Search the Community

Showing results for 'accutron' in topics.

-

Citizen HISONIC movement (3711A date only model)

khang posted a topic in Watch Repairs Help & Advice

Dear all, I always wanted an Accutron but you know they are quite expensive (converted ones a little cheaper). So I purchased a Citizen HISONIC for a reasonable price from Yahoo Auctions and learned my lesson :). You get what you pay for. The case had and the crystal had a lot of scratches, which is not a biggy but the movement is dead. When I looked with a loupe, I saw that index jewel is missing, pawl jewel bent badly, one of the coils smashed and more issues. So trying to replace these parts, especially the jewels is beyond my skill and it will be a challenge to find each and most probably will cost me almost an Accutron I assume. What would you do? Try to replace those parts or find a new movement? Where is the best place to source a new movement or parts? Watch shops here in Japan are asking crazy expensive prices. ¥40.000 - ¥60.000 (around $400 - $600) to fix it and I cannot afford even if I could, I'd buy myself a nice Accutron instead. I was so happy until I unscrewed the back cover, auctions are not my thing I guess :). Thank you in advance. Cheers.- 3 replies

-

- citizen hisonic

- caliber 3711a

-

(and 1 more)

Tagged with:

-

-

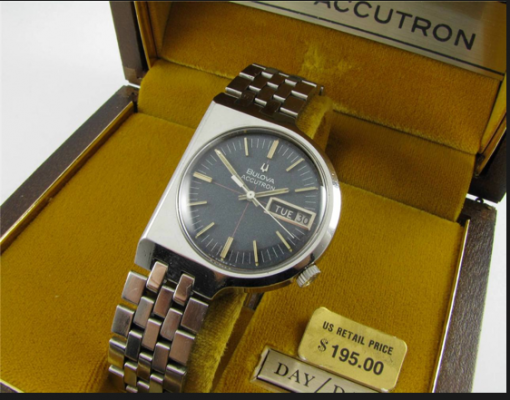

https://www.ebay.com.sg/itm/BULOVA-Accutron-Automatic-Watch-Swiss-Made-Sapphire-Crystal-100m-All-Stainless-/234164475111?mkcid=16&mkevt=1&_trksid=p2349624.m2548.l6249&mkrid=705-154756-20017-0 This is what I mean. Bulova did use the name Accutron for watches that were not using tuning fork technology. I just got a 10 watch lot labelled as Accutrons. All of them were quartz.

-

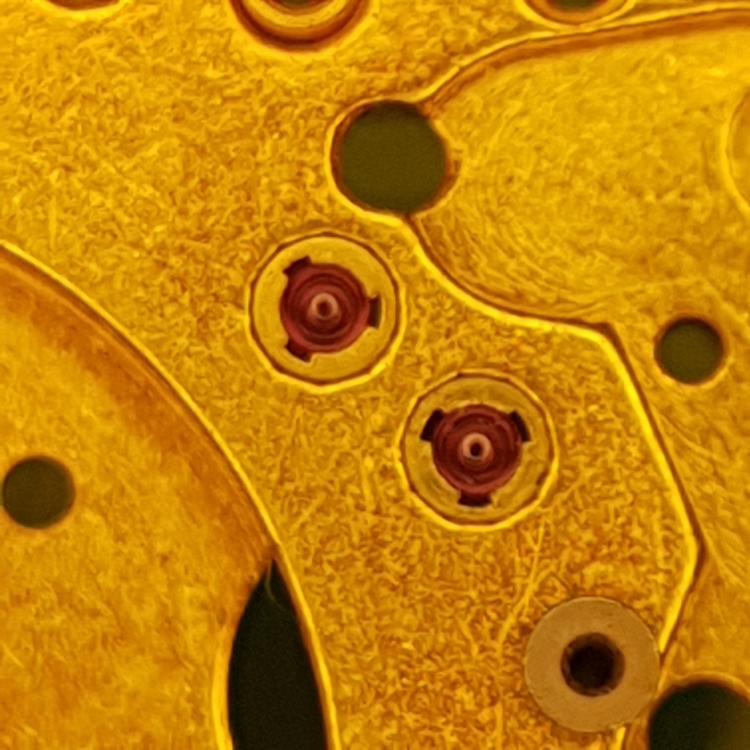

Hello, I am new at this forum, and I have a question right at start. I have got an accutron for a year, and I looked into it with a microscope first time (only with loupe earlier). I found out that fingers are dirty, looks like oxidation. I put photo of them. Is it possible to clean them without disassembling the movement? I have read that someone has applied naphta to the index wheel while running... Thanks in advance for help! BR Jukka

- 20 replies

-

- Accutron

- Index finger

-

(and 2 more)

Tagged with:

-

I have a problem. Ive got this Slava Transistor watch--the one the Russians ripped off in the 60's of the American Bulova Accutron 214.... Its a fairly close match,-- visually they look identical, quite an achievement IMO... My issue is this. Its third wheel has a rusted off pivot, fairly common on the Accutron version due to moisture or batt leaks and there's fair evidence of a leak in this one.. The Accutron 3rd wheel wont fit--2nd Moscow Watch Co (Slava, Seconda, Vostock etc) in their infinite wisdom made their staff smaller in diameter than the Americans, no idea why... My only solutions as trying to find a correct good third for this mega-oddball are near impossible, are- 1/ machine down Accutron third wheel pivots.... 2/ Replace the jewels but dont know if plate holes are the same size and I dont have the equipment to deal with jewel replacement anyway. So--Anyone good with the watchmakers lathe fancy having a look?

-

Although I was trying to be good and not purchase anything till I had sorted out the multitude of watches I have in the queue, I saw this Accutron on the bay and bought it for £32.49 plus about $5 postage to my sons place in LA. I had not got an Accutron 2210 up to this point in time, and to be honest the movement does not have a particularly good rep for reliability. However, the parts are comparitively cheap compared to the 214 and 218 and through a quirk of fate I have quite a few NOS 2210 parts that were amongst a job lot of 214 and 218 bits I bought some time ago. It is a 1973 movement and coincidentally that is when these were first produced and the movement is quite small, being used in lots of ladies watches which do not command the same prices as the mens accutrons - good for getting parts. I queried with the vendor the size and was advised it is 34mm excluding the crown so it is in a mans case. Condition was described as "Awesome" but I will settle for reasonably good seeing it is over 40 years old, there are some scratches on the glass and I deduce from the back that the case is gold plated which is difficult to tell from the photos, but I will take what comes. It will be a while until it is sent over to me along with some 218 coils I took a punt on but I look forward to seeing it. Was not going to buy any more repair jobs but I weakened, however, I am definitely back on the wagon for a while. Cheers, Vic

-

I found this definition quite interesting ACCUTRON stands for“ACCUracy through ElecTRONic. This would then mean that any basically electric watch would qualify including a quartz watch but I'm going to assume tuning fork watches what you're asking about . How easy are they? I suppose it depends on a variety of factors. For instance Bulova had an issue with the watch first came out as watchmakers didn't know what the make of this newfangled watch that didn't have a balance wheel. But that was also a generation of the watchmaker who didn't understand what to do with any of electric watches. So Bulova wasn't the only company with training for their electric watches. Although Bulova's certificate if you past was much nicer than everyone else's. Problem is their vintage and all vintage watches have a problem with parts availability and of course parts wearing out. Fortunately there is eBay where new old stock materializes from time to time. But I doubt that that's going to last forever so at some point in time there will be no more index wheels and circuits even if people are at least one person is rewinding the coils. Then there is the battery voltage issue work reverses silver cell. But there is a phasing procedure that seems to work well and then the watch will run at the right rate and still maintain current consumption within specifications. Frank basically if you have really good hand eye coordination because the fingers have to be absolutely perfect. It understand the test equipment the electronics part than servicing these is no different than any mechanical watch except. The exception is you do it be very careful on procedures of how things are disassembled and reassembled. Our Jeff to pay attention to where the fingers are when you're disassembling things 70 careful with the index wheel you can't just toss that in the place.

-

Supplement For A Repair To Accutron 2185

Vich posted a topic in WATCH REPAIR TUTORIALS & INFORMATION

This may help out with Accutron 2185 problems Bulova-Accutron-2185- Pages 58 to 71 Supplement for Hour and Date Settings Manual.pdf Cheers, Vic -

Sorry, I missed that you had actually taken the course yourself. Heck, you must be older than me. Hopefully you don't FEEL older than I. As far as oiling those endstones that generally stay in the plate, I just bought an Horotec wire oiler that is made for getting through holes into shock-protection jewels, specifically Inca. It seems to work OK. I suspect you have the Bergeon automatic oiler(s)? I wonder if the Moebius oils with the UV activated coloration would be visible, and therefore helpful. I think that's what I bought last time for both 9010 and HP1300/9104, FWIW. Good luck with your Accutron. Cheers.

-

You talk about the notes jotted in the service manuals. I guess a lot of these were ones used by the students during the Accutron certification classes. There are a few notes in my 218 service manual relating to the sequence of setting the train wheels. I tried it the way the notes seem to say to do it but I found a sequence that worked better for me. I think I go Third wheel, fourth wheel, second wheel, index wheel. And while some say they have an easier time getting the pivots home by leaving off the lower fourth wheel jewel until after the other pivots are set, I found it easier having the jewel installed. Cheers. I'd sure love to attend one of those Frystack-type classes today. But his 214 presentation is certainly helpful, even applied to the other models. Presently I'm waiting on the service manual for the 221 series. I have one that's running and am considering trying to get it to run better, or at least without self-destructing. Heck. that's what it has me for.

-

@JohnR725, Thanks for the link to the video. I will check it out. I know what you mean about some of the obnoxious music, etc., that people use. Obviously my days as a prime demographic sailed long ago. Some make it obvious that they never read, or at least don't reference during work, the very instructive Accutron service guides. These watches are tricky even with the guides. Thanks again. Cheers. I had watched this video a while back, but figured it wouldn't come in any more handy than the manual. I was wrong. I may have made another fatal error on this Accuquartz. I knew I had seen something about removing, or not removing parts from the US cleaner while the cleaner was activated. I didn't realize it was this video. And when I was forced to us the US to clean the finger jewels, I do like I usually do, and this is pull the basket as the cleaner is activated. Apparently, I may have demagnetized the fork. Hmm...I may have rendered a decent Accuquartz to a non-runner. I wonder if the forks are the same strength of magnetization on the 218's and 224's? Rats. I'll keep messing with it to learn more of what not to do. Thanks again for the link, JohnR725. Cheers.

-

Hi there HectorLooi, here is some dating info for Bulova from 50s through to 2000s For Bulova watches created in 1950 or later, the manufacturer switched to a two-digit alpha-numeric code system. These codes are usually found on the backcase, but some can be found on the inside movement near the set-screw.[4] The first digit of the code corresponds to the decade. The second digit of the code corresponds to the specific year. The decade codes are as follows: 1950s: L 1960s: M 1970s: N 1980s: P 1990s: T 2000s: A The second digit of the code matches the ending digit of the year in which the watch was manufactured. When "0" is used, the end of the year was a "0" (1950, 1960, 1970, and so on). When "1" is used, the end date of the year was a "1" (1951, 1961, 1971, and so on). This pattern continues for digits "0" through "9." For example, a Bulova watch marked with "N2" was manufactured in 1972. A Bulova watch marked with "T8" was manufactured in 1998.The original Spaceview was not intended for sale at all – it was a demonstrator model, whose purpose was to appear in ads and in store display windows. The Spaceview showed off not only the forward gliding motion of the seconds hand, but also the distinctive green baseplate and contrasting copper coils for the tuning fork, as well as the transistor essential to the operation of the watch. They usually are priced on rarity, condition, and case material, box and papers etc. hence the huge price range. Bulova released an Accutron collection with quartz movements in 1976. One year later, the tuning fork Accutron production was stopped once and for all after more than 5 million pieces were sold. That year marked also the end of Bulova’s golden age.The last 214's were made in 1977. During the 17 years that tuning fork watches were made they were the most accurate production timepieces on the Earth, and in space.

-

I contacted a respected watch repairer to ask about repairing Bulova accutron tuning fork watches. The reply came back that parts were impossible to source so he couldn't help me. Does anyone on this form repair these watches. I have 2 that were working but now don't and I would prefer to pay for the repairs rather than go through the whole process of trying to learn how to do it myself. Life's too short to start another field, I just want to get to grips with mechanical watches. I started this thread because another member posted about receiving coils which were damaged in the post and it got me thinking.

-

Hi all! I'm new to the forum, but have a few used Accutrons (214, 218) I Picked up in the 80s (before Mercury cells went away) and some recent 218s that came with silver oxide cells - some within original accuracy spec and others not. I've heard of Accucells and people installing schottky diodes in their watches (which seems like the better approach) but never thought much about it till recently. I'm a retired electrical engineer and remember that one of the benefits of schottky diodes was lower forward voltage drop and .2 volts was an often mentioned number. However, what that drop actually is depends on the particular diode temperature and the actual forward curent. For an Accutron, it's 8 to 10 microamps. And for the diode part number you are using: https://www.digikey.com/en/products/detail/rohm-semiconductor/RB520CM-30T2R/5955710 the typical forward drop in that curent range is: 25C .15 volts -25C .24 volts 75C .06 volts 31C .14 volts estimated (skin temp) The numbers will all be about .02 volts lower at 8 microamps drain. It makes me wonder if a resistor (small axial, or SMT) wouldn't be a better choice. With a 1.55 volt cell, a 21.5K 1% metal film resistor will provide a voltage range (including current extremes and resistor tolerance) of 1.333 to 1.379 with lower sensitivity to off wrist temperature swings. The one concern that comes to mind is the initial circuit drain when the battery is first connected - and the related consideration for 218 versions that break the battery circuit when hacked. I'm guessing the coils could be modeled as resistors and capacitors as their ESRs (plus knowing the transistor specs) to estimate initial current and 21.5K voltage drop. It's a possible issue the diode wouldn't have. Any thoughts?

-

Getting my Bulova Accutron running...

MrRoundel replied to mmitsch's topic in Quartz and Tuning Fork Battery Operated Watches

Thanks for the welcome, HectorLooi. I haven't worked on a 214 yet. It's on my bucket list. Unfortunately, they seem to go for a lot more money than 218 series and such. I had a friend that was into pocket watches when I first got into them in the nineties. Not long after we met, he started going after Spaceview wrist watches. I remember him talking about the "real deal" vs modified versions. I had no interest in wristies at the time, and certainly not electrified watches with weird vibrating forks. What started me down this road/rabbit-hole, was a guy who didn't want to spend what it would take to fix a 2182 that was his dad's. He offered it, gratis, to the first taker. I was the second one who saw it, but the first guy was out of the country and the owner had said he'd only ship to the US. Lucky for me, I think. That 2182 is still not running right, but rather fast and stuttering with a 1.55V battery. I'll probably end up replacing the index wheel. I won't get a good look at the teeth on the existing index wheel until I get my doubling Barlow lens that will take me to 90X magnification. Good luck with your problem-child 214. The 214, Spaceviews in particular, really are the classic Accutron. But the later models did have some nice improvements that apparently made them less finicky to work on. Cheers. -

Welcome to the world of humming watches @MrRoundel. It's really strange that so few people are willing to work on Accutrons but yet every Accutron that appear on eBay gets snapped up. Sometimes at ridiculous prices. The recalcitrant 214 that has been giving problems turned up again. This time the coil on the component side gave up it's ghost. Finally the mystery got solved. The problem was a defective coil which was about to break. I feel relieved and vindicated. Now to hunt for a new coil.

-

Recently I got an early 214 from 1963 that had a faulty coil. The coils on these are in two parts, a cell-coil and component coil, joined by three fine insulated single-core wires. The Cell coil had gone O/C due to water/battery leak rotting out the fine wires where they attach to the soldered binding-posts--Mainly because Bulova hadn't covered a small section of the wire with any protective varnish. A replacement cell-coil was bought from the guy in Bulgaria and the old one replaced on the coil assay. Fitting to the movement, it didn't run. It would go for about 5-10 seconds after plucking the fork, but the hum would slowly die away. I assumed the resistor and capacitor were messing round --so replaced these in the component coil side. Still the same. I checked the transistor--but it looked good in testing--I replaced it anyway, using a silicon device tacked in to test, altering the bias by changing the resistor from 3.9 meg to 2.2 meg, to accomodate the different bias requirements between a Silicon and the old Germanium device it was replacing and tried again. Exactly the same! I monitored the current using my home-made PSU, it would initially pin the meter and that would die away to 5uA, but the movement still not running and no hum either. Plucking the fork, it would run for 5-10 seconds, then the hum would die away, and no appreciable difference in current draw. The clue was the constant current it was drawing after the initial pulse. It was perfectly clear when I dragged the Scope out and checked. The coil set was oscillating at 200 odd KHz! When the fork was plucked, the 360Hz was modulating the 200KHz. I guess a Long-wave radio could have picked it up if it was close by! Fortunately,--Bulova had also run into this problem as well and on some coils added an extra capacitor to the component-coil to damp out the radio-frequency oscillations. A 0.01uF (1 Nanofarad, 1000pF) cap was installed at the point the wires from the cell-coil attach to the component-coil. Its placed between the leads of the drive coil (Red wire) and the feedback coil (Green wire). Doing likewise with an 0805 1nF SMD cap cured the issue completely and the movement runs normally, even self-starting--with lots of wires and components hanging out of it! I just now need to rebuild it all properly and neatly into the component-coil recess--Which should be fun!. I'm guessing that the inductance of certain Cell-coils must be just right to cause this oscillation so they added the extra cap on those causing troubles.

-

Accutron tuning fork 218 and 224

HectorLooi replied to HectorLooi's topic in Watch Repairs Help & Advice

I was hoping that with your vast servicing experience that you would be able to tell me how to do it. I've read all the instructions for phasing the 218 and 224. I have the Accutron test meter but I don't have the 224 movement holder with the IC phasing test probe. I can't seem to find any good photos of this test probe. I can't tell from the blurry photo in the 224 service manual whether it is a simple probe connection or whether it has a bias resistor connected to it. I've tried phasing it by connecting the +ve and _ve leads of the Accutron meter to the movement. I can get the index wheel to run but I can't get it to "run-stop-run" as stated in the Bulova service manual. Tonight I'll try balancing the forks first, then connect the +ve test clip to the test point and see what happens. Wish me luck! -

Looking for a good cell-coil for a 214. original is a three-wire coil, but I can re-wire a two-wire cell coil into a three to work in place, if you have one going spare, maybe from a set with a duff component-coil. Thanks.

-

Watchmaster MK II

clockboy replied to rob1crazydude's topic in Watch Timing & Testing Equipment / Timegraphers

Found this which might help as it shows pics of a Bulova watch being tested. https://jestineyong.com/bulova-accutron-watchmaster-600/ -

Hi, Brad Kuhn here. I really appreciate a well designed and well made device be it mechanical or electrical, cars, machines, or watches. I am completely new to the watch repair world, although I have worn and appreciated a Rolex for many years. One reason I am here is that the Accutron 2181, given to my father in 1976 as a retirement gift, no longer hums, and I want to try to repair it myself. The other reason is that I found the discussions on this forum (that I read) to be congenial, informative, encouraging, and free of rancor. I am starting pretty much at zero, although I do have an Accutron 218 movement holder, some seemingly decent tweezers and screwdrivers. Although I do not intend to become a fully qualified watch repair man, I do have the Accutron repair and two other movements that I could improve. My initial thoughts are: what tools are necessary? What book/books should I read? What online courses should I take (would rather not take a course)? Anyway, here I am, not sure how to start. Any input would be appreciated. Thanks, Brad Kuhn

-

Hi all , After not winning auctions on a few watches ,.. a similar model to this one , 2 Accutron Astronauts , 2 Omega SeaMasters , I pulled the trigger on this Beauty . It had a BIN price of $899,99 or make offer . I had been watching this watch for about a month along with about 20 or 30 other watchers . The date code N1 places it as a 1971 model . I made an offer that was accepted by the seller and now this Baby is on its way to me .

-

I also came across similar jewels in Accutron 218s. I was told to leave them alone and just clean them in the ultrasound. I suspect the 3 notches are not designed for any special tool to remove them but to allow cleaning fluid to circulate between the cap and hole jewel. I oil them from the hole side.

-

Hi All , The postman delivered this Accutron 2180 today . In good condition and running smooth . The dial fades from dark blue to light blue . I installed a new Bulova strap I had and will install a new crystal soon . The date on the back says N3 , which translates to 1973 . Also on Craigslist here on Oahu , Hawaii I picked up this Tissot Visodate Heritage for an offer under $200 . I had been looking at them on the "Bay" , and at the local Auth. Dealer . I'm Stoked...