Search the Community

Showing results for 'accutron' in topics.

-

Howdy, y'all, from sunny South Carolina! I'm just starting my horological adventure, inspired by a 50-year-old Accutron (218D) purchased for my 50th birthday last April. There was a sentimental consideration when selecting a family present for a my semi-centennial celebration: What's more appropriate than a historically significant timepiece that has been ticking as long as my own ticker? (OK, before my fellow Accutron brothers and sisters speak up, it hums not ticks.) Before that, my interest in watches was strictly practical and job-specific. As an outdoorsman and Scout leader, my "collection" consisted of G-Shocks, Suuntos and Garmins, with a smattering of analogs from Fossil (yes, I know). Since that fateful birthday, my interest in "real" timepieces has exploded. Who knew one could spend hours window-shopping online for watches on eBay, or watching repair videos on YouTube?! I purchased a second, non-functioning Accutron (N3-218D) with the goal of learning how to repair it. Then came from Amazon shipments of tweezers, loupes, movement holders and all of the accoutrements necessary for the task, as well as the skeptical looks from my lovely wife... I found a source for the appropriate coil that seems to be the most common culprit and stripped the movement down to individual parts. And then ... Without a 20+ power microscope, I'm stuck; thus, the wait continues as I source an affordable microscope that won't draw more severe looks from the love of my life. I've started a small, thought-out and affordable collection of watches, including a new Seiko 5 sport (4R36) and a Tissot Chemin Des Tourelles (Powermatic 80) dress watch. And just this week, I received two vintage (can't believe I'm saying vintage) 80s- to 90s-era Seiko 5s from eBay: a functioning 7009-876A and a non-functioning 7S26C (from which the balance cock screw is currently hiding in the berber carpet of my home office). Along the way, I dragged my teenaged son into this new world. One of his 15th birthday presents was a simple Orient Bambino, and on his own volition and using his neighborhood lawn-mowing earnings, he purchased a beautiful Seiko Presage dress watch for church. I suspect I will be tapping into the vast experience of this forum often as I semi-ignorantly dive head first into this new adventure, and in advance, I thank you for your patience and guidance! -Mattutron (North Augusta, SC)

-

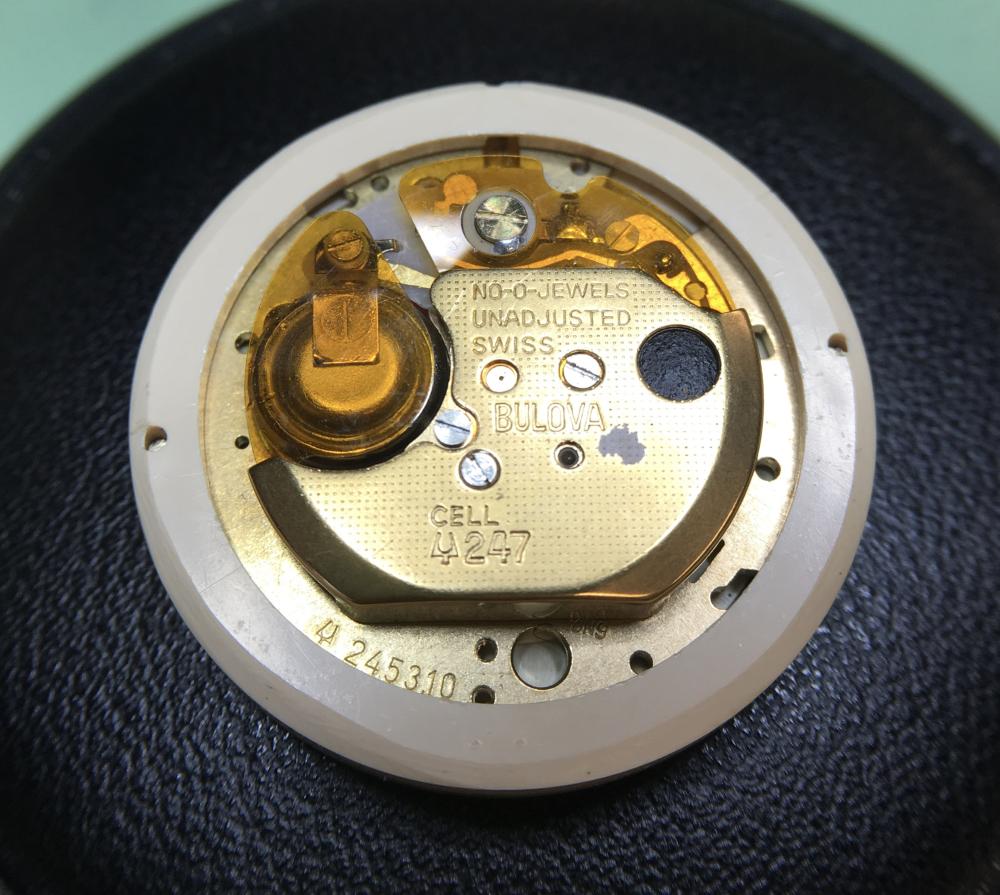

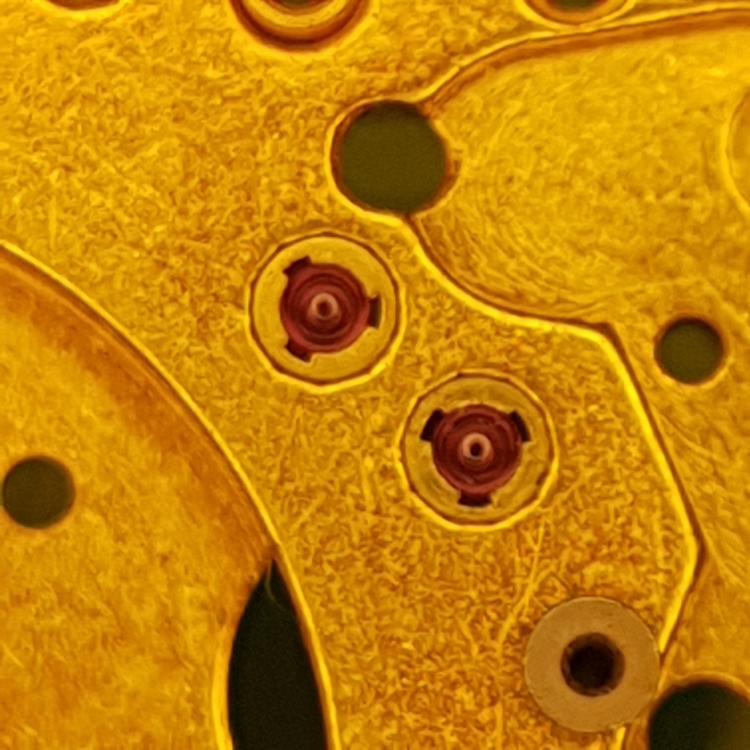

Any chance someone has technical information on this Bulova 2453.10 conversion? It replaced the 218 that was originally in a 1965 Accutron. If no one has a technical manual (I checked the internet for it, Cousins, etc. with no luck), does anyone know the seconds hand size? I'm replacing the hands with something closer to the original and was able to measure the hour and minute (1.2 and .7 respectively) but can't get an accurate measurement of the seconds hand. The original seconds on the 218 is .18mm and I think the conversion is smaller, but I'm not sure. Here is a photo of the conversion: Thanks!

-

Tension Ring Crystal Nuance

GuyMontag replied to RickTock's topic in Watch Glasses/Crystals and Glass Gaskets

The Accutron Bullova Caravelle case parts catalog doesn't seem to have that number listed, it could be the watch was released after the last catalog was printed (1979). -

When I first started being interested in watches, mom passed on her dad's Accutron to me. He died back in 2004 and was a huge part of my life growing up, so this is a treasure to me. So I put it in a drawer and didn't touch it until I felt ready. I bought several other 218 movements to practice on, as well as the Accu-cell 1.35v battery. I've got the Model 700 test kit, the service manual, and watched all of Henry Frystack's videos, so I feel like I'm ready to dive in. Today I thought maybe start with putting a fresh battery in--looks like an old mercury cell is still in there--and see what happens. Then I put it under the microscope and found clouds of gunk on the index wheel and pawls and decided against it. Guess it's time for a cleaning!

-

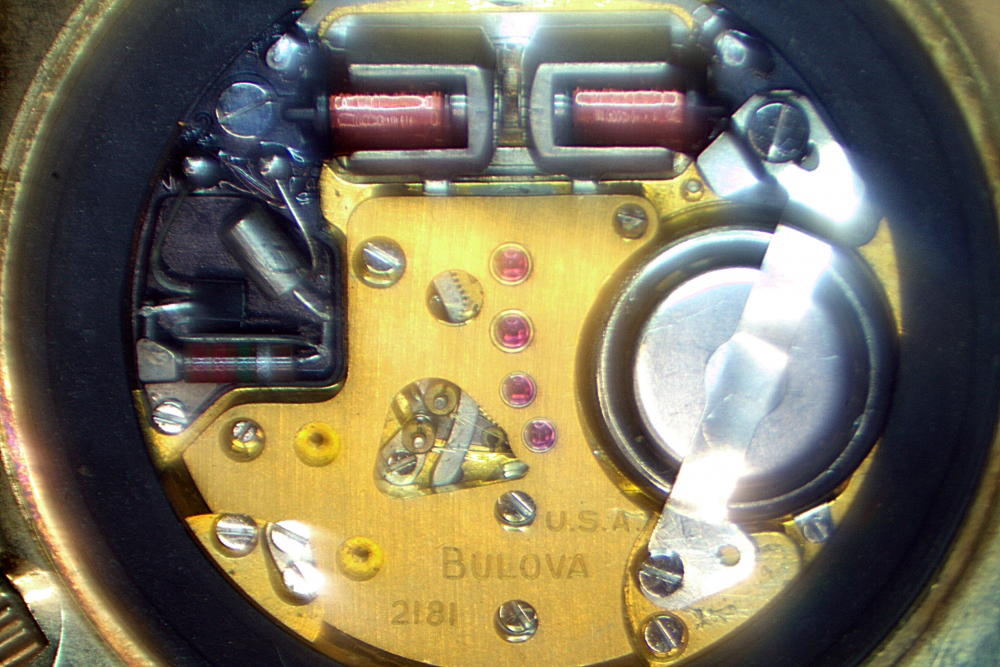

I just got this non-working Bulova Quartz this week. It houses a Bulova 2426.10 movement. When power was applied, the motor just twitches. My Bulova meter showed that the pcb appears to be functioning. A resistance check of the motor was around 640 ohms. When 1.5V was applied directly across the motor contacts, the rotor only twitches. This is something that another member, @PastorChris, experienced a couple of months earlier. I decided to cut open the motor to investigate. The pivot of the pinion was so brittle that it snapped off the moment I pulled on it. The spot weld of the top cover was so weak that my razor blade cut through it with one tap and went straight into the coils, thus cutting it. The lower cover took a bit of bashing to remove it. I discovered a couple of metal filings across the leaves of the magnet. That was probably shorting out the magnetic field and the cause of the twitching. This is a really brilliant design but probably very expensive to produce. I'll be on the lookout for another similar movement.

-

Hello @VWatchie, If I understand your situation (and I am not sure I do), I believe what you are experiencing is a timepiece that is not providing the expected isochronous timekeeping that you seem (I think) to feel that a fine watch "should" provide: https://www.google.com/search?q=isochronous+meaning (please forgive me if you are already well-accomplished in this aspect of horology) One of the reasons why time pieces are tested in (typically) six positions (DU, DD, PU, PD, PL, PR) is the very real fact that their consistency of their timekeeping (isochronism) is heavily constrained by certain expected physical characteristics and demand requirements, one of which is that the time piece must at least satisfy minimum Display requirements. In other words, the watch needs to enable the observer to be able to "tell the time" - which, interestingly, is one of the criteria that you mention in your above message as being almost trivial...considering your access to both digital and atomic time keeping. A design expectation for watches is that the Display must offer a minimum visibility to the wearer when they need it and are looking at it. In the modern era (and especially with respect to wrist watches) the movement is not in the position we typically need it to assume when we want to "tell the time". For most people, the device is mounted on the wrist in such a way that you need to raise your arm to look at its Dial, at which point the device (hopefully) tells you the accurate time. Your beef is that this is not happening. You are not getting "the accurate time". This is a claim (I think) that the isochronism of your mechanical wristwatch becomes unreliable when you are vigorously moving about. Most wrist watches are not designed to handle situations you are putting your wristwatch in, where it is being subjected to the kind of physical forces that you might generate in while working out. Interestingly, I have read recently about how sub-par isochronism might be somewhat self-cancelling through the random motions we generate as we move through the day. Obviously that is not happening for you. Part of this is the rhythmic and regular motions that a workout might produce. This will certainly wind an automatic watch. It may also be affecting the supplementary arc of your movement in ways you do not desire, amplifying the beat in one direction suppressing it in another. According to my understanding, Breguet came up with the Overcoil in an attempt to enhance isochronism, and I would also classify his Torbillon as another attempt to make the isochrononism of split balance time pieces more reliable, and of time pieces in general through another degree of mechanical isolation. In my studies, I have not (yet) seen a mechanical escapement designed in such a way as to be isochronous in an environment characterized by high-G. Temperature - yes. Humidity - Yes. High-G? Not yet. My suspicion is, if that research was ever performed, it would have been performed with escapements that are not purely mechanical in nature due to the inherent limits placed upon us by the Swiss Lever (and others) escapements. My instincts tell me that electro-mechanical escapements have a natural advantage in both high-G and No-G environments. This may help to explain the presence of the Accutron "Tuning Fork" movement in various facets of the Space Program (SR-71 control panel, Apollo control panel, Satellites & Astronaut watches). If you wanted a High-G/No-G resistant isochronous movement, my suspicion would be that it would need to be mounted somehow on a gyroscope - and I do not know personally how well a gyroscope handles instantaneous changes in direction. My guess is the gyroscope would fail. I also believe that there are serious limitations to the use of the Archimidean Spiral in High-G/No-G environments. I welcome any observations and insights from other members regarding the above. But you have a happy alternative: Buy yourself a Timex Ironman Triathlon, which seems to have been purpose-built for your design question. I myself used them for over a decade while engaging in armored combat, which is a very high-force and very fun pastime. My examples kept time just fine. I just had to change them yearly because the case eventually broke due to being rained with blows...even through the armor. But they still kept the time. As you can probably guess, I find this aspect of Horology fascinating, and I could go on further - but I've not got the time (right now) as I am working on a project that uses extremely high-precision clocks to instantaneously determine the origin of specific sound signatures in an urban environment in a Public Safety context. g. ---

-

Looking through my Dad's tools, I have multiple Accutron back wrenches. I also found three index wheels. Cannot tell which model they are for, however. I put an accutron on my Vibrograf B200A and I get squirrelly results. Frankly, I never understood how the vibrograf was supposed to be able to read an accutron--knowing the principle of the vibrograf operation. I never gave it much thought until today. But, the accutron is keeping good time...maybe 3-4 seconds a day. --------------------------*** AHAAA!! Push two buttons...the Accutron button plus one other. And just like that, my Vibrograf is useful again!!

-

I found this definition quite interesting ACCUTRON stands for“ACCUracy through ElecTRONic. This would then mean that any basically electric watch would qualify including a quartz watch but I'm going to assume tuning fork watches what you're asking about . How easy are they? I suppose it depends on a variety of factors. For instance Bulova had an issue with the watch first came out as watchmakers didn't know what the make of this newfangled watch that didn't have a balance wheel. But that was also a generation of the watchmaker who didn't understand what to do with any of electric watches. So Bulova wasn't the only company with training for their electric watches. Although Bulova's certificate if you past was much nicer than everyone else's. Problem is their vintage and all vintage watches have a problem with parts availability and of course parts wearing out. Fortunately there is eBay where new old stock materializes from time to time. But I doubt that that's going to last forever so at some point in time there will be no more index wheels and circuits even if people are at least one person is rewinding the coils. Then there is the battery voltage issue work reverses silver cell. But there is a phasing procedure that seems to work well and then the watch will run at the right rate and still maintain current consumption within specifications. Frank basically if you have really good hand eye coordination because the fingers have to be absolutely perfect. It understand the test equipment the electronics part than servicing these is no different than any mechanical watch except. The exception is you do it be very careful on procedures of how things are disassembled and reassembled. Our Jeff to pay attention to where the fingers are when you're disassembling things 70 careful with the index wheel you can't just toss that in the place.

-

It's not that difficult. But you'll need a microscope, Accutron test meter, ultrasonic cleaner and Accutron adjustment tools. Since your father was repairing Accutrons, he would probably have had all the tools. The most difficult part in repairing any tuning fork is getting replacement coils and index wheels. IMO most non-working Accutrons would need replacing a coil or index wheel or both. The design of tuning fork watches is such that if the index wheel stops moving and the fork continues to hum, the pawl/index jewels would probaly damage the index wheel. I have tried to repair some by increasing the tension on the pawl/index fingers to compensate for tooth wear of the index wheel, but that results in higher current consumption and shorter battery life. So until someone finds a way to manufacture new index wheels or finds a stash of NOS index wheels, I'll probably turn down Accutron repair jobs. But just for the experience, I would encourage you to try it yourself. It's like trying durian for the first time. That's what we say in South East Asia.

-

@JohnR725Thanks for the great download! I'll spend time with it. I guess I was a little light on the oiling by using the wire oiler without another conventional oiler first. I did see oil in the recess. But I will know in the future that the wire is more of a finish step to draw the oil onto the cap. At least that what I think I'm picking up from your comments. Thanks for clearing that up. On the Moebius oils, I just replaced some rather old Nye oil that I've had. I was using the 9010 for all wheels except the center wheel, on which I'm using the Synt-HP 1300. I hope that's not a terrible thing. It seemed to make sense to me. So the train in an Accutron is under more pressure, thereby requiring the 9020 oil? I was under the impression that there was less pressure in the Accutron. It's probably a good thing I don't work on watches for a living. I seem to remember reading that Samantha had worked at Bulova, I just wasn't certain. Thanks. Cheers.

-

@JohnR725Forget I ever mentioned anything about age. Is there really such a thing today as "Synta Visco Lube"? I was wondering what the Moebius equivalent would be for the two oils (OK, one grease, one oil) that the manual suggests. I have Moebius 9000 for quartz watches. Would that be a good substitute? I've been using 9010. BTW, have you seen the Horotec oiler I mentioned? I don't recall having seen them sold until very recently. It's possible that they've been around for years but I just missed them. The wire that they use is very thin indeed. Maybe even .06mm, if that's possible? I received the Accutron index/pawl post tool yesterday and I'll see how that works for getting the pawl finger sitting better. Maybe I'll get lucky and I didn't de-mag the fork by pulling it from the US while it was running. I hope I wouldn't have to be lottery-winning lucky for it to be possible. Cheers. @JohnR725Oh, and BTW, since you attended Accutron class, and are obviously quite knowledgeable about them, I'm wondering if you know an Accutron expert named "Samantha"? She used to post Accutron related posts on the NAWCC board but I haven't seen her for a couple of years now. She seemed to really know her way around them. I'm just curious to what happened to her? Cheers.

-

Sorry, I missed that you had actually taken the course yourself. Heck, you must be older than me. Hopefully you don't FEEL older than I. As far as oiling those endstones that generally stay in the plate, I just bought an Horotec wire oiler that is made for getting through holes into shock-protection jewels, specifically Inca. It seems to work OK. I suspect you have the Bergeon automatic oiler(s)? I wonder if the Moebius oils with the UV activated coloration would be visible, and therefore helpful. I think that's what I bought last time for both 9010 and HP1300/9104, FWIW. Good luck with your Accutron. Cheers.

-

You talk about the notes jotted in the service manuals. I guess a lot of these were ones used by the students during the Accutron certification classes. There are a few notes in my 218 service manual relating to the sequence of setting the train wheels. I tried it the way the notes seem to say to do it but I found a sequence that worked better for me. I think I go Third wheel, fourth wheel, second wheel, index wheel. And while some say they have an easier time getting the pivots home by leaving off the lower fourth wheel jewel until after the other pivots are set, I found it easier having the jewel installed. Cheers. I'd sure love to attend one of those Frystack-type classes today. But his 214 presentation is certainly helpful, even applied to the other models. Presently I'm waiting on the service manual for the 221 series. I have one that's running and am considering trying to get it to run better, or at least without self-destructing. Heck. that's what it has me for.

-

@JohnR725, Thanks for the link to the video. I will check it out. I know what you mean about some of the obnoxious music, etc., that people use. Obviously my days as a prime demographic sailed long ago. Some make it obvious that they never read, or at least don't reference during work, the very instructive Accutron service guides. These watches are tricky even with the guides. Thanks again. Cheers. I had watched this video a while back, but figured it wouldn't come in any more handy than the manual. I was wrong. I may have made another fatal error on this Accuquartz. I knew I had seen something about removing, or not removing parts from the US cleaner while the cleaner was activated. I didn't realize it was this video. And when I was forced to us the US to clean the finger jewels, I do like I usually do, and this is pull the basket as the cleaner is activated. Apparently, I may have demagnetized the fork. Hmm...I may have rendered a decent Accuquartz to a non-runner. I wonder if the forks are the same strength of magnetization on the 218's and 224's? Rats. I'll keep messing with it to learn more of what not to do. Thanks again for the link, JohnR725. Cheers.

-

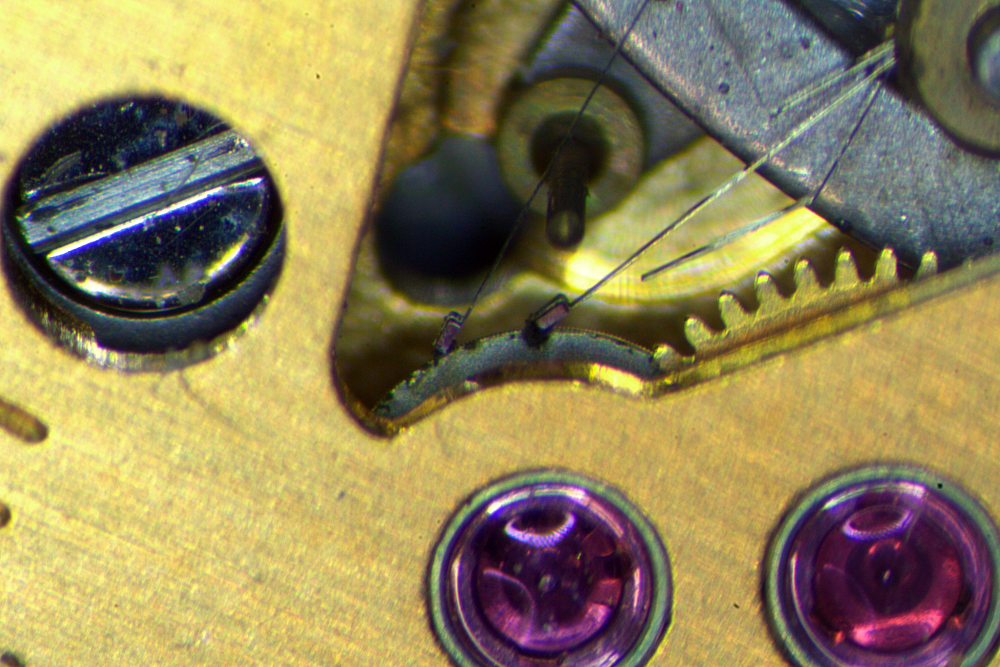

Greetings all, I've been working on a few Accutrons of late. It started with one that was gift to me. I find them very interesting, and marvel at their engineering. Who wouldn't, right? Of the two that are on my bench right now, one needs an index wheel, the other needed the index and pawl jewels cleaned better than a dip in One-Dip. Of course I didn't realize that until I put it (A 2242 Accuquartz) back together and it wasn't staying running and I looked at the jewels under higher magnification. Despite some advising against putting the fork/index finger/jewel and pawl-bridge/finger/jewel in the ultrasonic, I was told by an Accutron expert that it would be OK, so I did so. I definitely cleaned off the gunk. I used fresh cleaner and ran a rare earth magnet through the cleaner before putting the parts basket in. The issue I'm dealing with now is that the pawl finger got bent. It must have been sitting too low, or the upper fork screw was sitting too high. When I spun the finger around to avoid damaging it, it hung up on that screw. Then it somehow got lifted over the hack pin as I was trying to get the index wheel in position without high enough magnification to notice it happening. Anyway, I am now working to straighten the finger. It's not terrible, but I guess it needs to be rather perfect to work properly. First the jewel wasn't squaring with the index wheel. Then it was riding over the index wheel. Right now it will get the watch running slightly but it won't stay, at least at lower phasing voltages. It looks pretty square now, and isn't riding over the index wheel. The only obvious issue is that the stress limiter on the pawl finger is not engaged with the finger at all. Since the jewel was sitting so squarely with the index I decided it was worth at try, but the stress limiter may be more important than I hoped. These fingers are so fragile, and manipulation has to be done under pretty high magnification, I just want to know if I should give it up and buy a replacement or keep trying. Any help is appreciated. Thanks ahead of time. I'd include an image but I don't have a good way to do so with my microscope setup. Cheers.

-

Hi all! I'm new to the forum, but have a few used Accutrons (214, 218) I Picked up in the 80s (before Mercury cells went away) and some recent 218s that came with silver oxide cells - some within original accuracy spec and others not. I've heard of Accucells and people installing schottky diodes in their watches (which seems like the better approach) but never thought much about it till recently. I'm a retired electrical engineer and remember that one of the benefits of schottky diodes was lower forward voltage drop and .2 volts was an often mentioned number. However, what that drop actually is depends on the particular diode temperature and the actual forward curent. For an Accutron, it's 8 to 10 microamps. And for the diode part number you are using: https://www.digikey.com/en/products/detail/rohm-semiconductor/RB520CM-30T2R/5955710 the typical forward drop in that curent range is: 25C .15 volts -25C .24 volts 75C .06 volts 31C .14 volts estimated (skin temp) The numbers will all be about .02 volts lower at 8 microamps drain. It makes me wonder if a resistor (small axial, or SMT) wouldn't be a better choice. With a 1.55 volt cell, a 21.5K 1% metal film resistor will provide a voltage range (including current extremes and resistor tolerance) of 1.333 to 1.379 with lower sensitivity to off wrist temperature swings. The one concern that comes to mind is the initial circuit drain when the battery is first connected - and the related consideration for 218 versions that break the battery circuit when hacked. I'm guessing the coils could be modeled as resistors and capacitors as their ESRs (plus knowing the transistor specs) to estimate initial current and 21.5K voltage drop. It's a possible issue the diode wouldn't have. Any thoughts?

-

Getting my Bulova Accutron running...

MrRoundel replied to mmitsch's topic in Quartz and Tuning Fork Battery Operated Watches

Thanks for the welcome, HectorLooi. I haven't worked on a 214 yet. It's on my bucket list. Unfortunately, they seem to go for a lot more money than 218 series and such. I had a friend that was into pocket watches when I first got into them in the nineties. Not long after we met, he started going after Spaceview wrist watches. I remember him talking about the "real deal" vs modified versions. I had no interest in wristies at the time, and certainly not electrified watches with weird vibrating forks. What started me down this road/rabbit-hole, was a guy who didn't want to spend what it would take to fix a 2182 that was his dad's. He offered it, gratis, to the first taker. I was the second one who saw it, but the first guy was out of the country and the owner had said he'd only ship to the US. Lucky for me, I think. That 2182 is still not running right, but rather fast and stuttering with a 1.55V battery. I'll probably end up replacing the index wheel. I won't get a good look at the teeth on the existing index wheel until I get my doubling Barlow lens that will take me to 90X magnification. Good luck with your problem-child 214. The 214, Spaceviews in particular, really are the classic Accutron. But the later models did have some nice improvements that apparently made them less finicky to work on. Cheers. -

Welcome to the world of humming watches @MrRoundel. It's really strange that so few people are willing to work on Accutrons but yet every Accutron that appear on eBay gets snapped up. Sometimes at ridiculous prices. The recalcitrant 214 that has been giving problems turned up again. This time the coil on the component side gave up it's ghost. Finally the mystery got solved. The problem was a defective coil which was about to break. I feel relieved and vindicated. Now to hunt for a new coil.

-

Watchmaster MK II

clockboy replied to rob1crazydude's topic in Watch Timing & Testing Equipment / Timegraphers

Found this which might help as it shows pics of a Bulova watch being tested. https://jestineyong.com/bulova-accutron-watchmaster-600/ -

If it hasn't run "in years" there's a good chance it just needs an overhaul, no parts. My mom got an accutron (for my birth), 1973, changed batteries every 12-18 months, then I serviced it in 1998, 25 years later (I was in watchmaking school). It was impeccable, sorry to say, but I've also serviced Rolexes for friends where I'm assured it hasn't seen a bench in decades. Yes, if lube goes wrong after 5 years you can get wear. But 10 years, good watch, epilame your stuff, yeah . Accutron, you can go double service interval easy and then, it grinds itself to death. If you google "accutron service" you'll get the like 1 or 2 last dudes who do this as a passion. If they even manage to get a tiny bit of oil where needed your watch will outlive you!

-

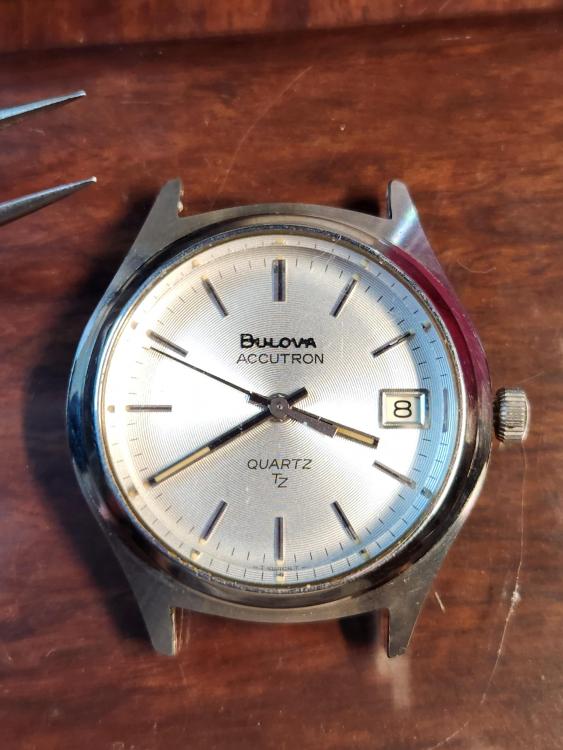

I have a Bulova Accutron that I got in the late 70's. It looks similar to the one below (mine is silver with a gold bezel). I would like to try to remove the back cover and replace the battery. Would anybody know the battery I would need? I've heard these used some type of mercury battery that's no longer used. And, is there a gasket I should try to buy in advance or should I be treating the threads with some type of sealant? And, to remove the back, should I use something like the Harbor Freight Tool shown (it's at https://www.harborfreight.com/watch-case-opener-91550.html). Should I also buy a holder for the watch? I've never done this before and actually am looking forward to it. Not sure if it'll work or not but I figure I should try. Anything else I should check on the watch? Sorry for all the stupid questions but I am a novice.

-

I also came across similar jewels in Accutron 218s. I was told to leave them alone and just clean them in the ultrasound. I suspect the 3 notches are not designed for any special tool to remove them but to allow cleaning fluid to circulate between the cap and hole jewel. I oil them from the hole side.

-

I recently picked up a late 1970's Bulova Accutron Deep Sea 19810 "devil diver" with the Caliber 242 movement. It is a very impressive movement in terms of its modular design and I would love to see it running again. I have taken apart the movement, cleaned the mechanicals and put it back together with everything running smoothly when manually manipulated. I installed a fresh battery and the stepper motor will click twice in one direction, not enough to move the seconds hand, and then reverse direction for a couple of clicks. This goes back and forth a bit then stops. Just to be sure I removed the hacking lever and checked the mechanicals and cannot find any fault. So I am guessing this is a problem with the stepper motor. I would appreciate hearing if: a. Does anyone have any further ideas about what might be wrong/ what I might try b. Does anyone have a 242 movement or stepper motor that they would sell me for this project? I have searched the web for a motor and cannot find one in stock, but that is not much of a surprise. Thanks in advance.