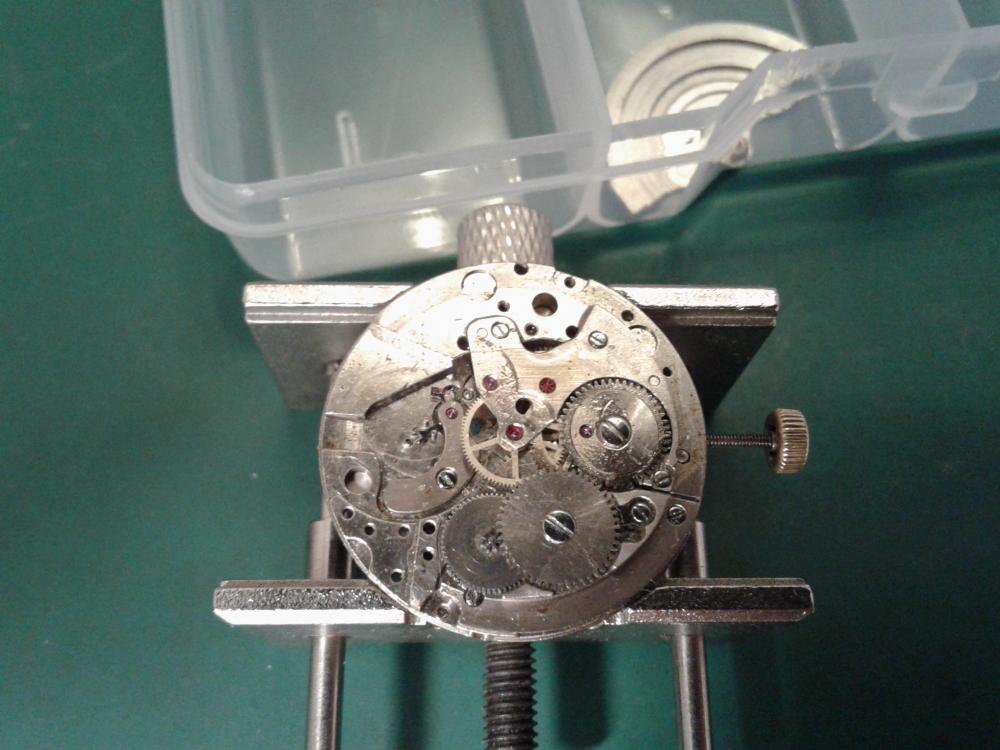

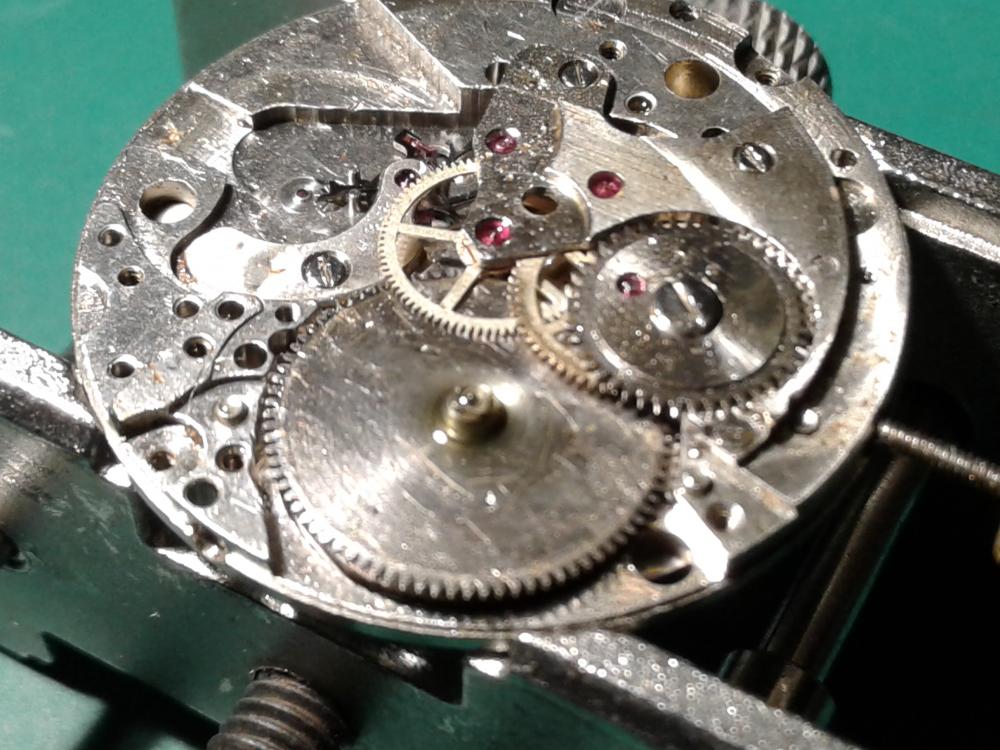

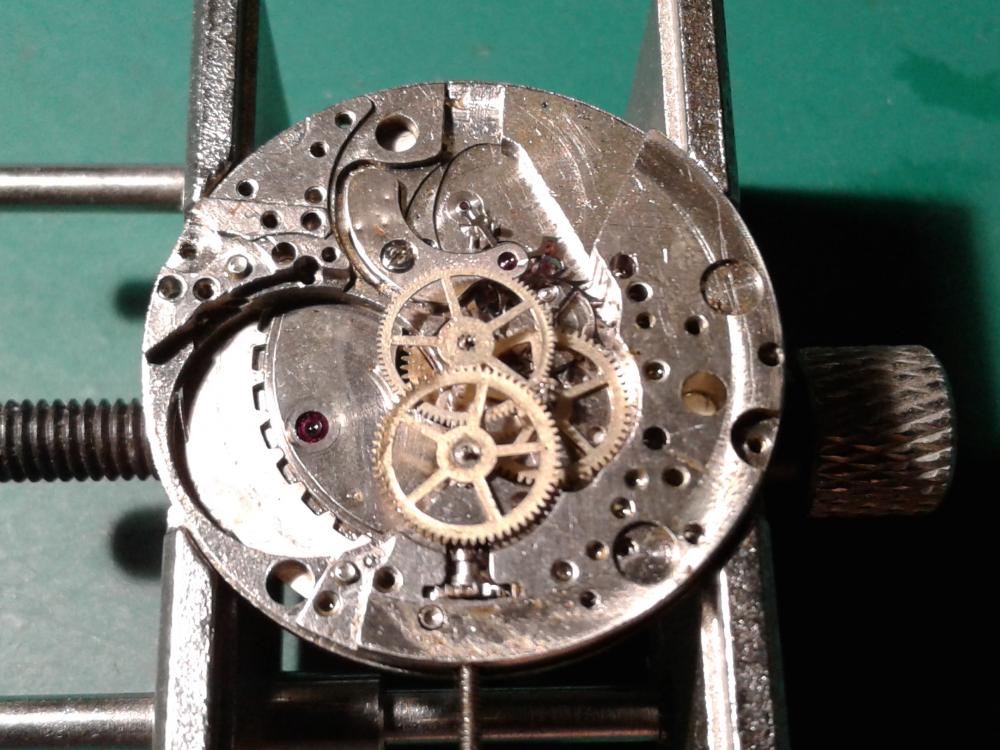

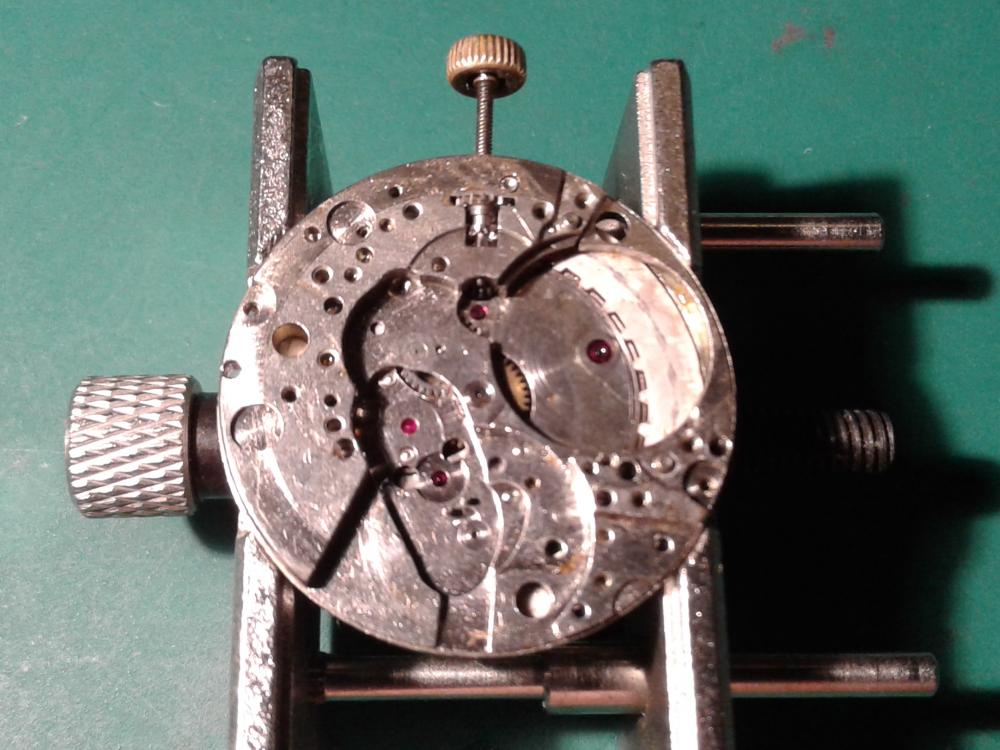

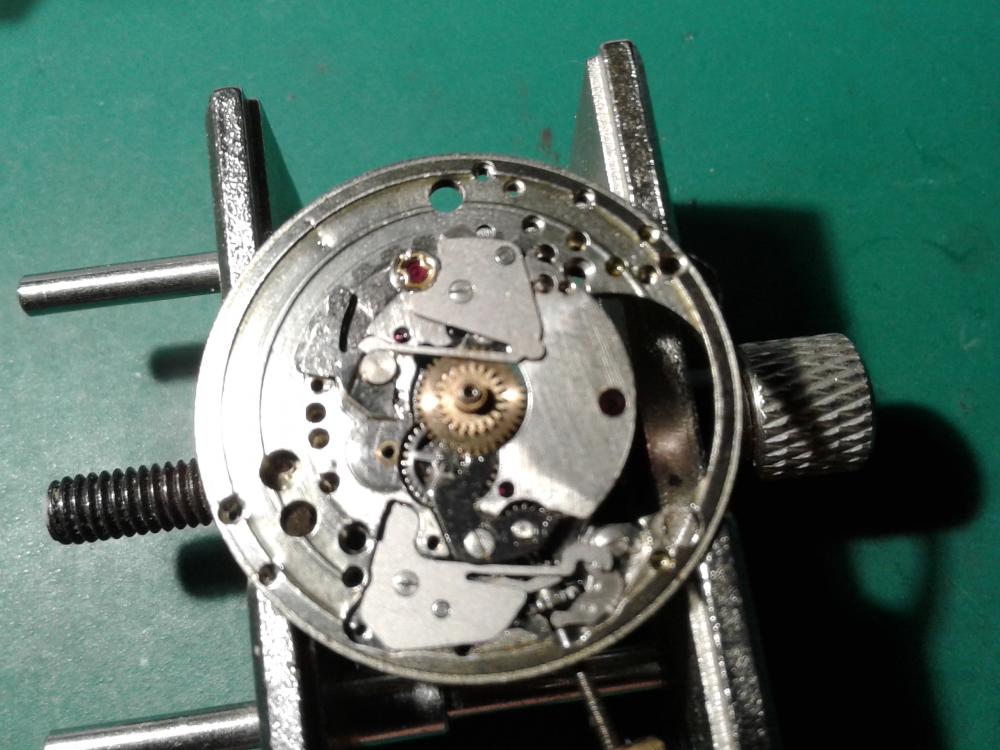

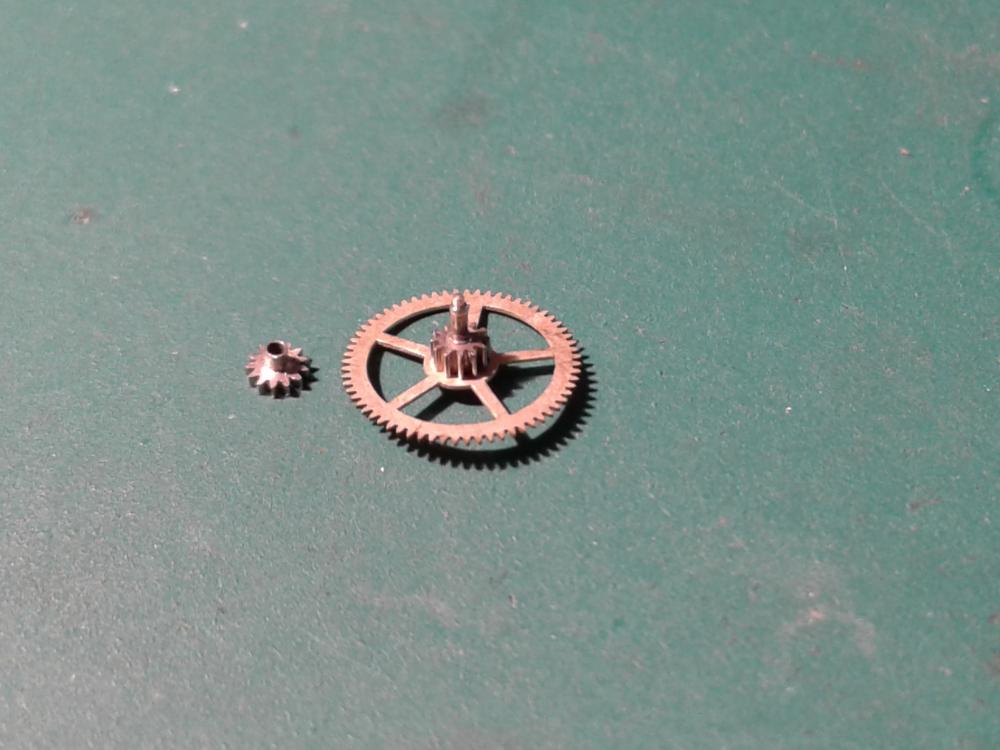

I was lucky enough to win on the bay a Zodiac 70/72 automatic at a reasonable price. I knew the hairspring was shot but wasn't expecting what I found. On receiving the watch and opening the bag I thought I know that smell "OIL" Looks ok dial needs a bit of a clean but the case is in good Nick. The back shows hardly any wear so a good polish should sort that out. So I open it up and once again the over powering smell of 3 in 1 hits me like a slap to the face. The stud holder has come off but luckily is in tact. I start to strip down the movement. Out of the case and case ring removed. Dial looks ok hopefully dust a light wash in soapy water will get rid of the oil and remove alot of the spotting. Dial removed and my first glimpse of oil. Flip it over and take a closer look it the movement the hair springs a mess and the balance is wobbling like a 16 year old on a night out. Rotor off. Reversing wheels a bit of staining and more oil. Auto wind wheels and balance removed now like a fool I forgot to take a photo of the spaghetti mess of the hairspring and the staff had a broken bottom pivot. I decide to drop John at obsolete watch parts an e-mail and luckily he has a complete balance at a very reasonable price and further more if I post the movement to him when I've cleaned it as we are unsure whether its the correct one for the movement as according to J boreal the base caliber was a AS 1649 he will try it before I buy bit now that's service for you . Look at the oil its dripping in the stuff. crown and ratchet wheels Now the barrel on this caliber is a sealed unit and has wrote on it very faintly do not open. But I'm not worried about it being oiled it has enough oil on it to last forever. Look at all that oil its been dipped I'm sure. Barrel out. Train bridge off. That side is stripped just alot of oil and a bit of staining. Dial side more oil date ring a bit stained. Oily That's It stripped down and ready for the ultrasonic. The cleaning went well and the assembly was just a reverse of the strip down. I then sent the movement of tho John and he fitted the balance and returned it all within 2 days the man's a star. On reassembly and leaving to run after I had adjusted it on the timing machine I noticed the hands were only moving 5 minutes in the hour. This was the culprit a slipping clutch wheel on the offset cannon pinion. Luckily Rogart69 heard my call for help and directed me in the right direction as to how to tighten it many thanks to him. So here it is running nice and looking good.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

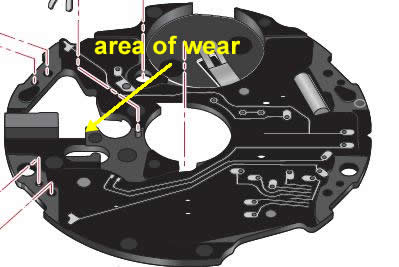

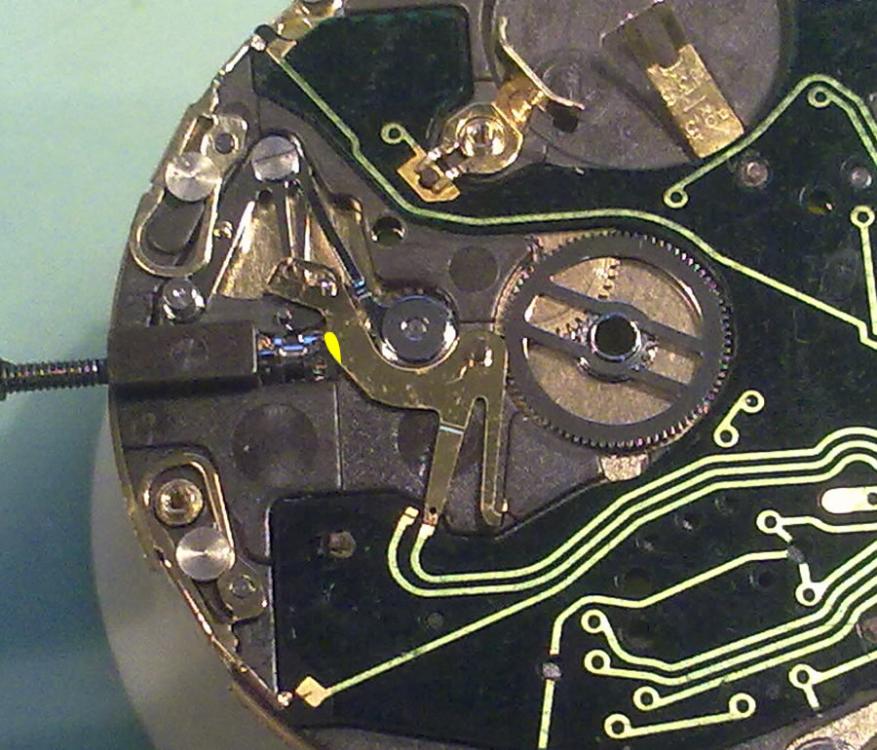

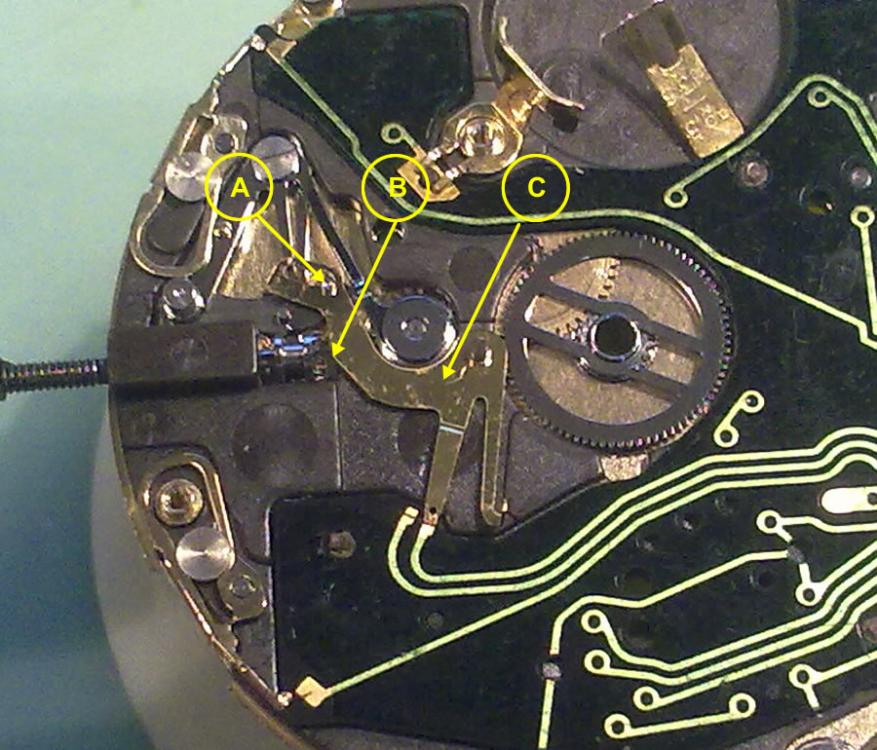

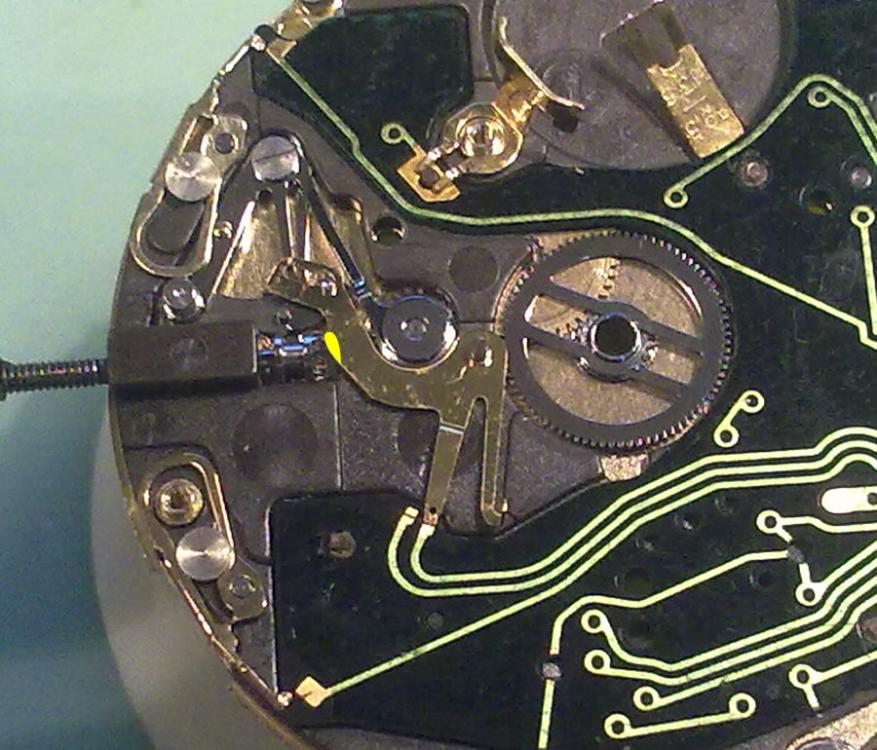

I've just serviced and refurbished a Tissot P372/472-1 chronograph, this has the ETA 251.272 movement. There was a problem with the keyless works. After reassembly and setting the stem to normal position, then second and third position and repeating this a few times, the centre second stop lever which is also a switch, 'C' in the photo, tended to jump off of the setting lever stud, 'A' in the photo. On close inspection of the lever, I could see that the tip of stem while set to normal position was jamming underneath the stop lever at 'B' in the photo and lifted the lever off the the setting lever stud. The solution was to remove part of the stop lever, indicated in yellow, at the point of interfearence as shown in the second photo. It seams that over time, the tip of the stem had worn away an area of the electronic module, thus allowing too much travel of the stem. Finaly, the finished Tissot P372/472-1 with ETA 251.272 movement. I love it.1 point

-

Hmmm. Sometimes rental properties are sold on with sitting tenants... I would have offered to buy, but I have my matrimonial credit score to manage, not to mention my WAGES (Watch Acquisition Greatly Exceeds Servicing) rate! And you never know when the ideal Chronostop will show up on eBay. ;-) S1 point

-

If you are unhappy that the bezel doesn't rotate, then I will happily look after this watch for you to resolve your misery1 point

-

Well spotted Eric, This looks to me like the pivot has broken off, not worn. It's quite possible that this happened during repeated disassembly / assembly, so dont be disheartened if you fit a replacement and still have the fault. However, a damaged pivot is more likely to catch and break when assembling or disassembling so may be the original cause. Take a really good look for the part which has broken off! You don't want to leave anything in the patient that shouldn't be there! Cousins has the escape wheel, but I'm sure you can find one in the US S1 point

-

How you do this depends on the movement. See here... http://mb.nawcc.org/showthread.php?110608-Need-help-Remove-a-stem-from-Elgin-Pocket-watch but as jdm says, you need to know you have got all the pieces out and understand why it broke in the first place. Could be more damage elsewhere. S1 point

-

Gentlemen, we have a diagnosis! On re-inspection, I noticed that the reflection of the escapement wheel pivot (in its jewel in the top plate) was variable as I manually caused that wheel to turn. I disassembled the watch—again!—and find that the upper escapement wheel pivot (on the pinion side of the wheel) is worn away to almost nothing. (See photo). So, indeed the problem was a pivot. But instead of the lower pivot being too tight, the upper one was too loose. I don't have the skill or lathe to create a new arbor for the escapement wheel, so I'm going to try to buy a replacement for it. Thanks for your help, advice, and encouragement. —Eric Sent from my iPhone using Tapatalk1 point

-

That you take it completely apart, clean, check every piece and put it back together freshly lubricated?1 point

-

1 point

-

1 point

-

1. It ran well before. 2, It started to run erratically. 3. Cleaning didn't help. Assuming that the cleaning was done well, this probably means something else has happened to cause the erratic running. This usually happens when the watch is dropped, resulting in.. a. Mushroomed pivots.. if the watch is dropped dial down, the pivot will mushroom at its tip. Perversely it will run ok dial down but when placed dial up, the mushroomed bit will 'hang' on the hole jewel and the watch will stop. b.Hairspring got caught up on the regulator or the regulator has moved as a result of the drop. c. One problem I encountered was where the screw for the pallet cock was not correct, the head of the screw was too thick so that when the watch was dial down the hairspring touched the screw head and resulted in the watch stopping. Worth checking on this. In your case, the original problem could have been a dirty movement but an oversight during the service may have created a new problem. Go back to basics, assemble the train without the pallet fork and balance. put some wind on the mainspring..see that it winds down smoothly. On a handwind movement, you should see a bit of 'backspin' as the last ounce of energy from the mainspring is dissipated. If you nudge the escape wheel and it continues to spin another few rounds then your escapement needs attention. Once you're satisfied that the escapement is fine, remove the train and fit the pallet-fork and balance (the escapement). At rest the pallet fork should be at the center of its travel with the balance installed. Your watch seems to have a movable stud holder so this is easy to do. On watches with a fixed stud holder the hairspring will need to be adjusted at the collet. Here you would also examine the pivots closely and triple check that the hole jewels are clean and clear. Endshake should be present but not measurable, The balance should move slightly when you move the movement (balance installed). Next re-assemble the train wheel and pallet cock, wind the barrel a turn. using a trimmed down pegwood, manipulate the pallet fork to and fro while observing the interaction of the pallet jewels viz escape wheel. Its hard to explain but one stone should catch immediately as the other releases... no dead space. If after all this and it still doesn't work, put the watch away and start with another.. this will relieve your frustration and allow you to come back with a clearer frame of mind after a decent interval. Anil1 point

-

Thanks for all your answers and help folks, the watch is now assembled and in testing - my first complete job as a total service, repair, made a Horween leather strap for it, and cast a sterling silver buckle and aged it. i wanted an authentic look close to the 1940's version, but with an automatic movement1 point