Leaderboard

Popular Content

Showing content with the highest reputation on 03/13/24 in all areas

-

For years, since I didn't know how much further I would take "watch-repair", I've been "scrubbing" my watch parts in Zippo lighter fluid........ Recently I decided to "up" my cleaning game. Bought a 2nd hand Elma S15H ultra-sonic and the "official" chemicals (in my case Elma WF pro (cleaning), Elma Suprol (rinse) and Isopropyl alcohol (IPA). That made a world of difference ! So, if you are serious in continuing this hobby, fed up scrubbing with lighter fluid and want to "up" your cleaning game to near professional levels; get the decent stuff3 points

-

I've been fiddling with watches for about 8 years. We all get a bit over confident, then put in our place with a movement we cannot figure out. It happens to us all. I'm just trying to sort out a Smiths with a similar oscillating trace. There seems to be a repeating pattern every 4-5 mins. Third wheel? Might be worth checking the teeth. There's a known problem on some ETA movements (I've mentioned it before) - I think this might be one. The 'intermediate wheel (I think it's called) has too much end play, allowing it to touch the bottom of the barrel, and give readings like yours. Kalle (Chronoglide) has described it as a design fault. I always check on ETA movements, and often have to reduce the end-shake2 points

-

I'd never heard of a linear bumper before this. I love all the weird ways people have come up with to solve these problems.2 points

-

I use water based cleaners with ammonia for clocks but I prefer water free cleaners for watches. Do a "foil test' in your ultrasonic cleaner to see if the unit is working properly.2 points

-

See what @ColdWind has said and check (look) if the hairspring touches the studd whhen the balance is rotated right to the max of it's movement. If so, this will explain the eratic rate. The distance changes much when the spring is not well centered to the collet1 point

-

1 point

-

It does look a bit large, though the pins look straight, so maybe it's meant to be like this? Also I've come across plenty of bent centre seconds wheels, which can catch on the bridge, but I'm sure you would have spotted that.1 point

-

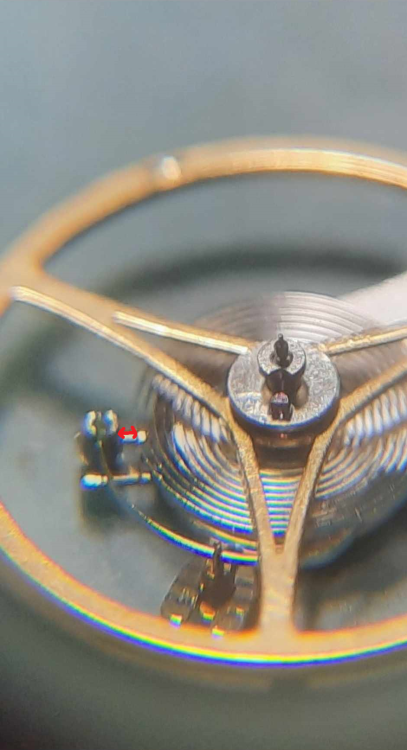

Sorry for the crappy photo, I don't have a better one in my phone. ETA movement with erratic rate hm, if it is the "consistent type of erratic" then I would suspect a faulty wheel from the chain but this wasn't it, yours is all over the place. I believe this must be a hairspring problem. Speak from my own experience if the distance (marked red) is somehow close enough the hairsrping could sometimes touch the stud making the erractic rate you are experiencing.1 point

-

Welcome, Jens, from New York! (and thanks for the Geo lesson, VWatchie!) I am also new to the group, and have already found it invaluable! Looking forward to learning with you. Corky1 point

-

1 point

-

the problem with this method of cleaning your cleaner is it only removes solid particles. Anything that can dissolve into the solution like old lubricants will not be filtered out. You can't actually clean your cleaning fluid by filtering. then a minor confusion on my part are we discussing clock cleaning or watch cleaning here? normally in watch cleaning things are a little confusing in that the entire process is cleaning. So even though the first product is called the cleaner because it does more aggressive cleaning all the rest of the things normally called rinse are part of the cleaning process. If you're cleaning a watch typically would have at least two separate rinses with each one getting cleaner and cleaner. What you're trying to do is put everything in the solution remove it from whatever your cleaning. The rinses continue to clean and reduce the concentration of stuff on the plates until finally there's nothing left. this seems to be very common which is why the final final rinse should be alcohol. Basically her rinsing off the rinse that doesn't like the dry ever and using something that will dry. Then heat is really a good thing for drawing as opposed to letting it sit around hoping it might dry heat will really speed things up considerably. I suppose it depends upon which expensive machine you'd like to purchase. Some of them do a really nice job although you'd never be able to justify the cost of thing in your lifetime unless you take up professional watch repair. Then you can even find videos on YouTube where people of thrown money at their expensive machines and still unhappy with the cleaning. interesting website below https://zenithsolutions.net/product-list what makes the website interesting is it doesn't actually say how to use the products? thinking of your cleaning methods you didn't say other than the chemicals procedural things? Like how long do you leave it in the watch cleaning fluid and you elevate the temperature. How many rinse cycles and are they also filtered or do you have a clean clean rinse at the very end?1 point

-

For me, a bit of a "kinky" side step; two partially broken vintage quartz watches no less ! They do run and the chronograph functions do work, but, from both, the small chronograph seconds recorder (1/10 sec) doesn't reset and they don't run I've found some instructions on how to reset the small seconds recorder, but it doesn't say whether the recorder hand should run, or not, after a battery change; "Resetting the Chronograph to Zero: If your chronograph and 1/10 seconds subdial hand are not aligned after a battery change, do not worry as this is common and easily fixed. Simply make sure the crown is in normal position (pressed in against the case), the push Button C (bottom left) twice. The second hand will move, press C again. Pull out the crown to time setting mode. Now you can adjust the two misaligned hands: Button A will advance the central second hand forward, Button B will advance the 1/10 second hand forward. Push the crown back in." So, since both of them do have the same problem, it could be simple and the seller didn't know how to reset, or there could be more to it? Is it a coincidence that both movements do run (cal. 3510 + cal 3530) and do have the same problem ?? They added thrill is that these Citizen / Miyota 3510 movements (12 jewels ! ) are discontinued and apparently (very) hard to get (??). Perhaps one of those: "There is a thin line between a Hero and a Zero" Anyhow, without further ado here some pictures of what should be in the post;1 point

-

1 point

-

I know they used that type years ago and are rare and unique as are Pierce chronographs, but they were not 25 jewel movements, the watch you show for sale is new than the linear in my opinion....good luck either way1 point

-

Its quite common for folk new to watch repair to struggle for a lttle while finding the right cleaning method using the limited start up equipment. We come into this hobby not knowing if we are capable or how long we will stay interested. That then limits what we are prepared to spend on equipment, we hold back until we know for sure we are in it for the long haul. The ckeaning medium is only one aspect of the process, drying also plays a big part and there are more than one way to go about it. Letting them just sit to dry will be the least effective, get some warm flow introduced, it will make a big difference.1 point

-

Oops, sorry then, I don't know why I thought it was a 4006 Whoever, the power reserve check still aplies for a breakinggrease problem.1 point

-

1 point

-

Have a look at this it covers a lot of three train movements Dell https://mb.nawcc.org/wiki/Encyclopedia-Subjects/Clock-Repair/Chime-Clock-Basics1 point

-

their minor variations to this. Like for instance take a tiny piece of Rodico on the pivot of the staff hold the balance wheel an attempt to rotate the staff with your pin vice the pin vice is supposed to slip because yes the rivet really does have to be very secure if it rotates you'll see whatever you stuck on the end rotate.1 point

-

Listen to DAD, trust me, as has been said he probably has forgotten more than most of us know. Having sat next to you at the bench with his knowledge, trust me one day of sitting with Dad is the equivalent of say 4 months of trying to learn this stuff by yourself. Use youtube to aid you on your way but you have what so many people can only dream of and thats your own personal mentor for free.1 point

-

Hi. My setup uses the 12v . The chargers have over current protection built in and are safe. The high current is at the rod end where it meets the dial and only a fraction of a second long enough to melt the solder paste or chips which ever you use. I apply the tip to the rod and watch the joint as soon as the solder flows remove rod.1 point

-

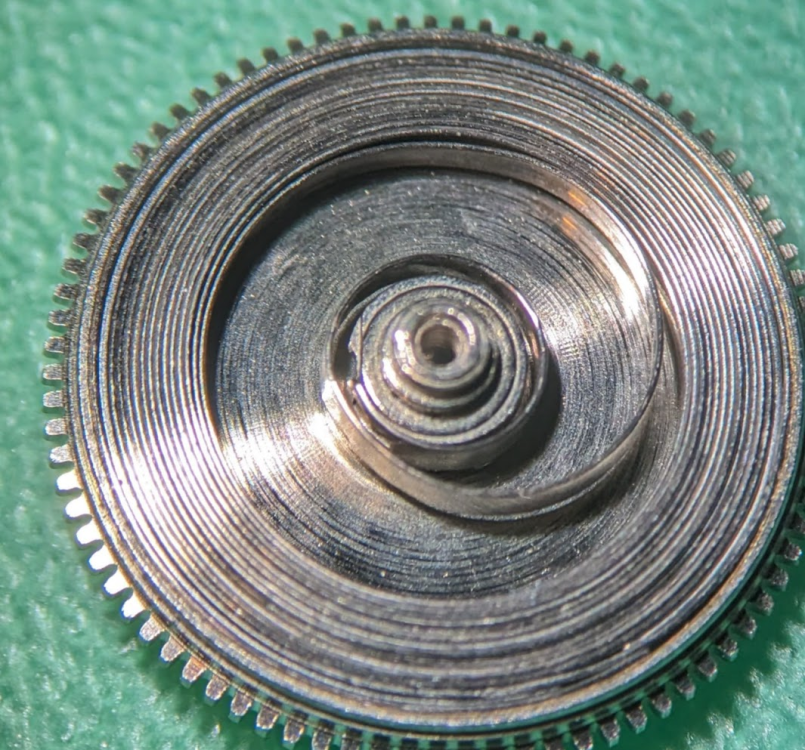

So i just put in the 2377x into a 7s26 barrel. It looks like the inner coil is too damn big for the arbor. Have you had an issue with this? I'm basing what i said on this vid. THis guy generally gives great advice. Length not being critical would fall under the category of there being leeway. I"m just saying you don't have to have one identical to the factory one from what i understand.1 point

-

No there isn't. The height has to be close to fit in the barrel correctly. A spring is like a beam bending, whose moment of inertia is (height*thickness³)/12. i.e. it varies with thickness cubed. So if you go from a thickness of 0.11 to 0.12mm, the 'strength' increases by (0.12/0.11)³ = 30%. That's a lot. So you need to be close on thickness. The length is not as critical, as long as it's not too long to fit properly. If it's shorter than specified, you will just lose out on run time.1 point

-

I recall a while back watching a horology lecture about sizing mainsprings. Probably on YouTube. One of those unflashy, classroom style, guy in front of a whiteboard sort of affairs. Went through the whole deal on the formula for how to size a mainspring to a barrel. I imagine what you're missing in your attempts at going solo sourcing these is knowing where and how to fudge. I.e., you can get away with a thicker spring, just has to be longer by X% per .001mm thickness provided you don't exceed Ymm^3 or something. Learning the hows and whys of mainspring sizing will probably open your options up considerably by opening up the specific size to a range of sizes.1 point

-

The 4006 mainspring is GR2378X as shown by Cousins (which agrees with the GR database). I downloaded all the GR database PDFs from Cousins, but the spreadsheet is much easier, or go online here https://watchguy.co.uk/cgi-bin/mainsprings I can't find any reference to the alarm spring. I have two BellMatics and didn't have to change either alarm spring, so didn't measure them. Just use your measurements (are you sure about your thickness, it doesn't agree with the GR database?). As it's only ringing the alarm you don't need to be an exact match. People have listed various springs to use for 7S26. My last one, I used GR2377X1 point

-

1 point

-

I don't think they are ever plated, just machined from solid brass alloys, or gold etc. See them being hand made : I've just stripped and Omega 620, so the wheels are a coppery colour to match the mainplate and bridges. I assume it's a brass alloy with more copper in to get the colour.1 point