Leaderboard

Popular Content

Showing content with the highest reputation on 04/24/24 in all areas

-

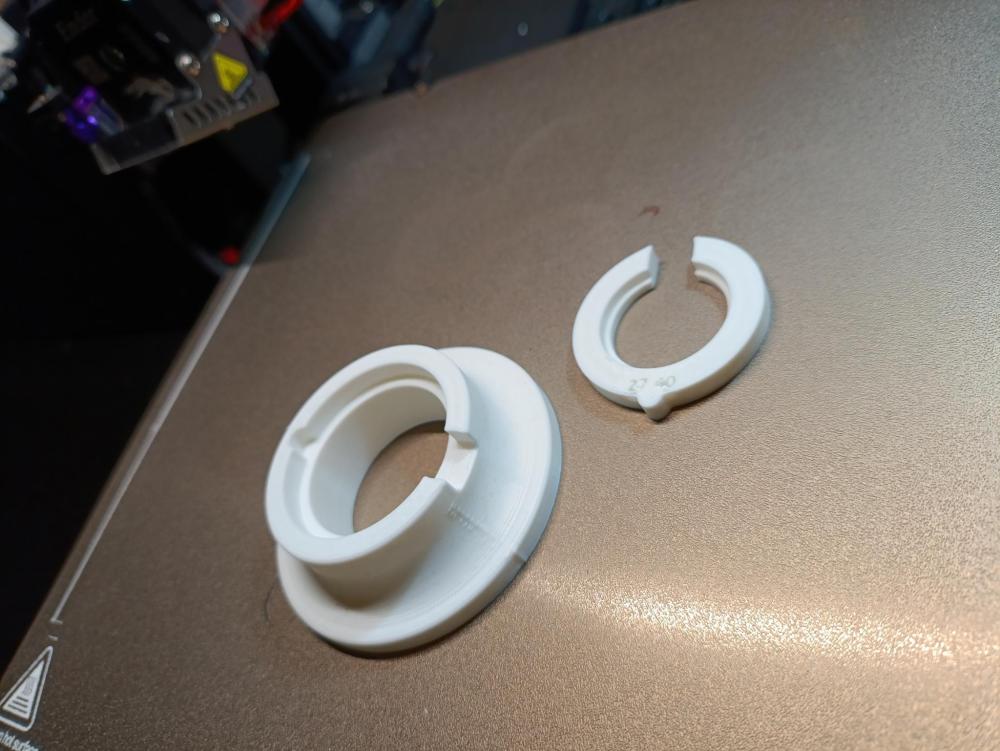

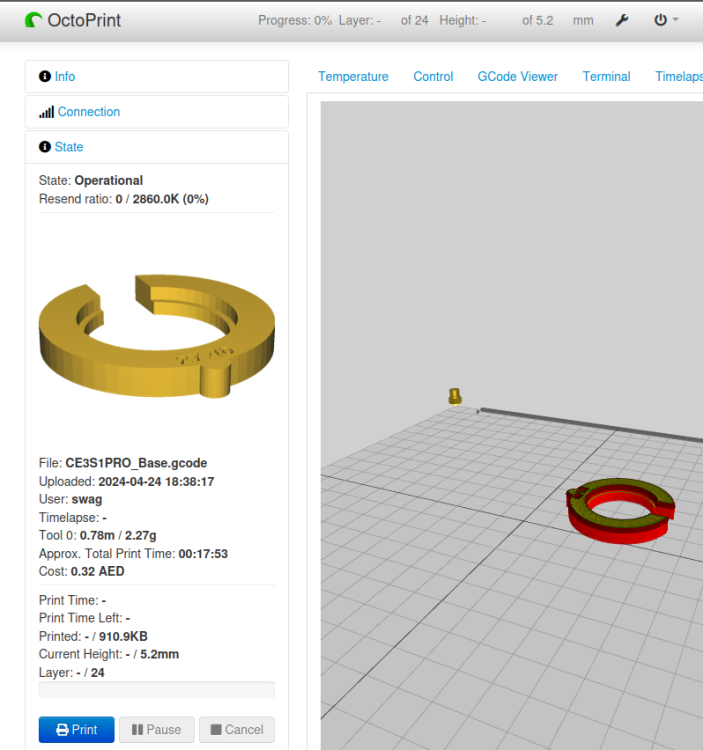

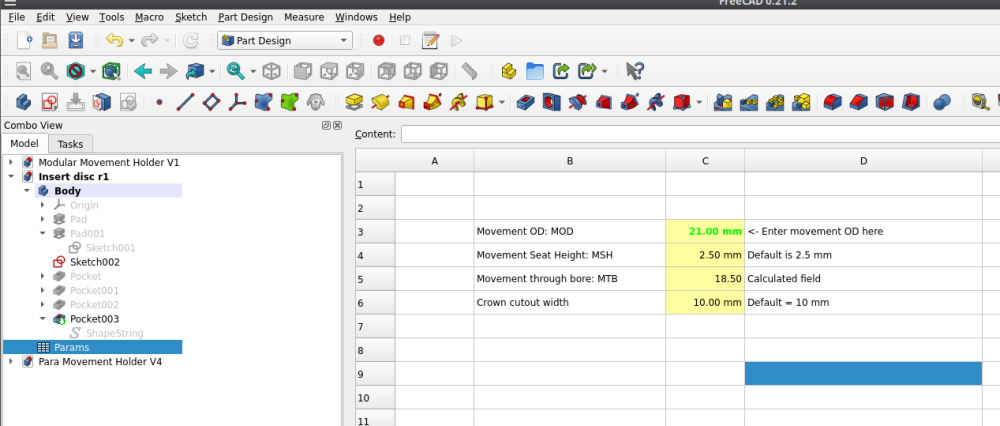

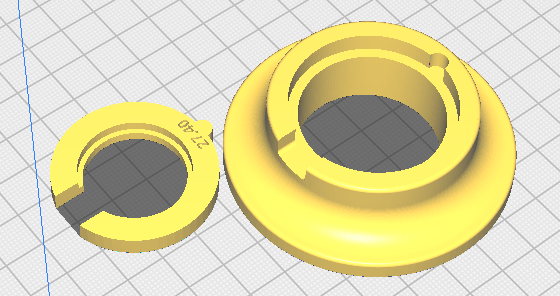

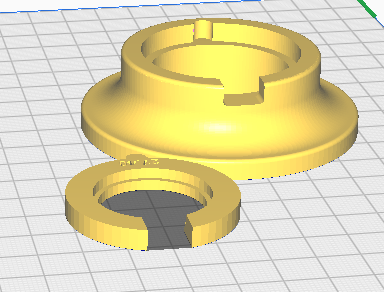

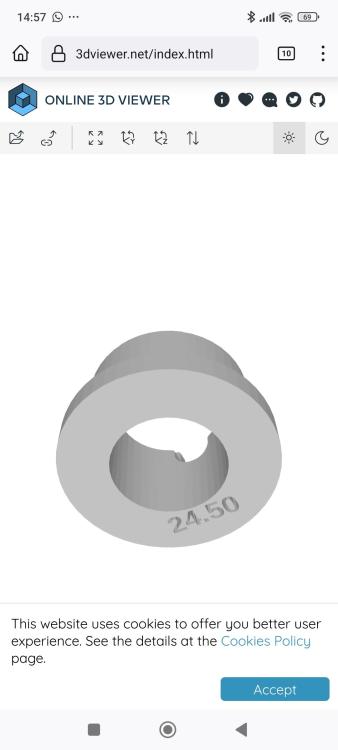

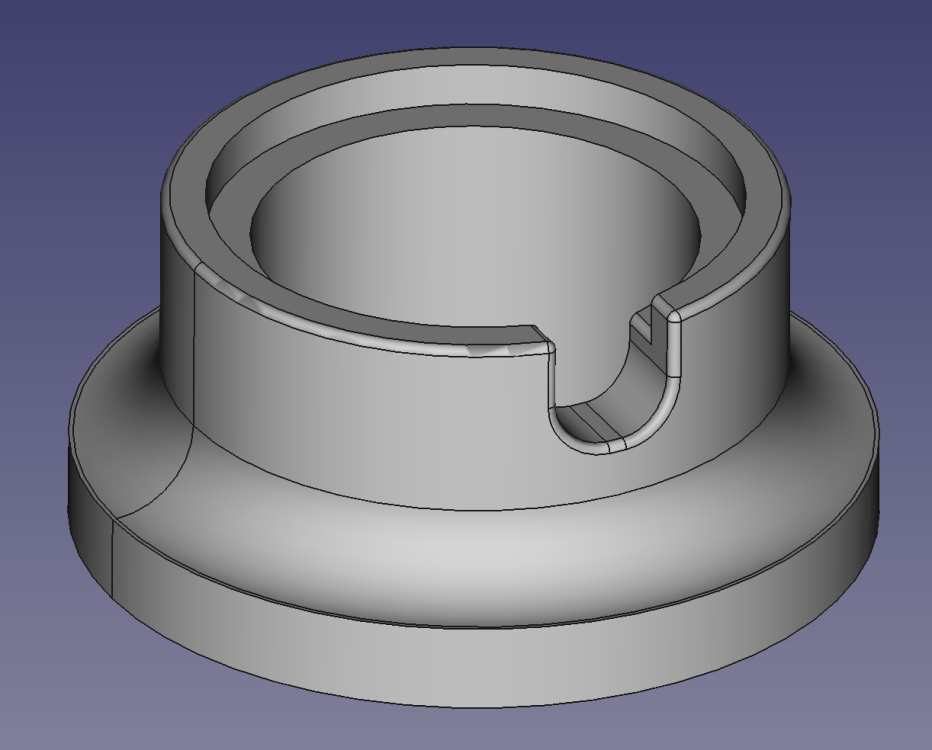

All Done, Here are the finished pictures: This one shows the generic "one-size-fits-all" base which accepts the bespoke rings - notice that the parametric movement OD (27.40 mm) automatically prints on the ring From another angle: Here is the ring about to go into the base: And finally the base and ring together: Here it is next to a pen for scale: On my system with 20% fill each ring will take about 18 mins to print, but I am sure this could be optimised: Here is the screenshot of the spreadsheet in FreeCAD, you just need to change one value to create the ring in cell C3, (the base doesn't need any changes). I just uploaded the files to printables link here, but also include here as a fake pdf, please change the .pdf to .zip to make the file work once downloaded: Modular Movement Holder.pdf Any feedback welcome! I'm also going to make a parametric ring insert for rectangular/oval movements - but I just finished a parent teacher evening so too tired now6 points

-

Hello everybody, sorry for the late reply. Thank you all so much for your help and your tips. I got lucky and found a replacement wheel bridge for cheap which actually ended up being in decent condition. I decided not to do anything about the mainspring barrel pivot since I didn't have the right tools and the barrel didn't have much endshake anyhow. I am happy to report that the watch now runs great, I have regulated it to about +-10/s day which is fine by my standards. The timegrapher result looks decent as well, although beat error is around 0.6ms which could be better I suppose. Amplitude reaches over 230 quite consistently which I'm happy with also. My lighter fluid has also been replaced by balance spring cleaning solution and now the springs don't stick to themselves anymore - who would have thought. I'm super happy with this watch, it might not be worth a whole lot but it's awesome that I could restore it and it makes me wear it with pride. To me it's a genuinely good lucking watch, it'll be my daily driver for a while. Thanks again to everybody for their input! I couldn't have done the repair without your help. Here are some images for those interested, the bracelet isn't original but I don't really mind:5 points

-

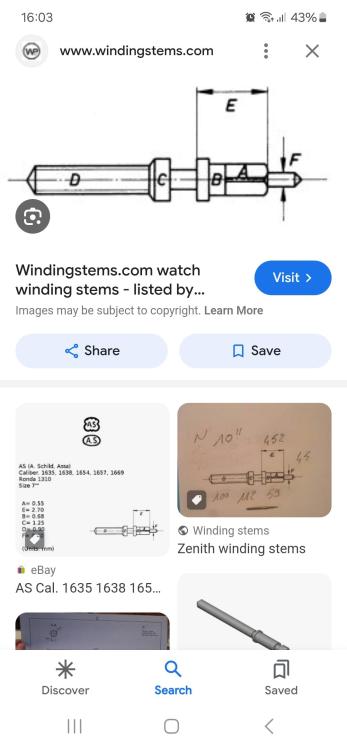

The movement is so called 'Tongji', standard chinese movement. The stem can still be used with the help of extender.3 points

-

To identify movements the standard practice is the actual diameter of the movement, and a front on image of both the movement side and the dial side- minus the dial. The setting mechanism (under the dial) is considered the "fingerprint" of the movement and 9/10 leads to full identification.3 points

-

2 points

-

2 points

-

2 points

-

Hi. Breaks like this can br fixed with conductive paint like the paint used to repair a car rear screen heater. I have used it successfully, you don’t need much and unlike solder there is no heat 6020A-1.pdf2 points

-

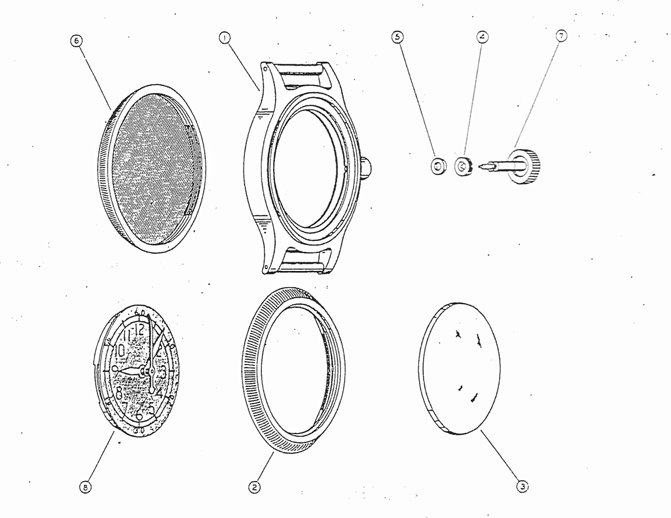

I have an image of what the case is supposed to look like disassembled. then an interesting website https://www.mybulova.com/vintage-bulova-catalogs there's all sorts of interesting things here for anyone in watch repair. but for the particular subject these are the two I recommend. You can see page 7 is where I got the image of the case. Then the word apartment technical manual is really a training manual of watch repair covers wristwatches and pocket watches everybody should have a copy of this.2 points

-

Yes, it looks like GT Revue 30. Doctor, You can not replace escape wheel by the dimensions You listed. One needs to know much more things like number of leaves of the pinion and it's diameter, the position in high of the table and the pinion, the hight between the pivots, the exact pivots diameter... And then, even if suitable wheel is found, one will need to know how to adjust the pallets position correctly. Restoring antique movements is something different than replacing parts. In older movements parts are not interchangeable, this means spare parts do not exist. Here the case is different, but still escapement adjustment will be needed if a wheel from a donor is found. So may be it will be easier to restore the donor for You...Restoring antique movements usually means making of the parts needed and this requires knowlage and working on lathes skill. In this case repivoting of the wheel is the natural solution, but there is a long way that one must walk untill getting ready for such work.2 points

-

Just a note for those who come searching for information on this topic in the future. I did eventually find the Mark's video on how to replace these springs, as someone observed, he does in fact make the replacement look easy. (It actually is relatively easy once you have the knack of it.) If you're enrolled in one of Mark's online courses, the demonstration of how to replace this spring is in the Bonus Videos section of his course site, and is called "C2B1 – Sea-Gull Style Shock Springs".1 point

-

Nice result, and a really handsome watch! You'll enjoy putting that on every single time.1 point

-

Hi guys, I wrote a set of five lessons for my second year students regarding the Landeron 248 chronograph watch, which incidentally we are meeting tonight. They are going to be polishing pivots and pinion leaves of their 248s, before putting the movements through the cleaning machines. This is number one of five. I posted number two of five the other day HERE There are seven eccentric studs on this movement, so understanding what the studs do, how to set them, their actions and interactions with other parts of the chronograph mechanism is vitally important. I found there is very little out there on the internet to help understand the principles of these eccentric studs, especially video content to show various faults and alleviations, so I put together quite detailed walkthroughs of various complicated movements usually consisting of 15 to 18 hours of learning/servicing in the workshop per movement/module With any watchmaking, especially with complicated work, only make one adjustment and measure the results, if any. Be methodical in your approach. The lesson was originally in PowerPoint and I had to convert it to PDF to post here, so a lot of the video content won't play, but the PowerPoint version is in my cloud storage here. https://docs.google.com/presentation/d/10KJJ58P0v2BglKZSilIv9o69xBsbrQPI/edit?usp=sharing&ouid=107902587627140904870&rtpof=true&sd=true You'll need quite a newer version of Microsoft Office (PowerPoint) so the video content will play, otherwise it won't. I hope you find this lesson useful and begin to get a better understanding of how to set eccentric studs. Sometimes you'll come across a stud that is too loose, or even too tight. Usually if one is problematic it will be because it is loose. This can't be left, as the stud will turn whilst the chronograph is stopped, started and reset, throwing the chrono mechanism setting off which could lead to the movement grinding to a halt. Don't fool yourself in thinking it will hold. Either a replacement stud is fabricated to suit the enlarged hole, or the hole can be closed up. In turning and setting the eccentric studs prior to disassembly of the movement, we are able to set the chronograph mechanism, especially the minute register mechanism correctly and test for any faults, such as a bent wheel over fourth arbor, or incorrect depth of the dart tooth with the sliding gear, or a mis-set minute runner jumper spring, to name a few possible faults and mis-settings. Also in turning these eccentric studs we can gain a 'feel' for how tight they are in the mainplate or bridge. The more they are turned the more the chance of the stud becoming looser increases. So once set correctly prior to cleaning, the less chance they will need setting once the chrono mechanism is assembled, only if a stud isn't tight enough in its setting in the first place. This is for setting Landeron 248 eccentric studs, but once an understanding of their uses and actions is gained through theoretical aspects together with practical application, then this skill and knowledge can be used in most vintage chronographs to set their eccentric studs and even in modern timepieces where you'll find very few eccentric studs, such as an Omega Speedmaster or Tag Heuer Calibre 01 chronographs Enjoy! Lesson 22. Landeron 248 Chronograph.pdf1 point

-

Hi Rich, now i realise that you spring broke. how did it broke, may be when grinding the fixator part with the dremel? If so, then guess You have let it to vibrate free, this is wrong. One must keep the spring pressed with finger to boost the vibrations, other vice it resonates and breaks.1 point

-

I will advice to share the idea first here before doeing something to the movement1 point

-

1 point

-

I'm going to give that a go next time, thanks for a great idea @rossjackson01 One of my students uses this tool and swears by it https://www.cousinsuk.com/product/wheel-hand-roller-remover-bergeon?code=W1851 which is very like getting two sticks of pegwood under the wheel and rolling them in your fingers so they create a slight prying from underneath motion, I suppose. Maybe bind one end of the two sticks of pegwood so they are like tweezers.1 point

-

Thank you. I spent a lot of time on that. It never ceases to amaze me that there are so many slight adjustments that can be made to the chronograph mechanism through setting the eccentric studs to get them all to a concerto, like an orchestra with everything in time and to its most optimum. Understanding that setting one stud to the desired effect may throw another out is the fun of working on vintage chronographs. Great pic of the 3133 dart tooth interaction and tilt of the tooth. I love working on 3133s. Slightly better than the 7733 in my opinion and you get a date at 6!1 point

-

1 point

-

1 point

-

According to a couple of sites I've found, it could be an AS1688 ? https://marketplace.watchcharts.com/listing/1712969-rare-girard-perregaux-33-cal-1688-17-jewel-watch-movement Edit, missed the second link.. https://ameblo.jp/t-watch-blog/entry-12814000875.html1 point

-

1 point

-

1 point

-

I agree with you completely for older watches, but the Revue 30 dates from 1910 onwards. They were still being made up until at least WW2, and there is reasonable parts interchangeability in my experience, assuming same jewel count. Very early Revue 30 movements will be less tolerant of replacement parts being fitted without adjustment than the later ones. Escapement parts were the last to require hand fitting to eachother in each watch and are thus unique to the movement but the other parts from even an early Revue 30 should be interchangeable within watches with the same jewel count. Since the escape wheel is part of the escapement there is no guarantee, but it’s likely an escape wheel from another 7 jewel Revue 30 will fit this watch. The escapement will need adjustment (pallet stones, safety action etc) may need adjustment to set up the escapement optimally, though. Best Regards, Mark1 point

-

the problem with vintage watches and yes quartz watches can be vintage is availability of parts will be a problem. I have a link below where we can cross reference the coil and I was hoping for more. Another problem for vintage parts are everyone on the group gets used to ordering from online. Conceivably the physical material houses that still exist out there might have the part and you'd have to reach out to them and see if anyone has one. this is because they don't list every single part that they have online with the exception of cousins where everything they do is online work just doesn't exist but the other material houses can have stuff not listed. Otherwise just set up a search on eBay and sooner or later it will possibly show up if you're lucky. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_6020A1 point

-

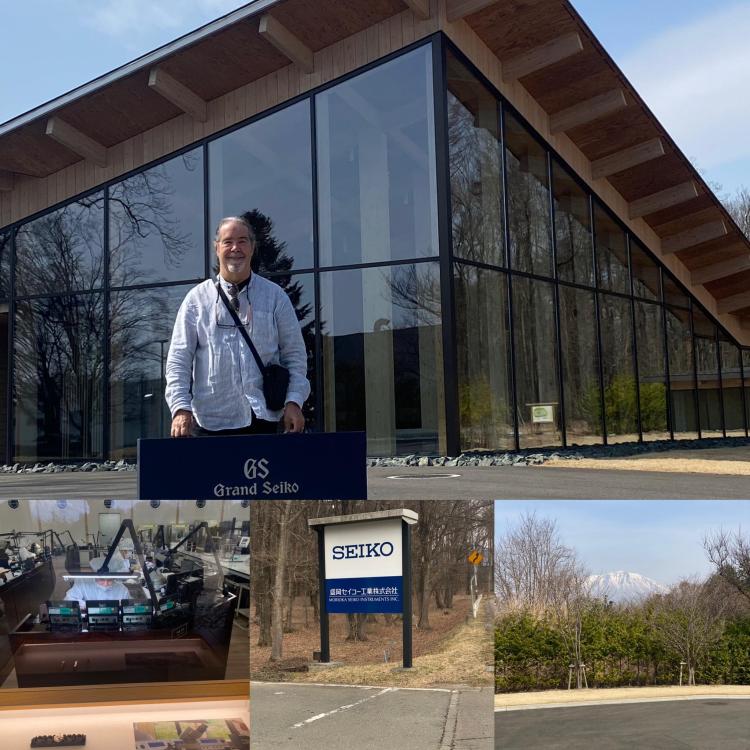

I am an Australian American living in the beautiful Gold Coast, Queensland Australia. I love Grand Seiko and Seiko watches, and recently came back from the Grand Seiko Shizukuishi Studio in northern Japan where I was blown away by the design artistry and technical excellence. More later on that (including photos, if interested!)1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. What happened you have already made 7 posts1 point

-

This is a very valid point and a subtlety that I was unaware of until fairly recently, learning all the time, the video below explains this point well:1 point

-

1 point

-

1 point

-

Nickelsilver is right, movement diameter and keyless works ‘fingerprint’ are important for identifying movements. That said, this appears to be a 7 jewel version of the a Revue 30 movement. A quick search with google turns up parts movements, and individual parts should be quite easy to come by. Hope that helps, Mark1 point

-

Sometimes surface damage like this can be repaired with solder. Run pre-tinned soldering iron tip with a tiny blob of solder over the damaged area and pray that the Gods of watchmaking are on your side.1 point

-

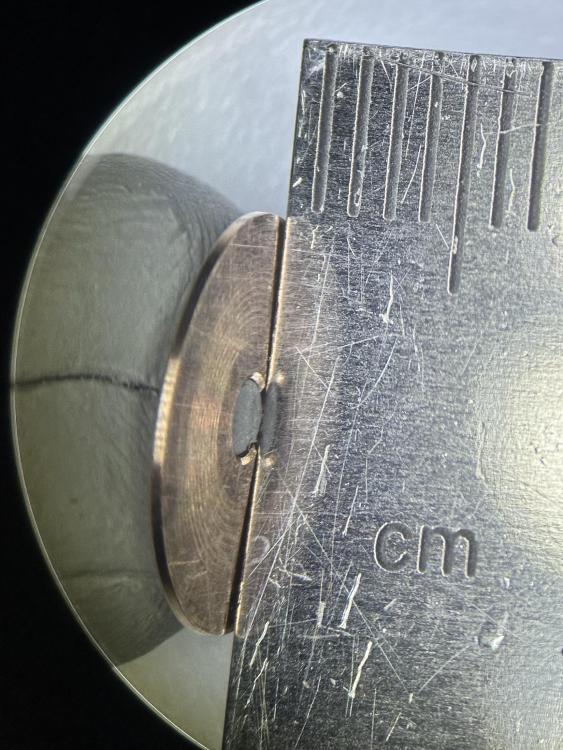

Thanks for the screenshots. That's very helpful even the drawing which resembles a Bergeon 6160 so I know what you're saying. Most probably I'll get the horotec clone from Ali-x. Yes, looks like time to go shopping for the tool. Alix for the removing took and Cousins for the pushers. They do come with the gasket in-built yeah? I guess I'll find out. Thanks guys for your input. Keep up the horology work!1 point

-

1 point

-

1 point

-

These are all American movements (with the exception of the "Rubis"), and are all almost certainly "negative set" which means the stem is part of the case. So it's normal that they are all missing- they are with their cases. You will need male square bench keys to wind/disarm them. Vintagewatchstraps has a great writeup on the different systems. But basically, any American "x" size movement will fit any case for that size, possibly with some adjusting of the stem position. With Swiss movements, there is some interchangeability between calibers, usually within the same maker's range, but not really overall- there are thousands of different stems out there.1 point

-

Double Oooooo Removal tool? Dreamed of one of these. However, Kalle on Chronoglide showed everyone my system with the pegwood. Worked a treat. Felt so chuffed to be mentioned. https://www.youtube.com/watch?v=tTFrXjiyGKc 46:40 for the wheel removal. Mentions me at 50:00 and does the removal with the pegwood. Felt like my 15 minutes of fame.1 point

-

Sirius. Thank you for helping others with that information. This is why this forum is so good.1 point

-

I use the exact OD and it fits in with a little force and a pleasing 'click' so it's snug and wont rotate within the holder, but that depends on how you have set up and calibrated your printer so you may need to play with the settings/dimensions a little to allow for any discrepancies in your printer calibration. PS I just finished (2 days ago) a new revision which automatically prints the movement OD on the bottom of the holder, I'll see if I can upload it here Here is rev 4 remember to change the .pdf to .FCStd so it will open in FreeCAD - also you may need to install the LiberationSansBold font and tell FreeCAD where it lives on your PC, or change the font to something you already have on your system. Para Movement Holder V4.pdf Examples below:1 point

-

1 point

-

1 point

-

One of the things that I've been bothered with lately is timekeeping? For instance a 90-year-old pocket watch what so to timekeeping was it supposed to keep? They publish railroad timekeeping but I don't know how well normal non-railroad watches were supposed to keep time. The reason why the question comes up for me is I spend a lot of time at work adjusting watches to keep really really good time because I have to please my boss where as when the watch was made I have to wonder what kind timekeeping would've been acceptable. After all they typically didn't have timing machines 100 years ago and they were timing and six positions certainly not for the non-railroad grade watch. On the other hand I do get paid by the hour so maybe I shouldn't be concerned of how much time I Spend trying to make everything keep chronometer timekeeping almost. Citing a Delta of 40 seconds for a 90-year-old watch is quite outstanding.1 point

-

If you have no Powerpoint at Hand (but Libre-Office or whatever..), to get Access to the Videos in the pptx, make a Copy of the File, rename it to blabla.zip and unzip the File. Now in the Folder ppt/media you have all Pictures and Videos...... hope this helps some of us regards, Ernst1 point

-

1 point

-

Instead of using tweezers, put a piece of rodico onto a toothpick or pegwood. Then set your spring to the rodico, this way the spring is not under any tension when floating it back into the bloc. As you bump into the bloc when trying to find the entrance the rodico will give but still holds onto the spring ie. You wont have the rigidity of tweezers.1 point

-

New version of parametric movement holder, link HERE, updated based on feedback from other WRT members and removed a few bugs. I have printed in PLA+ and PETG and prints well, rendering below: I uploaded FreeCAD, step and .stl versions to printables web site as this seems to have replaced thingiverse as the go-to place for 3D models - opinions? Note, parametric functionality only works in the FreeCAD file version All you need to do is measure your movement outer diameter (OD) and then put this value into the model spreadsheet and it will generate a bespoke model of the holder to fit your movement that will look something like the one above. Depending on your settings the print time will be around 1 hour. How do you upload the FCStd and stl files here? Whenever I try I get a warning box saying that the file format is not allowed.1 point

-

That would be slugs and snails and puppy dog tails as they nicely counteract the carcinogenic effects of tetrachloroethylene. Or does that only work for the dextro isomer of hexane?!1 point

-

Totally agree with John and Stephen on this one. I do a lot of research before purchasing anything and have saved myself a fortune in the process. Here's a typical example, great quality and works perfectly. Price from a reputable UK source including VAT and postage £593. Price imported from China including shipping £144. Same machine with a total saving of £449. I have purchased many items of similar good quality without the magic Swiss names and have saved a fortune.1 point