Leaderboard

Popular Content

Showing content with the highest reputation on 03/09/24 in all areas

-

You seem to have posted 8 pictures the same, each one tells no more than the previous except what trousers you are wearing . Ebel was one of the brands used by the British MOD during WW2 ( ATP ) this looks military ? so it should have something decent inside.But we wont know that unless we can see it, this brand doesn't come up too often so will be interesting to see. The movement will give a date range to it's age, value is usually estimated, its only worth what one/some want to pay for it. Crack it open .4 points

-

I have experience with enamel dials. The base metal is copper. They can easily bear heating to 500 degr. celsius with no damage. But they can't survive sudden local heating while the rest of the dial is cool. The enamel on this local heated place breaks. If You solder melts at about 180 degr., then You need to heat the whole dial to 150-60 degr and hold it on this temperature, then it can be soldered easily with normal soldering iron (for electronic components soldering) without danger of damaging the enamel. You heat a big metal plate to constant 160 degr. and put the dial on it, wait for a while so the dial heats from the plate and then solder the leg(s) with the soldering iron. If the plate is to hot, then the solder will not harden, so You will not be able to solder the second leg without loosing the position of the first one. If it is to cool, then it will be very hard to heat the leg place on the dial enough so the solder will melt there.2 points

-

Thank you, Randy. I have indeed learned that it's a Miyota movement (6M55) which is no longer available. Ali Baba sells a purported generic equivalent for $8 with additional $8 shipping from China. I will give that a try.2 points

-

2 points

-

in earlier generation watches they were glued in with a variety of substances. So you always want to look at the dial before cleaning to make sure that it's not glued together. later on they switched over to soldering them in place.2 points

-

The subdials usually are soldered with led. But it is easier to glue it in place with some epoxy (applied on the back side!) I see some legs are missing - new legs can be soldered in place. This is easier done when the dial is heated to about 160 degr. celsius, for example on elctric stove plate, which has been switched off after reaching this temperature. Than use normal soldering iron to solder the legs with led containing solder. The coper 1mm circle around the leg holes must be cleaned from the enamel first. The missing pieces in 8 min. position and aroun center hole can be filled with white UV nail polish and then hardened under UV lamp2 points

-

1 point

-

The extreme hype around this watch was difficult to understand, but it shows that what really matters is looks and brand. Other than that, a plastic quartz watch, not making me too excited.1 point

-

Hi Rixy as it happens I have been going through a similar process with a Russian submarine clock. Been battered and the staff was broken at both ends. Managed to source a spare and although they will fit any Russian sub clock I swapped the balance into the other escapement , it fitted ok and spun up with the blower but when fitted to the clock , no go. So returned to the status quo . And worked out I could move the escape wheel pinion guard for it to fit it now works but more to do. Although they look the same they might not be exact and be an expensive £85 spare. Iwould try to get the old one re staffed. I have some staffs for my clock on their way with the intention of repairing the old one . I mention this as a guide but the descision is one only you can make All the best and good luck. Is the replacement off an Elliot and are the dimensions the same and remember the drop of the escapement pinion as re gardens the mesh with the contrate wheel1 point

-

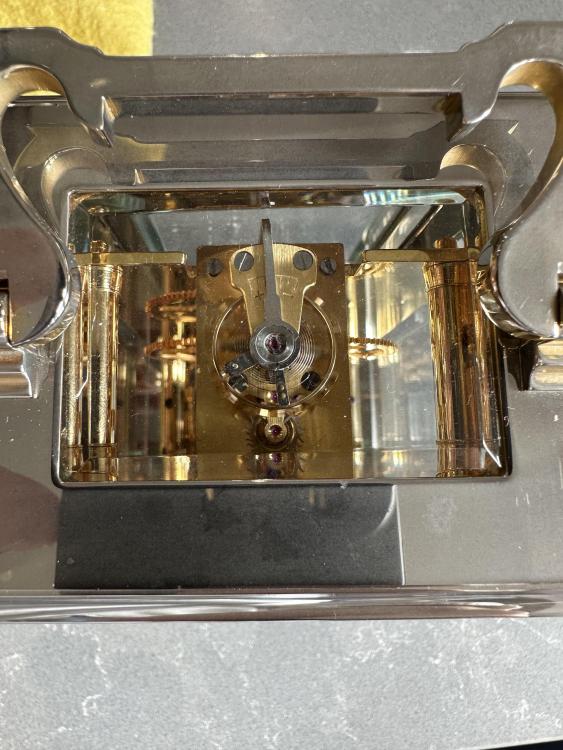

This points to a broken pivot. With an oiler gently lift one side of balance wheel as you keep an eye on pivots, in case a pivot don't stay in jewel hole its broken. Better yet is detaching balance complete from the cock and show a close up side view of pivots. Rgds1 point

-

1 point

-

I'm a startup guy. I've been a co-founder, early hire, and currently on one that's just me and will hopefully do big things once I'm comfortable enough with the prototype to file patent and get it out in the world. My default is to go it alone. More risk, but also more reward... and lots more fun! In this application though, it kinda depends what you're doing. If you're servicing watches, and Swatch wants you in their repair network, I'd probably jump on that. I feel like watchmaking and watchmakers are a dying breed, and an indie mostly just swaps out watch batteries (boring, but pays the bills). With smart watches becoming or having become the norm, those just get thrown away and upgraded every few years. No servicing. No work for watchmakers. Having a steady flow of interesting work, some job security, etc. would be very attractive. If, on the other hand, you're starting up a microbrand or something and... I guess Swatch group again... approaches you for acquisition, that's a very different situation. If the big guys are after you, it's a question of whether or not you're ready to exit/ready for an extended battle royalle. That approach means you have something they want that will make your business better. If it's easily emulated, they're talking acquisition as a means of avoiding having to get around you legally or otherwise. So you can exit, take your payout, and not have to deal with it, or you can lawyer up and keep trucking. Kinda depends on whether or not you're ready for something else. If you're being approached by a microbrand to start a microbrand for its own sake, that falls under the typical startup umbrella, and I'd probably go for it.1 point

-

1 point

-

1 point

-

When I talked about older dials, I was refering to silvered or plated dials. I'm not sure about enameled dials. Enameled dials are coated with powdered ceramic powder and fused at very high temperature to form an amorphous layer of porcelain. If you look at enameled dials, the enamel is applied to both sides of the dial to prevent warpage and crazing of the porcelain. After heating the porcelain to such high temperatures (sometimes around 1000°C), there will be a lot of shrinkage when it cools. The coefficient of shrinkage of the porcelain and metal dial must be very similar or else cracks or flaking will result. I've never tried soldering an enameled dial. I suspect the base metal is not brass but a higher melting point metal. Do we have a ceramist in our forum to confirm this.1 point

-

That would be the micro adjustment on the clasp corky, but good suggestion for the op that may work.1 point

-

you're looking for the this assembly, reassembly and lubrication I assume? The best of my knowledge they do not exist. The most you're going to find is the parts catalogs which will list the parts. here's a training manual on watch repair it covers the couple 16 size pocket watches and wristwatches etc. https://archive.org/details/TM9-15751 point

-

I doubt if such schematics exist. Here is an old textbook for watchmaking, all needed for learning pocket watches A practical course in horology by Harold C. Kelly(1).pdf1 point

-

@Qutadah, see, You first need to have the watch in You hands, or at least to have good pictures of the movement. What the seller says is useless, as if He understands enough of watchmaking, He would repair the watch. We need to see this hairspring, as it may be really bad, but it may be quite easily repairable too. And it concerns not only the hairspring, but all the other parts... The main problem that I see is that You intend to repair this small and fragile calibre without having any experience. Such attempts usually end up with ruined hairspring and/or broken pivots. Actually, the hairsprings end up ruined never by themselves, but only because someone did'nt handle them properly.1 point

-

Not been involved in the watch industry and not knowing the opportunity it’s hard to say. I do know from my work experience often there was a training claw back if you left within X number of years so you need to assess that for yourself. It is however an opportunity to train and gain experience with I assume a known name in watchmaking which could stand in good stead for further employment or reputation setting up on your own. Tom1 point

-

Rusty, Please take my comments with a grain of salt, and apologies for using incorrect terminology. I'm a novice. If you have enough "slack" to discard a link, you might be able to connect two of the links; a male and female. I had a Tissot with a similar bracelet, and the professional watch repair person was able to eliminate one link and adjust the length on the adjustable portion and it works fine. Best, Corky1 point

-

Hi @Qutadah and all, I can guarantee you that you will struggle a lot to get spare parts for a movement like this. You might have to buy a complete donor movement and they will be extremely expensive. Maybe it will be impossible to find at all. Hairsprings from back then are also much "softer" and susceptible to bending, damage and breaking (if bent back-and-forth too many times). Hairspring work is difficult in general, but much harder on these old ones. Practicing on a ST36 is not fully preparing you for that. Lastly, these old movement are not perfectly standardized -- much more one-by-one work was done by watchmakers back then. Specifically, you may find that the hairspring length between yours and the potential donor/replacement hairspring are a bit different. To compensate, the watchmakers may have used the timing screws or timing washers to ensure that the watch keeps time within the margin of the regulator arm. I talk from experience with an Omega T17 from the 1930s, where a replacement hairspring was a a few millimeters shorter than the original one. Consequently, the watch runs over 10min fast even with the regulator arm all the way back to maximum "slow". I'm now waiting for timing washers to correct that. In sum, if you know that the watch has a hairspring issue, I'd suggest you stay away from it.1 point

-

1 point

-

We all start with an interest in watches, then watch fettling, that quickly degenerates into being a tool collector and restorer. Tom1 point

-

This could be an inexpensive movement to learn a bit about pushers, levers, etc. in order to start understanding chronographs, but this does not function like a typical chronograph. Unless I am mistaken, this is one of the cheap mono pushers that actually use the entire movement as a stop watch, in effect just a hacking function. You can set the hands where you want them and then start and stop the movement, but it won't be telling the actual time simultaneously as a traditional chronograph does.1 point

-

It does look like there are parts missing AND the lever is broken. My guess is this was already used for a parts watch.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)